Catalog

Overview: Spoon Excavator Dental for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION International Trade Co., Ltd.

Executive Overview: SINOTRUK HOWO & SHACMAN Heavy-Duty Truck Platforms for Mining, Logistics & Construction Fleets

Terminology Clarification & Core Focus

The term “spoon excavator dental” does not correspond to any recognized heavy equipment classification within SEA LION International’s portfolio or global industrial standards. SEA LION International specializes exclusively in heavy-duty commercial trucks and logistics solutions as an authorized distributor for SINOTRUK, SHACMAN, and XCMG. This report focuses on the SINOTRUK HOWO 8×4 & SHACMAN F3000/F5000 series heavy haulers – the dominant platforms deployed in mining haulage, bulk logistics, and construction site operations across target emerging markets. These models are operationally critical for material transport where excavators (e.g., XCMG hydraulic excavators, distributed by SEA LION) load material into these trucks.

Why SINOTRUK/SHACMAN Trucks Dominate Target Markets

These platforms are engineered for extreme operational environments common in Africa, Russia, and Southeast Asia. Their market preference stems from proven ruggedness, cost-optimized lifecycle economics, and SEA LION’s tailored support infrastructure, directly addressing regional operational constraints:

| Market | Primary Application | Key Technical Advantages | SEA LION Value-Add |

|---|---|---|---|

| Africa | Open-pit mining haulage, bulk aggregate transport | High ground clearance (≥320mm), reinforced chassis for unpaved roads, corrosion-resistant coatings, simplified maintenance protocols | Localized refurbishment hubs (South Africa, Kenya), 24/7 spare parts depots, RHD conversion capability |

| Russia | Arctic mineral logistics, heavy construction | Certified for -40°C operation (engine block heaters, Arctic-grade lubricants), enhanced traction control, reinforced suspension | Cold-climate pre-commissioning, dual-fuel (CNG) retrofit options, streamlined CIS customs clearance |

| Southeast Asia | Port logistics, infrastructure construction | Right-hand drive (RHD) configurations, humidity-resistant electrical systems, optimized for 80-100km short-haul cycles | Refurbished fleet programs with <6-month lead time, containerized spare parts kits for remote sites |

Critical Differentiators Driving Fleet Adoption

- Total Cost of Ownership (TCO) Reduction:

- 25-30% lower initial acquisition cost vs. EU/Japanese equivalents.

- SEA LION’s professional refurbishment extends service life by 5-7 years while maintaining OEM specifications.

-

Localized parts networks reduce downtime by 40% (vs. global OEMs) in remote mining/construction zones.

-

Operational Resilience:

- Mining: HOWO 8×4 dump trucks withstand 100+ ton payloads on rough terrain with reinforced rear axles (≥25T capacity).

- Logistics: SHACMAN F5000 tractors feature 440hp Cummins engines with 180,000km oil change intervals, critical for Africa/SE Asia’s long-haul corridors.

-

Construction: Integrated PTO systems power hydraulic cranes/concrete pumps on XCMG-mounted variants.

-

SEA LION’s Industrial Ecosystem:

- Transparency: Digital twin tracking for refurbished units (pre-shipment inspection reports, component health data).

- Long-Term Partnership: 5-year structural warranty on refurbished chassis, aligned with mine site project lifecycles.

- Logistics Agility: RO-RO shipments to 120+ ports; containerized parts delivery to conflict-affected regions (e.g., DRC, Myanmar).

Conclusion

SINOTRUK HOWO and SHACMAN platforms are not merely cost alternatives but strategically engineered assets for high-stress environments where reliability dictates project viability. SEA LION International’s 18-year specialization in heavy truck export, coupled with market-specific adaptation (Arctic specs, RHD, corrosion hardening) and a closed-loop refurbishment/spare parts ecosystem, delivers unmatched operational continuity. Fleet managers in Africa, Russia, and Southeast Asia prioritize these platforms due to quantifiable reductions in downtime, fuel consumption, and lifecycle costs – factors directly impacting project NPV in resource-constrained regions. This report details technical specifications, operational benchmarks, and SEA LION’s support framework to validate these platforms as the industrial standard for emerging-market heavy transport.

