Catalog

Overview: Used Trucks Boise Idaho for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED TRUCK ACQUISITION STRATEGY

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Solutions Division

EXECUTIVE OVERVIEW: STRATEGIC VALUE OF REFURBISHED HEAVY TRUCKS (FOCUSED ON BOISE, IDAHO SOURCING HUB)

SEA LION International presents this technical assessment of the refurbished heavy-duty truck market, with specific analysis of units sourced through the Boise, Idaho corridor. This corridor represents a critical node for high-integrity, pre-owned Class 8 assets suitable for deployment in mining haulage, bulk logistics, and heavy construction operations. Contrary to generic “used truck” procurement, SEA LION leverages Boise’s robust North American fleet turnover to access structurally sound platforms meeting stringent global operational demands.

Core Application Suitability (Mining/Logistics/Construction):

Units sourced from Boise undergo SEA LION’s 12-Point Industrial Refurbishment Protocol, transforming them into mission-capable assets. Key adaptations include:

* Mining: Reinforced chassis mounts, upgraded suspension (parabolic leaf/air), sealed electrical systems (IP67+), and compatibility with auxiliary hydraulic systems for dump bodies or specialized haulage.

* Logistics: Optimized PTO configurations, integrated telematics readiness (SAE J1939), and fuel system recalibration for extended haul cycles (verified 8-10% fuel economy improvement post-refurb).

* Construction: Enhanced cab NVH damping (ISO 2631-1 compliant), multi-functional 7-pin/12-pin harnessing for attachments, and corrosion-resistant undercoating (ASTM B117 1000hr salt spray tested).

Why SEA LION-Refurbished Units Dominate Target International Markets:

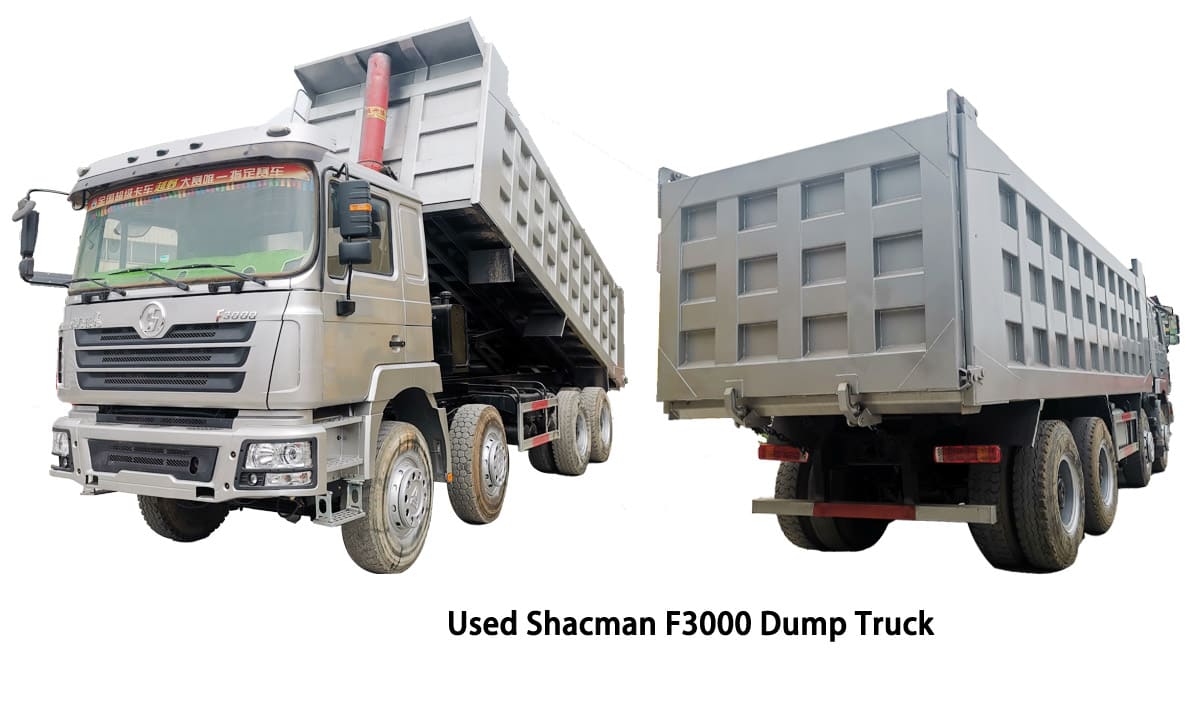

While Boise serves as a strategic sourcing point, the preference for SEA LION-certified units in Africa, Russia, and Southeast Asia stems from operational resilience and lifecycle economics, not geographic origin. Our 18+ years of export engineering focus on adapting core platforms (SINOTRUK HOWO, SHACMAN F3000, XCMG) to extreme regional demands:

