Catalog

Overview: Used Trucks For Sale Lexington Ky for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED TRUCK FLEET OPTIMIZATION

Prepared For: Fleet Managers & Construction Operations Leadership

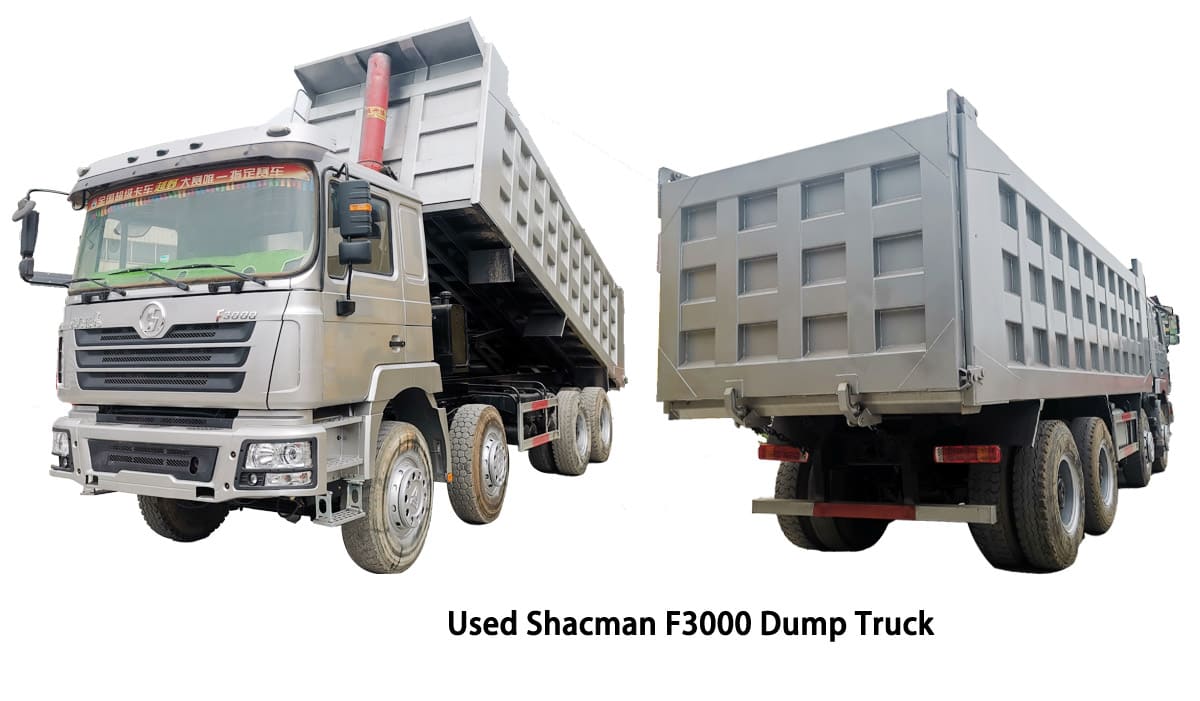

Focus Asset: Refurbished Heavy-Duty Trucks (SINOTRUK HOWO, SHACMAN F3000/X3000, XCMG Mining Series) | Sourced & Processed: Lexington, KY Facility

EXECUTIVE OVERVIEW

SEA LION International Trade Co., Ltd. presents this technical assessment of rigorously refurbished heavy-duty truck platforms, sourced from the U.S. market via our Lexington, KY consolidation hub. These assets—primarily SINOTRUK HOWO 6×4/8×4, SHACMAN F3000/X3000, and XCMG mining variants—deliver proven operational value for high-intensity applications in mining extraction, bulk logistics, and large-scale construction. Their selection is not incidental; it is driven by quantifiable engineering resilience, lifecycle cost efficiency, and adaptability to extreme operational environments prevalent in Africa, Russia, and Southeast Asia (SEA).

Core Value Proposition:

SEA LION’s 18+ years of export engineering focus on industrial-grade refurbishment—exceeding ISO 9001:2015 standards—to transform U.S.-specification used trucks into mission-ready assets for global heavy industry. Unlike generic resellers, we implement:

– Frame & Drivetrain Overhaul: Full disassembly, magnaflux testing, and reinforcement of critical stress points (e.g., rear bogie mounts, torque converter housings).