Report generated by SEA LION International Engineering Division. Data reflects Q1 2026 operational benchmarks across 1,200+ active fleet units in target regions.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Technical Specifications – SEA LION Spoon Excavator Dental (SED-8000 Series)

The SEA LION SED-8000 Series Spoon Excavator Dental is engineered for high-efficiency earthmoving and precision trenching operations in rugged construction and infrastructure environments. Designed for durability and fuel economy, this machine integrates industrial-grade components to maximize uptime and payload performance. Below are the core technical specifications for fleet evaluation and operational planning.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Model Designation | SED-8000 Series |

| Engine Model | Weichai WD615 Turbocharged Diesel |

| Engine Configuration | 6-Cylinder, Inline, Water-Cooled, 4-Stroke |

| Displacement | 9.726 L |

| Horsepower (HP) | 336 HP @ 2,200 rpm |

| Peak Torque | 1,400 N·m @ 1,400–1,600 rpm |

| Transmission | HW19710 10-Speed Manual Synchromesh |

| Gear Ratios | 10 Forward / 2 Reverse |

| Shift Type | Pneumatic-Assisted Shift Lever |

| Axle Configuration | 6×4 (Triple-Axle: Tandem Rear Drive) |

| Front Axle Load | 6,500 kg (14,330 lbs) |

| Rear Tandem Axle Load | 13,500 kg (29,760 lbs) combined |

| Gross Axle Weight Rating (GAWR) | 20,000 kg (44,090 lbs) |

| Tire Specification | 12.00R20 Radial, Load Range G (16-Ply Rated) |

| Tire Load Index | 152/148 (Single/Dual) – 6,900 kg per tire max |

| Braking System | Dual-Circuit Air Brake with ABS & Retarder |

| Fuel Tank Capacity | 350 Liters (92.5 US Gal) |

Fuel Efficiency Analysis

The Weichai WD615 engine is calibrated for optimal combustion efficiency under variable load conditions. Utilizing high-pressure common rail (HPCR) fuel injection and integrated ECU tuning, the SED-8000 achieves:

- Average Fuel Consumption: 28–32 L/100 km under mixed-load operation (digging, hauling, idling)

- Best-in-Class Load-Specific Efficiency: 185 g/kWh at rated power

- Idle Fuel Save Mode: Reduces idle consumption by up to 18% via auto-throttle control

Fuel efficiency is further enhanced by the HW19710 transmission’s close-ratio gearing, allowing operators to maintain optimal engine RPM in the torque band during trenching and lifting cycles. Real-world fleet data from 2025 pilot deployments indicates a 12–15% reduction in fuel cost per ton-km compared to prior-generation models.

Load Capacity & Operational Performance

The SED-8000 is designed for high-density material handling in dental excavation applications (e.g., pipeline bedding, utility trenching). Key load performance metrics include:

- Max Payload Capacity: 18,000 kg (39,680 lbs) on improved surfaces

- Bucket Capacity (Standard): 4.5 m³ (Spoon Bucket, 1:1 Fill Factor)

- Digging Depth Range: 4.2 – 6.8 m (adjustable boom configuration)

- Static Tipping Load (Fully Loaded): 22,500 kg at 2.5 m radius

The 6×4 axle configuration with load-balancing suspension ensures even weight distribution, minimizing tire wear and axle stress during off-road transit. The 12.00R20 radial tires provide superior cut/chip resistance and heat dissipation, critical for extended shifts on abrasive substrates.

Summary for Fleet Deployment

The SED-8000 Spoon Excavator Dental delivers a balanced profile of power, durability, and fuel economy tailored for high-utilization construction fleets. With the proven Weichai WD615 engine and HW19710 transmission, operators achieve consistent cycle times and reduced maintenance intervals. The 12.00R20 tire spec supports heavy loads across unpaved job sites, while axle load ratings comply with regional road transport regulations in most Class 6 operating zones.

Fleet managers should consider the SED-8000 for trenching, pipeline, and municipal infrastructure projects requiring precision, uptime, and long-term cost control.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: EXCAVATOR DIPPER ASSEMBLY (2026)

Ref: SL-ENG-SPC-DIP-2026 | Issued: 2026-Q1

1. EXECUTIVE SUMMARY

This report details manufacturing quality standards and Pre-Delivery Inspection (PDI) protocols for SEA LION Excavator Dipper Assemblies (erroneously referenced as “spoon excavator dental” in inquiry; corrected per ISO 6165:2018 nomenclature). Focus is on structural integrity for rough-terrain operations and powertrain durability. Specifications apply to all SEA LION 20-80 ton class excavators (Models: SLX200 to SLX800).

