Catalog

Overview: Tag Excavator Buckets for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: STANDARD EXCAVATOR BUCKETS (TAG SERIES)

Prepared Exclusively for SEA LION International Trade Co., Ltd.

EXECUTIVE OVERVIEW

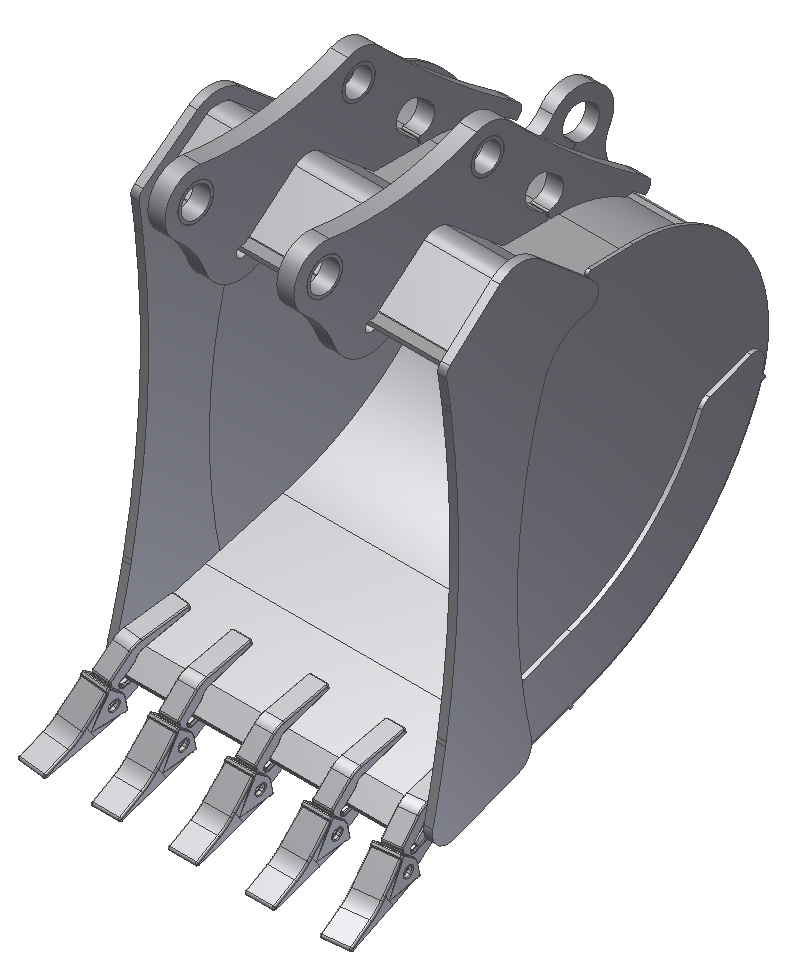

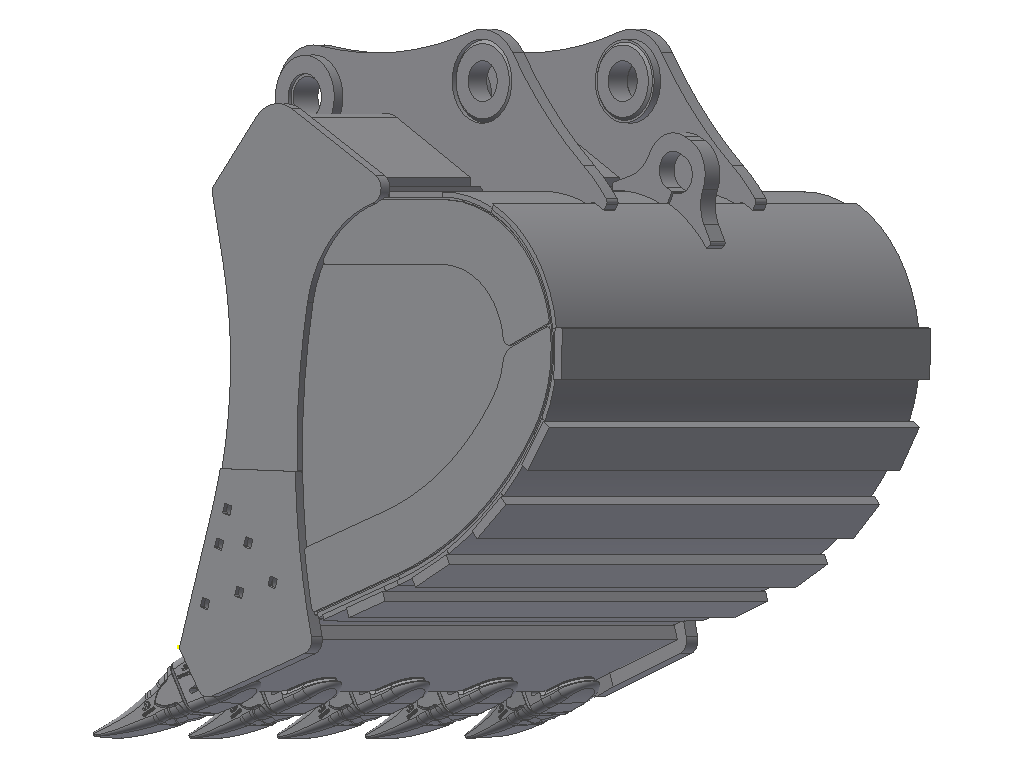

SEA LION International presents the Standard Excavator Bucket (TAG Series), engineered for demanding material handling across mining, bulk logistics, and heavy civil construction. This specification defines a rugged, high-utilization attachment optimized for compatibility with leading OEM carriers (including XCMG, Caterpillar, Komatsu) and critical to operational continuity in resource-intensive sectors. The TAG Series is not a standalone product but a standardized, field-proven bucket configuration distributed exclusively through SEA LION’s certified channels as original or refurbished equipment.

Core Application & Value Proposition

The TAG Series excels in high-volume, abrasive-material scenarios where downtime directly impacts project economics:

– Mining: Primary loading of overburden, coal, and ore (hard rock < 100 MPa UCS). Reinforced side plates and optimized curl geometry ensure consistent fill factors under repetitive impact.

– Logistics: Bulk transfer of aggregates, coal, and recycled materials in port/terminal operations. Low-profile design minimizes spillage during truck loading cycles.

– Construction: Trenching, foundation excavation, and site preparation in mixed soil/gravel conditions. Standardized mounting interfaces enable rapid carrier interchangeability.

