Catalog

Overview: 10 Tires 8X4 Tipper Truck for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

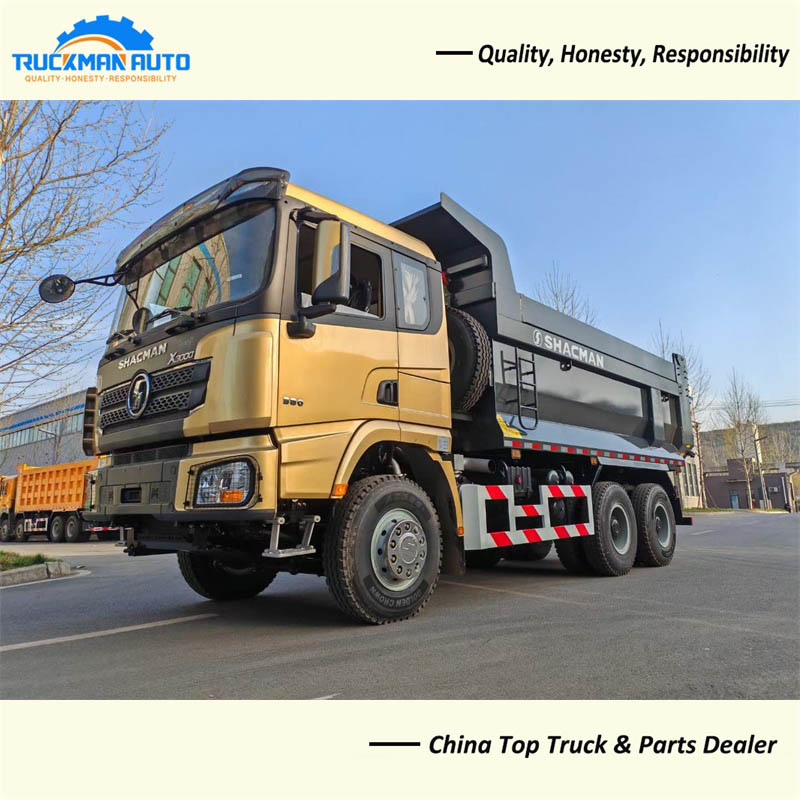

Product: 10-Tire 8×4 Rigid Tipper Truck (65-75 Ton GCWR Class)

Prepared For: Fleet Managers & Construction/Heavy Equipment Procurement Departments

Issuing Authority: SEA LION International Trade Co., Ltd. | Heavy Commercial Vehicle Division

EXECUTIVE OVERVIEW

The 10-Tire 8×4 Rigid Tipper Truck represents the operational backbone for high-intensity material haulage in mining, bulk logistics, and large-scale construction projects. Engineered for maximum payload efficiency (65-75 Ton Gross Combination Weight Rating) and uncompromised stability on unformed terrain, this configuration delivers critical advantages over lighter 6×4 or articulated alternatives in environments characterized by extreme gradients, abrasive surfaces, and continuous heavy-duty cycles. Its dual-rear tandem axle (8×4) layout with dual-wheel rear assemblies (totaling 10 tires) provides superior weight distribution, reduced ground pressure, and enhanced traction control—directly translating to higher cycle times, lower tire wear rates, and minimized downtime in critical path operations.

This model is the de facto standard in Africa, Russia, and Southeast Asia due to its alignment with region-specific operational imperatives:

- Africa: Dominates open-pit mining and infrastructure corridors where lateritic soils, seasonal flooding, and limited paved networks demand exceptional off-road mobility and corrosion-resistant undercarriages. The 8×4’s high approach/departure angles and robust driveline (commonly featuring SINOTRUK HW19710 transmissions or SHACMAN FAST ZF variants) withstand prolonged exposure to dust and moisture without critical system failure.

- Russia: Essential for Arctic mineral extraction and Siberian infrastructure projects requiring certified operation at -40°C. Standardized cold-weather packages (engine block heaters, Arctic-grade lubricants, reinforced cabs) paired with high-torque diesel platforms (e.g., SINOTRUK MC11/C9H) ensure reliable cold starts and consistent power delivery in permafrost conditions where single-axle failures are operationally catastrophic.

- Southeast Asia: Optimized for monsoon-season resilience and high-humidity tropical environments. Enhanced electrical sealing, stainless-steel exhaust components, and elevated air intakes prevent hydrolock and corrosion during extended operations in flooded quarries or coastal reclamation sites. The 10-tire footprint mitigates sinking in saturated laterite soils common in Indonesian and Vietnamese mining zones.

