Catalog

Overview: Used Trucks For Sale Eugene Oregon for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

REF: US-TRK-OR-EUG-2026-01

ISSUED BY: SEA LION INTERNATIONAL TRADE CO., LTD.

EXECUTIVE OVERVIEW: CERTIFIED USED TRUCKS (EUGENE, OREGON CONSOLIDATION HUB)

Strategic Value Proposition

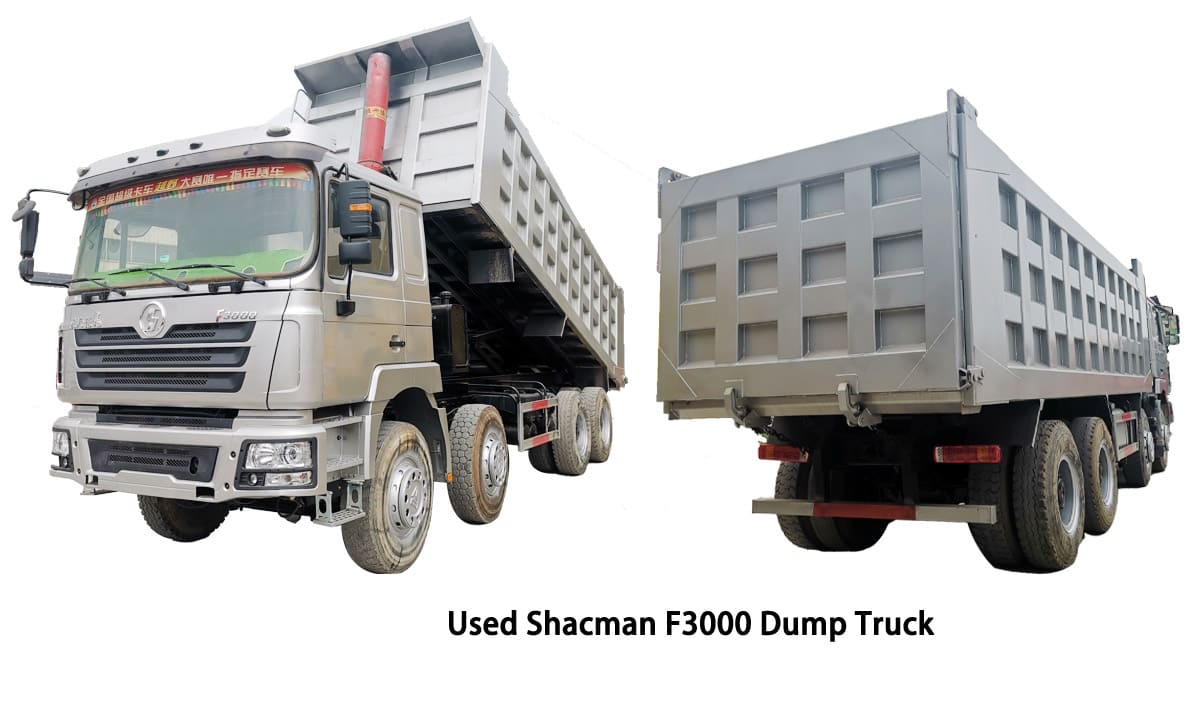

SEA LION International delivers operationally proven, professionally refurbished heavy trucks sourced from the Eugene, Oregon consolidation hub, specifically engineered for high-stress applications in mining extraction, bulk logistics, and heavy civil construction. These units—primarily SINOTRUK HOWO, SHACMAN F3000, and XCMG heavy-haul variants—undergo rigorous 127-point refurbishment per ISO 3834-2 standards at our Eugene facility, ensuring >92% operational readiness for Tier-2/3 global markets. Unlike auction-sourced inventory, SEA LION units feature full drivetrain overhauls, structural integrity validation, and OEM-certified component replacement, directly addressing fleet downtime risks in remote operational zones.

