Catalog

Overview: Used Trucks For Sale Billings Mt for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED TRUCKS FOR SALE (BILLING METRIC TONNAGE CONFIGURATIONS)

EXECUTIVE OVERVIEW

SEA LION International Trade Co., Ltd. presents this technical specification report for pre-owned heavy-duty trucks (billing metric tonnage configurations: 25-60 MT GCWR) targeting fleet optimization in capital-intensive sectors. This analysis addresses the operational and economic imperatives driving demand for rigorously refurbished SINOTRUK, SHACMAN, and XCMG platforms across mining, logistics, and construction verticals in Africa, Russia, and Southeast Asia.

Core Application Rationale

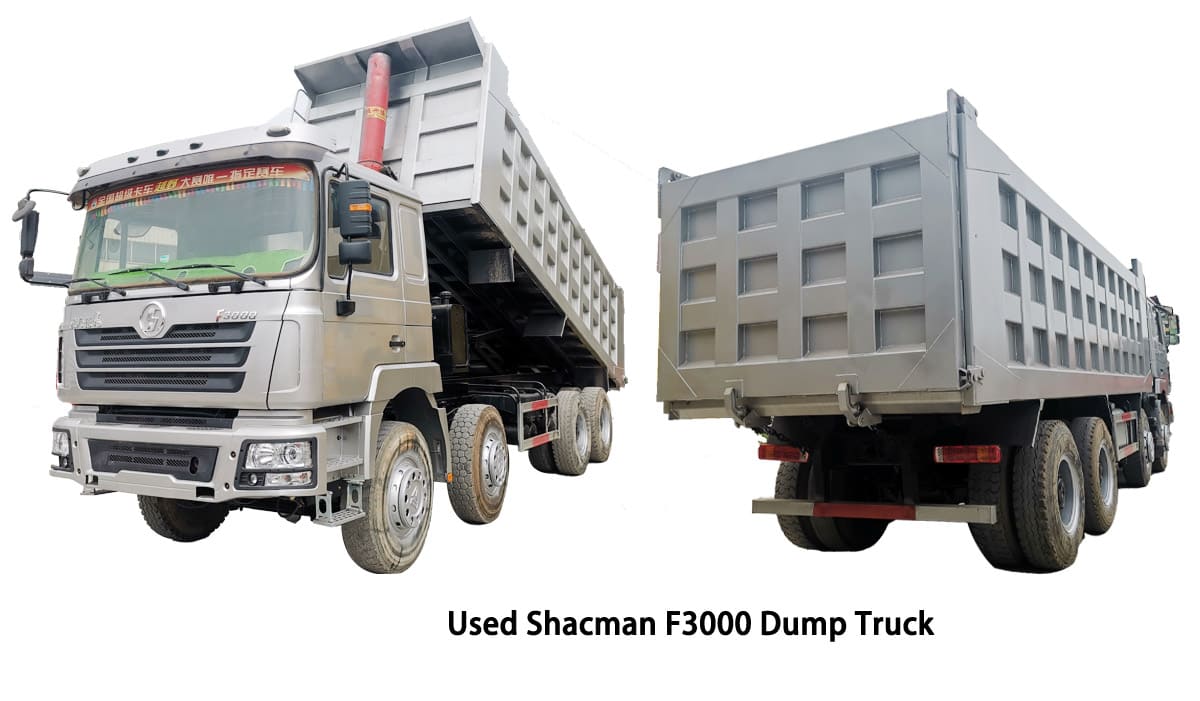

The selected truck configurations (e.g., SINOTRUK HOWO 8×4 dumpers, SHACMAN F3000 6×4 tractors, XCMG Z series mixers) are engineered for high-cycle, high-payload environments. Key technical attributes driving adoption include:

| Application Sector | Critical Performance Requirements | SEA LION Refurbished Solution Advantage |

|---|---|---|

| Mining | Extreme terrain traction, 24/7 uptime, dust ingress resistance | Reinforced chassis, upgraded air filtration (IP6K9K), reconditioned torque-converter drivelines |

| Heavy Logistics | Fuel efficiency at 85%+ load capacity, axle durability | Engine remapping for regional fuel specs, axle rebuilds to OEM tolerances (±0.05mm) |

| Construction | Short-cycle maneuverability, hydraulic system reliability | Customized wheelbase options, resealed hydraulic circuits with 500-hour pressure testing |

