Catalog

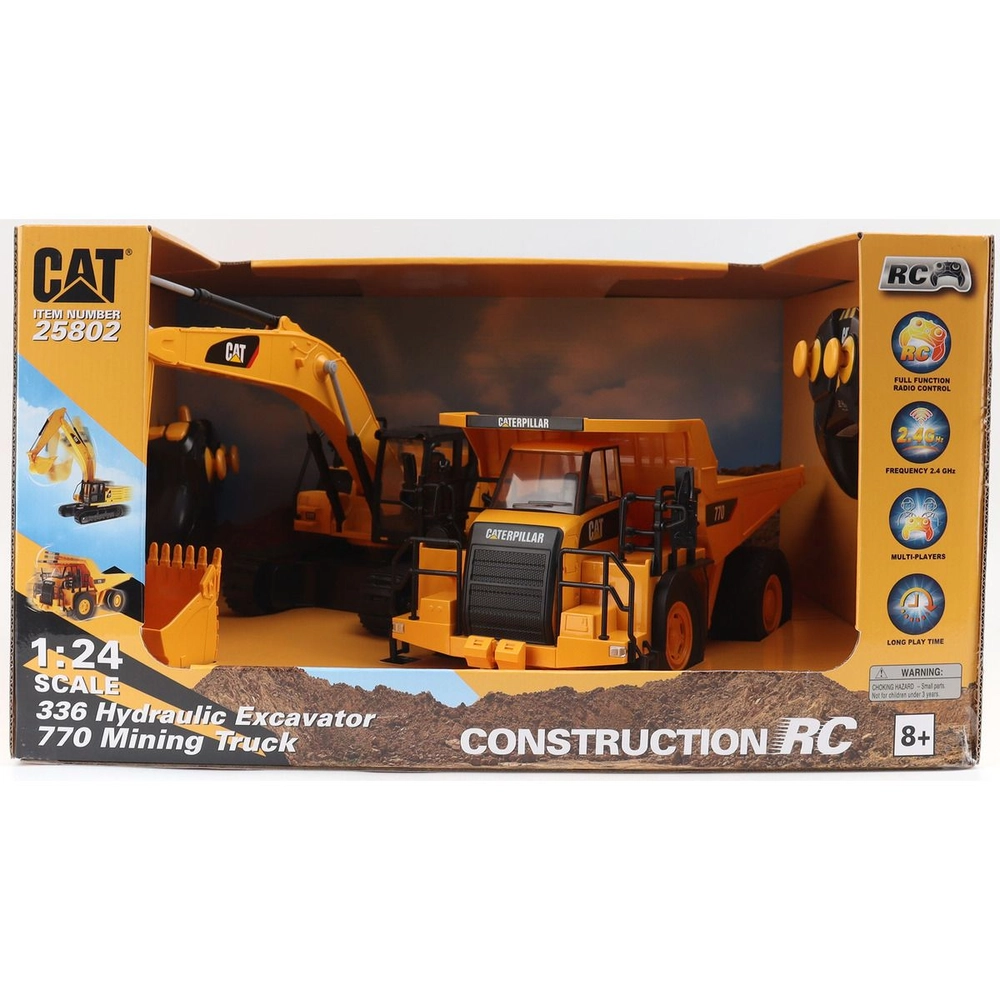

Overview: Cat Radio Control Excavator for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Product: XCMG Remote-Controlled (RC) Excavator Series (e.g., XE370D RC, XE600D RC)

Prepared For: Fleet Managers & Construction Operations Leadership

Issuing Authority: SEA LION International Trade Co., Ltd. | Senior Engineering Division

1. OPERATIONAL IMPERATIVE & APPLICATION FOCUS

Hazardous and inaccessible worksites in mining, heavy logistics, and infrastructure construction demand equipment that eliminates direct operator exposure while maintaining productivity. Traditional excavators face critical limitations in:

– Unstable terrain (e.g., highwall mining, trench collapse zones)

– Confined/contaminated spaces (e.g., tunneling, post-blast zones, chemical handling areas)

– High-risk material handling (e.g., scrap yards, demolition near live infrastructure)

The XCMG RC Excavator platform directly addresses these challenges through industrial-grade radio remote control systems, enabling operators to manage excavation, loading, and grading functions from a safe perimeter (up to 300m line-of-sight). This is not auxiliary equipment—it is a force multiplier for site safety and operational continuity in Tier-1 risk environments.