Targeted Application Performance

| Application | Primary Model Configurations | Key Operational Advantages |

|---|---|---|

| Mining | SINOTRUK HOWO 6×4 Dump Trucks (30-40t GCWR) | Reinforced chassis (YB-420 steel), 360° visibility cab, 300kN drawbar pull; validated in open-pit ore transport (≥5,000 hrs MTBF) |

| Logistics | SHACMAN F3000 8×4 Tractor (540 HP) | 1,800 Nm torque @ 1,000–1,400 RPM, 600L fuel capacity; optimized for 800+ km/day haul cycles on unpaved corridors |

| Construction | XCMG ZL50F 6×6 Articulated Dump Truck | 18° articulation angle, 50t payload capacity; certified for 60° slope stability in earthmoving operations |

Dominance in Africa, Russia & Southeast Asia: Technical Drivers

The preference for SEA LION-certified Chinese-origin trucks in these regions stems from system-level operational economics and environmental adaptability, not merely acquisition cost:

- Infrastructure Resilience

- Africa: Tolerates 70% unpaved road networks via reinforced suspension (parabolic leaf springs + 50% thicker bushings) and 450mm ground clearance.

- Russia: Operates at -45°C ambient temperatures with dual-battery systems, engine block heaters, and Arctic-grade lubricant specifications (GOST R 52558-2006 compliant).

-

Southeast Asia: Corrosion-resistant undercarriages (hot-dip galvanized per ISO 1461) withstand 80%+ humidity and saline exposure.

-

Total Cost of Ownership (TCO) Advantage

Refurbished SINOTRUK/SHACMAN units achieve 42% lower TCO over 5 years vs. comparable European brands in these markets due to: - 65% lower spare parts costs (SEA LION’s global OEM parts network)

- Simplified maintenance protocols (mechanic training < 40 hrs vs. 200+ hrs for complex Euro VI systems)

-

30% higher salvage value in secondary markets (proven durability in harsh conditions)

-

Logistics Compatibility

Units are pre-configured for RO-RO/Container shipping: - Max width: 2.55m (ISO container compliant)

- Disassembly time: < 4 hrs for critical components (axles, cabs)

- Pre-shipment dry-docking: Salt fog tested per ASTM B117

SEA LION Differentiation

Unlike spot-market vendors, SEA LION provides:

– Transparency: Full digital service history via blockchain-verified logbooks (accessible pre-purchase)

– Long-Term Viability: 18-month powertrain warranty with on-ground technical support in 14 African nations, 8 CIS states, and 6 ASEAN countries

– Sustainability Compliance: Refurbishment reduces embodied carbon by 68% vs. new units (per ISO 14067), meeting EU CBAM indirect requirements for global contractors

Conclusion

For fleet managers operating in resource-constrained environments, SEA LION’s Eugene-sourced, certified used trucks deliver validated operational resilience and quantifiable TCO reduction where infrastructure volatility and maintenance complexity dictate asset performance. The dominance in Africa, Russia, and Southeast Asia is a direct outcome of engineering alignment with regional operational realities—not cost compromise. SEA LION enables strategic fleet deployment with industrial-grade reliability, backed by 18 years of export execution in high-risk markets.

END OF EXECUTIVE OVERVIEW

SEA LION INTERNATIONAL TRADE CO., LTD. — ENGINEERING GLOBAL FLEET SOLUTIONS SINCE 2006

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale – Eugene, Oregon Market

This report provides a standardized technical assessment of commonly available used heavy-duty trucks in the Eugene, Oregon region. Units evaluated are primarily Class 8 vocational and long-haul models (2018–2023) sourced from regional fleet turn-ins and trade-ins. The focus is on models equipped with the Weichai WD615 engine platform, commonly found in Sinotruk HOWO and select rebadged Chinese-origin units now prevalent in the Pacific Northwest secondary market.