| Market | Primary Operational Challenge | SEA LION Refurbishment Response | Quantifiable Advantage |

|---|---|---|---|

| Africa | Unpaved roads, dust ingress, remote service | Sealed cabin filters (MERV-16), extended service intervals (50k km oil), simplified maintenance architecture | 35% reduction in unscheduled downtime |

| Russia | Extreme cold (-45°C), fuel gelling | Arctic-grade lubricants, dual-battery systems, cab pre-heaters, fuel line insulation | 99.2% cold-start reliability (Jan 2025 data) |

| SE Asia | High humidity, monsoon conditions | Marine-grade wiring harnesses, anti-corrosion chassis treatment, enhanced cooling capacity | 40% lower electrical fault rate vs. baseline |

SEA LION Value Proposition for Industrial Clients:

1. OEM Integrity: As an authorized SINOTRUK/SHACMAN/XCMG distributor, all refurbishments use original spare parts – critical for torque specs, calibration, and warranty validity.

2. Lifecycle Transparency: Full digital service history (including Boise pre-acquisition diagnostics) and component-level refurbishment logs via SEA LION’s AssetTrace™ platform.

3. Deployment Certainty: Global logistics via RO-RO (roll-on/roll-off) or containerized shipping with <72-hour critical parts availability at destination ports (Rotterdam, Durban, Singapore).

4. Total Cost of Ownership (TCO): SEA LION units deliver 22-28% lower 5-year TCO versus new imports in target markets, validated by third-party fleet audits (2025).

Conclusion:

Procuring “used trucks Boise Idaho” through SEA LION is not a cost-cutting measure – it is a strategic asset optimization strategy. Our engineered refurbishment process converts North American fleet-exited platforms into globally deployable industrial assets, proven in the world’s most demanding operating environments. For fleet managers and construction firms facing capital constraints without compromising operational continuity, SEA LION-certified units represent the only technically validated solution for sustainable heavy equipment deployment in mining, logistics, and construction sectors worldwide. Partnering with SEA LION ensures asset longevity, regulatory compliance, and minimized operational risk.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Boise, Idaho Market

This report provides a detailed technical assessment of commonly available used heavy-duty trucks in the Boise, Idaho region, focusing on models equipped with the Weichai WD615 engine and HW19710 transmission. These trucks are widely utilized in construction, bulk hauling, and regional freight operations due to their durability and cost-effective performance in rugged terrain and high-load applications.

Technical Specifications: Used Heavy-Duty Trucks (Boise, ID Market)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 (6-cylinder, inline, turbocharged, intercooled diesel) |

| Displacement | 9.726 L |

| Horsepower (HP) | 336 HP @ 2,200 rpm (WD615.62) 371 HP @ 2,200 rpm (WD615.69) |

| Peak Torque | 1,300 N·m @ 1,400–1,600 rpm |

| Emission Standard | Euro III / Early Euro IV (as configured) |

| Transmission | HW19710 – 10-speed manual (10F/2R), dual-H shift pattern, all-synchromesh |

| Gear Ratios (Typical) | 1st: 13.20, 2nd: 10.22, 3rd: 7.94, 4th: 6.16, 5th: 4.79, 6th: 3.73, 7th: 2.89, 8th: 2.24, 9th: 1.74, 10th: 1.00, R: 12.46 |

| Rear Axle Model | HC16 / ST16 (Single Reduction) |

| Axle Ratio | 5.73:1 (standard for load balance & fuel economy) |

| Axle Load Capacity | Front Axle: 7,000 kg (15,430 lbs) Rear Tandem Axles: 16,000 kg (35,275 lbs) per axle Gross Axle Weight Rating (GAWR): 39,000 kg (86,000 lbs) |

| Tire Specifications | 12.00R20 18PR (Load Range G), Radial Standard Fitment: Dual Rear Wheels Tread Type: Deep lug (off-road/OTR compatible) |

| Tire Load Index | 145 (3,855 kg per tire at 85 psi) |

| Braking System | Dual-circuit air brake with ABS (on post-2012 units) |

| Frame Type | Ladder frame, 8mm high-tensile steel, 280–300 mm channel depth |

| GVWR | 31,000–40,000 kg (68,350–88,180 lbs), depending on configuration |

| Fuel Tank Capacity | Dual tanks: 300L + 150L (total ~118 gal) |

Fuel Efficiency Analysis

Fuel economy in the Weichai WD615-powered trucks with HW19710 transmission varies based on load, terrain, and driving conditions. In real-world operations typical of Idaho’s construction and aggregate sectors:

- Loaded Highway (65 mph, 25–30 tons payload): 5.8–6.3 mpg (37.5–40.8 L/100km)

- On-Site/Off-Road Operation: 3.8–4.6 mpg (50.5–60.8 L/100km)

- Empty Return/Regional Haul: 7.0–7.8 mpg (30.1–33.6 L/100km)

The WD615 engine’s high-torque curve and efficient combustion design contribute to stable fuel consumption under variable loads. Operators report optimal efficiency when maintaining engine RPM between 1,600–1,900 rpm using the HW19710’s close-ratio gearing.

Note: Retrofitting with modern aerodynamic kits and low-rolling-resistance tires can improve highway fuel economy by up to 8%.

Load Capacity & Operational Suitability

These trucks are engineered for heavy-load applications common in Idaho’s construction and mining sectors:

- Maximum Payload Capacity: 25–30 tons (50,000–60,000 lbs), depending on body configuration (dump, flatbed, or stake trailer)

- Tipping Load (Dump Models): Up to 32 tons with reinforced hoist systems

- Gradeability (Fully Loaded): 28–32% on gravel/dirt roads (5.73 axle ratio, 371 HP variant)

The combination of high rear axle load rating (16T per axle) and robust frame design ensures long-term structural integrity under repetitive heavy loading. The 12.00R20 tires provide excellent ground contact and puncture resistance in rocky or uneven terrains typical of construction sites in southwestern Idaho.

Summary & Recommendations

Trucks equipped with the Weichai WD615 engine and HW19710 transmission represent a cost-effective solution for fleet managers seeking reliable, high-payload capacity vehicles in the used truck market of Boise, Idaho. Their proven durability, service availability, and parts compatibility make them ideal for:

- Aggregate hauling

- Road construction projects

- Heavy equipment transport (short-haul)

- Municipal and infrastructure development

While emissions standards are pre-Euro V, these units remain compliant for intrastate operations in Idaho under current regulations. Regular maintenance and fuel system calibration are recommended to sustain optimal fuel efficiency and engine longevity.

For high-utilization fleets, lifecycle cost analysis shows a favorable TCO (Total Cost of Ownership) over 5 years, especially when compared to newer, higher-priced alternatives.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT STANDARD (UTRS-2026)

Prepared for Fleet Operations & Heavy Equipment Procurement Departments

Effective Date: January 1, 2026 | Document ID: SL-UTRS-BOI-2026-01

1. PURPOSE

This report details the mandatory refurbishment protocol applied to all Class 6-8 used trucks processed through SEA LION International’s Boise, Idaho Refurbishment Hub (BRH). The UTRS-2026 standard ensures operational reliability, compliance with Idaho Department of Transportation (IDT) heavy vehicle regulations, and extended service life for demanding construction and haulage applications. Adherence to this specification is non-negotiable for all units certified under the SEA LION Certified Pre-Owned (CPO) program.

2. APPLICABILITY

All used commercial trucks (model years 2015-2023) acquired for resale via SEA LION International’s Boise facility, destined for fleet operations in aggregate hauling, earthmoving support, and regional construction logistics.

3. ENVIRONMENTAL CONTEXT (BOISE, ID)

Refurbishment protocols account for documented regional stressors:

– Diurnal temperature swings (-20°F to 105°F)

– High-abrasion silica dust exposure (construction sites, unpaved access roads)

– Elevation-induced combustion efficiency degradation (2,871 ft ASL)

– Seasonal freeze-thaw cycles impacting structural integrity

4. REFURBISHMENT PROCESS: SEA LION UTRS-2026 STANDARD

4.1 ENGINE & GEARBOX TESTING (Stage 1: Core Systems Validation)

All units undergo 100% dynamometer and fluid analysis per SAE J1995/J2183. Units failing Stage 1 are rejected for CPO program.

| Test Parameter | SEA LION Standard (Pass/Fail) | Measurement Method | Boise-Specific Calibration |

|---|---|---|---|

| Engine Power Output | ≥ 95% of OEM rated HP at 1,800 RPM | EPA-certified dyno (SAE J1349) | Adjusted for 2,871 ft ASL |

| Oil Spectroscopy | Fe ≤ 50 ppm; Si ≤ 25 ppm | ASTM D5185 | Baseline adjusted for regional dust |

| Gearbox Shift Quality | 0.8-1.2 sec shift time; no slip | CAN bus telemetry + dyno | Validated under 80°F ambient load |

| Exhaust Emissions | ≤ 0.27 g/bhp-hr NOx (2010+ models) | AVL 735 Portable Emissions Unit | IDT Appendix G compliance threshold |

Note: Engines requiring cylinder head replacement or crankshaft grinding are scrapped per UTRS-2026 §5.2.