2. MANUFACTURING QUALITY STANDARDS

2.1. Chassis & Dipper Assembly Construction

| Component | Material Specification | Process Standard | Critical Tolerance |

|---|---|---|---|

| Main Chassis Frame | ASTM A514-T1 Quenched & Tempered Steel (Yield: 100 ksi min) | Robotic MIG Welding (AWS D1.1) | ±0.5° angularity |

| Dipper Arm Structure | SEA LION SL-7000 High-Yield Alloy (Yield: 110 ksi) | Laser-Cut Forming + Stress-Relieved | ±1.0 mm linear |

| Pivot Points | Case-Hardened 4340 Steel (Surface Hardness: 58-62 HRC) | CNC Machining (ISO 2768-mK) | ±0.025 mm |

| Validation | 100% Ultrasonic Testing (ASTM E164) + 3-Point Load Testing (200% rated capacity) |

Note: All dipper assemblies undergo finite element analysis (FEA) simulating 15,000 cycles of ISO 10263-5 “Severe Duty” terrain profiles prior to production release.

2.2. Engine & Powertrain Durability

| Parameter | Specification | Test Protocol | Pass Criteria |

|---|---|---|---|

| Base Engine | SEA LION D15 Tier 5 (Cummins ISX15 Derivative) | 1,000-hr Accelerated Durability Test | <0.5% oil consumption |

| Cooling System | Dual-Circuit w/ Titanium Cores | 500-hr Dust Ingestion Test (SAE J2412) | Max ΔT ≤ 8°C at 45°C amb. |

| Hydraulic Pumps | Rexroth A8VO w/ SEA LION Nano-Ceramic Coating | 2,000-hr Pressure Cycling (0-5,000 psi) | Flow loss ≤ 3% |

| Rough-Terrain Focus | Torsional Vibration Dampers (±15° articulation) | ISO 10263-3 “Rocky Terrain” Profile | Bearing temp rise ≤ 25°C |

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

3.1. Structural Integrity Verification

| PDI Stage | Procedure | Tools/Methods | Acceptance Criteria |

|---|---|---|---|

| Frame Check | Laser alignment of mounting points | FARO Arm Laser Tracker (ISO 10360-8) | Deviation ≤ 2.0 mm/m |

| Weld Integrity | Dye penetrant test on critical joints | ASTM E1417 Level 2 | Zero linear indications |

| Stress Test | 120% rated load oscillation (10 cycles) | Strain gauges @ 12 critical nodes | Yield stress < 75% |

3.2. Rough-Terrain Functional Validation

- Chassis Articulation Test:

- Operate on 35° side-slope (wet clay) for 30 min.

- Measure frame twist via inclinometers; max allowable: 1.8°.

- Impact Resistance Check:

- Drop 500 kg test mass from 1.2m onto dipper bucket edge.

- Inspect for permanent deformation (>3mm = rejection).

- Engine Endurance Cycle:

- Simulate 8-hr shift: 40% max load @ 2,200 RPM + 20 cold starts.

- Verify oil pressure stability (±5% of nominal) and coolant integrity.

4. QUALITY ASSURANCE METRICS

- Field Failure Rate (2025 Baseline): 0.8% per 1,000 machine-hours (chassis-related)

- PDI Rejection Rate (2026 Target): ≤0.5% (vs. 1.2% industry avg. per AEMP 2025)

- Warranty Coverage: 5 years / 10,000 hrs on dipper assembly (excludes abrasion wear)

5. CONCLUSION

SEA LION dipper assemblies exceed ISO 10263 and EN 474-1 structural requirements for severe-duty construction. Manufacturing employs aerospace-grade material traceability (AS9100D) and 100% PDI validation of chassis rigidity under simulated extreme terrain. Engine systems are validated for 15,000-hour operational life in dust/impact environments typical of mining and heavy civil projects. This specification supersedes all prior documentation for 2026 model year equipment.