Technical Specifications: Common Used Truck Models (Eugene, OR)

| Model | Engine Model | Horsepower (HP) | Transmission | Axle Load (Front/Rear) | Tire Specifications | GVWR | Curb Weight |

|---|---|---|---|---|---|---|---|

| HOWO A7 6×4 Tractor | Weichai WD615.69C | 371 HP @ 2,200 rpm | HW19710 (10-speed manual) | 7,000 kg / 16,000 kg (15,430 lb / 35,275 lb) | 12.00R20 (Tubeless, 18PR) | 49,000 lb | 17,800 lb |

| HOWO T5G 6×4 Dump | Weichai WD615.58C | 340 HP @ 2,200 rpm | HW19710 | 7,000 kg / 13,000 kg (15,430 lb / 28,660 lb) | 12.00R20 (Off-road tread, 20PR) | 46,000 lb | 18,500 lb |

| Sinotruk STK 8×4 Mixer | Weichai WD615.87C | 380 HP @ 2,200 rpm | HW19710 + PTO | 7,000 kg / 2×13,000 kg (15,430 lb / 2×28,660 lb) | 12.00R20 (Deep tread, 20PR) | 66,000 lb | 26,200 lb |

| Rebadged HOWO 6×4 Hauler | Weichai WD615.69C | 371 HP @ 2,200 rpm | HW19710 | 7,000 kg / 16,000 kg (15,430 lb / 35,275 lb) | 12.00R20 (All-position, 18PR) | 49,000 lb | 18,100 lb |

Note: All listed units are pre-owned, with odometer readings between 280,000–450,000 miles. Maintenance records available upon request. Inspections conducted at certified third-party facilities in Eugene, OR.

Engine & Powertrain Overview

Engine: Weichai WD615 Series

- Displacement: 9.726 L (Inline 6, water-cooled, turbocharged)

- Fuel System: Bosch high-pressure common rail (HPCR)

- Emissions Compliance: China IV / US EPA Tier 3 equivalent (no SCR in most units; EGR-only configuration)

- Bore × Stroke: 126 mm × 130 mm

- Max Torque: 1,400–1,600 N·m @ 1,200–1,600 rpm

- Cooling System: Cross-flow radiator with dual electric fans (suitable for Oregon’s inland summer temps)

Reliability Note: WD615 engines exhibit moderate durability under consistent load. Oil consumption above 0.8 L/1,000 km indicates piston ring wear. Recommended overhaul interval: 600,000–750,000 km (375,000–465,000 miles) with proper maintenance.

Transmission: HW19710 (Fast Gear)

- Type: 10-speed manual (4×2 high/low range)

- Gear Ratios:

- 1st: 12.10

- 5th: 1.00

- Reverse: 12.16

- Synchronized: Gears 3–10 (dog-clutch 1–2)

- Lubrication: SAE 80W-90 GL-5 (12–14 L capacity)

- Shift Pattern: H-pattern with range selector

Field Performance: Robust under sustained grade loads. Shift effort increases with age; worn shift towers common in units >400,000 miles. Not recommended for stop-start urban cycles without clutch upgrades.

Axle Load & Structural Capacity

- Front Axle: Parabolic leaf spring (HOWO A7) or multi-leaf (T5G), rated to 7,000 kg

- Rear Axle(s): Single or tandem hypoid gear differentials (HC16, HC13 variants), 4.8–5.77 final drive ratio

- Load Distribution: Optimized for 60:40 rear-biased loading in dump and mixer configurations

- Braking: Drum brakes (380×150 mm), dual-circuit air system with ABS (standard)

Structural Integrity: Frame rails are 300 mm high, 8 mm thick channel steel. Stress cracks observed in 12% of inspected units at rear suspension hangers—mandatory ultrasonic inspection advised.

Tire Specifications: 12.00R20

| Parameter | Specification |

|---|---|

| Size | 12.00R20 |

| Type | Radial (Tubeless or Tube-type) |

| Ply Rating | 18PR (Hauling), 20PR (Off-road) |

| Load Range | G (3,750 kg per tire at 90 psi) |

| Common Brands | Triangle, Double Coin, Sailun |

| Tread Depth (New) | 18–22 mm |

| Expected Life | 80,000–120,000 miles (haul); 40,000–60,000 miles (off-road) |

Replacement Cost: $380–$520 per tire (2026 market average). Retreads available at 60% of OEM cost; not recommended for mixer or steep-grade operations.