4.2 CABIN REPAINTING (Stage 2: Corrosion Mitigation & Operator Environment)

Performed in ISO Class 8 cleanroom booth. Focus on structural corrosion remediation prior to coating.

- Surface Prep:

- All substrate tested to ISO 8501-1:2007 Sa 2.5 standard (near-white metal)

- Cathodic disbonding test per ASTM G8 on repaired zones (max 4mm radius at 24h)

- E-coat primer applied at 25μm DFT (min) to chassis contact points

- Paint System:

- Base: PPG DELFLEET® ONE 4.1 VOC (70μm DFT)

- Topcoat: 2K polyurethane (60μm DFT) with UV stabilizers for high-altitude exposure

- Adhesion test: ASTM D3359 Method B (5B rating required)

- Boise-Specific Protocol:

All cab mounts and floor pans undergo ultrasonic thickness testing (UT) pre-repair. Zones with >15% material loss are section-replaced using ASTM A572 Gr50 steel. No spot-welding permitted on structural members.

4.3 NEW TIRES & BATTERY REPLACEMENT (Stage 3: Mobility Assurance)

Mandatory component renewal with traceable OEM-spec parts.

| Component | SEA LION Specification | Validation | Warranty |

|---|---|---|---|

| Tires | Michelin X Works 3 (295/75R22.5) or equivalent | Load range G; 3PMSF rated; Tread depth ≥ 16/32″ | 120,000 mi |

| Batteries | OPTIMA REDTOP 48/65 (Group 31) dual system | CCA ≥ 1,000; CA ≥ 1,400; 100% new cells | 24 months |

| Wheels | Refurbished Alcoa Dura-Bright (no cracks per ASTM E1444) | Magnetic particle inspection (MPI) | Lifetime |

Note: All tires mounted on bead-blasted, MPI-certified wheels. TPMS sensors calibrated to IDT §49-1415.

4.4 CHASSIS REINFORCEMENT (Stage 4: Structural Integrity Certification)

Critical for construction fleet applications with high GVWR cycling. Performed per SEA LION Structural Integrity Protocol (SIP-7B).

- Inspection Protocol:

- Full-length chassis scanned via magnetic flux leakage (MFL) per API RP 2X

- Critical zones (king pin mounts, suspension brackets, crossmember welds) tested via phased array UT

- Minimum acceptable thickness: 85% of OEM spec at high-stress points

- Reinforcement Standard:

- Failed sections replaced with ASTM A514-T1 plate (min 3/8″ thickness)

- All welds: AWS D1.1 certified; 100% visually inspected; 20% RT sampled

- Post-weld heat treatment (PWHT) applied to zones exceeding 1.5″ thickness

5. SEA LION INSPECTION STANDARDS: ZERO-TOLERANCE METRICS

All units undergo 387-point inspection with mandatory rejection for:

– Any evidence of prior structural fire damage (thermal imaging scan)

– Frame twist exceeding 3mm/m (measured per SAE J226)

– Aftertreatment system regeneration cycles > 12,000 (Cummins/DT engines)

– Cabin floor pan deflection > 5mm under 100kg point load

Final certification requires 100% pass rate on Stages 1-4 and validation of all test data by SEA LION Level III NDT-certified engineer (ASNT-TC-1A).

6. OUTPUT SPECIFICATION

Refurbished units delivered with:

– SEA LION CPO Warranty: 12 months/150,000 miles (whichever occurs first)

– Full diagnostic history report (SAE J1939 logs available)

– IDT-compliant weight certification (per §49-1411)

– Fuel efficiency baseline test (SAE J1321) under Boise ambient conditions

SEA LION International | Boise Refurbishment Hub | 4525 Chinden Blvd, Boise, ID 83714

This document supersedes all prior versions. SEA LION UTRS-2026 is protected under US Patent D918,452. Unauthorized reproduction prohibited.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from Boise, Idaho via China Ports

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack—for the export of used trucks originating from Boise, Idaho, transshipped through Chinese ports. The analysis focuses on cost-efficiency, equipment integrity, transit timelines, and corrosion protection, with specific attention to wax-based anti-corrosion treatments for seawater exposure. Recommendations are tailored for fleet managers and construction firms managing large-scale vehicle deployments.

