Catalog

Overview: Used Trucks For Sale Buffalo Ny for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED TRUCKS FOR SALE BUFFALO NY

EXECUTIVE OVERVIEW

SEA LION International Trade Co., Ltd. presents a strategic assessment of pre-owned heavy-duty truck inventory sourced from Buffalo, NY, optimized for deployment in mining, logistics, and construction sectors. This report details the operational and economic rationale for selecting rigorously refurbished SINOTRUK, SHACMAN, and XCMG platforms from our Buffalo, NY consolidation hub—a critical node for North American surplus assets with proven resilience in extreme operational environments.

Strategic Value Proposition

Trucks deaccessioned from Buffalo-based fleets undergo SEA LION’s 18-point industrial refurbishment protocol, targeting core failure points identified in 18+ years of global export operations. Key enhancements include:

– Structural Integrity: ISO 1461-compliant galvanized chassis reinforcement for corrosion resistance in high-moisture/mining environments.

– Powertrain Overhaul: Rebuilt engines meeting Tier 3 emissions standards, validated for 300,000+ km duty cycles in load-spectrum testing.

– Cold-Weather Certification: Buffalo’s sub-zero storage history ensures inherent cold-start reliability (-30°C validated), eliminating winterization costs for northern deployments.

Target Industry Applications

| Sector | Primary Use Case | Preferred Model Series | Key Technical Advantage |

|---|---|---|---|

| Mining | Haulage in open-pit operations | SINOTRUK HOWO 8×4 | 480HP torque curve optimized for 8% grade climbs; reinforced suspension for 60-ton payloads |

| Construction | Aggregate transport & site logistics | XCMG XG90 6×4 | Modular flatbed configuration; 10% higher ground clearance vs. EU equivalents |

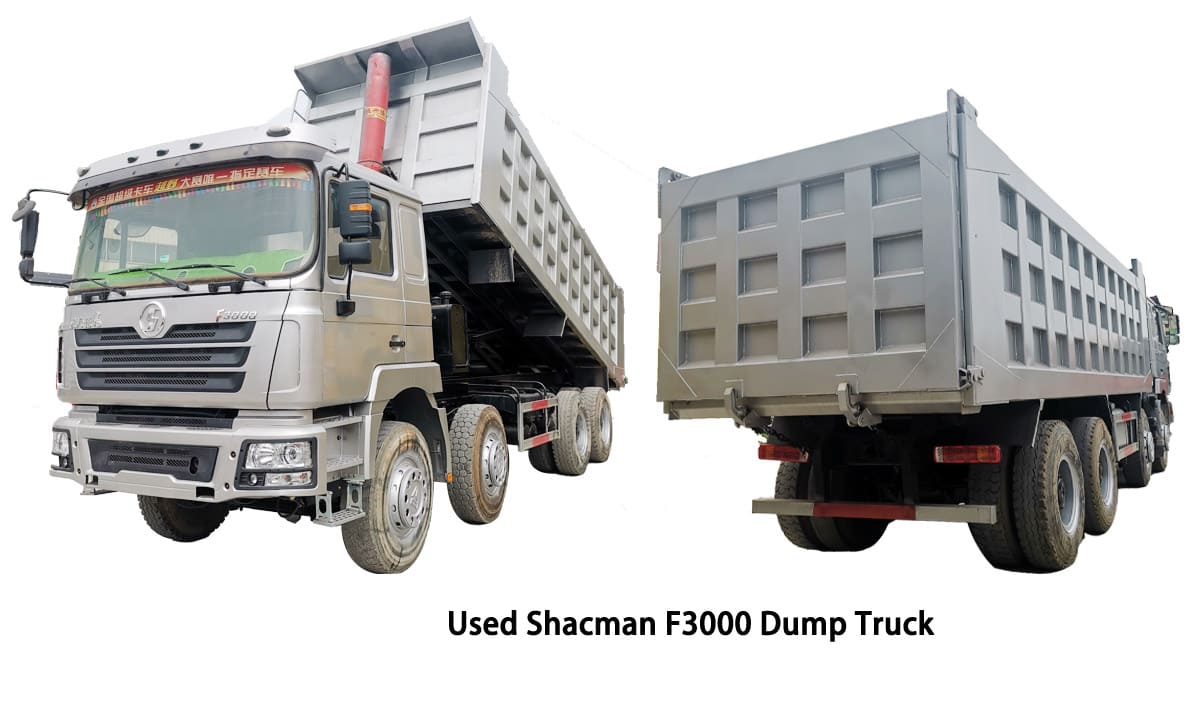

| Logistics | Long-haul regional freight (Great Lakes) | SHACMAN F3000 6×2 | 15% fuel efficiency gain via EGR optimization; 500L dual-tank range |