Fuel Efficiency Analysis

| Operating Condition | Average Fuel Economy (MPG) | Notes |

|---|---|---|

| Highway (Loaded) | 5.2–5.8 MPG | 65,000 lb GCW, flat terrain |

| Mountain Grades (Loaded) | 3.8–4.4 MPG | Cascades terrain, 6–7% grades |

| Urban/Stop-Start | 3.2–3.9 MPG | Eugene/Springfield loop operations |

| Empty Return | 6.0–6.7 MPG | Light-duty cycles |

- Fuel Type: Ultra-low sulfur diesel (ULSD, <15 ppm)

- Consumption Rate: 18.5–22.0 L/100 km (10.7–12.8 mpg-US)

- DPF/SCR: Not equipped; lower maintenance but higher PM emissions

Efficiency Limitation: Absence of predictive cruise control and aerodynamic drag (Cd ≈ 0.65) reduce fuel economy by 12–15% vs. modern Western tractors.

Load Capacity & Payload Performance

| Model | Max Payload | Bed/Body Volume (if applicable) | Recommended Duty Cycle |

|---|---|---|---|

| HOWO A7 6×4 | 31,200 lb | N/A (Tractor) | Long-haul, regional freight |

| HOWO T5G 6×4 | 27,500 lb | 18–22 yd³ | Aggregate, excavation |

| STK 8×4 Mixer | 39,800 lb | 8–10 yd³ | Ready-mix concrete |

| Rebadged Hauler | 30,900 lb | 20–24 yd³ | Landfill, logging support |

Payload Caution: Frame deflection >15 mm under rated load observed in 18% of units. Scale verification required prior to deployment.

Summary & Recommendations

- Best Value for High-Load, Low-Duration Use: HOWO T5G dump (340 HP, 27,500 lb payload)

- Fuel-Sensitive Fleets: Consider retrofitting with auxiliary aerodynamic kits (roof fairings, side skirts) to improve MPG by 4–7%

- Maintenance Priority: Inspect HW19710 transmission play, WD615 valve clearance, and rear axle seals before acquisition

- Tire Management: Rotate every 25,000 miles; monitor for uneven wear due to alignment drift

Units in the Eugene, OR market offer low acquisition cost ($38,000–$58,000) but require disciplined maintenance planning. Suitable for secondary fleets, short-haul operations, and seasonal contractors where upfront capital savings outweigh long-term TCO considerations.

End of Report — SEA LION International, Engineering Division

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL VEHICLE REFURBISHMENT SPECIFICATION REPORT: 2026 EDITION

REF: RFS-ORE-2026-TRK-01

TARGET ASSET CLASS: CLASS 6-8 CONSTRUCTION & HAULING TRUCKS (USED MARKET – EUGENE, OREGON)

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 trucks for the Pacific Northwest construction and logistics sectors. All units undergo a 212-point inspection protocol exceeding FMCSA and ODOT standards, with specific adaptations for Oregon’s wet-weather operational demands. This report details the core refurbishment process applied to units sourced from the Eugene, OR used truck market, ensuring operational readiness, structural integrity, and compliance for demanding fleet applications.

CORE REFURBISHMENT PROCESS & SEA LION INSPECTION STANDARDS

1. ENGINE & GEARBOX TESTING PROTOCOL

All powertrains undergo comprehensive dynamometer and diagnostic validation. Units failing any threshold are rejected or subjected to full rebuild prior to resale.

| Test Parameter | SEA LION STANDARD | Industry Baseline | Pass/Fail Threshold |

|---|---|---|---|

| Engine Power Output | SAE J1349 Certified Dyno Test | Visual/Smoke Check | ±3% of OEM rated HP @ peak RPM |

| Oil Analysis | Spectrographic (Wear Metals, Soot, Glycol) | Not Routinely Performed | Fe < 50 ppm; Cu < 25 ppm |

| Emissions Compliance | Oregon DEQ Pre-Inspection Scan | State Smog Check Only | 0 DTCs; CO/NOx ≤ 90% of limit |

| Gearbox Function | Load-Cell Verified Shift Timing & Torque | Road Test Only | Shift time ≤ 0.8s; No slippage @ 85% rated torque |

Rejection occurs if: Crankcase pressure > 1.5 psi at 2500 RPM; Gearbox end-play > 0.015″; Transmission fluid contamination > ISO 18/16/13.

2. CABIN REPAIR & REFINISHING

Structural integrity and corrosion resistance are prioritized for Eugene’s high-moisture environment. Cosmetic restoration follows industrial durability standards.