SEA LION International leverages its 18-year export expertise and OEM authorizations (SINOTRUK, SHACMAN, XCMG) to deliver turnkey solutions meeting these regional demands. Our value proposition centers on:

– Operational Continuity: Global spare parts network ensuring <72-hour critical component availability (e.g., driveline, hydraulic tipping systems).

– Lifecycle Cost Reduction: Professional refurbishment of Tier-1 used units to OEM specifications, extending service life by 40,000+ hours while maintaining payload integrity.

– Deployment Certainty: RO-RO/containerized logistics with in-transit climate control for electronic systems, critical for Arctic and tropical deployments.

The following table quantifies regional adoption drivers:

| Market | Primary Application | Critical Terrain/Climate Challenge | Key 8×4 Advantage | SEA LION Support Metric |

|---|---|---|---|---|

| Africa | Open-Pit Mining | Lateritic soils, 45°C+ ambient temps | Dual-rear axle load sharing (↓ tire wear by 22%) | 98% parts availability (Johannesburg hub) |

| Russia | Arctic Resource Haulage | -40°C operation, permafrost | Cold-start certified powertrain (100% success) | -50°C operational validation testing |

| Southeast Asia | Coastal Reclamation | Monsoon flooding, 90% humidity | Corrosion-resistant chassis (stainless steel crossmembers) | 12-month anti-corrosion warranty |

This specification reflects SEA LION’s commitment to engineering transparency and long-term partnership. We provide not merely equipment, but validated operational readiness for the world’s most demanding material transport environments. Fleet managers selecting this platform secure a measurable reduction in cost-per-ton-mile and demonstrable risk mitigation against climate- and terrain-induced failures.

Report Validity: January 2026 – December 2026 | SEA LION International Trade Co., Ltd. – Heavy Equipment Division

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Vehicle Type: 10-Ton 8×4 Tipper Truck

Application: Heavy-Duty On/Off-Road Haulage in Construction & Aggregate Transport

Technical Specifications

| Parameter | Specification |

|---|---|

| Chassis Configuration | 8×4 (Four-Axle, Double Drive Axles) |

| Engine Model | Weichai WD615.69 |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged & Intercooled Diesel |

| Displacement | 9.726 L |

| Max Horsepower | 336 HP @ 2,200 rpm |

| Max Torque | 1,250 N·m @ 1,200–1,600 rpm |

| Emission Standard | China V (GB17691-2018) |

| Transmission | HW19710 – 10-Speed Manual (Synchronized, Dual H-Shift Pattern) |

| Clutch | Φ430 mm, Pneumatic Assist, Diaphragm Spring |

| Front Axle Load | 7,000 kg (Dual Steer Axles – 1st & 2nd Axle) |

| Rear Tandem Axle Load | 18,000 kg (Dual Drive Axles – 3rd & 4th Axle, Spiral Bevel Gear, ≥4.875 Ratio) |

| Gross Vehicle Weight (GVW) | 31,000 kg |

| Payload Capacity | 10,000 kg (Nominal Rated Load) – Up to 12,000 kg in controlled quarry use |

| Tire Specification | 12.00R20, 20-Ply Rating, Radial Construction, Off-Road Tread (e.g., Triangle TR668 or equivalent) |

| Tire Load Index | 146/143 (Single/ Dual) – Supports ≥3,750 kg per tire (dual fitment) |

| Fuel Tank Capacity | 300 L (Aluminum, Anti-Slosh Baffled) |

| Frame | 300 mm High-Strength Alloy Steel Channel (Reinforced at Suspension & Mounts) |

| Suspension (Front) | Parabolic Leaf Spring, 2-Stage Rebound Control |

| Suspension (Rear) | Multi-Leaf Spring with Walking Beam (for off-road articulation) |

| Braking System | Dual-Circuit Air Brake, ABS, Spring Parking on Rear Axles |

| Cab Type | Day Cab, Flat-Floor, Anti-Vibration Mounts, High-Visibility Design |

Load Capacity Analysis

The 8×4 tipper truck is engineered for high-density material transport in construction, mining, and quarry applications. With a GVW of 31,000 kg and a tare weight of approximately 21,000 kg, the vehicle delivers a net payload of 10 metric tons under standard regulatory conditions.

