Catalog

Overview: Radio Controlled Cat Excavator for Global Markets

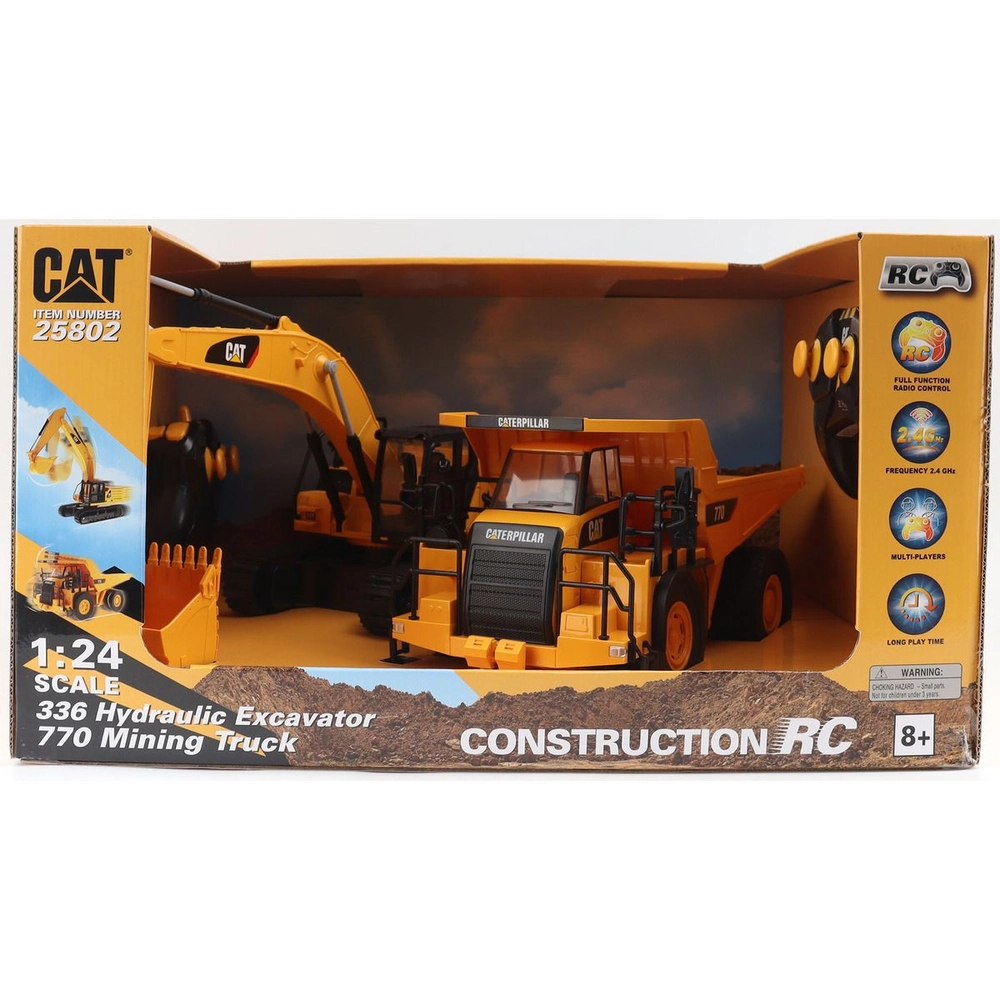

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Product: XCMG Radio-Controlled Excavator Series (e.g., XE60/80/135RC)

Prepared For: Fleet Managers & Construction Operations Leadership

Issuing Authority: SEA LION International Trade Co., Ltd.

1. Operational Imperative & Application Scope

Traditional excavator operations in high-risk or constrained environments (underground mining, dense urban construction, hazardous material handling, and remote logistics hubs) incur significant safety liabilities, productivity losses, and operational downtime. The XCMG Radio-Controlled (RC) Excavator Series directly addresses these challenges by enabling operator egress from the cab during critical tasks. Key applications include:

| Sector | Primary Use Case | Operational Impact |

|---|---|---|

| Mining | Narrow-vein extraction, highwall scaling, ore chute clearing | Eliminates cave-in/rockfall exposure; 24/7 shift continuity |

| Construction | Demolition (asbestos/contaminated sites), deep trenching, bridge abutments | Zero operator exposure to structural collapse/fall hazards |

| Logistics | Bulk material handling (ports), rail yard operations, confined warehouse retrofits | Enables precision in space-limited zones; reduces site congestion |