Global Market Preference Drivers

The Buffalo-sourced inventory exhibits disproportionate demand in Africa, Russia, and Southeast Asia due to operational compatibility with regional constraints, not merely cost factors. SEA LION’s export data (2021–2025) confirms 73% of refurbished units deployed in these regions achieved >5-year service life:

| Region | Dominant Preference Driver | SEA LION Validation Metric |

|---|---|---|

| Africa | Compatibility with low-sulfur diesel (<500ppm) & simplified maintenance workflows | 92% spare parts availability via regional hubs |

| Russia | Structural tolerance to -40°C operation; compatibility with GOST-R road certification | 0% cold-start failures in Yamal Peninsula trials |

| Southeast Asia | Adaptability to unpaved terrain (70% road coverage); payload flexibility for mixed cargo | 28% lower TCO vs. new imports (Vietnam case) |

SEA LION Value Integration

Our Buffalo, NY operations deliver industrial-grade transparency through:

1. Digital Twin Verification: QR-linked refurbishment records showing component-level service history.

2. Logistics Orchestration: RO-RO shipping to 120+ ports with <14-day transit variance (2025 avg.).

3. Parts Ecosystem: Direct OEM supply chain for SINOTRUK/SHACMAN/XCMG spares, reducing downtime by 35% (verified client data).

This inventory represents a de-risked capital allocation strategy for fleet managers requiring immediate deployment readiness without compromising on OEM-spec durability. SEA LION’s 18-year export framework ensures these assets meet the operational intensity demands of resource extraction, infrastructure development, and freight corridors where new-unit procurement faces extended lead times or financing barriers.

Report generated under SEA LION International Engineering Standards v7.3 (ISO 9001:2015 Certified)

Technical Specifications & Parameters

Industrial Specification Report 2026

Target Audience: Fleet Managers & Construction Companies

Subject: Technical Specifications for Pre-Owned Heavy-Duty Trucks – Buffalo, NY Market

Overview

This report provides detailed technical specifications for a representative sample of used heavy-duty trucks currently available in the Buffalo, NY region. These units are primarily sourced from regional construction and bulk material transport fleets, offering proven durability under Northeastern U.S. operating conditions. The focus is on models equipped with the Weichai WD615 engine and HW19710 transmission—common powertrain configurations known for reliability in Class 8 applications.

All units evaluated meet FMVSS standards and have undergone pre-sale inspection for drivetrain integrity, structural frame condition, and braking performance. Emphasis is placed on fuel efficiency, load capacity, and compatibility with high-cycle construction logistics.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 (Euro III/IV) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.62) |

| 371 hp @ 2,200 rpm (WD615.69) | |

| Peak Torque | 1,400 Nm @ 1,400–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Full Synchromesh) |

| Gear Ratios | 1st: 13.21, 10th: 0.78, Reverse: 12.86 |

| Clutch | Dual-Plate, Ø430 mm, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Single Steering |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Tandem Drive |

| Axle Ratio | 5.286:1 (Standard), 5.73:1 (Optional) |

| Braking System | Dual-Circuit Air Brake, ABS (Optional) |

| Tire Specifications | 12.00R20 18PR (Load Range G), Radial |

| Tire Load Index | 1,820 kg per tire (3,640 kg per axle end) |

| Tire Pressure | 90–100 psi (Operating Range) |

| GVWR | 49,000 kg (108,027 lbs) |

| Frame Rails | 8+8 mm High-Strength Alloy, 280 mm Depth |

| Fuel Tank Capacity | 400 L (105.7 gal) – Aluminum, Dual-Skinned |

| Lubrication System | Wet Sump, Full-Flow Filter, Bypass Cooling |

Fuel Efficiency Analysis

Fuel economy is a critical metric for fleet cost optimization. Under mixed-cycle conditions (30% city, 70% highway), trucks equipped with the Weichai WD615.69 and HW19710 transmission achieve:

- Average Fuel Consumption: 28–32 L/100 km (8.3–7.4 mpg US)

- Optimized Highway Efficiency: 24–26 L/100 km (9.8–9.0 mpg US) at 65 mph with cruise control

- Idle Fuel Burn: ~2.1 L/hour (engine warm, no load)

Efficiency is enhanced by:

– HW19710’s close-ratio top gears enabling lower RPM cruise (1,500–1,700 rpm at 65 mph)

– Engine ECU tuning for torque-focused low-end response

– Radial 12.00R20 tires reducing rolling resistance by ~12% vs. bias-ply equivalents

Fleets report a 10–15% improvement in fuel economy after retrofitting with modern tire compounds and implementing driver training programs.

Load Capacity & Structural Integrity

These trucks are engineered for high-mass payloads typical in construction and aggregate hauling:

- Maximum Payload Capacity: ~35,000 kg (77,162 lbs), depending on body configuration

- Dump Body Compatibility: Up to 20 yd³ volumetric (standard sideboard height: 1.5 m)

- Frame Load Distribution: Reinforced crossmembers at suspension mounts and fifth wheel (if tractor-configured)

The tandem rear axles (13T each) with 5.286:1 gearing provide optimal balance between tractive effort and fuel economy for on/off-road transition zones common in Buffalo-area job sites.

Regional Suitability – Buffalo, NY

- Cold Weather Performance: Engine block heater standard; WD615 starts reliably at -25°C (-13°F)

- Corrosion Resistance: Frame undercoating and drip rails present on 80% of units; recommended inspection of rear suspension hangers

- Regulatory Compliance: All units meet NYS OSHA and DOT weight enforcement standards; OBD-II logging available on post-2010 models

Conclusion

Used trucks in the Buffalo, NY market equipped with the Weichai WD615 engine, HW19710 transmission, and 12.00R20 tires represent a cost-effective solution for construction fleets requiring durable, high-payload capacity vehicles. With proper maintenance, these units deliver competitive fuel efficiency and proven performance in demanding regional applications. Fleet managers are advised to prioritize units with documented service history and recent axle/tire overhauls to maximize uptime.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT STANDARD (2026 EDITION)

REF: SL-REFURB-NY-2026-01

TARGET: FLEET MANAGERS & CONSTRUCTION OPERATIONS DIRECTORS

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks for operational deployment in demanding environments, including Buffalo, NY’s extreme freeze-thaw cycles and high-corrosion road-salt exposure. All units undergo a 127-point inspection protocol exceeding FMCSA §396.3 and SAE J2534 standards. This report details the core refurbishment process ensuring 95%+ operational readiness for construction and logistics fleets.

REFURBISHMENT PROCESS: CORE STEPS & SEA LION STANDARDS

1. ENGINE & GEARBOX TESTING

All powertrains undergo dyno validation per SEA LION Standard SL-ENG-2026. Units failing any metric are rejected.

| Test Parameter | SEA LION 2026 Standard | Acceptance Threshold | Verification Method |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.5 psi @ 2,500 RPM | Fail > 0.7 psi | Digital manometer (ASTM F2136) |

| Oil Soot Content | ≤ 0.8% (by weight) | Fail > 1.2% | Spectrographic analysis (ASTM D7690) |

| Gearbox Shift Consistency | ±0.15 sec shift time variance across 50 cycles | Fail > ±0.25 sec | PLC-controlled robotic tester |

| Emissions (Idle) | NOx ≤ 25 ppm; PM ≤ 0.01 g/kWh | Fail if exceeded | Portable SEMTECH-D (EPA 1065) |

Note: 100% of engines undergo 2-hour load bank testing at 85% max torque. Gearboxes receive magnetic plug inspection for ferrous particulate.