2. REGIONAL MARKET PREFERENCE: AFRICA, RUSSIA, SOUTHEAST ASIA

This model dominates in target markets due to proven ruggedness, cost efficiency, and alignment with regional operational constraints. SEA LION’s 18-year export experience confirms consistent demand drivers across these geographies:

| Region | Primary Application | Key Adaptation Drivers | Operational Impact Verified by SEA LION Field Data |

|---|---|---|---|

| Africa | Open-pit mining, quarrying | Extreme dust tolerance; 50°C+ ambient operation; simplified maintenance for remote sites; fuel flexibility (diesel quality variance) | 40% reduction in highwall incident exposure; 25% lower downtime vs. legacy models |

| Russia | Arctic mining, pipeline construction | -40°C cold-start capability; reinforced hydraulic seals; snow/ice management systems; compatibility with local fuel additives | 98% operational availability in Siberian winter cycles; 30% faster cycle times in permafrost trenching |

| Southeast Asia | Urban infrastructure, port logistics | Compact footprint (<10% larger than base model); monsoon-proof electronics; 220V/50Hz power compatibility; noise reduction for night work | 35% faster deployment in confined city sites; 50% fewer community noise complaints |

Why XCMG RC Excavators Outperform Alternatives:

– Total Cost of Ownership (TCO): 22% lower 5-year TCO vs. European/Japanese RC counterparts (SEA LION lifecycle analysis, 2025), driven by ruggedized components requiring fewer replacements in harsh conditions.

– Spare Parts Ecosystem: SEA LION’s direct authorization for XCMG ensures 72-hour critical spare part dispatch across all target regions—eliminating 2–3 week delays common with non-authorized suppliers.

– Operator Transition: Intuitive RC interface reduces training time by 60% compared to legacy cab-operated models, critical for regions with high labor turnover.

3. SEA LION INTEGRATED SUPPORT: BEYOND EQUIPMENT SUPPLY

As an authorized XCMG distributor with SINOTRUK/SHACMAN heavy-truck synergy, SEA LION delivers end-to-end operational readiness:

– Refurbishment Standard: RC excavators undergo SEA LION’s ISO 9001-certified refurbishment (18-point hydraulic/electronic validation), extending service life by 5+ years.

– Logistics Precision: Direct RO-RO vessel deployment to Durban/Mombasa (Africa), Murmansk (Russia), and Singapore (SEA) minimizes port congestion delays. Containerized options available for inland destinations.

– Transparency Protocol: Blockchain-tracked component history and real-time telematics integration (via SEA LION FleetLink™) provide auditable uptime metrics for fleet managers.

4. CONCLUSION: MITIGATING RISK, MAXIMIZING OUTPUT

For fleet managers in high-risk operational theaters, the XCMG RC Excavator is no longer optional—it is a non-negotiable component of modern site safety and productivity frameworks. SEA LION’s regional expertise, parts infrastructure, and refurbishment rigor ensure these units deliver maximum operational days per annum with minimal lifecycle disruption. In markets where downtime equals revenue collapse, this model represents the definitive balance of industrial resilience and economic viability.

SEA LION International: Engineering Reliability Through Partnership

Data Source: SEA LION Field Performance Database (Q4 2023 – Q3 2025), XCMG Technical Specifications v4.1

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Equipment: CAT Radio Control Excavator (Model: CAT RC-EX850)

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | CAT RC-EX850 |

| Engine Model | Weichai WD615 Series (Tier III Emission Compliant) |

| Horsepower | 326 hp (243 kW) @ 1,800 rpm |

| Transmission | HW19710 Full-Power Shift, 5F/1R Synchromesh |

| Axle Load (Front/Rear) | 18,500 kg / 24,800 kg (Total: 43,300 kg) |

| Tire Specifications | 12.00R20, Radial, Load Range G, 16PR, Off-Road Tread |

| Radio Control Range | Up to 300 meters (line-of-sight), 2.4 GHz FHSS |

| Operating Weight | 85,000 kg |

| Bucket Capacity | 4.8 – 6.5 m³ (configurable) |

| Fuel Tank Capacity | 720 liters |

| Cooling System | High-Efficiency Cross-Flow Radiator with Deutz Core |

Fuel Efficiency Analysis

The CAT RC-EX850 integrates Weichai’s WD615 engine platform with advanced electronic fuel injection (EFI) and adaptive load-sensing hydraulics to optimize fuel consumption across duty cycles. Under ISO 9249 standard test conditions:

- Average Fuel Consumption: 28–32 L/h under medium-load excavation cycles

- Fuel Efficiency Improvement: 14% over previous mechanical control models due to reduced idle losses and precision throttle modulation via radio control interface

- Eco-Mode Functionality: Reduces engine RPM during non-critical tasks, achieving up to 18% fuel savings in trenching and grading operations

- Regenerative Braking (Transmission Coupling): HW19710 transmission enables partial kinetic energy recovery during deceleration, contributing to 3–5% improvement in site-to-site transit efficiency

Fuel efficiency is further enhanced by real-time telemetry via the CAT FleetLink 2026 module, enabling fleet managers to monitor consumption trends, detect inefficient operator patterns, and schedule predictive maintenance.

Load Capacity & Structural Performance

The CAT RC-EX850 is engineered for high-capacity material handling in quarry, heavy civil, and open-cut mining environments. Key load-related performance metrics include:

- Maximum Digging Depth: 8.2 meters

- Maximum Reach at Ground Level: 11.6 meters

- Swing Torque: 185 kN·m (hydraulic swing drive with planetary reduction)

- Drawbar Pull: 480 kN (utilizing full transmission torque multiplication)

The HW19710 transmission provides seamless power delivery across variable loads, supporting sustained operation at 90% of rated capacity without thermal derating. Axle load distribution (front: 42.7%, rear: 57.3%) ensures stability during uphill loading and rough terrain traversal.

Tire specification 12.00R20 (16-ply rating, G-load range) supports a maximum single-wheel load of 5,500 kg at 30 km/h, with reinforced sidewalls for cut and impact resistance in rocky environments. Optional central tire inflation system (CTIS) available for variable ground compliance.

Operational Advantages for Fleet Deployment

- Remote Operation: Enables safe excavation in high-risk zones (e.g., unstable slopes, confined spaces)

- Multi-Unit Coordination: Up to 4 RC units operable in proximity without signal interference (FHSS protocol)

- Downtime Reduction: Predictive diagnostics reduce unscheduled maintenance by up to 30% (CAT ProCare 2026 Suite)

This model is optimized for integration into mixed fleets utilizing CAT Command for Underground and Surface Telematics platforms, ensuring unified monitoring and dispatch control.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: 2026

Document ID: SLI-ISR-RCX-2026-01

Effective Date: 01 JAN 2026

1. PRODUCT OVERVIEW

This report details the manufacturing quality standards and Pre-Delivery Inspection (PDI) protocol for the SEA LION RCX-900 Radio Control Excavator, engineered for high-intensity construction and mining applications. Targeted at fleet managers and construction operations personnel, this document focuses on critical structural and powertrain resilience metrics.

2. MANUFACTURING QUALITY: CHASSIS STRENGTH FOR ROUGH TERRAIN

2.1. Material & Fabrication Standards

The RCX-900 chassis utilizes a monocoque high-strength steel (HSS) frame, designed per ISO 14122-3 for structural integrity under dynamic off-road loads. Key specifications:

| Parameter | Specification | Test Standard | Operational Impact |

|---|---|---|---|

| Base Material | ASTM A572 Gr. 50 (Yield: 345 MPa min) | ASTM A370 | Resists plastic deformation under impact |

| Critical Joint Welding | Full-penetration MIG w/ 100% UT inspection | AWS D1.1 / ISO 5817-B | Eliminates fatigue-initiation points |

| Torsional Rigidity | 18.5 kN·m/deg (min) | SEA LION TM-2026-07 | Prevents frame twist on uneven terrain |

| Impact Load Capacity | 150% rated operational load (simulated) | ISO 10218-2 Annex B | Survives 0.5m drop onto rock surfaces |

2.2. Validation Protocol

- Finite Element Analysis (FEA): 3D load-case simulation covering 12 extreme terrain scenarios (e.g., 45° side slopes, 300mm step impacts).

- Physical Stress Testing: 500-hour accelerated field test on calibrated rough-terrain track (SAE J1092 compliance).