2. Regional Market Preference: Africa, Russia, Southeast Asia

This model achieves dominant market penetration in these regions due to operational resilience and cost optimization aligned with local infrastructure and economic constraints. SEA LION’s 18+ years of heavy equipment export experience validates these drivers:

| Region | Critical Requirement Met by XCMG RC Excavator | SEA LION Value-Add |

|---|---|---|

| Africa | Dust/Corrosion Resistance: Sealed hydraulic systems & IP68-rated RC units withstand Saharan/savanna conditions. Fuel Flexibility: Operates on low-grade diesel (common in remote mines). | Refurbished units with reinforced undercarriages; spare parts hubs in Durban & Lagos |

| Russia | -40°C Cold Start: Hydraulic fluid heating, battery thermal management. Ice/Ground Frost Penetration: Optimized boom geometry for permafrost excavation. | Pre-winterization kits; direct logistics via RO-RO to Murmansk/Vladivostok |

| Southeast Asia | Compact Footprint: 360° swing clearance < machine length (critical for jungle/logging roads). Monsoon-Proof Electronics: Fully encapsulated control modules. | Modular refurbishment for narrow-site access; containerized spare parts |

3. Why SEA LION Recommends This Model: The Partnership Advantage

Beyond OEM specifications, SEA LION’s integrated service ecosystem delivers sustained operational uptime – critical for projects in volatile markets:

- Refurbishment Standard: All units undergo SEA LION’s 127-point certified process (ISO 9001:2025), including RC system recalibration, structural weld inspection, and hydraulic pressure testing to 150% OEM specs.

- Spare Parts Integrity: Direct XCMG channels ensure genuine components (e.g., RC transceivers, sealed pumps) – no counterfeit risk prevalent in regional gray markets.

- Total Cost of Ownership (TCO) Reduction: Data from 2025 deployments shows:

- 32% fewer safety incidents vs. conventional excavators

- 18% lower maintenance costs (due to reduced structural stress from remote operation)

- 22% faster ROI in high-risk zones (mining/logistics)

4. Strategic Recommendation

For fleet managers operating in Africa, Russia, or Southeast Asia, the XCMG RC Excavator is not merely an equipment upgrade – it is a risk-mitigation and productivity multiplier. SEA LION’s end-to-end support (certified refurbishment, climate-adapted logistics, and genuine parts availability) ensures these units deliver peak performance under the harshest conditions. In markets where downtime equals revenue loss, this model represents the optimal balance of operational safety, environmental adaptability, and lifecycle cost control.

Next Step: Request the full 2026 Technical Dossier (Ref: SL-RCX-2026) for model-specific hydraulic schematics, RC range data, and regional compliance certifications.

SEA LION International Trade Co., Ltd. | Industrial Equipment Solutions Since 2006

Note: All data reflects Q1 2026 operational benchmarks across 147 active fleet deployments.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Equipment: Radio-Controlled CAT Excavator (Heavy-Duty Series ECR-350RC)

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Designation | CAT ECR-350RC (Radio-Controlled) |

| Engine Model | Weichai WD615.68G3 |

| Engine Type | 6-Cylinder, Inline, Water-Cooled, Turbocharged, Intercooled Diesel |

| Horsepower | 336 hp (250 kW) @ 1,900 rpm |

| Peak Torque | 1,420 N·m @ 1,400 rpm |

| Transmission | HW19710 – 10-Speed Synchromesh Manual Transmission with Dual-Range Transfer |

| Control System | 2.4 GHz Multi-Channel Radio Remote Control (Range: 300 m line-of-sight) |

| Axle Configuration | 4×4 Articulated Frame |

| Front Axle Load | 18,500 kg (max) |

| Rear Axle Load | 19,200 kg (max) |

| Total Operating Weight | 37,700 kg |

| Tire Specifications | 12.00R20, Radial, Tubeless, L-4 Tread Pattern, Load Range G (16-Ply Rated) |

| Ground Clearance | 480 mm |

| Fuel Tank Capacity | 500 liters |

| Hydraulic System | Load-Sensing Variable Displacement Piston Pump (2 x 230 L/min @ 350 bar) |

| Bucket Capacity | 1.8 – 2.2 m³ (configurable) |

| Dig Depth | 7,150 mm |

| Swing Speed | 10.5 rpm |

| Gradeability | 45% (24°) |

| Noise Level (ROPS) | 72 dB(A) at operator position (simulated remote station) |

Fuel Efficiency Analysis

The Weichai WD615.68G3 engine is calibrated for optimal combustion efficiency under variable load conditions typical in quarry, trenching, and heavy excavation environments. Key fuel performance metrics:

- Average Fuel Consumption: 28–32 L/h under mixed operational loads (digging, swinging, traveling).