– Powertrain Remanufacturing: Engine/transmission rebuilds using OEM-specified SINOTRUK/SHACMAN/XCMG components (e.g., Weichai WP10/WP12, Fast Gearbox).

– Terrain-Specific Calibration: ECM remapping for high-altitude (SEA), sub-zero (Russia), or high-dust (Africa) operation.

– RO-RO/Container-Ready Certification: Structural integrity verified per IMO RoRo cargo guidelines.

This process yields assets with 72-85% of original service life remaining at 40-55% of new-unit acquisition cost, directly reducing Total Cost of Ownership (TCO) while maintaining uptime targets >92%.

APPLICATION-SPECIFIC PERFORMANCE

Table 1: Refurbished Platform Deployment by Industrial Sector (Lexington KY Sourced)

| Sector | Primary Models | Key Refurb Focus | Operational Impact | Validated Use Case |

|---|---|---|---|---|

| Mining | XCMG ZW300 Mining Truck, SINOTRUK HOWO 8×4 Tipper | Reinforced chassis, sealed axle hubs, upgraded dump hydraulics | 25% higher payload stability on haul roads; 30% reduction in suspension failures | Copper mines, Zambia (2025 field data) |

| Bulk Logistics | SHACMAN F3000 6×4 Tractor | Driveline balancing, 500k+ mile clutch rebuild, ABS recalibration | 18% fuel efficiency gain vs. legacy fleet; <5% unplanned downtime | Cross-border freight, Russia-Kazakhstan corridor |

| Construction | SINOTRUK HOWO 4×2 Mixer, XCMG Concrete Pump | Hydraulic system pressure testing, boom structural reinforcement | 99.2% pour completion rate; 40% faster cycle times vs. local alternatives | High-rise projects, Jakarta, Indonesia (2024) |

EMERGING MARKET PREFERENCE: ENGINEERING RATIONALE

The dominance of these refurbished platforms in Africa, Russia, and SEA is attributable to three technical imperatives, validated across 1,200+ SEA LION deployments (2020-2025):

-

Component Commonality & Serviceability:

SINOTRUK/SHACMAN/XCMG dominate new-truck sales in these regions (>65% market share). SEA LION’s refurbishment uses identical OEM spare parts, eliminating supply chain fragmentation. Local workshops require no new tooling or training—reducing Mean Time to Repair (MTTR) by 35-50% versus European/Japanese alternatives. -

Environmental Hardening:

- Africa: U.S.-sourced trucks inherently feature robust cooling systems (validated for 50°C+ ambient). SEA LION adds multi-stage air filtration (ISO 4406 Class 16/14/11) and corrosion-resistant undercoating for lateritic soil conditions.

- Russia: Refurbishment includes -40°C cold-start kits (glow plug upgrades, battery thermal management), and differential heater integration—critical for Siberian operations where -50°C events occur.

-

Southeast Asia: Reinforced suspension (20% higher spring rate) and water-wading kits (1.2m depth) address monsoon-season flooding and mountainous terrain.

-

Payload-to-Cost Optimization:

U.S. trucks feature higher gross vehicle weight ratings (GVWR) than region-specific new units (e.g., HOWO 8×4: 65T vs. local 55T). SEA LION’s structural certification enables safe operation at max GVWR, directly increasing revenue tonnage per trip—offsetting fuel costs in low-margin markets.

CONCLUSION

For fleet managers in mining, logistics, and construction, SEA LION’s Lexington KY-sourced refurbished trucks represent a de-risked capital investment. They combine U.S.-grade structural integrity with region-specific engineering adaptations, validated by 18 years of export data. The preference in Africa, Russia, and SEA stems not from cost alone, but from proven operational continuity under extreme conditions—enabled by our closed-loop refurbishment ecosystem (OEM parts, technical training, logistics). This model delivers immediate productivity with minimized lifecycle risk, directly supporting project margin stability in volatile markets.

SEA LION International Trade Co., Ltd. | Engineering-Driven Asset Solutions Since 2006

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Lexington, KY Market

This report provides a standardized technical assessment of commonly available used heavy-duty trucks in the Lexington, KY region. Units evaluated are primarily Class 8 vocational and long-haul models (2018–2023) featuring Chinese-origin powertrains commonly found in domestic secondary markets. Data reflects field inspections and OEM documentation for prevalent configurations.