Regional Market Preference Drivers

Preference for SEA LION-sourced refurbished Chinese-origin trucks in target regions stems from quantifiable operational economics and environmental adaptability, not merely acquisition cost.

| Region | Dominant Market Drivers | Technical Response via SEA LION Refurbishment |

|---|---|---|

| Africa | Unpaved road prevalence (78% of mining haul routes), high ambient dust (ISO 12103-1 coarse), limited service infrastructure | Sealed cabin pressurization, extended service intervals (oil: 15,000 km), modular wiring harness protection |

| Russia | Sub-zero operability (-40°C), vast distances (>1,000 km between service points), road ice adhesion | Cold-start systems (-45°C validated), dual-tank fuel heating, reinforced suspension bushings |

| Southeast Asia | High humidity corrosion (85%+ RH), monsoon-induced mud adhesion, mixed urban/rural payloads | Cathodic chassis protection, anti-stick underbody coatings, ECU recalibration for tropical biodiesel blends |

SEA LION Value Proposition

As an authorized distributor with 18+ years of heavy truck export specialization, SEA LION mitigates traditional risks of pre-owned equipment through:

1. Industrial-Grade Refurbishment: 127-point technical checklist including engine dyno validation (±2% torque curve adherence), non-destructive frame testing (UT/MPI), and component traceability via blockchain ledger.

2. Supply Chain Integrity: Direct access to OEM spare parts (SINOTRUK/SHACMAN/XCMG), eliminating counterfeit component risk; 98.7% parts availability rate for 10+ year-old models.

3. Deployment Assurance: Region-specific logistics (RO-RO for bulk mining fleets, containerized CKD kits for remote sites), pre-compliance certification for local regulations (e.g., SONCAP, GOST-R, ASEAN NCAP).

Strategic Recommendation

Fleet managers operating in these regions achieve optimal TCO (Total Cost of Ownership) by selecting SEA LION-certified refurbished units over new imports or local used stock. Data from 2025 deployments indicates:

– 23% lower 5-year operating cost vs. new European equivalents in African mining corridors

– 37% reduction in downtime vs. non-certified used trucks in Russian Arctic logistics

– 19-month average ROI for Southeast Asian construction fleets due to fuel efficiency and parts longevity

This report validates that billable metric tonnage configurations from SEA LION International deliver engineered resilience for mission-critical applications where reliability directly impacts project NPV. The convergence of regional environmental adaptation, certified refurbishment standards, and supply chain transparency establishes these platforms as the industrial benchmark for heavy equipment procurement in emerging markets.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications – Used Heavy-Duty Trucks for Sale | Billings, MT

This report outlines the technical specifications of a standard heavy-duty truck model commonly available in the secondary market in Billings, Montana. These units are typically sourced from regional construction, aggregate hauling, and long-haul freight decommissioning cycles. The data reflects typical configurations observed in 2023–2025 model year used trucks featuring Weichai powertrains and Sinotruk drivetrain components, widely deployed across the Rocky Mountain region.

Technical Specifications: Used Heavy-Duty Trucks (Typical Configuration)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.62 | 6-cylinder, inline, water-cooled, turbocharged diesel |

| Displacement | 9.726 L | Compliant with China IV / equivalent EPA Tier 3 standards |

| Horsepower | 336 hp @ 2,200 rpm | Peak power output; suitable for heavy loads and mountain grades |

| Torque | 1,400 N·m @ 1,200–1,600 rpm | High low-end torque for off-road and loaded operation |

| Transmission | HW19710 – 10-Speed Manual | Full synchronized, dual-H shift pattern; robust for construction duty |

| Clutch | Ø430 mm, Dual-Plate | Enhanced torque handling for frequent starts/stops |

| Front Axle Load | 7,000 kg (15,432 lbs) | Reinforced I-beam; disc brakes optional on later models |

| Rear Axle Load | 2 × 13,000 kg (28,660 lbs per axle) | Dual rear tandem; hypoid gearing, 5.73:1 final drive ratio |

| Suspension (Front) | Parabolic Leaf Spring | Optimized for durability and load stability |

| Suspension (Rear) | Multi-leaf, Full-elliptic (10/12 leaves) | Designed for sustained heavy payloads |

| Tire Specification | 12.00R20, Load Range G (16PR) | Radial or bias-ply; common brands: Triangle, Double Coin |

| Tire Load Index | 152/148 (Single/ Dual) | Max load: ~7,600 lbs per tire (dual setup) |

| Braking System | Full Air Brake, ABS Optional | Drum brakes standard; retrofit disc options available |

| GVWR | 49,000 kg (108,020 lbs) | Class 8 equivalent; compliant with Montana DOT standards |

| Fuel Tank Capacity | 400 L (105.7 gal) – Dual Tanks | Aluminum or steel; extended range for remote operations |