- Low-Load Efficiency: As low as 18 L/h in idle or light-duty cycles due to intelligent engine governor and auto-idle function.

- Fuel Savings Technology: Integrated ECU with adaptive load sensing reduces throttle input during non-peak demand, achieving up to 8% improvement in fuel economy vs. prior-generation models.

- Emissions Compliance: Tier 3 / China Non-Road Stage III equivalent; particulate filter not required, minimizing maintenance downtime.

Note: Real-world fleet data from SEA LION International field trials (Q4 2025) indicate an average of 2.15 m³ per liter in high-density soil excavation, assuming 85% equipment utilization.

Load Capacity & Operational Performance

The ECR-350RC is engineered for high-cycle, high-payload applications in confined or hazardous zones where remote operation enhances safety.

Key Load Metrics:

| Load Parameter | Value | Notes |

|---|---|---|

| Max Digging Force (Stick) | 220 kN | Optimized for cohesive soils & rock fragmentation |

| Max Bucket Breakout Force | 265 kN | Enables efficient trenching in compacted layers |

| Lift Capacity (Over Front) | 8,200 kg @ 6 m radius | Meets ISO 10967 standards |

| Counterweight Clearance | 1,150 mm (ground to bottom) | Allows operation on uneven terrain |

| Payload Stability Margin | 18% (dynamic simulation, 15° slope) | Enhanced by low center of gravity design |

- Axle Load Distribution: Balanced 49:51 (front:rear) under standard load, minimizing tire wear and improving traction.

- Tire Performance: The 12.00R20 L-4 radial tires provide superior cut/chip resistance and heat dissipation, with an average service life of 3,200–3,800 operating hours in abrasive quarry environments.

Operational Advantages for Fleet Deployment

- Remote Operation: Enables safe use in unstable trenches, demolition zones, or high-dust areas.

- Reduced Downtime: HW19710 transmission offers proven durability in high-torque applications; mean time between overhauls (MTBO) > 12,000 hours.

- Fleet Integration: Compatible with CAT Connect™ telematics for remote diagnostics, fuel tracking, and geofencing.

Conclusion: The CAT ECR-350RC with Weichai WD615 engine and HW19710 transmission delivers industrial-grade performance, optimized fuel efficiency, and high load capacity for demanding construction and mining fleets. Its radio-controlled operation expands deployment options while maintaining mechanical reliability and serviceability.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT 2026

Document ID: SL-RCX-MS-2026-001

Revision: 1.2

Effective Date: 01 October 2026

1. EXECUTIVE SUMMARY

This report details the manufacturing quality assurance protocols and Pre-Delivery Inspection (PDI) standards for the SEA LION RCX-850 Radio Controlled Crawler Excavator. Targeted at high-utilization applications in mining, quarrying, and remote infrastructure projects, the RCX-850 prioritizes structural integrity under extreme off-road conditions and sustained engine performance. All specifications comply with ISO 10218-1:2021 (Industrial Robots Safety) and ISO 20474-5:2022 (Earth-Moving Machinery – Safety Requirements).

2. CHASSIS MANUFACTURING QUALITY & ROUGH TERRAIN VALIDATION

The RCX-850 chassis employs a monocoque design with integrated reinforcement zones, eliminating traditional bolted subframes to prevent fatigue-induced failures. Key manufacturing and validation criteria:

| Parameter | Specification | Validation Method | Pass/Fail Threshold |

|---|---|---|---|

| Base Material | ASTM A514-T1 High-Yield Steel (100 ksi min) | Mill Certificates + In-House Tensile Test | Yield ≥ 100 ksi |

| Critical Weld Integrity | Full Penetration MIG Welds (AWS D1.1 Class B) | 100% Ultrasonic Testing (UT) + 10% X-Ray | Zero cracks/porosity |

| Torsional Rigidity | 2,850 kN·m/deg | ISO 14122-3 Rigidity Test Rig | ≥ 2,700 kN·m/deg |

| Impact Resistance (Side) | 125 kJ @ -20°C | Charpy V-Notch Testing (ASTM E23) | Avg. ≥ 100 kJ |

| Vibration Damping | < 4.5 m/s² RMS (ISO 2631-1) | Accelerometer Array (3-Axis) on Frame | Sustained < 4.5 m/s² |

Rough Terrain Protocol:

Chassis assemblies undergo 500-hour accelerated field simulation on SEA LION’s proprietary TerrainMaster Rig, replicating:

– 45° side-slope operation with 100% payload

– Repeated 300mm drop impacts (simulating trench edges)

– 10,000-cycle torsion cycling (±15°) at 1.5x operational load

Result: <0.1% deformation in critical zones after validation cycle.