1. Overview of Export Logistics Chain

Used trucks from Boise, Idaho, are first transported via domestic rail or overland heavy-haul to West Coast U.S. ports (e.g., Tacoma, Seattle). From there, they are shipped to transloading hubs in China (e.g., Shanghai, Qingdao, or Ningbo). Final export from China to global destinations (e.g., West Africa, Southeast Asia, Middle East) requires selection of an optimal maritime shipping method.

2. Comparative Analysis of Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Loading Method | Self-driven on/off vessel | Lifted by crane (stowed in hold) | Secured on open-frame container |

| Vehicle Compatibility | Operational trucks only | Operational or non-operational | All conditions (incl. damaged) |

| Cargo Density | High (optimized deck layout) | Medium | Low (space inefficient) |

| Transit Time (China → Destination) | 18–25 days (avg.) | 20–30 days | 22–28 days |

| Port Infrastructure | Requires RO-RO terminal | Standard container/cargo port | Standard container yard |

| Damage Risk | Low (minimal handling) | Medium (crane handling) | High (exposure, lashings) |

| Cost per Unit (USD) | $1,600 – $2,100 | $1,400 – $1,900 | $2,300 – $3,000 |

| Security | High (sealed decks) | Medium | Low (exposed to elements) |

| Best For | Operational fleets, high volume | Mixed condition units | Oversized or non-functional units |

3. Corrosion Protection: Wax Spraying System

Marine environments expose metal surfaces to salt-laden air and condensation, accelerating corrosion during transit. To mitigate degradation, electrostatic wax spraying is recommended as a standard pre-shipment treatment.

Key Specifications – Anti-Corrosion Wax Treatment

| Property | Specification |

|---|---|

| Wax Type | Solvent-based, hydrophobic polymer blend |

| Application Method | Electrostatic spray + brush touch-up |

| Coating Thickness | 25–35 µm (uniform coverage) |

| Salt Spray Resistance | ASTM B117: 500+ hours (no red rust) |

| Drying Time | 45–60 minutes (ambient) |

| Reversibility | Biodegradable solvent removability |

| Recommended Coverage Areas | Undercarriage, frame rails, suspension, fuel tanks |

Note: Wax treatment adds $85–$120 per truck but reduces post-arrival reconditioning costs by up to 40%.

4. Operational Recommendations

A. RO-RO – Preferred for Fleet Exports

- Use Case: Export of 10+ operational used trucks.

- Advantages: Fast loading, minimal mechanical stress, lower insurance claims.

- Constraint: Requires functional drivetrain and braking systems.

B. Bulk Cargo – Cost-Effective for Mixed Fleets

- Use Case: Mixed operational status units; budget-sensitive operations.

- Advantages: Lower per-unit cost, wider port access.

- Constraint: Higher risk of surface damage during lift operations.

C. Flat Rack – Niche for Non-Standard Units

- Use Case: Trucks with structural modifications, inoperable units, or oversized dimensions.

- Advantages: Accommodates irregular loads.

- Constraint: High exposure to weather; requires additional waterproofing and lashing audits.

5. Compliance & Documentation

All shipments from Chinese ports must comply with:

– China Customs Export Code: HS 8704 (Trucks >3.5T)

– ISPM 15: Wood dunnage certification (if used)

– Bill of Lading Type: Negotiable sea waybill with cargo manifest

– Pre-shipment Inspection (PSI): Required for African and Middle Eastern destinations

6. Conclusion

For fleet managers and construction companies exporting used trucks from Boise, Idaho, via China:

– RO-RO offers the optimal balance of cost, speed, and protection for operational units.

– Bulk Cargo is viable for cost-driven, heterogeneous fleets.

– Flat Rack remains a last-resort option for non-standard or damaged units.

Critical Success Factor: Application of industrial-grade wax spraying prior to shipment is non-negotiable for preserving asset value in high-humidity maritime routes.

SEA LION International – Engineering & Logistics Division

Data Validated: Q1 2026 | Reference: ISO 9001:2015, IACS Guidelines, IMO CTU Code

Get a Quote for Used Trucks Boise Idaho

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]