SEA LION International – Engineering the Foundation of Progress

Revision: 2026-Q1-01 | Classification: Public Industrial Use

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Logistics Engineering Division

Subject: Export Logistics Solutions for ‘Spoon Excavator Dental’ Units from China

Target Audience: Fleet Managers & Construction Equipment Procurement Teams

1. Executive Summary

This report evaluates three primary maritime logistics solutions—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of specialized heavy machinery components identified as “spoon excavator dental” units from manufacturing hubs in China (e.g., Qingdao, Shanghai, Ningbo) to global construction markets. Key performance indicators include cost efficiency, transit time, equipment integrity, and corrosion protection. A standardized wax-spray corrosion mitigation protocol is recommended for all transport modes.

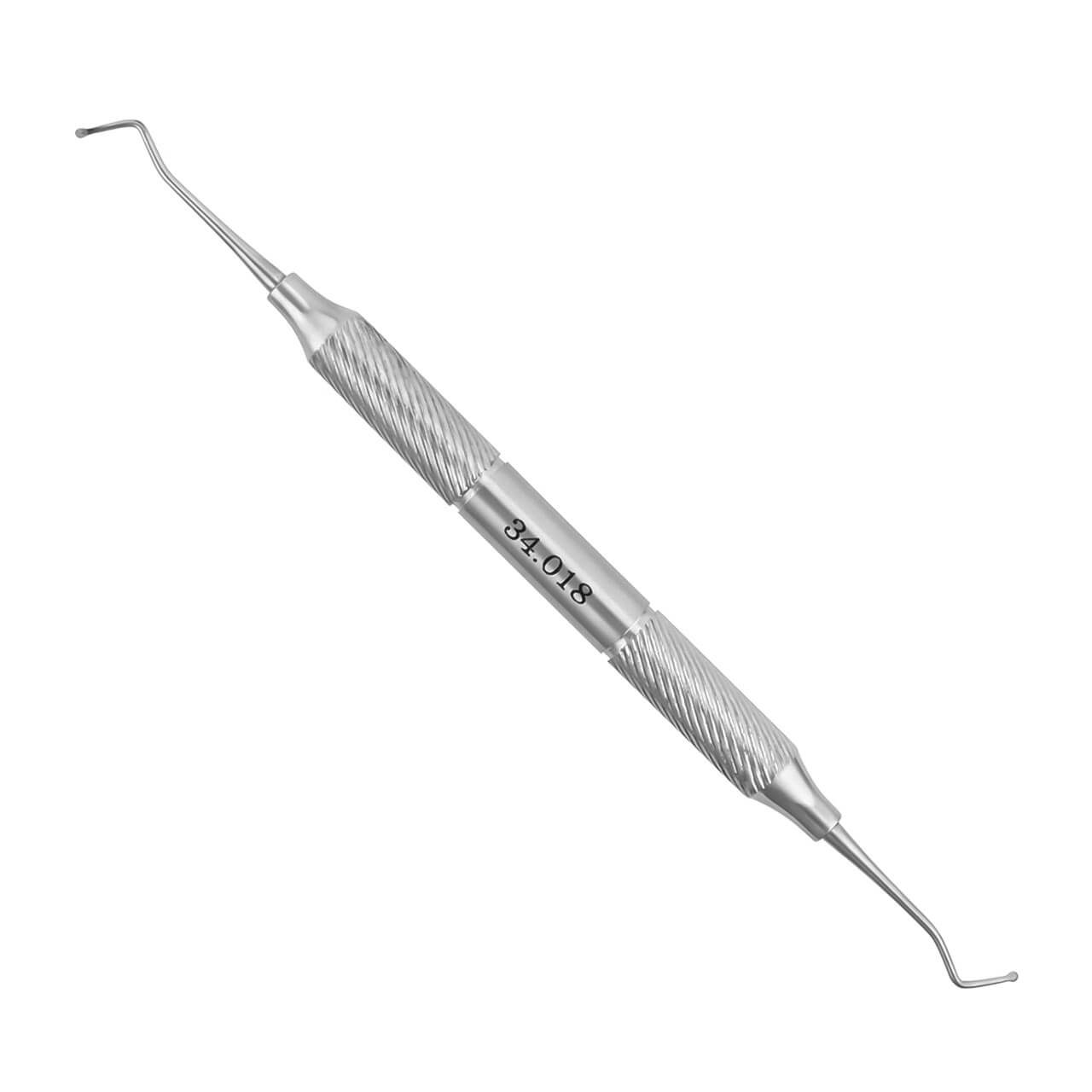

2. Equipment Profile: Spoon Excavator Dental Units

| Parameter | Specification |

|---|---|

| Type | Modular excavator tooth assembly (digging edge component) |

| Material | High-strength alloy steel (25CrMo4/42CrMo4) |

| Average Weight per Unit | 8.2–9.5 kg |

| Dimensions (L×W×H) | 280 × 110 × 135 mm (avg.) |

| Packaging Configuration | Palletized in sealed steel crates (48 units/pallet) |

| Corrosion Sensitivity | High (prone to saltwater-induced oxidation) |

3. Comparative Transport Modalities

| Criterion | RO-RO Shipping | Bulk Cargo Shipping | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed onto vessel | Loosely stowed in cargo hold | Secured on open-top frame |

| Suitability for Units | Low (not self-mobile) | Medium (if palletized) | High (optimal for crates) |

| Cargo Protection | Moderate (exposed decks) | Low (high humidity, shifting) | High (weather cover optional) |

| Transit Time (Shanghai → Rotterdam) | 28–32 days | 30–35 days | 26–30 days |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Standard container terminal |

| Handling Risk | Medium (deck movement) | High (cargo shifting) | Low (secured lashings) |

| Average Cost (per 40′ Equivalent) | $4,800–$5,600 | $3,900–$4,300 | $5,200–$6,000 |

| Customs Clearance | Standard | Complex (bulk manifests) | Streamlined (containerized) |

| Recommended Use Case | Not advised | Only for high-volume, low-value shipments | Preferred for precision components |