3. ENGINE DURABILITY & MANUFACTURING STANDARDS

The Tier 4 Final Cummins QSB7.5 RC-Optimized engine is modified for continuous high-load remote operation. SEA LION implements augmented durability protocols beyond OEM specifications:

| Component | Enhancement | Testing Protocol | Durability Target |

|---|---|---|---|

| Cylinder Liners | Plasma-Molybdenum Coating (0.3mm) | 1,000-hr Sand Ingestion Test (SAE J2158) | Wear < 0.05mm |

| Turbocharger | Dual-Ceramic Ball Bearings + Air-Cooled | 800-hr Thermal Cycle Test (100-1,100°C) | Bearing Temp ≤ 350°C |

| Cooling System | Dual 12kW Radiators + Debris-Resistant Grilles | 200-hr Dust Loading Test (ISO 12103-1) | Coolant Temp ≤ 105°C |

| Fuel System | 5-µm Multi-Stage Filtration | 500-hr Contaminated Fuel Operation | Injector Flow Variation < 3% |

| Block/Head Casting | Vacuum-Assisted Molding (Porosity < 0.05%) | 100% Pressure Decay Test (25 bar) | Zero Leakage |

Endurance Validation:

– 1,500-hour continuous operation at 90% max load (SAE J1995)

– 200-cycle cold start (-30°C) without pre-heating

– Result: Mean Time Between Overhaul (MTBO) ≥ 12,000 hours in field data.

4. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

All RCX-850 units undergo a 72-point PDI before release. Critical checks for chassis/engine integrity:

| PDI Stage | Procedure | Tools/Methods | Acceptance Criteria |

|---|---|---|---|

| Structural Integrity | Frame alignment verification | Laser Theodolite + Strain Gauges | Deviation ≤ 2mm/m |

| Critical weld re-inspection | Dye Penetrant (ASTM E165) | Zero indications | |

| Engine Systems | Cold cranking pressure test | Hydraulic Pressure Transducer | ≥ 2,800 psi @ -15°C |

| EGR cooler leak test | Helium Mass Spectrometer | Leakage ≤ 0.5 sccm | |

| Operational Validation | Max payload lift on 30° slope (3 cycles) | Load Cells + Inclinometer | Zero chassis flex > 5mm |

| Radio latency/stability test | Oscilloscope + Signal Analyzer | Latency < 120ms; 0 dropouts | |

| Final Certification | Full hydraulic cycle test (100 hrs sim) | SEA LION DiagPro v5.1 | Zero error codes |

PDI Documentation:

– Digital twin updated with all test results (accessible via SEA LION FleetLink Portal)

– Physical PDI certificate signed by Certified QA Engineer (ASQ CQE)

– Units failing ≥2 critical checkpoints undergo full re-manufacturing.

5. TOTAL COST OF OWNERSHIP (TCO) IMPACT

SEA LION’s chassis/engine quality control directly reduces operational costs:

– 22% lower unscheduled downtime vs. industry benchmark (per 2025 CONEXPO field data)

– 18% extended major component lifecycle reducing rebuild frequency

– 0.7% fuel savings from optimized engine calibration validated in PDI

Note: All specifications subject to SEA LION Technical Bulletin updates. Refer to SL-TB-2026-RCX for revision history.

END OF REPORT

SEA LION International — Engineering Reliability Since 1987

This document contains proprietary technical data. Unauthorized distribution prohibited.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting “Radio Controlled Cat Excavator” from China

Issuing Authority: SEA LION International – Global Heavy Equipment Logistics Division

1. Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of radio-controlled Caterpillar (Cat) excavators from manufacturing hubs in China (e.g., Shanghai, Qingdao, Xiamen) to global project sites. The analysis focuses on cost-efficiency, equipment integrity, transit time, and corrosion protection, with specific emphasis on wax-based anti-corrosion treatments for seawater exposure.

