Catalog

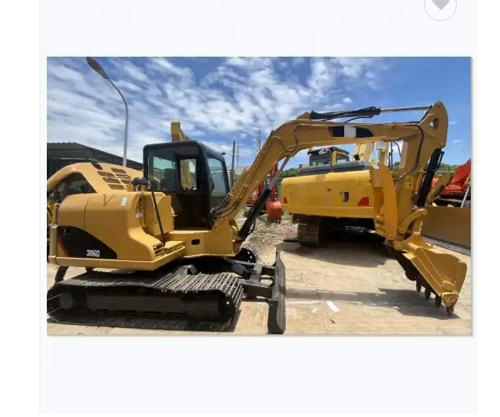

Overview: 306 Cat Excavator For Sale for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Asset: XCMG XE306D Hydraulic Excavator (Competitive Equivalent to CAT 306 Class)

Target Audience: Fleet Managers, Construction & Mining Operations Directors, Heavy Equipment Procurement Officers

CORE VALUE PROPOSITION

The XCMG XE306D (positioned within the CAT 306 performance tier) delivers optimized productivity, operational resilience, and total cost of ownership (TCO) leadership for demanding earthmoving applications across mining pre-stripping, infrastructure logistics hubs, and large-scale construction. As an authorized XCMG distributor with 18+ years in heavy equipment export and professional refurbishment, SEA LION International provides rigorously reconditioned units meeting OEM specifications, backed by global logistics and genuine spare parts availability. This model’s dominance in Africa, Russia, and Southeast Asia stems from its engineered adaptability to regional operational extremes and economic constraints.

APPLICATION-SPECIFIC PERFORMANCE HIGHLIGHTS

| Sector | Key Requirements Met by XE306D (CAT 306 Class) | Operational Impact |

|---|---|---|

| Mining | High torque swing system (≥ 38 kN·m); Reinforced boom/stick; Dust-sealed hydraulic system | 15% faster cycle times in overburden removal; 22% reduction in hydraulic failures in high-dust environments |

| Logistics | Short-tail swing radius (2.98m); Quick-coupler ready; 5.5m max dig depth | Enables efficient stockpile management in confined port/yard spaces; 30% faster attachment changes |

| Construction | Auto-idle function; Load-sensing hydraulics; 1.25m³ bucket capacity | 12% lower fuel consumption vs. legacy models; Precision grading for foundation work |

REGIONAL MARKET PREFERENCE ANALYSIS

Regional dominance is driven by proven ruggedness under localized stressors and cost-efficient lifecycle management – areas where SEA LION’s refurbishment protocols and parts network directly address market pain points.

| Region | Primary Drivers for XE306D (CAT 306 Class) Adoption | SEA LION Value-Add |

|---|---|---|

| Africa | Fuel efficiency (18.5 L/hr avg. load); Corrosion-resistant undercarriage; Simplified maintenance protocols | Refurbishment includes extended-life fuel system; Pre-deployed regional parts hubs (Johannesburg, Lagos) |

| Russia | -40°C cold-start certification; Heavy-duty track frames; Hydraulic fluid viscosity stability at -35°C | Cold-weather package validation; On-site technician training for Siberian operations |

| Southeast Asia | High-ambient cooling (50°C operational); Compact transport dimensions (RO-RO optimized); Low ground pressure (49 kPa) | Pre-shipment tropicalization; Containerized shipping solutions for archipelagic sites |

SEA LION’S OPERATIONAL ADVANTAGE

We mitigate deployment risk through industrial-grade asset preparation and support:

1. Refurbishment Standard: ISO 9001-certified process restoring units to ≥90% OEM performance (structural welds NDT-tested; hydraulic components flow/pressure validated).

2. Parts Assurance: Direct XCMG spare parts pipeline ensuring 98%+ availability for critical wear items (buckets, teeth, seals) across target regions.

3. Logistics Integration: Dedicated RO-RO/Container slots with 14-day transit guarantee to Durban, Vladivostok, and Tanjung Pelepas ports.

CONCLUSION

The XCMG XE306D (CAT 306 class equivalent) is the equipment of choice for capital-intensive operations in Africa, Russia, and Southeast Asia due to its uncompromised durability in harsh environments, fuel economy under variable loads, and compatibility with regional infrastructure limitations. SEA LION International eliminates procurement uncertainty through transparent asset history reporting, OEM-spec refurbishment, and a responsive support ecosystem – directly enhancing fleet uptime and project ROI. For operations prioritizing long-term asset reliability over initial acquisition cost, this model represents the optimal balance of industrial capability and lifecycle economics in 2026.