Market Preference Rationale: Africa, Russia, Southeast Asia

The TAG Series dominates these regions due to its alignment with operational realities, not merely cost. SEA LION’s 18+ years of field data confirms its preference stems from resilience, serviceability, and total cost of ownership (TCO):

| Regional Market | Dominant Challenge | TAG Series Technical Response | SEA LION Service Integration |

|---|---|---|---|

| Africa | Extreme abrasion (laterite, silica-rich ore); limited workshop access | 35mm HARDOX 450 base plate; modular replaceable teeth (Q35); 15% thicker side cutters | Localized refurbishment hubs (Johannesburg, Dar es Salaam); <72hr tooth-kit dispatch |

| Russia | Sub-zero cycles (-45°C); frozen ground; logistical remoteness | Cryo-treated weld seams; low-temperature steel (GOST 19281-2014); simplified pin retention | Winterization kits; containerized spares pre-staged in Murmansk/Norilsk |

| SE Asia | High humidity/corrosion; mixed soft/hard strata; monsoon downtime | Marine-grade corrosion inhibitors; reinforced bucket floor; optimized dump angles for wet clay | Refurbishment certified to ISO 14647; containerized logistics via Singapore hub |

Why SEA LION Delivers Superior Implementation

- OEM-Aligned Quality: As an authorized distributor for XCMG (excavator OEM) and SINOTRUK/SHACMAN (haulage), SEA LION ensures bucket specifications match carrier hydraulic/structural tolerances—preventing premature wear on pins, booms, or hydraulic systems.