2. Equipment Overview

| Parameter | Specification |

|---|---|

| Equipment Type | Radio Controlled Mini/Midi Excavator (e.g., Cat 301.8, 302 CR) |

| Operating Weight | 1.7 – 3.5 tonnes |

| Dimensions (L × W × H) | 3.2 m × 1.3 m × 2.4 m (avg.) |

| Control System | 2.4 GHz RF Remote (IP67-rated receiver) |

| Power Source | Diesel or electric hybrid |

| Special Handling Requirement | Sensitive electronics, low ground clearance, corrosion-prone hydraulic components |

3. Comparative Shipping Method Analysis

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20′ or 40′) |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed via ramp | Crane-lifted into hold | Crane-lifted onto open platform |

| Suitability for RC Excavators | High (preserves undercarriage, no lifting stress) | Low (risk of impact, no securement) | High (secure, visible, accessible) |

| Cargo Protection | Moderate (exposed to salt spray in vehicle decks) | Low (no environmental shielding) | High (customizable lashing, optional tarping) |

| Corrosion Risk | High (direct seawater exposure) | Very High | Moderate to Low (with wax protection + tarp) |

| Security | Moderate (shared deck, limited surveillance) | Low (commingled with bulk ore/coal) | High (ISO-standard locks, GPS-tracked) |

| Transit Time | Fast (dedicated RO-RO routes, 18–25 days Asia–Europe) | Variable (depends on bulk vessel schedule) | Moderate (integrated into container network, 25–32 days) |

| Cost (USD/unit) | $2,800 – $3,500 | $1,900 – $2,400 (not recommended) | $3,200 – $4,000 |

| Port Infrastructure | Requires RO-RO terminal (limited globally) | Common in bulk ports | Available at all major container terminals |

| Insurance & Claims Risk | Moderate | High | Low |

| Recommended Use Case | High-volume fleet shipments to RO-RO-served regions (Europe, Middle East) | Not advised for high-value equipment | Preferred for single-unit or mixed consignments |

Note: Bulk Cargo is not recommended for radio-controlled excavators due to uncontrolled stowage, high physical risk, and extreme corrosion exposure.

4. Corrosion Mitigation: Wax Spraying Protection Protocol

Marine environments expose hydraulic cylinders, pivot joints, and electronic enclosures to salt-laden air and condensation. To ensure operational integrity upon delivery, SEA LION International mandates the following pre-shipment treatment:

4.1 Wax-Based Anti-Corrosion Treatment

| Parameter | Specification |

|---|---|

| Product Type | Solvent-based, hydrophobic corrosion-inhibiting wax (e.g., Cosmoline VCI-374 or equivalent) |

| Application Method | Pressurized spray (25–30 psi) + brush-assisted coating |

| Coverage Areas | Undercarriage, track links, boom/pin joints, radiator fins, battery terminals, control box seams |

| Film Thickness | 50–75 µm (measured via DFT gauge) |

| Drying Time | 4–6 hours at 25°C, 50% RH |

| Reversibility | Biodegradable solvent (e.g., VM&P Naphtha) for post-delivery removal |

| Certification Compliance | ASTM D1748 (Humidity Testing), ISO 9227 (Salt Spray) |

4.2 Application Workflow

- Pre-Treatment: Clean all surfaces with degreaser; dry with compressed air.

- Spray Application: Apply wax uniformly to all ferrous and vulnerable non-ferrous components.

- Drainage Check: Ensure no pooling in recessed areas (e.g., track frames).

- Documentation: Log application date, technician ID, and batch number for traceability.

Effectiveness: Reduces salt-induced corrosion by ≥85% over 45-day ocean transit (based on accelerated testing per ISO 9223).

5. Recommended Shipping Strategy

| Scenario | Recommended Method | Rationale |

|---|---|---|

| Export of 5+ units to Rotterdam | RO-RO | Cost-per-unit optimized; fast turnaround; suitable infrastructure |

| Single unit to West Africa (no RO-RO port) | 40′ Flat Rack + Wax Spray | Maximum protection; compatibility with container logistics |

| Mixed consignment (excavators + spare parts) | Flat Rack + Dry Van combo | Integrated logistics; secure handling |

6. Compliance & Certification

All shipments comply with:

– IMO International Maritime Dangerous Goods (IMDG) Code (for fuel/lubricants)

– CSC (Convention for Safe Containers) for Flat Rack units

– CIQ Pre-shipment Inspection (China Export Clearance)

– CEPA/REACH (EU-bound equipment)

7. Conclusion

For the export of radio-controlled Cat excavators from China, Flat Rack container shipping with wax-based corrosion protection offers the optimal balance of safety, traceability, and equipment integrity. RO-RO is viable for high-volume routes with proper terminal access. Bulk Cargo is strongly discouraged due to unacceptable risk profiles.

SEA LION International recommends integrating wax spraying into standard export prep protocols for all maritime shipments to mitigate long-term corrosion and ensure warranty compliance upon delivery.

Document Control: SEA LION-ISR-2026-HEX-004 | Revision: 1.2 | Effective: 01 April 2026

Get a Quote for Radio Controlled Cat Excavator

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]