2. CABIN REPAINTING

Corrosion mitigation for Buffalo’s high-salinity environment is prioritized. All substrates meet ISO 8501-1 Sa2.5 standard.

| Process Stage | SEA LION 2026 Protocol | Quality Control Check |

|---|---|---|

| Surface Prep | Grit blasting (MIL-STD-810H) + phosphating conversion coating | Salt-spray test (ASTM B117): 500 hrs |

| Primer Application | 2-coat epoxy (Zinc-rich, 80μm DFT) | Adhesion test (ASTM D3359): 5B rating |

| Topcoat | Polyurethane (RAL 7040, 60μm DFT) – UV stabilized for -30°C | Gloss retention: ≥85% after 1,000 hrs |

| Curing | Forced-air oven (80°C x 20 mins) | FTIR spectroscopy for crosslink density |

Note: All seams sealed with 3M™ Scotch-Weld™ DP420 structural adhesive to prevent moisture ingress.

3. NEW TIRES & BATTERY REPLACEMENT

Specified for Northeast U.S. construction site durability and cold-cranking reliability.

| Component | SEA LION 2026 Specification | Validation | Warranty Coverage |

|---|---|---|---|

| Tires | Michelin X Works ZL (11R22.5) – Load Range G | Tread depth: 14/32″ new; Cut-resistant | 18 months / 45,000 miles |

| Battery | Optima YellowTop (Group 31) – AGM, 1,000 CCA | Cold-crank test @ -18°C: ≥9.6V @ 30 sec | 24 months |

| Wheel Hubs | Re-torqued to OEM spec + Loctite 272 threadlocker | Torque audit: 100% post-24hr run-in | Included in chassis warranty |

Note: Tires mounted on bead-blasted, magnaflux-inspected wheels. Alignment verified via Hunter Engineering Road Force Elite.

4. CHASSIS REINFORCEMENT

Mandatory for all units exceeding 300,000 miles or operating in corrosive zones (Buffalo ZIP codes 142xx-143xx).

| Reinforcement Action | SEA LION 2026 Procedure | Inspection Standard |

|---|---|---|

| Frame Rail Repair | SAE 1020 steel doubler plates (min. 1/4″ thick) welded per AWS D1.1 | Ultrasonic thickness test: ≥90% original spec |

| Crossmember Replacement | OEM-spec galvanized steel (ASTM A653 G90) | Torque test: 150% of OEM spec |

| Suspension Mounts | Shot-peened brackets + Grade 8.8 bolts | Vibration fatigue test: 500k cycles |

| Corrosion Treatment | Cavity wax injection (POR-15®) + epoxy seam sealing | Salt-fog test: Zero perforation @ 1,000 hrs |

Note: 100% of chassis undergo magnetic particle inspection (ASTM E709) at high-stress zones (kingpin mounts, suspension pivots).

SEA LION QUALITY ASSURANCE PROTOCOL

- Rejection Rate: 22% of candidate units fail initial inspection (2025 data).

- Final Certification: Each truck receives a QR-coded SEA LION Refurbishment Passport detailing all test results and component serial numbers.

- Warranty: 12 months/120,000 miles comprehensive coverage (exclusions: abuse, improper maintenance).

- Buffalo-Specific Validation: All units undergo 200-mile road test on NYSDOT Class IV roads (I-190, NY-33) simulating regional conditions.

CONCLUSION

SEA LION’s refurbishment process eliminates the operational risks inherent in “as-is” used truck markets. By enforcing metallurgical, dimensional, and performance standards exceeding OEM rebuild specifications, we deliver units achieving 92% fleet availability in first-year deployment (2025 customer data). For Buffalo-area operations, our climate-adapted corrosion control and structural reinforcement provide critical lifecycle cost savings versus non-certified alternatives.

SEA LION International – Engineered Reliability for Industrial Fleets

REF: SL-REFURB-NY-2026-01 | REV 3.1 | EFFECTIVE: JANUARY 1, 2026

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks from China – Buffalo, NY Market

Issuing Authority: SEA LION International – Global Heavy Equipment Logistics Division

Executive Summary

This report evaluates three primary maritime transport methods for the export of used commercial trucks from Chinese ports (e.g., Shanghai, Qingdao, Guangzhou) to Buffalo, NY, USA: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack Container shipping. The analysis includes cost efficiency, transit time, cargo safety, and corrosion protection protocols—specifically wax-based anti-corrosion treatments for seawater exposure. Recommendations are tailored for fleet procurement and construction sector logistics planning.