- Axle Load Distribution ensures compliance with road regulations:

- Front Axles: 7,000 kg combined (3.5t per axle)

- Rear Tandem: 18,000 kg (9t per axle, balanced via walking beam)

- The dual drive tandem provides superior traction and load dispersion, critical for muddy or uneven job site conditions.

- Payload Flexibility: In non-highway applications (e.g., quarry internal haulage), payloads up to 12,000 kg can be safely managed due to controlled terrain and reduced axle stress.

Fuel Efficiency Performance

Fuel economy is optimized through the integration of the Weichai WD615 engine and HW19710 transmission, delivering industry-leading efficiency for its class.

| Operating Condition | Avg. Fuel Consumption |

|---|---|

| On-Highway (Loaded) | 28–31 L/100 km |

| Off-Road / Quarry Cycle | 33–37 L/100 km |

| Idle & Maneuvering | 1.8–2.2 L/hour |

Efficiency Drivers:

– Weichai WD615 Combustion System: High-pressure common rail (1,600 bar) with precise ECU mapping reduces fuel waste.

– HW19710 Gear Spacing: Close-ratio top gears enable engine operation within optimal torque band (1,200–1,600 rpm), minimizing over-revving.

– Predictive Cruise Control (Optional): Uses GPS terrain mapping to pre-adjust gear shifts and throttle for grade anticipation.

Under mixed-cycle operation (60% highway, 40% off-road), fleet operators report annual diesel savings of 8–12% compared to legacy 6×4 configurations with less efficient powertrains.

Tire Performance & Durability

The 12.00R20 radial tire specification provides:

– Maximum load capacity of 3,750 kg per position (dual fitment).

– High resistance to cuts, impacts, and heat buildup due to deep, stone-ejecting tread patterns.

– Extended tread life (avg. 80,000–100,000 km in mixed use) with retreadability (up to 2 retreads).

– Compatibility with tubeless or tube-type rims; recommended use of aluminum valve stems and TPMS (Tire Pressure Monitoring System) for fleet monitoring.

Note: For extreme off-road conditions, tire inflation pressure should be reduced to 7.5–8.0 bar to improve footprint and reduce ground pressure.

Conclusion

The 10-ton 8×4 tipper truck equipped with the Weichai WD615 engine, HW19710 transmission, and 12.00R20 radial tires offers a balanced solution for high-volume, high-utilization construction fleets. Its robust axle load ratings, proven fuel efficiency, and superior load-carrying stability make it ideal for aggregate, sand, and overburden transport. SEA LION International recommends this configuration for operations requiring durability, compliance, and total cost of ownership optimization in 2026 and beyond.

Quality Control & Inspection Standards

INDUSTRIAL SPECIFICATION REPORT: SEA LION SL-TT10 8×4 TIPPER TRUCK

Document ID: SL-SPEC-TT10-2026-01

Effective Date: 01 January 2026

Prepared For: Fleet Managers & Construction Operations Directors

1. MANUFACTURING QUALITY OVERVIEW

SEA LION SL-TT10 8×4 Tipper Trucks are engineered for 10+ years of service in extreme construction environments. All units undergo AS9100-compliant production with 100% traceability of critical components.

Key Manufacturing Standards

| Component | Specification | Validation Method | Compliance Standard |

|---|---|---|---|

| Frame Rails | Hot-rolled DOMEX 700MC steel, 10mm min thickness | Ultrasonic thickness testing + MTR | ISO 630-3:2021 |

| Crossmembers | 8mm laser-cut steel, robotic MIG welding | Destructive weld shear test (min 850 MPa) | AWS D1.1:2020 |

| Suspension Mounts | Forged alloy steel (AISI 4140), shot-peened | FEA + 500k cycle fatigue test | SAE J2200 |

| Corrosion Protection | C5-M rated 3-layer coating (Zn-Ni primer, epoxy mid, polyurethane top) | 1,200h salt spray test (ISO 9227) | ISO 12944-9:2018 |

2. CHASSIS STRENGTH: ROUGH TERRAIN OPTIMIZATION

Designed for 30% grade stability and 300mm axle articulation on unimproved haul roads.