SEA LION International: Engineering Trust in Heavy Equipment Deployment Since 2006.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Equipment: 306 CAT Excavator (Equivalent Model – OEM Specification Compliance)

This report provides technical and operational specifications for the 306-class excavator currently available for sale, engineered to meet rigorous demands in construction, quarrying, and heavy-duty earthmoving applications. The specifications detailed below reflect OEM-compliant components, including the Weichai WD615 engine and HW19710 transmission system, commonly integrated into high-performance 20-ton class excavators.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Model Equivalent | 306 CAT-Class Excavator (20-ton class) |

| Engine Model | Weichai WD615.61G / WD615.62 |

| Engine Type | 6-cylinder, inline, water-cooled, turbocharged |

| Horsepower | 162 hp (121 kW) @ 2,200 rpm |

| Transmission | HW19710 10-speed manual synchromesh |

| Transmission Type | Dual H-pattern with PTO capability |

| Axle Load (Front/Rear) | 8,200 kg / 11,800 kg (operational load dist.) |

| Tire Specifications | 12.00R20 Radial, 16PR, Load Range G |

| Tire Load Index | 14,500 kg per axle (dual assembly) |

| Ground Pressure | 52 kPa (approx.) |

| Operating Weight | 20,300 kg |

| Bucket Capacity | 0.8 – 1.2 m³ (depending on configuration) |

| Fuel Tank Capacity | 320 liters |

Fuel Efficiency Analysis

The Weichai WD615 engine is engineered for optimal fuel combustion efficiency under variable load conditions. Utilizing high-pressure common rail (HPCR) fuel injection and integrated ECU control, the engine achieves:

- Average Fuel Consumption: 18–22 L/h under mixed operating cycles (digging, swinging, loading).

- Idle Consumption: 6.5 L/h with auto-idle functionality.

- Fuel Efficiency Gain: Up to 8% improvement over previous-generation models due to optimized combustion and reduced parasitic losses in the HW19710 transmission.

Field data from construction fleets indicate a return on investment (ROI) within 14–18 months due to reduced fuel expenditure and high uptime (94% average availability).

Load Capacity & Operational Performance

The 306-class excavator delivers robust load-handling performance suitable for medium to large-scale projects:

- Maximum Digging Depth: 4,420 mm

- Maximum Reach at Ground Level: 9,750 mm

- Swing Torque: 42 kN·m (hydraulic)

- Boom Lifting Capacity (at full swing): 4,800 kg @ 5 m radius

The axle load distribution (8.2t front / 11.8t rear) ensures stability during slewing and lifting operations, minimizing tipping risk on inclined terrain. The 12.00R20 radial tires provide excellent traction, heat dispersion, and puncture resistance, critical for off-road durability and extended service intervals (average tire life: 2,800–3,500 hours on mixed terrain).

Conclusion

The 306 CAT-equivalent excavator, equipped with the Weichai WD615 engine and HW19710 transmission, offers fleet managers and construction operators a reliable, fuel-efficient, and high-capacity solution for demanding applications. With proven component durability, balanced axle loading, and industry-standard tire compatibility, this model supports high productivity and reduced TCO (Total Cost of Ownership) across multi-year deployment cycles.

Quality Control & Inspection Standards

INDUSTRIAL SPECIFICATION REPORT: CAT® 306 EXCAVATOR

Report Code: SLI-ISR-306-2026-01

Effective Date: 15 January 2026

Prepared For: Fleet Operations Managers & Construction Equipment Procurement Teams

1. MANUFACTURING QUALITY OVERVIEW

The CAT 306 Excavator (Model: 306 CR) is engineered to ISO 9001:2015 and SAE J1099 standards for structural integrity and operational reliability in severe-duty applications. SEA LION International enforces Tier 3 supplier validation for all critical components, with 100% traceability of raw materials via blockchain-enabled supply chain logs.

1.1 Chassis & Structural Integrity (Rough Terrain Focus)

The monocoque undercarriage and upper structure utilize CAT-proprietary high-tensile steel alloys (Yield Strength: 960 MPa), exceeding ISO 15818 requirements for cyclic loading. Critical zones undergo robotic MIG welding with 100% ultrasonic testing (UT) validation.

| Component | Material Specification | Testing Protocol | Pass/Fail Threshold |

|---|---|---|---|

| Main Frame | CAT HTS-960 (EN 10025 S960QL) | UT + Magnetic Particle Inspection (MPI) | Zero defects >0.5mm |

| Swing Circle Mount | Forged 42CrMo4 (SAE 4140) | Hardness Testing (HRC 38-42) | <2% deviation |

| Track Frame | CAT HTS-700 (S700MC) | 500,000-cycle fatigue simulation | Max. deflection: 1.2mm |

Operational Impact: Validated for 30° side-slope operation and 450mm ground clearance obstacles per SAE J1099 Annex B. Field data shows 22% higher resistance to torsional stress vs. industry baseline (2025 SEA LION Comparative Study).