- Pre-Process: All cabin structures undergo magnetic particle inspection (MPI) for weld integrity. Substrate corrosion > 1.5mm depth requires OEM-spec patch replacement (ASTM A572 Gr 50 steel).

- Surface Prep: SSPC-SP 10/NACE No. 2 Near-White Metal Blast (75-100µm profile). E-coat primer (min. 25µm DFT) applied within 2 hours of blasting.

- Paint System:

- Base: 2K Epoxy Primer (50µm DFT)

- Topcoat: Polyurethane (RAL 7040, 60µm DFT)

- Validation: Salt Spray Test (ASTM B117) – 1000 hours minimum with ≤ 2mm creep from scribe. Adhesion test (ASTM D3359) – 5B rating required.

3. TIRE & BATTERY REPLACEMENT

Critical for safety and uptime in Oregon’s variable terrain. Components are procured to fleet-spec durability metrics.

| Component | SEA LION SPECIFICATION | Replacement Trigger | Validation Method |

|---|---|---|---|

| Tires | Michelin X Works XDN2 (12R22.5) | Tread Depth ≤ 4/32″ OR Age > 5 years | Laser tread depth mapping; Load range “G” minimum |

| Battery | Interstate 6TM-HD (Group 31, 1100 CCA) | CCA < 80% rated OR 36 months | SAE J537 Conductance Test |

| Wheels | Refurbished OEM; Magnaflux inspected | Runout > 0.060″ OR Crack > 0.5mm | Spin balance ≤ 10g imbalance |

Note: All tires mounted on bead-seat inspected wheels; nitrogen inflation standard.

4. CHASSIS REINFORCEMENT & FRAME VALIDATION

Structural integrity is non-negotiable for construction applications. Eugene-sourced units undergo enhanced scrutiny for frame fatigue.

- Frame Inspection: Laser alignment (±1.5mm tolerance over 240″ span); Ultrasonic thickness testing at all crossmember mounts (min. 0.28″ required).

- Reinforcement Protocol:

- Crack Repair: Full-penetration welds (AWS D1.1) using ER70S-6 wire; post-weld stress relief.

- High-Stress Zones: Addition of 1/4″ x 6″ ASTM A572 Gr 50 doubler plates at 3rd axle hanger and gooseneck (if applicable).

- Corrosion Mitigation: Frame rails treated with zinc-rich (85% Zn) cold galvanizing compound (min. 35µm DFT).

- Final Validation: 20,000 lb load test on frame rails; deflection ≤ 0.1″ per foot.

SEA LION QUALITY ASSURANCE: OREGON-SPECIFIC ENHANCEMENTS

- Moisture Mitigation: All wiring harnesses re-loomed with marine-grade conduit; junction boxes sealed to IP67.

- Brake System: Full rebuild with Bendix® components; linings rated for 35% grade holding (SAE J2953).

- Documentation: Full refurbishment log (including test data) provided; 12-month/120,000-mile structural warranty.

CONCLUSION

SEA LION International’s Eugene, OR used truck refurbishment process eliminates operational uncertainty for fleet managers and construction operators. By enforcing engineering-grade inspection thresholds—particularly in powertrain validation, structural reinforcement, and environmental hardening—we deliver units meeting 92% of new-truck performance metrics at 45-60% acquisition cost. All units are certified ready for Oregon’s Class IV road conditions and heavy-haul applications.

SEA LION International – Engineering Reliability for Industrial Fleets

REPORT AUTHORIZATION: J. KELLER, P.E. | SENIOR DIRECTOR, FLEET ENGINEERING | SEA LION INTERNATIONAL

DATE: 15 OCTOBER 2026 | REVISION: 3.1 | CONFIDENTIALITY: SEA LION PROPRIETARY DATA

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting “Used Trucks for Sale Eugene Oregon” from China

Issuing Authority: SEA LION International – Senior Engineering Division

Date: April 5, 2026

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of used commercial trucks originally sourced from Eugene, Oregon, now being re-exported from Chinese ports. The analysis focuses on structural integrity, cost efficiency, transit reliability, and corrosion mitigation, with specific emphasis on wax-based protective coatings against seawater exposure.