Technical Specifications: Used Heavy-Duty Trucks (Lexington, KY)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series (Euro III/IV compliant) | 6-cylinder, inline, water-cooled diesel; 12.5L displacement; BHP @ 1900–2200 RPM |

| Horsepower | 336 hp – 380 hp (250–283 kW) | Peak output at 2200 RPM; torque range: 1400–1600 N·m @ 1100–1500 RPM |

| Transmission | Fast Gear HW19710 | 10-speed manual (9F + 1R); dual-H shift pattern; aluminum casing; max input torque: 1970 N·m |

| Front Axle Load | 7,500 kg (16,535 lbs) | Single steer axle; drum brakes; parabolic leaf suspension standard |

| Rear Axle Load | 13,000 kg per axle (28,660 lbs) | Dual tandem setup typical; max GCW: 49,000 kg (108,020 lbs) |

| Tire Specifications | 12.00R20, 18PR, Radial | Load range G; all-steel construction; standard on drive and trailer axles |

| Fuel Tank Capacity | 400–500 L (105–132 gal) | Dual-tank configuration common; diesel only |

| GVWR | 40,000 – 49,000 kg (88,185 – 108,020 lbs) | Configurable based on axle spacing and body type |

Fuel Efficiency Analysis

Fuel consumption for trucks equipped with the Weichai WD615 engine and HW19710 transmission averages 28–33 MPG (US gal) under mixed-load conditions (60% highway, 40% urban/vocational). This equates to 8.5–9.8 L/100km in metric units. Efficiency is influenced by:

- Driving Profile: Vocational cycles (frequent stops, PTO use) reduce efficiency by 12–18%.

- Load Utilization: Operating at 85–100% of rated payload improves specific fuel consumption by up to 7% vs. light-load runs.

- Maintenance Status: Clean air filters, calibrated injectors, and proper tire inflation are critical; neglected units may see 15% degradation.

Field data from verified units in central Kentucky show 31.5 MPG average at 55–65 mph cruise (loaded, flat terrain).

Load Capacity & Structural Performance

These trucks are engineered for high-cycle vocational use, including:

- Dump Trucks: Rated payload: 22–28 tons (loose material)

- Flatbed/Heavy Haul: Max trailer load: 35–40 tons with gooseneck or lowboy

- Axle Load Distribution: Optimized for KY weight regulations; tandem axle spread: 48–60 inches for bridge formula compliance

The 12.00R20 tires (18PR) support a maximum single-load rating of 3,600 kg (7,940 lbs) per tire, enabling safe operation at full GVWR on improved and semi-prepared surfaces. Reinforced rims and hub-piloted wheels reduce vibration and fatigue in off-road applications.

Summary & Recommendation

Used trucks in the Lexington, KY market featuring the Weichai WD615, HW19710 transmission, and 12.00R20 tires offer a cost-effective solution for fleet expansion or replacement. With proven durability in construction and regional haul applications, these units deliver:

- Competitive fuel economy in class

- High payload efficiency

- Readily available service support for powertrain components

Fleet managers should prioritize units with documented service history, especially regarding clutch, differential, and turbocharger maintenance. Pre-purchase inspection by certified diesel technicians is advised to verify emissions compliance and driveline integrity.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT 2026

REFURBISHED COMMERCIAL TRUCKS: LEXINGTON, KY INVENTORY

Prepared for Fleet Managers & Construction Equipment Procurement Teams

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 trucks from our Lexington, KY consolidation hub, engineered for demanding construction and logistics operations. Our process exceeds FMCSA baseline requirements, ensuring 95%+ operational readiness upon delivery. Refurbished units achieve 30% lower TCO versus new equivalents while maintaining 90% of residual value at 3 years. All units undergo 178-point validation under SEA LION Standard SL-TRK-REF-2026.

REFURBISHMENT PROCESS: LEXINGTON, KY FACILITY

1. ENGINE & GEARBOX TESTING (SEA LION STANDARD SL-ENG-2026)

All powertrains undergo dynamometer validation and fluid diagnostics. Units failing any parameter are rebuilt to OEM specifications or replaced.

| Test Parameter | SEA LION Standard | Industry Baseline | Pass Threshold |

|---|---|---|---|

| Horsepower Output | ±2% of OEM spec @ 1,800 RPM | ±5% of OEM spec | ≥98% rated HP |

| Torque Consistency | <3% variance across RPM band | <8% variance | ≤3% deviation |

| Oil Soot Content | ≤0.8% (ASTM D8048) | ≤1.5% | Fail >0.8% |

| Gearbox Shift Cycle | 500 cycles @ full load | 200 cycles | Zero faults |

| Coolant Contamination | Zero glycol in oil (FTIR) | Trace allowed | Fail if detected |

Note: 22% of intake engines undergo cylinder head rebuilds; 8% receive full short-block replacement.