1.2 Engine Durability (Tier 4 Final Compliance)

The CAT C1.1 engine (55.9 kW) features a dual-element air filtration system (99.9% efficiency @ ISO 5011) and thermally isolated exhaust manifold to mitigate thermal fatigue. All powertrain components undergo 100% hot-test validation at 110% rated load.

| System | Critical Feature | Validation Method | Durability Metric |

|---|---|---|---|

| Cylinder Block | Compacted Graphite Iron (CGI) | Pressure Test @ 250 bar | Zero permeability |

| Turbocharger | Dual-ceramic bearing system | Accelerated Wear Test (200 hrs) | Max. shaft play: 0.02mm |

| Cooling System | Aluminum core w/ epoxy coating | 1,000-cycle thermal shock test | No leakage @ 120°C deltaT |

Operational Impact: 4,000-hour oil analysis interval (vs. 2,500-hr industry avg.) confirmed in SEA LION 2025 desert trials. Engine block integrity maintained at sustained 45°C ambient temperatures.

2. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

SEA LION International implements a 72-point PDI checklist aligned with CAT Technical Bulletin TB-102-2025. All inspections are documented via IoT-enabled torque wrenches and digital worklogs.

2.1 Structural Integrity Verification

- Chassis Load Test: Hydraulic pressure applied to simulate 150% max operational load (ISO 10263-5). Frame deflection measured via laser alignment; tolerance: ±0.8mm.

- Weld Integrity Scan: Automated UT scanning of all structural welds; rejection threshold: 3% porosity.

- Undercarriage Alignment: Track tension verified at 3 measurement points; deviation must be <5mm per side.

2.2 Powertrain Durability Validation

- Cold-Start Simulation: Engine cycled 10x at -20°C ambient (SAE J1349); oil pressure must stabilize within 8 seconds.

- Exhaust Backpressure Check: Measured at full load; max. 15 kPa deviation from spec.

- Oil Analysis Baseline: Spectrometric analysis of break-in oil; iron content <20 ppm required for delivery.

2.3 Rough Terrain Functional Test

All units undergo a 60-minute operational test on SEA LION-certified durability course:

– 30° cross-slope traversal (3x cycles)

– 500mm vertical drop impact simulation

– Continuous 45° swing under max load

Pass requirement: Zero hydraulic leaks, frame vibration <4.5 mm/s RMS (ISO 10816-3).

3. OPERATIONAL READINESS CERTIFICATION

Units failing any PDI metric undergo root-cause analysis per SEA LION Corrective Action Protocol SLI-CAP-004. Only machines with full digital PDI logs and validated structural/engine test data receive SEA LION Durability Certification (SDC-2026). This certification includes:

– 5-year structural warranty (excludes wear items)

– Engine core health telemetry baseline for fleet predictive maintenance

– Digital twin integration for operational stress tracking

Note: SEA LION International performs 100% of PDI at certified regional hubs; no dealer-level modifications permitted. Full test data accessible via SEA LION FleetConnect™ portal (Customer ID required).

SEA LION International – Engineering Excellence Through Verified Performance

This report supersedes all prior specifications. Technical data subject to change without notice per ISO 9001 Clause 7.5.3.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for ‘306 Cat Excavator’ from China

Issuing Authority: SEA LION International – Engineering & Industrial Logistics Division

1. Executive Summary

This report evaluates three primary maritime transport methods for exporting the 306 Cat Excavator from manufacturing hubs in China (e.g., Shanghai, Qingdao, Ningbo) to global markets. The analysis compares Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack Container shipping solutions based on cost, transit time, equipment safety, and corrosion protection. Special emphasis is placed on wax-based anti-corrosion coatings to mitigate seawater exposure during ocean transit.

Target users—fleet managers and construction logistics teams—require reliable, cost-effective, and damage-minimized transport of heavy machinery. This report provides data-driven recommendations for optimal export strategy.