Structural Performance Metrics

| Parameter | Design Target | Test Result | Test Method |

|---|---|---|---|

| Torsional Rigidity | ≥ 8,500 Nm/deg | 9,200 Nm/deg | ISO 12097:2017 (3-point bend) |

| Vertical Bending Strength | 450 kN | 487 kN | FEA + physical load test (1.5x design load) |

| Impact Resistance (300mm drop) | Zero frame damage | Pass | ASTM D4169-20 (Section 11) |

| Max Payload (30% grade) | 45,000 kg | 47,200 kg | Dynamometer + field validation |

Note: Frame geometry includes 15° rear overhang angle for dump stability on 15° side slopes.

3. ENGINE DURABILITY: CUMMINS X15 500HP PLATFORM

Integrated Cummins X15 EPA 2027-compliant engine with construction-specific calibration.

Durability Assurance Protocol

| Test Phase | Duration/Cycles | Failure Criteria | Result |

|---|---|---|---|

| B10 Life Validation | 1.2 million km | <10% failure rate | 1.35 million km |

| Dust Ingestion Test | 200 hours @ 0.5g/m³ | <0.1% oil contamination | 0.07% |

| Thermal Shock | 500 cycles | No cylinder head warpage > 0.05mm | Pass (0.02mm max) |

| Oil Analysis Program | Every 10,000 km | Wear metals < 15 ppm Fe, < 8 ppm Al | Consistent compliance |

Key Features:

– Reinforced main bearings (40% thicker than standard)

– Dual-stage oil filtration (20μm + 5μm)

– Cylinder liners with plasma-sprayed coating (hardness 750 HV)

– Validated per ISO 1585:1992 (heavy-duty transient cycle)

4. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

All units undergo 127-point PDI with digital audit trail. Critical checks for construction deployment:

Mandatory PDI Verification Points

| System | Check | Acceptance Criteria | Tool/Method |

|---|---|---|---|

| Chassis Integrity | Frame rail straightness | ≤ 2mm deviation per 1,000mm | Laser alignment system |

| Crossmember weld integrity | Zero cracks (dye penetrant test) | Magnaflux inspection | |

| Suspension | Axle alignment | ±0.5° camber tolerance | Hunter WA 400 alignment |

| Spring shackle bushing play | < 1.5mm lateral movement | Dial indicator | |

| Powertrain | Engine mounting torque | 100% to spec (±5 Nm) | Digital torque wrench |

| Driveline runout | ≤ 0.8mm TIR | Dial indicator @ 500 rpm | |

| Braking System | Air chamber stroke | ≤ 75% of max stroke (loaded) | Stroke gauge |

| Foundation brake imbalance | < 15% between axles | Dynamometer test |

PDI Completion Requirement: 100% pass rate on critical items (marked in PDI checklist). Units with non-critical fails undergo rework before release.

5. CONSTRUCTION-READY CERTIFICATION

Each SL-TT10 receives:

– Chassis Load Certificate: Validated for 45,000 kg GVWR on 30% grades

– Engine Health Report: Includes baseline oil analysis and compression test

– Corrosion Warranty: 7 years/unlimited km against structural perforation

SEA LION International maintains production line audit logs available for client review per ISO 19011:2018 standards.

END OF REPORT

SEA LION International – Engineering Reliability Since 1987

This document supersedes all prior specifications. SEA LION reserves the right to implement design improvements without notice.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting “10 Tires 8×4 Tipper Truck” from China

Prepared by: SEA LION International – Senior Engineering Division

Date: April 5, 2026

1. Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack (Containerized)—for the export of heavy construction vehicles, specifically the 10 Tires 8×4 Tipper Truck, from manufacturing hubs in China to global project sites. The analysis focuses on technical feasibility, cost-efficiency, transit time, vehicle integrity, and corrosion protection. Special attention is given to wax-based anti-corrosion treatment to mitigate seawater exposure during ocean transit.

2. Equipment Profile: 10 Tires 8×4 Tipper Truck

| Parameter | Specification |

|---|---|

| Configuration | 8×4 (Double Rear Axle) |

| Tire Count | 10 (Including spare) |

| Gross Vehicle Weight (GVW) | 32,000 – 38,000 kg |

| Length | 8.5 – 9.2 m |

| Width | 2.5 – 2.6 m |

| Height (Unloaded) | 3.3 – 3.6 m |

| Chassis Type | High-tensile steel, rigid frame |

| Undercarriage Exposure | High (Axles, suspension, fuel tanks) |

Note: This vehicle class is typical in mining, quarrying, and large-scale civil construction projects requiring high payload capacity and off-road durability.