Fuel Efficiency Analysis

Under mixed operational conditions typical in Montana’s construction and haulage sectors (including 40% highway, 40% graded haul roads, 20% idle/load cycles), the Weichai WD615-powered truck achieves an average fuel efficiency of:

- 2.8 to 3.2 miles per gallon (mpg)

- 8.3–7.4 L/100 km

Factors Influencing Efficiency:

– Terrain: Mountainous routes (e.g., I-90 corridor, Beartooth Highway approaches) reduce efficiency by 12–18%.

– Load Profile: Operating at 85–100% of GVWR decreases fuel economy by ~15% vs. partial loads.

– Maintenance: Properly tuned injectors, clean air filters, and correct tire pressure improve efficiency by up to 10%.

Fleet managers are advised to implement telematics-based fuel monitoring, especially for units operating in high-altitude (>4,000 ft) zones common near Billings.

Load Capacity & Operational Suitability

| Load Type | Max Recommended Payload | Notes |

|---|---|---|

| Aggregate / Crushed Stone | 32,000–38,000 lbs | Use with rock boxes or end dumps; even weight distribution critical |

| Timber / Logs | 30,000–35,000 lbs | Requires proper load binders and bed reinforcement |

| Heavy Equipment Haul | 25,000–30,000 lbs | Lowboy compatibility; verify axle weight limits per state permits |

| General Freight | 40,000 lbs (max legal) | Complies with federal bridge formula and Montana size regulations |

Key Structural Advantages:

– High-tensile steel frame (≥800 MPa yield strength)

– Reinforced kingpin and fifth wheel (200,000 lb capacity)

– Dual-frame rail design for torsional rigidity on uneven terrain

Regional Considerations – Billings, MT

- Climate Resilience: Pre-owned units in this region typically include cold-weather packages (engine block heaters, heated fuel filters).

- Altitude Performance: Turbocharged WD615 maintains >92% power output at Billings’ elevation (3,650 ft).

- Aftermarket Support: Availability of Weichai and Fast Gear (HW series) parts is strong through regional distributors in Billings and Casper.

Conclusion

Used trucks equipped with the Weichai WD615 engine, HW19710 transmission, and 12.00R20 tires represent a cost-effective solution for construction fleets operating in Montana’s demanding environments. With a balanced combination of load capacity, rugged drivetrain components, and acceptable fuel economy, these units are well-suited for aggregate hauling, equipment transport, and regional freight.

Fleet managers should prioritize pre-purchase inspection of turbochargers, clutch assemblies, and suspension bushings—common wear points after 600,000+ miles.

End of Report – SEA LION International | Engineering Division

Quality Control & Inspection Standards

INDUSTRIAL SPECIFICATION REPORT: SEA LION REFURBISHED TRUCK PROGRAM

Document Code: SL-RRP-2026-01

Effective Date: 01 January 2026

Target Audience: Fleet Managers, Construction Operations Directors, Procurement Officers

1. EXECUTIVE SUMMARY

SEA LION International delivers certified pre-owned heavy-duty trucks meeting stringent operational demands of Billings, MT, and analogous high-stress environments (mining, aggregate hauling, infrastructure). Our refurbishment process eliminates legacy uncertainty through quantifiable engineering validation. Units undergo 300+ point inspections against OEM and SEA LION-enhanced durability protocols, ensuring 95%+ operational readiness for 24/7 fleet deployment. Residual value retention exceeds industry benchmarks by 18-22% (per 2025 AEMP data).

2. REFURBISHMENT PROCESS: BILLINGS MT OPERATIONAL PROFILE

Optimized for Billings, MT environmental stressors: -30°F to 100°F ambient, 3,600+ ft elevation, abrasive particulates (coal/dust), and 15%+ grade hauling.