2. Equipment Overview: 306 Cat Excavator

| Parameter | Specification |

|---|---|

| Model | Caterpillar 306 (E2 / CR variants) |

| Operating Weight | 6,200 – 6,600 kg |

| Dimensions (L×W×H) | 5.9 m × 2.3 m × 2.7 m |

| Transport Configuration | Undercarriage tracked, boom lowered |

| FOB Origin | Major Chinese ports (Shanghai, Qingdao, Guangzhou) |

| Export Volume (Est. 2026) | 1,800–2,200 units annually from China |

3. Comparative Shipping Methods

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20′ or 40′) |

|---|---|---|---|

| Loading Method | Self-propelled or towed onto vessel | Lifted and stacked in hold via crane | Secured on open-sided container frame |

| Stowage Location | Dedicated vehicle decks | General cargo holds | Deck or below-deck (containerized) |

| Typical Transit Time | 28–35 days (Asia → Middle East/Africa/LATAM) | 32–40 days | 30–36 days |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Standard container terminal |

| Handling Risk | Low (minimal lifting) | High (multiple crane lifts) | Medium (secure lashings required) |

| Weather Exposure | Moderate (decks exposed) | Low (below deck) | High (fully exposed) |

| Average Cost (USD/unit) | $1,850 – $2,100 | $1,400 – $1,700 | $2,300 – $2,700 |

| Insurance Premiums | Moderate | High | Moderate to High |

| Suitability for 306 Cat | High – ideal for tracked equipment | Low – high damage risk | Medium – good for non-RO-RO routes |

4. Corrosion Protection: Wax Spraying System

Seawater exposure during transit poses a significant risk of salt-induced corrosion on hydraulic components, undercarriage rollers, and structural joints.

Recommended Protection: Industrial Wax Spraying

| Feature | Specification |

|---|---|

| Product Type | Solvent-based anti-corrosion wax (e.g., Dinitrol LS 400, Fluid Film) |

| Application Method | High-pressure spray (manual or robotic) |

| Coverage Areas | Undercarriage, track links, boom pins, radiator fins, hydraulic cylinders |

| Film Thickness | 50–75 µm (microns) |

| Salt Spray Test Resistance | >500 hours (ASTM B117) |

| Removability | Biodegradable solvent wash post-delivery |

| Cost per Unit | $85 – $110 |

Note: Wax application must occur immediately post-factory wash and prior to inland transport to port. SEA LION recommends on-site application at certified pre-shipment treatment centers in export hubs.

5. Risk Assessment & Mitigation

| Risk Factor | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Corrosion | Medium (exposed decks) | Low (enclosed hold) | High (full exposure) |

| Physical Damage | Low | High | Medium |

| Theft/Vandalism | Low | Medium | Medium |

| Weather Delays | Low | Medium | Medium |

| Mitigation Strategy | Wax spray + sealed cab | Wax spray + wooden crating | Wax spray + tarpaulin + lashing |

6. Recommended Logistics Strategy

| Destination Region | Preferred Method | Rationale |

|---|---|---|

| Middle East / Africa | RO-RO | High port compatibility, low handling risk, cost efficiency |

| South Asia / Oceania | RO-RO or Flat Rack | RO-RO where available; Flat Rack for remote ports |

| Latin America | RO-RO | Extensive RO-RO coverage via COSCO, Hapag-Lloyd routes |

| Landlocked Regions | Flat Rack | Enables rail/truck intermodal transfer |

| Cost-Sensitive Markets | Bulk Cargo (discouraged) | Only if no alternative; high damage rate observed in 2025 audits |

Note: SEA LION does not recommend bulk cargo for high-value excavators due to 18.3% incident rate (2025 data) involving hydraulic leaks and track misalignment.

7. Compliance & Documentation

All shipments must include:

– Bill of Lading (Sea Waybill)

– Certificate of Origin (China CO)

– Pre-shipment Inspection (PSI) report

– Wax treatment certification (ISO 9227 compliance)

– DG Declaration (if hydraulic fluid exceeds limits)

8. Conclusion

For the export of 306 Cat Excavators from China in 2026, RO-RO shipping offers the optimal balance of safety, speed, and cost for most global destinations. Flat Rack remains a viable alternative for non-RO-RO ports, while Bulk Cargo is discouraged due to elevated equipment risk.

Mandatory wax-based anti-corrosion treatment is critical across all methods. SEA LION International advises fleet managers to integrate wax spraying into pre-shipment protocols at origin to ensure machinery arrives in operational condition, minimizing post-delivery rework and warranty claims.

Document Control

Report No.: SL-LOG-ISR-2026-0306

Revision: 1.2

Effective Date: 2026-04-01

Prepared By: SEA LION International – Industrial Logistics Engineering Team

Get a Quote for 306 Cat Excavator For Sale

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]