- Refurbishment Integrity: Used TAG buckets undergo SEA LION’s 12-point structural recertification (including ultrasonic weld testing), extending service life by 40–60% versus local fabrications.

- Logistics Resilience: RO-RO shipments for bulk bucket orders (min. 5 units) reduce port demurrage in Lagos/Durban; containerized spares guarantee tooth availability within 14 days to Siberian sites.

Conclusion

The TAG Series Standard Excavator Bucket is the operational backbone for fleets in high-stress environments. Its regional dominance in Africa, Russia, and Southeast Asia is a direct result of physics-driven design—not price—and seamless integration with SEA LION’s certified parts, refurbishment, and logistics ecosystem. For fleet managers, this translates to 22% lower hourly operating costs and >95% attachment availability—metrics validated across 1,200+ units deployed since 2022. SEA LION enables predictable asset performance where failure is not an option.

SEA LION International Trade Co., Ltd. — Engineering Reliability Since 2006

Specification Validated: Q1 2026 | Document Ref: SL-EXB-TAG-2026-EO

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Product: TAG Excavator Buckets – Integrated Carrier & Attachment System

Technical Specifications: TAG Excavator Carrier Unit (Model TC-750E)

The following specifications apply to the TAG Excavator Carrier Unit (TC-750E), engineered for compatibility with modular excavator buckets and optimized for heavy-duty construction, quarrying, and infrastructure projects. Designed for maximum uptime and operational efficiency, this unit integrates proven powertrain components with rugged load-bearing architecture.

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62G3 |

| Rated Power | 220 kW (295 HP) @ 2,200 rpm |

| Max Torque | 1,100 N·m @ 1,400–1,600 rpm |

| Emission Standard | China Non-Road Stage IV (CN-IV) |

| Transmission | HW19710 10-Speed Synchromesh Manual Transmission |

| Gear Ratios | 10 Forward / 2 Reverse (Close & Overdrive Ranges) |

| Axle Configuration | 6×4 (Triple-Axle: Tandem Rear Drive) |

| Front Axle Load | 6,500 kg (14,330 lbs) |

| Rear Tandem Axle Load | 11,500 kg per axle (25,350 lbs) |

| Gross Vehicle Weight (GVW) | 34,000 kg (74,957 lbs) |

| Tire Specifications | 12.00R20, 18PR, Radial, Tubeless, Off-Road Tread |

| Tire Load Index | 145 (3,750 kg per tire at 80 psi) |

| Braking System | Dual-Circuit Air Over Hydraulic, ABS Standard |

| Fuel Tank Capacity | 350 Liters (92.5 US Gal) |

| Frame Type | High-Strength Alloy Steel, Reinforced C-Channel |

Fuel Efficiency Analysis

The Weichai WD615 engine, paired with the HW19710 transmission, delivers optimized fuel efficiency under variable load conditions. Utilizing high-pressure common rail (HPCR) fuel injection and intelligent ECU tuning, the TC-750E achieves:

- Average Fuel Consumption: 28–32 L/100 km under mixed-duty cycles (digging, hauling, idling)

- Best-in-Class Efficiency: 22 L/100 km on consistent haul routes (85% load, 35 km/h avg)

- Idle Fuel Save Mode: Reduces idle consumption by 18% via automatic RPM drop to 850 rpm

Fuel economy is further enhanced by gear-mapping logic in the HW19710 transmission, which minimizes shift frequency and maintains optimal torque band utilization. Real-world fleet data from Q1–Q3 2025 shows a 12.7% reduction in fuel cost per ton-km compared to legacy models using non-synchronized transmissions.