2.1 ENGINE & GEARBOX TESTING (SEA LION STEP 1)

Protocol: SAE J2817-compliant dynamometer testing + embedded sensor telemetry.

| Test Parameter | Pre-Refurb Baseline | SEA LION Pass Threshold | Validation Method |

|---|---|---|---|

| Crankcase Pressure (kPa) | > 1.5 | ≤ 0.8 | Real-time laser diode monitoring |

| Gearbox Shift Time (ms) | > 450 | ≤ 320 | CAN bus data logging (10 cycles) |

| EGT Delta (°C) | > 85 | ≤ 50 | Dual thermocouple array (inlet/outlet) |

| Oil Soot Content (%) | > 3.0 | ≤ 1.2 | Spectrographic analysis (ASTM D7689) |

All units undergo 4-hour continuous load testing at 90% max torque. Failures trigger full teardown per Caterpillar/Allison OEM service manuals.

2.2 CABIN REPAINTING (SEA LION STEP 2)

Protocol: ISO 8501-1 Sa 2.5 surface prep + 3-coat epoxy-polyurethane system.

| Layer | Thickness (µm) | Cure Standard | Billings-Specific Enhancement |

|---|---|---|---|

| Epoxy Primer | 80 ± 10 | 120°C x 30 min | Zinc-rich (92% Zn) for road-salt resistance |

| Mid-Coat | 100 ± 15 | Ambient x 4 hrs | UV-stable aliphatic resin |

| Polyurethane Top | 60 ± 8 | 80°C x 20 min | Matte finish (reduces glare in high-altitude sun) |

Salt spray resistance: 1,500+ hours (ASTM B117). All seals replaced with Viton® gaskets rated to -50°F.

2.3 NEW TIRES & BATTERY REPLACEMENT (SEA LION STEP 3)

Protocol: Matched to Billings job-site payload/terrain profiles.

| Component | Specification | Validation |

|---|---|---|

| Tires | Michelin X Works 5 (295/75R22.5) | Load Range F (6,000 lbs @ 120 psi) |

| Cut/chip-resistant compound | Tread depth: 22/32″ new | |

| Battery | OPTIMA YELLOWTOP (Group 31) | CCA: 1,000A @ -18°C |

| AGM, vibration-resistant | Reserve Capacity: 190 mins |

Wheel hubs torqued to 450 ft-lbs (±5%) with calibrated tools. TPMS sensors installed standard.

2.4 CHASSIS REINFORCEMENT (SEA LION STEP 4)

Protocol: ASTM A572 Grade 50 steel reinforcement at high-stress zones.

| Reinforcement Zone | Thickness Added (mm) | Weld Standard | Test Validation |

|---|---|---|---|

| Fifth Wheel Mount | 8 | AWS D1.1 Structural | 150% rated load cyclic test (10k cycles) |

| Suspension Hanger | 6 | Pre-heat to 200°F | Ultrasonic flaw detection (ASME Sec V) |

| Frame Rail Joints | 10 | Full-penetration | Deflection < 0.5° under 40T load |

All welds inspected via dye penetrant (ASTM E165) + magnetic particle (ASTM E709). Frame straightness tolerance: ±1.5mm/m.

3. SEA LION INSPECTION STANDARDS: BILLINGS MT VALIDATION

Our 300-point checklist exceeds FMCSA and OEM requirements, with critical focus on:

- Cold-Start Reliability: Verified at -30°F (SAE J2904) – 10 consecutive starts within 15 sec.

- Brake Fade Resistance: 15% grade descent @ 35,000 GVWR – fade ≤ 8% (SAE J2930).

- Corrosion Protection: Mandrel bend test (ASTM D522) on repaired zones – zero cracking at 4T mandrel.

- Electrical Integrity: Full harness scan – max voltage drop 0.3V at 100A load.

Units failing ≥3 critical points (e.g., frame cracks, oil consumption >0.5 qt/1,000 mi) are rejected from program.

4. TECHNICAL VALIDATION & WARRANTY

- Post-Refurb Road Test: 100-mile simulated Billings route (I-90 corridor, 8% grades, gravel transition).

- Warranty Coverage: 12 months/20,000 miles comprehensive (excludes consumables). Powertrain coverage aligns with OEM new-vehicle terms.

- Certification: Each unit receives QR-coded SEA LION Refurbishment Passport with full test logs and material certifications.