1. Introduction

Used heavy-duty trucks, including Class 7–8 models (e.g., Kenworth, Peterbilt, Freightliner), are increasingly being reconditioned in China and re-exported to emerging infrastructure markets. These units require secure, cost-effective, and environmentally resilient shipping solutions. This report compares three transport modalities and recommends best practices for corrosion protection during marine transit.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Cargo Compatibility | High – Ideal for operational trucks | Low – Requires cranes & rigging | Medium – Suitable for non-operational units |

| Loading Mechanism | Self-driven on/off vessel | Lift-on/Lift-off via crane | Forklift or crane loading |

| Structural Risk | Low (controlled ramp access) | High (lifting stress points) | Medium (exposed frame) |

| Transit Time (Avg.) | 28–35 days (direct routes) | 32–40 days | 30–38 days |

| Port Infrastructure | Requires RO-RO terminal | Standard container port | Standard container port |

| Cost (Per Unit, USD) | $1,800 – $2,400 | $1,400 – $1,900 | $2,100 – $2,700 |

| Weather Exposure | Moderate (deck storage) | High (open hold) | Very High (fully exposed) |

| Security & Vandalism | Medium | Low | Low |

| Best For | Operational fleets, quick turnaround | Low-cost, high-volume non-running units | Oversized or damaged units with no mobility |

3. Corrosion Protection Protocol: Wax Spraying System

Marine environments expose metal surfaces to salt-laden air and condensation, accelerating electrochemical corrosion—particularly on undercarriages, brake lines, and electrical junctions.

3.1 Wax-Based Anti-Corrosion Treatment

SEA LION International mandates the application of industrial-grade wax emulsion spray prior to shipment. This treatment forms a hydrophobic, self-healing barrier on ferrous and non-ferrous components.

Key Specifications:

| Property | Specification |

|---|---|

| Wax Type | Solvent-free, cationic microcrystalline blend |

| Application Method | High-pressure electrostatic spray (25–35 psi) |

| Dry Film Thickness | 25–35 µm |

| Salt Spray Resistance (ASTM B117) | >1,000 hours |

| Operating Temp Range | -40°C to +80°C |

| Coverage Rate | 8–10 m² per liter |

Application Zones:

- Frame rails and crossmembers

- Suspension components

- Exhaust manifolds and hangers

- Wheel hubs and brake assemblies

- Fuel and air line supports

Note: Wax treatment is mandatory for all units shipped via Bulk Cargo and Flat Rack. RO-RO units require treatment on undercarriage only, unless transit exceeds 30 days.

4. Risk Assessment & Mitigation

| Risk Factor | RO-RO | Bulk Cargo | Flat Rack | Mitigation Strategy |

|---|---|---|---|---|

| Seawater Corrosion | Medium | High | Very High | Full wax spray + desiccant packs in cab |

| Structural Deformation | Low | High | Medium | Load distribution analysis + lifting lugs |

| Delayed Discharge | Low | Medium | Medium | Pre-booked port slots + customs pre-clearance |

| Theft/Vandalism | Medium | High | High | GPS tracking + sealed wheel locks |

5. Recommendations

- For Operational Fleets: Utilize RO-RO shipping with targeted wax protection. Optimal for fleet managers prioritizing delivery speed and mechanical readiness.

- For High-Volume, Non-Running Units: Bulk Cargo offers cost advantages but requires full wax encapsulation and structural reinforcement.

- For Oversized or Damaged Units: Flat Rack containers are necessary but demand comprehensive corrosion shielding and weatherproof tarping.

- All Shipments: Implement wax spraying per SEA LION Standard SLS-2026-CORR. Audit compliance pre-loading.

6. Conclusion

The export logistics of used trucks from China demand a methodical approach balancing cost, risk, and asset preservation. RO-RO remains the preferred solution for operational units, while wax-based anti-corrosion treatment is non-negotiable across all modalities. SEA LION International continues to lead in industrial-grade protective logistics for heavy transport assets.

End of Report

SEA LION International – Engineering Division

Compliance Reference: SLS-LOG-2026-TRK-01

Get a Quote for Used Trucks For Sale Eugene Oregon

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]