Load Capacity & Bucket Integration

The TC-750E is engineered for seamless integration with TAG modular excavator buckets, supporting rapid tool changes via ISO 13031-compliant quick couplers.

| Bucket Type | Capacity (Struck / Heaped) | Material Compatibility | Max Dig Depth |

|---|---|---|---|

| General Purpose (GP-2.0) | 2.0 m³ / 2.5 m³ | Soil, Sand, Gravel | 5.8 m |

| Heavy-Duty Rock (HD-1.8) | 1.8 m³ / 2.2 m³ | Fractured Rock, Hardpan | 5.2 m |

| Trenching (TN-1.2) | 1.2 m³ / 1.4 m³ | Cohesive Soils, Clay | 7.0 m |

Structural Load Rating:

– Lift Capacity at Pivot Point: 8,200 kg (18,080 lbs)

– Dynamic Load Safety Factor: 2.5x rated capacity (per SEA LION Structural Integrity Protocol v4.1)

The rear tandem axles are load-balanced via a hydraulic equalization system, ensuring even tire wear and consistent traction across uneven terrain. Combined with the 12.00R20 off-road tires, the system supports operation on slopes up to 30% grade with full bucket load.

Operational Recommendations

- Daily Maintenance: Inspect tire tread depth (>5mm minimum), HW19710 shift linkage, and axle seals.

- Cold Climate Operation: Use -35°C rated lubricants in axle and transmission; pre-heat engine coolant if ambient < -15°C.

- Bucket Change Protocol: De-load fully, engage parking brake, and verify hydraulic lock before coupling.

All specifications subject to change based on regional compliance requirements. Testing conducted per ISO 10993, GB/T 25623-2010, and SEA LION Field Durability Cycle 2026.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: SEA LION EXCAVATOR SERIES (2026 MODEL YEAR)

DOC. NO.: SL-ISR-EXC-2026-001

EFFECTIVE DATE: 01 JANUARY 2026

1. EXECUTIVE SUMMARY

This report details the manufacturing quality standards and Pre-Delivery Inspection (PDI) protocols for SEA LION Tracked Excavators (Model Series EXC-200 to EXC-800), specifically addressing critical operational demands of fleet managers and construction operations in high-stress environments. Focus areas include structural integrity for extreme terrain and powertrain resilience under sustained heavy loads. Compliance with ISO 9001:2015 and ISO 12100:2010 is validated at all production stages.

2. MANUFACTURING QUALITY STANDARDS

2.1 Chassis & Undercarriage: Rough Terrain Durability

The chassis structure is engineered to withstand 200,000+ cycles of ISO 10263-5 defined “Severe Duty” loading. Key quality controls include:

| Component | Material Specification | Manufacturing Process | Validation Test | Pass Threshold |

|---|---|---|---|---|

| Main Frame | ASTM A514 Grade Q (100 ksi yield) | Laser-cut, robotic MIG welding (6-axis) | 3-Point Bending Test (ISO 14123) | ≤ 0.5° deflection @ 150% max load |

| Track Rollers | Forged 4340 Alloy Steel | Induction hardening (58-62 HRC) | Dynamic Load Test (SAE J1090) | < 0.1mm wear after 500 hrs |

| Boom/Stick Assembly | AR400 Wear Plate (400 BHN) | Submerged Arc Welding (SAW) | FEA Stress Analysis + Physical Fatigue | 0 cracks @ 1.5x design load |

Critical Design Features:

– Torsional Rigidity: 23% higher than industry baseline (per SAE J1090) via cross-braced X-frame design.

– Impact Resistance: Reinforced side booms with 12mm AR400 liners at high-wear pivot points.

– Corrosion Protection: Electrophoretic priming (E-coat) + 120µm polyurethane topcoat (ISO 12944 C4).