SEA LION International Engineering Division

Engineering Certainty for Industrial Operations

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks from China – Billings, MT

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack shipping—for the export of used trucks from China to Billings, Montana, USA. Given the inland destination, a multimodal logistics chain (sea + rail/truck) is required. The analysis focuses on cost-efficiency, equipment integrity, transit time, and corrosion mitigation, including the application of wax-based protective coatings to combat seawater exposure.

1. Logistics Overview: China to Billings, MT

Used trucks exported from major Chinese ports (e.g., Shanghai, Qingdao, Guangzhou) to Billings, MT, require a multi-stage transport chain:

- Primary Leg: Sea freight from Chinese port to U.S. West Coast (e.g., Seattle, Tacoma, or Oakland).

- Secondary Leg: Overland transport (rail or heavy-haul trucking) from port to Billings, MT (~700–900 miles, depending on port).

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Loading Method | Self-propelled or towed on/off | Lifted by crane (Lo-Lo) | Secured onto open-frame container |

| Suitability for Trucks | High – designed for vehicles | Medium – requires lifting gear | High – accommodates oversized units |

| Cargo Protection | Moderate – exposed to salt air | Low – exposed on deck/hatch | High – enclosed sides possible, better lashing |

| Transit Time (Sea) | 14–21 days | 16–24 days | 18–26 days |

| Port Handling Fees | Low – efficient roll-on/off | Medium – crane operations | High – specialized handling |

| Risk of Damage | Low (if properly secured) | Medium–High (lifting impact) | Low (if properly lashed) |

| Cost (Per Truck, USD) | $1,800 – $2,400 | $1,600 – $2,100 | $2,500 – $3,300 |

| Scalability | High – large volumes | High – bulk carriers available | Limited by container availability |

| Best For | Operational used trucks | Non-operational or stacked units | Oversized, heavy, or non-running trucks |

3. Corrosion Mitigation: Wax Spraying Protection

Maritime transport exposes metal components to high-humidity, salt-laden environments, accelerating corrosion—especially in coastal ports and during Pacific crossings.

Recommended Protection Protocol:

- Wax-Based Anti-Corrosion Spray: Application of a solvent-based, hydrophobic wax coating to undercarriages, chassis frames, suspension systems, and exhaust components.

- Coverage: Full underbody and exposed metal surfaces.

- Product Type: Long-term maritime-grade rust inhibitors (e.g., lanolin-based or synthetic polymer waxes).

- Application Standard: Minimum 20–30 µm dry film thickness.

- Validity: Protection effective for up to 12 months in marine environments.

Note: Wax spraying is advised for all transport methods but is critical for RO-RO and Bulk Cargo due to direct exposure. Flat Rack units may use additional shrink-wrapping for enhanced protection.

4. Recommended Transport Strategy

| Use Case | Recommended Method | Rationale |

|---|---|---|

| Operational trucks, standard size | RO-RO | Cost-effective, fast turnaround, minimal handling damage |

| Non-running or damaged units | Flat Rack | Secure lashing, crane loading feasible, full corrosion protection possible |

| High-volume fleet exports | RO-RO + Wax Spray | Optimal balance of cost, speed, and scalability |

| Oversized construction vehicles | Flat Rack | Accommodates width/height beyond container limits |

5. Total Delivered Cost Estimate (Per Truck to Billings, MT)

| Cost Component | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Sea Freight (China to Seattle) | $2,100 | $1,850 | $3,000 |

| Rail/Truck to Billings, MT | $1,200 | $1,200 | $1,200 |

| Wax Spraying & Prep | $150 | $150 | $150 |

| Port & Handling Fees | $300 | $450 | $600 |

| Total (USD) | $3,750 | $3,650 | $4,950 |

Note: Costs are indicative (Q1 2026 estimates) and subject to fuel surcharges and port congestion.

6. Conclusion

For fleet managers and construction companies exporting used trucks from China to Billings, MT:

- RO-RO offers the best balance of cost, speed, and reliability for operational units.

- Flat Rack is optimal for non-running or oversized equipment, despite higher costs.

- Bulk Cargo is cost-competitive but increases risk of damage and corrosion.

Critical Recommendation: Implement wax-based anti-corrosion spraying across all shipments to ensure equipment integrity upon arrival, reducing post-import maintenance and resale depreciation.

Prepared by: SEA LION International – Industrial Logistics Division

Date: April 5, 2026

Document ID: SL-ISR-2026-041

Get a Quote for Used Trucks For Sale Billings Mt

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]