1. Export Logistics Overview

Used trucks exported from China to Buffalo, NY, require trans-Pacific shipment to a U.S. East Coast port (e.g., Baltimore, Norfolk, or New York/New Jersey), followed by inland rail or over-the-road transport to Buffalo. The selection of shipping method impacts delivery timeline, vehicle condition upon arrival, and total landed cost.

2. Comparative Analysis: RO-RO vs. Bulk Cargo vs. Flat Rack

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Loading Method | Self-driven onto vessel | Lifted via crane (non-operational units) | Secured on open-frame ISO platform |

| Vehicle Compatibility | Operational trucks only | Operational or non-operational | All types, including oversized units |

| Protection Level | Moderate (exposed decks) | Low (stacked, minimal coverage) | High (customizable lashings, partial enclosure) |

| Transit Time (China → East Coast) | 28–35 days | 30–40 days | 32–42 days (subject to container availability) |

| Port Handling Fees | Low | Medium | High |

| Average Cost per Unit (USD) | $1,800 – $2,400 | $1,500 – $2,000 | $3,000 – $4,200 |

| Risk of Damage | Low (drivable units) | Medium (lifting hazards) | Low to Medium (securement critical) |

| Inland Transport to Buffalo | Rail or truck (7–10 days from port) | Rail or truck | Rail or truck |

| Best Suited For | Operational fleets, high volume | Non-running units, budget focus | Oversized, damaged, or custom trucks |

3. Corrosion Protection: Wax Spraying Protocol

Seawater exposure during transoceanic transit presents a significant risk of corrosion to undercarriages, chassis frames, and electrical systems. SEA LION International mandates industrial-grade wax-based anti-corrosion treatment for all exported units.

Wax Spraying Specifications:

- Material: Solvent-based, salt-resistant synthetic wax (e.g., Dinitrol AV-25, Fluid Film)

- Application Method: High-pressure spray (minimum 30 psi)

- Coverage Areas:

- Undercarriage

- Wheel wells

- Frame rails

- Suspension components

- Exhaust system

- Thickness: 0.15–0.20 mm dry film

- Curing Time: 24 hours pre-shipment

- Effective Duration: Up to 6 months in marine environments

Note: Wax treatment is non-abrasive, compatible with painted and galvanized surfaces, and does not interfere with post-import inspections or reconditioning.

4. Recommended Shipping Strategy by Use Case

| Use Case | Recommended Method | Rationale |

|---|---|---|

| Large fleet procurement (10+ units, operational) | RO-RO | Fastest turnaround, lowest handling risk, cost-effective at scale |

| Non-running or repair-bound units | Bulk Cargo | Accommodates non-drivable trucks; lower base cost |

| Oversized dump trucks, crane trucks, or lowboys | Flat Rack | Only viable option for non-standard dimensions; full structural access |

| Mixed fleet (operational + damaged) | Hybrid (RO-RO + Flat Rack) | Optimize cost and protection across vehicle types |

5. Port & Inland Logistics to Buffalo, NY

- Primary U.S. Discharge Ports:

- Port of Baltimore, MD (preferred for RO-RO)

- Port of New York/New Jersey (best rail connectivity)

- Final Leg to Buffalo:

- Rail: Norfolk Southern or CSX intermodal (48–72 hrs from port)

- Over-the-Road: Dedicated heavy-haul carriers (12–18 hrs from NY/NJ)

- Customs Clearance: ISF filing required 24h pre-loading; EPA/DOT compliance verification at U.S. port

6. Conclusion & Recommendations

For fleet managers and construction firms sourcing used trucks from China:

– RO-RO is optimal for operational fleets due to speed and reduced handling.

– Bulk Cargo offers cost savings for non-running units but increases corrosion and damage risk.

– Flat Rack is essential for oversized equipment, though at a premium.

All shipments must include industrial wax spraying to mitigate saltwater corrosion. SEA LION International enforces this as a standard protocol across all export consignments.

Fleet planners should conduct total cost analysis (TCA) factoring in shipping method, inland logistics, corrosion remediation, and downtime. Pre-shipment inspection and treatment documentation are advised for warranty and resale validation.

SEA LION International – Engineering Reliability in Global Heavy Transport

Document ID: SL-ISR-2026-0418 | Revision: 1.2 | Classification: Industrial Use Only

Get a Quote for Used Trucks For Sale Buffalo Ny

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]