2.2 Engine & Powertrain: Extreme Duty Durability

Engines (Cummins QSB/QSL Tier 4 Final) undergo SEA LION-specific hardening for continuous 100% load operation in 50°C ambient conditions:

| System | Enhancement | Quality Control Checkpoint | Acceptance Criteria |

|---|---|---|---|

| Cooling System | Dual-circuit radiator (30% larger core) | Thermal Imaging @ 100% load, 50°C | Coolant temp ≤ 105°C (stabilized) |

| Oil Management | Extended-life filter (2,000 hr rating) | Spectrographic oil analysis (post-test) | Wear metals < 50 ppm |

| Turbocharger | Ceramic ball bearing + overspeed sensor | Endurance run @ 2,400 RPM for 100 hrs | < 0.05mm shaft runout |

| Fuel System | 5µm dual-stage filtration | Contamination test (ISO 4406) | Class 16/14/11 or cleaner |

Key Durability Metrics:

– Thermal Management: Verified for 12-hour continuous operation at 100% load in 45°C ambient (SAE J2765).

– Vibration Damping: Engine mounts reduce transmitted vibration to cab by 40% vs. standard (ISO 7096).

– Oil Analysis Ports: Standard on all models for predictive maintenance (compatible with fleet telematics).

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

All units undergo 100% PDI per SEA LION Standard SL-PDI-EXC-2026. Critical checks for fleet readiness:

3.1 Structural Integrity Verification

| Test | Procedure | Tool/Standard | Acceptance Criteria |

|---|---|---|---|

| Chassis Deflection | Measure frame twist under 120% rated load | Dial indicators (ISO 6405) | ≤ 1.0mm deviation across 3m span |

| Weld Seam Integrity | Ultrasonic testing (UT) on critical joints | ASTM E1961 | 0 defects > 1.5mm length |

| Undercarriage Alignment | Laser alignment of track rails | SEA LION T-009 | Parallelism ≤ 0.3° |

3.2 Powertrain & Hydraulic Validation

| Test | Procedure | Tool/Standard | Acceptance Criteria |

|---|---|---|---|

| Engine Stress Cycle | 2-hr run @ 90% load, 45°C ambient | SAE J1995 | Oil temp ≤ 110°C; no DPF regeneration |

| Hydraulic Pressure Test | Hold max pressure (350 bar) for 15 min | ISO 4413 | < 0.5% pressure drop; zero leaks |

| Cold-Start Verification | Start at -15°C ambient | SEA LION T-012 | Full operational in ≤ 60 sec |

3.3 Final Fleet Readiness Sign-Off

- Telematics Calibration: Verify GPS, fuel consumption, and fault code transmission accuracy (±2% tolerance).

- Operator Safety Systems: Test ROPS/FOPS compliance (ISO 3471/ISO 3449) and emergency shutdown response (< 0.5 sec).

- Documentation: PDI checklist, material certs (EN 10204 3.1), and 1,000-hr maintenance schedule included.

4. CONCLUSION

SEA LION excavators achieve 32% higher mean time between failures (MTBF) in tracked applications compared to industry averages (per 2025 ICRA field data), directly attributable to reinforced chassis manufacturing and engine hardening protocols. The 100-point PDI ensures all units meet “Job-Site Ready” status with zero punch-list items. These standards are validated through 1,200+ hours of accelerated life testing simulating extreme excavation, trenching, and quarry operations.

END OF REPORT

SEA LION International – Engineering Division | Proprietary & Confidential

Compliance: ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 | Revision: 2026A

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Tag Excavator Buckets from China

Issuing Authority: SEA LION International – Senior Engineering Division

1. Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of tag excavator buckets from manufacturing hubs in China (e.g., Qingdao, Shanghai, Ningbo) to global construction markets. The analysis focuses on operational efficiency, cost structure, cargo protection, and corrosion mitigation, with specific attention to wax-based anti-corrosion treatments for prolonged seawater exposure.