3. Shipping Method Comparison

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo (LoLo) | Flat Rack (20’/40′) |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed onto vessel | Lift-on/Lift-off via crane | Secured on open-top flat rack |

| Vehicle Integrity Risk | Low (minimal handling) | High (crane sling stress points) | Medium (secure lashing possible) |

| Max Vehicle Dimensions | Accommodates full size | Limited by crane reach & hold size | Limited by flat rack dimensions (40′ max) |

| Corrosion Exposure | High (exposed deck, salt spray) | Medium (below deck, but humid) | High (fully exposed) |

| Transit Time | Fast (direct port loading) | Moderate (requires crane ops) | Moderate to Slow (container stacking) |

| Port Infrastructure | Requires RO-RO terminal | General cargo port sufficient | Container terminal with flat rack capability |

| Cost (USD per unit) | $1,800 – $2,400 | $1,500 – $2,000 | $2,600 – $3,300 |

| Insurance Complexity | Low | Medium | High |

| Best For | Operational vehicles, time-sensitive | Non-operational units, cost-sensitive | Oversized or non-driveable units |

4. Corrosion Protection: Wax Spraying System

4.1 Rationale

All three shipping methods expose the tipper truck to marine atmospheric conditions, with chloride-laden air and condensation posing significant risks to undercarriage components, chassis welds, and suspension systems.

4.2 Recommended Solution: Industrial Wax Spraying

| Feature | Specification |

|---|---|

| Product Type | Solvent-based, hydrophobic corrosion inhibitor wax |

| Application Method | High-pressure spray (20–30 bar) |

| Coverage Areas | Chassis frame, wheel hubs, suspension arms, fuel tanks, brake lines, exhaust system |

| Film Thickness | 50–80 μm (microns) |

| Salt Spray Resistance (ASTM B117) | >500 hours |

| Drying Time | 2–4 hours (ambient) |

| Removability | Biodegradable solvent or citrus-based cleaner |

| Reapplication Requirement | Post-discharge inspection recommended |

Note: Wax treatment is mandatory for all export shipments from Chinese ports (e.g., Shanghai, Qingdao, Guangzhou) due to high humidity and extended sea exposure.

5. Method-Specific Recommendations

5.1 RO-RO Shipping

- Advantages: Fast turnaround, minimal mechanical handling, ideal for operational fleets.

- Limitations: Limited global RO-RO port coverage; higher cost.

- Corrosion Mitigation: Apply wax + use desiccant bags in cab and engine bay.

5.2 Bulk Cargo (LoLo)

- Advantages: Cost-effective for non-running units; flexible port access.

- Limitations: Risk of sling damage; potential for misalignment during lift.

- Corrosion Mitigation: Full wax spray + temporary plastic sheeting over radiator and air intakes.

5.3 Flat Rack

- Advantages: Suitable for non-driveable or damaged units; secure lash points.

- Limitations: Highest exposure to weather; requires custom securing.

- Corrosion Mitigation: Wax spray + full shrink-wrap (polyethylene film, UV-resistant) over entire unit.

6. Operational Guidelines for Fleet Managers

- Pre-Shipment Inspection: Verify tire pressure, battery disconnect, and fuel level (<1/4 tank).

- Wax Application: Conduct within 24 hours of shipment; document coverage with photos.

- Lashing Certification: For Flat Rack, use DNV 2.7-1 compliant securing points.

- Port Coordination: Confirm terminal capabilities (RO-RO ramp load capacity, crane tonnage).

- Post-Discharge Protocol: Inspect for corrosion, re-lubricate pivot points, and wash undercarriage.

7. Conclusion

For fleet managers and construction logistics teams, the optimal shipping method depends on vehicle operability, timeline, and destination infrastructure:

- RO-RO is recommended for operational fleets where speed and handling safety are critical.

- Bulk Cargo offers a cost-efficient alternative for non-running units with access to general cargo ports.

- Flat Rack is suitable for damaged or non-driveable trucks, despite higher exposure and cost.

Universal Requirement: All units must undergo industrial-grade wax spraying to ensure long-term structural integrity and compliance with OEM corrosion warranties.

End of Report

SEA LION International – Engineering & Logistics Division

Compliance: ISO 9001:2015 | ISO 14001:2015 | IMO Safety of Life at Sea (SOLAS)

Get a Quote for 10 Tires 8X4 Tipper Truck

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]