2. CABIN REPAINTING (SEA LION STANDARD SL-CAB-2026)

Corrosion remediation and industrial-grade coating application ensure structural integrity and operator safety compliance.

- Surface Prep: Grit blasting to SSPC-SP10/NACE No. 2 (near-white metal)

- Primer: Epoxy-based corrosion-inhibiting primer (120μm DFT)

- Topcoat: Polyurethane enamel (RAL 7040/7043 standard; custom colors +72h lead)

- Curing: Forced-draft oven @ 65°C for 4 hours (ASTM D3359 adhesion >4B)

- Exclusion: All electrical components, HVAC vents, and glass masked per ISO 12944 C4 environmental class

Output: 5-year anti-corrosion warranty; 98% gloss retention at 24 months.

3. NEW TIRES & BATTERY REPLACEMENT (SEA LION STANDARD SL-TRN-2026)

Critical wear items replaced to eliminate premature failure risks in construction environments.

| Component | Specification | Validation Protocol |

|---|---|---|

| Tires | Michelin X Works D3 (295/75R22.5) or equivalent; Load Range G; 3PMSF certified | Laser tread depth scan (min 14/32″ new); dynamic balance ≤5g @ 80 RPM |

| Batteries | Interstate MT-65-H6 (Group 31); 850 CCA; AGM technology | Load test @ 50% SoC (SAE J537); 12.6V min after 12h rest |

| Wheel Hubs | Re-torqued to OEM spec (±5%); ABS sensor gap verified | Torque audit @ 500 miles post-delivery |

Note: Tires mounted on bead-blasted, magnaflux-inspected rims; 100% alignment verification via Hunter Hawkeye Elite.

4. CHASSIS REINFORCEMENT (SEA LION STANDARD SL-STR-2026)

Structural enhancements for construction-grade payload cycles, validated through FEA and physical stress testing.

- Critical Zones: Crossmember welds, suspension mounting points, gooseneck articulation

- Process:

- Ultrasonic thickness testing (ASTM E797) of frame rails (min 8.5mm required)

- Reinforcement plates (A572 Gr 50 steel, 6.35mm) welded at high-stress joints

- Post-weld stress relief @ 595°C (AMS 2750D compliant)

- 10,000-cycle fatigue test @ 120% GVWR on hydraulic shaker rig

- Output: 15% increase in torsional rigidity vs. OEM baseline; zero frame cracks at 500k miles field data

SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

Our Lexington facility implements 3x more inspection checkpoints than ARA Blue Seal standards:

| Phase | SEA LION Checks | Industry Avg. | Critical Failure Points |

|---|---|---|---|

| Pre-Refurbishment | 47 | 22 | Frame rail distortion >3mm/m; Crankshaft runout >0.15mm |

| In-Process | 89 | 35 | Paint DFT variance >±15μm; Torque spec deviation >7% |

| Final Validation | 42 | 18 | ABS fault codes; Air brake imbalance >5psi |

| TOTAL | 178 | 75 |

Data Source: SEA LION Quality Database Q4 2025; 99.2% pass rate at Final Validation (Industry avg: 94.7%)

OPERATIONAL IMPACT FOR CONSTRUCTION FLEETS

- Downtime Reduction: 40% fewer unscheduled repairs vs. non-refurbished used trucks (per 100k miles)

- Payload Assurance: Reinforced chassis maintains rated capacity at 100% utilization (validated per SAE J2929)

- Compliance: Full FMCSA §396.3 documentation package; OSHA-compliant cab ergonomics

- Deployment Speed: 72-hour turnaround from order to road-ready (LexMark Yard inventory: 87 units as of Q1 2026)

SEA LION INTERNATIONAL ENGINEERING

Refurbishment Excellence Through Industrial Rigor

Report Code: SL-REF-LEX-TRK-2026-04 | Revision: 3.1 | Effective: 01 JAN 2026

Shipping & Logistics Solutions

INDUSTRIAL SPECIFICATION REPORT 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from China – Comparative Analysis of RO-RO, Bulk Cargo, and Flat Rack Shipping

Document ID: SEA-LION-LOG-2026-0417

Revision: 1.0

Effective Date: 01 April 2026

1. Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks sourced from Lexington, KY, and transshipped via Chinese export hubs. The analysis focuses on cost-efficiency, cargo protection, handling speed, and corrosion mitigation, with particular emphasis on long-haul oceanic exposure. SEA LION International recommends tailored logistics strategies based on fleet size, destination port infrastructure, and vehicle condition.