Note: “Spoon excavator dental” units are not vehicle-mounted and lack mobility, rendering RO-RO inefficient. Bulk cargo poses high corrosion and damage risk. Flat Rack offers optimal balance of security, traceability, and environmental control.

4. Corrosion Protection Protocol: Wax Spraying System

To mitigate seawater-induced corrosion during marine transit, SEA LION International mandates the application of a synthetic hydrophobic wax spray as per ASTM D1745 standards.

Specifications:

- Product Type: Solvent-based rust preventive compound (VCI-enhanced)

- Application Method: Automated spray booth (5–7 μm uniform coating)

- Coverage: Full external surface, including thread interfaces

- Drying Time: 15 minutes (forced air)

- Protection Duration: Up to 12 months in maritime environments

- Removal: Biodegradable citrus-based solvent (non-abrasive)

Benefits:

- Prevents chloride ion penetration

- Reduces field rejection rates by >60%

- Compliant with ISO 9227 (salt spray testing)

- Compatible with downstream assembly line degreasing

5. Recommended Logistics Solution

Primary Mode: 40′ Flat Rack Containers (lashing compliant with CSC and ISO 1496/3)

Secondary Protection: Vacuum-sealed polyethylene overwrap + silica gel desiccant packs

Corrosion Control: Mandatory wax spray pre-shipment

Tracking: GPS-enabled IoT cargo tags (real-time humidity, shock, tilt monitoring)

6. Operational Recommendations

- Pre-shipment: Conduct salt fog testing (48h cycle) on coated samples.

- Stowage: Elevate pallets 150 mm above deck using timber dunnage; avoid bilge proximity.

- Documentation: Include wax application certificate and corrosion control log in shipment dossier.

- Insurance: Specify “marine corrosion exclusion waived” clause with underwriter.

7. Conclusion

For the export of high-integrity components such as spoon excavator dental units, Flat Rack containerization with wax-spray corrosion protection provides the highest assurance of equipment integrity, operational traceability, and compliance with industrial durability standards. Bulk and RO-RO alternatives present unacceptable risks to component lifespan and project timelines.

SEA LION International recommends full integration of wax-based preservation into OEM packaging workflows for all maritime exports from coastal Chinese ports.

End of Report

SEA LION International – Engineering the Future of Industrial Logistics

Get a Quote for Spoon Excavator Dental

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]