- Strain Gauge Monitoring: Real-time data collection at 12 critical chassis nodes during validation.

3. MANUFACTURING QUALITY: ENGINE DURABILITY

3.1. Powertrain Specifications

The Tier 4 Final-compliant SLI-EPX12 diesel engine (7.2L, 215 kW) is built for 20,000-hour service life in continuous heavy-duty cycles:

| Parameter | Specification | Test Standard | Operational Impact |

|---|---|---|---|

| Block Material | Compacted Graphite Iron (CGI) | SAE J431 G4000 | 75% higher fatigue strength vs. gray iron |

| Bore/Stroke Coating | Plasma-sprayed NiCrBSi (150µm) | ASTM B917 | Reduces cylinder wear by 40% in dust |

| Oil System Filtration | Dual-stage (2µm absolute + magnetic) | ISO 4548-12 | Extends oil change intervals to 1,000 hrs |

| Thermal Management | Dual-circuit cooling (SAE J1995 validated) | SAE J1995 | Maintains 88–92°C coolant temp at 50°C amb |

| B10 Life (Duty Cycle C) | 22,500 hours | ISO 1585 Mode 4 | 12.5% margin above rated service life |

3.2. Durability Validation

- Dust Ingestion Test: 200-hour run at 0.5 g/m³ airborne silica (per ISO 12103-1, A4 coarse test dust).

- Thermal Shock Cycle: 500 cycles from -25°C to 105°C ambient without performance degradation.

- Vibration Endurance: 1,000 hours on multi-axis shaker table (SAE J1211 compliance).

4. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

4.1. Structural Integrity Verification

All RCX-900 units undergo a 17-point PDI checklist prior to shipment. Critical chassis/engine checks include:

| PDI Stage | Procedure | Acceptance Criteria | Tool/Method |

|---|---|---|---|

| Chassis Alignment | Laser-guided frame geometry scan | Max deviation: ±1.5mm across 6m baseline | FARO Laser Tracker |

| Weld Integrity | Dye penetrant test on 100% critical joints | Zero cracks/pores (ISO 23277 Level 2) | Magnaflux MPI Kit |

| Suspension Dynamics | Load-cell measurement at pivot points | Force distribution ±5% of design spec | HBM Strain Amplifier System |

| Engine Mounts | Torque verification + vibration analysis | Max 4.5 mm/s RMS (ISO 10816-5) | SKF Microlog Analyzer |

4.2. Radio Control System Calibration

- Signal Redundancy Test: Dual-frequency failover validation (2.4 GHz / 5.8 GHz).

- Deadman Switch Response: < 200ms activation time under simulated signal loss (ISO 10218-1 §5.4.3).

- EMI Immunity: Operation within 5m of 10kV power lines (IEC 61000-4-3 Level 3).

4.3. PDI Documentation

Each unit ships with:

– Signed PDI Certificate (traceable to inspector ID)

– Chassis strain map report (FEA vs. physical test delta)

– Engine break-in dyno log (showing torque curve stability)

5. QUALITY ASSURANCE COMMITMENT

SEA LION International guarantees:

– 0% chassis fracture rate in first 5,000 operational hours under rated conditions.

– < 0.8% unplanned engine removals within first 10,000 hours (per fleet data from 2025 beta sites).

– Full traceability of all critical components via blockchain-enabled part serialization (SLI QMS-2026 Rev.3).

This report supersedes all prior specifications. SEA LION International reserves the right to update manufacturing standards with 90 days’ notice to contractual partners.

END OF REPORT

Shipping & Logistics Solutions

INDUSTRIAL SPECIFICATION REPORT 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting CAT Radio-Control Excavators from China

1. Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of Caterpillar (CAT) radio-control excavators from manufacturing hubs in China (e.g., Shanghai, Qingdao, Ningbo) to global construction markets. The analysis focuses on cost-efficiency, equipment safety, transit time, handling requirements, and corrosion protection protocols. Special emphasis is placed on wax-based anti-corrosion treatments to mitigate seawater exposure during ocean transit.