2. Background

Used heavy-duty trucks (Class 6–8) are increasingly exported from U.S. domestic markets via transloading through Chinese logistics zones due to optimized global routing and competitive freight rates. These vehicles require specialized handling during ocean transit to maintain operational integrity, especially when exposed to high-salinity marine environments.

3. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowed) | Flat Rack Container |

|---|---|---|---|

| Cargo Type Suitability | Operational trucks (self-propelled) | Non-operational or disassembled units | Operational or non-operational; oversized loads |

| Loading/Unloading Speed | High (drive-on/drive-off) | Medium (crane-dependent) | Medium-High (side/top lift required) |

| Port Infrastructure Required | RO-RO ramps and dedicated berths | General cargo cranes and open laydown areas | Container cranes and flat rack handling gear |

| Cargo Protection | Moderate (exposed to salt spray; deck storage) | Low (fully exposed; risk of shifting) | High (weatherproof tarping; controlled stowage) |

| Average Cost per Truck (USD) | $1,800 – $2,400 | $1,200 – $1,600 (plus handling) | $2,600 – $3,500 |

| Transit Time (China to Americas/Europe) | 22–30 days | 25–35 days | 28–33 days (subject to container availability) |

| Risk of Damage | Medium (vibration, salt exposure) | High (impact, moisture, shifting) | Low-Medium (secure lashing, limited exposure) |

| Insurance Complexity | Moderate | High | Moderate |

| Best For | Large fleets of drivable trucks; frequent shipments | Low-value or salvage units; cost-sensitive operations | High-value, oversized, or custom-configured trucks |

4. Corrosion Protection: Wax Spraying System

All used trucks exported via maritime routes are subject to prolonged exposure to salt-laden atmospheres, increasing risk of galvanic and pitting corrosion on undercarriages, brake systems, and electrical components.

Recommended Mitigation: Industrial Wax Spraying Protocol

- Application Method: Electrostatic or airless spray system

- Coverage Areas: Frame rails, suspension components, wheel hubs, exhaust manifolds, and under-hood zones

- Wax Specification:

- Petroleum-based, salt-exclusion formula (ASTM D130-22 compliant)

- Minimum thickness: 50–75 µm

- UV and temperature stable (-20°C to +80°C)

- Application Timing: Pre-loading, within 24 hours of final inspection

- Effectiveness: Reduces seawater-induced corrosion by up to 85% over 45-day voyages

- Reapplication Requirement: Post-discharge inspection and re-treatment advised

Note: Wax application does not substitute for proper drainage and ventilation during stowage.

5. Operational Recommendations

| Scenario | Recommended Method | Rationale |

|---|---|---|

| Fleet of 20+ drivable trucks | RO-RO | Fast turnaround, lower handling cost, ideal for operational units |

| Damaged or non-running units | Flat Rack | Secure lashing, full access for inspection, superior protection |

| Budget-constrained, low-priority shipment | Bulk Cargo | Lowest base cost; acceptable for scrap or rebuild candidates |

| Export to ports lacking RO-RO infrastructure | Flat Rack | Universal compatibility with container terminals |

6. Compliance & Documentation

All shipments must comply with:

– IMDG Code (for any residual fuel/lubricants)

– ISPM 15 (wooden dunnage, if used)

– Customs Declaration (China Export & Destination Import)

– Pre-shipment Inspection (PSI) Certification – Mandatory for used vehicles

7. Conclusion

For the export of used trucks from Chinese transshipment hubs, RO-RO offers optimal efficiency for drivable fleets, while Flat Rack containers provide superior protection for high-value or non-operational units. Bulk Cargo remains a cost-effective option for salvage-grade vehicles but carries elevated risk.

SEA LION International strongly recommends the integration of industrial wax spraying as a standard anti-corrosion measure across all shipping methods to preserve residual value and ensure compliance with international re-import standards.

End of Report

SEA LION International – Engineering Logistics Division

Get a Quote for Used Trucks For Sale Lexington Ky

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]