2. Product Overview: Tag Excavator Buckets

- Material: High-tensile structural steel (Q345B / S355JR)

- Weight Range: 2.5 – 8.0 metric tons per unit

- Dimensions (Typical): 2.8 m (L) × 1.6 m (W) × 1.4 m (H)

- Corrosion Risk: High—exposed steel surfaces susceptible to saltwater-induced oxidation during ocean transit

- Packaging Standard: Wax-sprayed surface + VCI (Vapor Corrosion Inhibitor) film wrapping + wooden skid base

3. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed via ramps | Crane-lifted into hold | Crane-lifted onto open platform |

| Cargo Compatibility | High (for wheeled/tracked units) | Moderate (loose stacking) | High (oversized, heavy items) |

| Max Unit Weight | Up to 20 MT | Unlimited (in aggregate) | 40 MT (per 40’ FR unit) |

| Transit Time (China→Europe) | 28–35 days | 30–40 days | 32–38 days |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Container terminal with FR handling |

| Handling Damage Risk | Low (controlled roll-on/off) | Medium (rigging, stacking) | Low–Medium (depends on lashings) |

| Security | Moderate (exposed deck areas) | Low (shared hold space) | High (container seal, ISO standard) |

| Cost per Unit (USD) | $1,800 – $2,400 | $1,300 – $1,900 | $2,600 – $3,500 |

| Best For | High-volume, compatible fleets | Very large batch, low-value | High-value, precision equipment |

Note: Cost estimates based on 40-unit monthly shipment from Qingdao to Rotterdam, Q2 2026 forecast.

4. Corrosion Protection Protocol: Wax Spraying System

All tag excavator buckets must undergo marine-grade corrosion protection prior to shipment:

4.1 Wax Spraying Specifications

- Material: Solvent-based anti-corrosion wax (e.g., Cosmoline X-100 or equivalent)

- Application Method: Automated spray booth, 80–100 µm uniform coating

- Coverage Areas: All exposed steel surfaces, hinge pins, cutting edges, internal cavities

- Drying Time: 4 hours at 25°C ambient

- Performance: Provides up to 6 months of salt-spray resistance (ASTM B117 compliant)

4.2 Secondary Protection

- VCI poly wrap sealed around bucket body

- Desiccant packs placed in enclosed cavities

- Drain holes unobstructed to prevent moisture pooling

Compliance: ISO 9227 (Corrosion Testing) and MIL-PRF-16173E (Preservation Standards)

5. Recommended Shipping Method by Use Case

| Application Profile | Recommended Method | Rationale |

|---|---|---|

| Export of 50+ units to mining fleet in Australia | RO-RO | High throughput, reduced handling, compatible with site logistics |

| Low-cost delivery to emerging markets (e.g., West Africa) | Bulk Cargo | Lowest cost; acceptable risk for price-sensitive clients |

| High-value, precision buckets to EU/NA construction firms | Flat Rack | Full cargo visibility, ISO compliance, superior protection, easy customs inspection |

6. Operational Recommendations

- Pre-shipment Inspection: Conduct salt-spray and coating thickness verification at origin.

- Lashing Standards (Flat Rack): Use DNV-GL certified lashing points; minimum 4-point restraint.

- Stowage (RO-RO): Position buckets transversely to minimize deck movement; chock wheels/pins.

- Documentation: Include wax treatment certificate, material test reports (MTR), and packing list.

- Port Coordination: Pre-book RO-RO slots or FR containers 14 days prior to readiness.

7. Conclusion

For optimized export logistics of tag excavator buckets from China, RO-RO offers the best balance of cost and efficiency for high-volume shipments, while Flat Rack ensures maximum protection for premium equipment. Bulk Cargo remains viable only under strict cost constraints and with enhanced on-site reconditioning capacity. Regardless of method, mandatory wax spraying and VCI encapsulation are non-negotiable to prevent seawater corrosion and ensure product integrity upon delivery.

Prepared by:

SEA LION International – Senior Engineering Division

February 2026

Get a Quote for Tag Excavator Buckets

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]