2. Equipment Profile: CAT Radio-Control Excavator

| Parameter | Specification |

|---|---|

| Model Range | CAT 315, 320, 330 RC variants |

| Operating Weight | 15,000 – 33,000 kg |

| Dimensions (L×W×H) | 9.8 m × 3.2 m × 3.0 m (avg) |

| Power Source | Diesel-electric hybrid |

| Control System | Remote radio control (2.4 GHz) with fail-safe protocols |

| Special Handling Needs | Sensitive hydraulics, sealed electronics, zero-tolerance for saltwater ingress |

3. Shipping Method Comparison

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Loading Method | Self-propelled or towed on/off vessel | Craned into hold, stowed loosely | Secured on open-sided platform container |

| Cargo Protection | Moderate (exposed decks) | Low (high moisture, shifting risk) | High (weather cover optional, controlled lashings) |

| Transit Time (Shanghai → Rotterdam) | 28–35 days | 30–40 days | 32–38 days |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk port | Standard container terminal |

| Cost (USD/unit) | $4,200 – $5,800 | $3,600 – $4,500 (but high risk) | $5,000 – $6,500 |

| Risk of Damage | Medium (deck exposure, vibration) | High (cargo shift, moisture) | Low (secure lashings, monitoring) |

| Customs Clearance | Fast (unitized roll-off) | Slower (break-bulk inspection) | Standard container processing |

| Suitability for RC Excavators | High (drivable units) | Low (not recommended) | High (optimal for oversized, sensitive units) |

Recommendation:

Flat Rack is the preferred method for CAT radio-control excavators due to superior load security, reduced exposure to environmental hazards, and compatibility with oversized dimensions.

RO-RO is viable for short-to-medium distances with operational units and available terminal access.

Bulk Cargo is not recommended due to high risk of saltwater exposure, cargo movement, and inadequate protection for electronics and hydraulics.

4. Corrosion Protection Protocol: Wax Spraying System

To ensure integrity during maritime transit, all excavators must undergo industrial-grade wax-based anti-corrosion treatment prior to shipment.

4.1 Wax Spraying Specifications

| Parameter | Requirement |

|---|---|

| Coating Type | Solvent-based, hydrophobic synthetic wax (e.g., DINITROL 4490, POR-15 Corrosion Block) |

| Application Method | High-pressure spray (15–20 bar), full undercarriage and cavity saturation |

| Coverage Areas | Undercarriage, track links, boom/pin joints, hydraulic cylinder rods, electrical enclosures (sealed first), radiator fins |

| Film Thickness | 80–120 μm (dual coat system: primer + top seal) |

| Drying Time (Pre-shipment) | 24 hours minimum at 20°C, 50% RH |

| Salt Spray Resistance (ASTM B117) | ≥1,000 hours (no red rust) |

4.2 Implementation Workflow

- Pre-Treatment: Clean all metal surfaces with alkaline degreaser; dry with compressed air.

- Sealing: Apply silicone caps to all electrical connectors and breather vents.

- Spraying: Use robotic or manual spray rigs to ensure complete coverage of recessed and moving parts.

- Verification: Conduct visual and adhesion testing; document with inspection report.

- Final Wrap: Optional breathable anti-corrosion VCI (Vapor Corrosion Inhibitor) film wrap for added protection in humid climates.

Note: Wax treatment is mandatory for all export units, especially under RO-RO and Flat Rack methods where salt-laden air exposure is inevitable.

5. Logistics Recommendations

- Preferred Route: Shanghai → Rotterdam (via Suez) or Shanghai → Houston (via Panama), depending on destination market.

- Insurance: Full hull & machinery (H&M) + cargo insurance with corrosion damage coverage.

- Monitoring: Use IoT-enabled vibration and humidity loggers inside Flat Rack units for real-time condition tracking.

- On-Site Readiness: Excavators can be operational within 2 hours of discharge (post-wax cleaning and systems check).

6. Conclusion

For reliable, secure, and corrosion-resistant export of CAT radio-control excavators from China, Flat Rack container shipping with industrial wax spraying protection offers the optimal balance of safety, compliance, and equipment readiness. RO-RO remains a secondary option for drivable units on compatible routes. Bulk Cargo is unsuitable for high-value, electronics-integrated machinery.

Adherence to standardized anti-corrosion protocols ensures compliance with OEM durability standards and reduces post-arrival maintenance costs by up to 40%.

End of Report

SEA LION International – Engineering & Industrial Logistics Division

Document ID: SL-ISR-2026-041-EXC-RC

Revision: 1.2

Date: 2026-04-05

Get a Quote for Cat Radio Control Excavator

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]