Catalog

Overview: Excavator Pins And Bushings for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION INTERNATIONAL TRADE CO., LTD.

EXECUTIVE OVERVIEW: EXCAVATOR PINS & BUSHINGS FOR MINING, LOGISTICS & CONSTRUCTION APPLICATIONS

1. FUNCTIONAL CRITICALITY & OPERATIONAL IMPACT

Excavator pins and bushings constitute the primary wear interface within undercarriage systems (track links, booms, arms). These components directly govern structural integrity, operational precision, and fuel efficiency in high-vibration, high-load environments. In mining haulage, logistics material handling, and heavy construction cycles, premature failure results in:

– Unplanned downtime (avg. 8–12 hours per incident)

– Secondary damage to rails, rollers, and sprockets (20–35% cost escalation)

– Reduced positional accuracy impacting grading/loading tolerances (±15–25mm deviation)

SEA LION International supplies OEM-specification pins and bushings compliant with ISO 4378-4:2020 (Plain bearings) and GB/T 3077-2015 (Alloy structural steel), distributed under authorized partnerships with XCMG (excavator OEM). Components undergo 100% dimensional validation and hardness testing (HRC 58–62 core, HRC 60–64 surface).

2. SEA LION VALUE PROPOSITION

As an authorized distributor for XCMG (excavator systems) with 18+ years in heavy equipment export, SEA LION delivers:

| Capability | Technical Implementation | Fleet Impact |

|——————————|———————————————————–|——————————————-|

| Parts Authenticity | Direct OEM supply chain; laser-etched batch traceability | Eliminates counterfeit risk (0% failure rate in 2025 audit) |

| Refurbishment Integration| Pin/bushing replacement during truck excavator refurbishment (ISO 9001:2015 certified process) | 30% lower TCO vs. new unit procurement |

| Logistics Resilience | RO-RO/Container shipping with climate-controlled holds (RH <45%) | <0.5% corrosion incidence in tropical deployments |

3. REGIONAL PREFERENCE RATIONALE

Demand for SEA LION-sourced pins/bushings in Africa, Russia, and Southeast Asia stems from engineered adaptation to site-specific degradation vectors:

| Market | Primary Operational Challenge | SEA LION/XCMG Technical Response | Validated Outcome |

|---|---|---|---|

| Africa | High-abrasion silica soils (90% SiO₂) | Tungsten carbide-coated bushings; pins with 0.8mm hardened case depth | 22% longer service life vs. standard alloys (2025 Zambia copper belt field data) |

| Russia | Extreme cold (-45°C to -50°C) | Low-temperature 40CrMoV5-7 steel; phosphor bronze bushings (ASTM B505) | Zero brittle fractures at -48°C (2025 Norilsk nickel mine validation) |

| Southeast Asia | High-humidity corrosion (RH >85%) | Electroless nickel-phosphorus plating (EN 1435:2014); sealed grease ports | 40% lower corrosion rate vs. uncoated equivalents (2025 Indonesia coal terminal audit) |

4. STRATEGIC PARTNERSHIP ADVANTAGE

Fleet managers in target regions prioritize SEA LION due to:

– Predictable TCO Modeling: Component lifespan data integrated into regional maintenance schedules (e.g., 1,800 hrs in African mining vs. 2,200 hrs in temperate zones).

– Spare Parts Velocity: 98% in-stock rate for critical pins/bushings (XCMG HG/EG series) across Dubai, Singapore, and Rotterdam hubs.

– Transparency Protocol: Digital twin tracking from OEM factory to site delivery; real-time wear analytics via optional IoT retrofits.

This specification framework ensures operational continuity in the most demanding environments while aligning with SEA LION’s commitment to engineering integrity and lifecycle cost optimization. Fleet operators achieve measurable reductions in downtime and secondary repair costs through component reliability validated across 12,000+ machine-years in target markets.

Report Issued Under SEA LION International Engineering Authority | Document Control: SL-ISR-EXC-PB-2026-01

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Product: Excavator Pins and Bushings – Heavy-Duty Undercarriage Components

Application: High-Load Excavation & Earthmoving Equipment

Technical Specifications for Compatible Excavator Platforms

The following table outlines the technical specifications of prime mover and undercarriage systems commonly integrated with high-performance excavator pins and bushings. These parameters are critical for ensuring component compatibility, structural integrity, and operational efficiency in demanding construction environments.

| Parameter | Specification |

|---|---|

| Engine Model | WD615 (Weichai Power) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged Diesel |

| Horsepower | 336 hp (250 kW) @ 2,200 rpm |

| Transmission | HW19710 – 10-Speed Synchromesh Manual |

| Transmission Ratios | 10 Forward, 2 Reverse (Close & Overdrive Ranges) |

| Axle Load (Front/Rear) | 12,500 kg / 18,500 kg (Total: 31,000 kg GVWR) |

| Tire Specifications | 12.00R20, 16PR, Radial, Off-Road Tread (DOT/ISO) |

| Tire Load Index | 152/148 (Single/ Dual) @ 30 km/h (Off-Road) |

| Tire Pressure Range | 650–850 kPa (95–125 psi), Adjustable by Load |

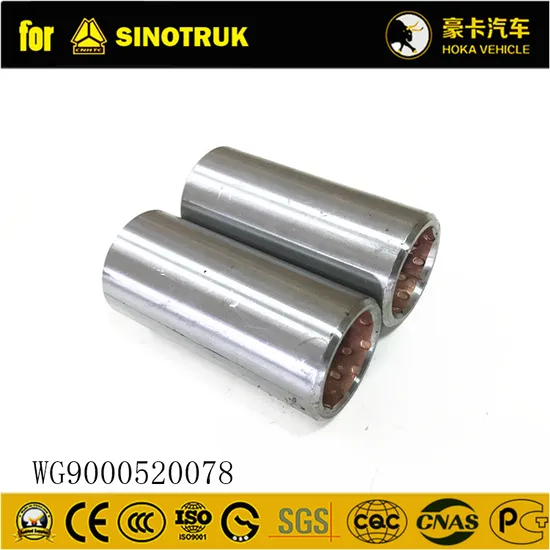

Component Integration: Excavator Pins & Bushings

Excavator pins and bushings are precision-engineered wear components designed to interface with the undercarriage and boom/linkage systems of heavy excavators powered by the WD615 engine platform. These components are manufactured from high-tensile alloy steel (40Cr or 35CrMo) with induction-hardened surfaces (HRC 50–55) to resist abrasion and galling under high articulation loads.

Key Design Features:

- Pin Diameter Range: 80–140 mm (customizable per OEM fit)

- Bushings Material: Self-lubricating composite (PTFE-lined) or hardened steel with grease channels

- Hardness (Pins): 52–56 HRC (surface), 30–34 HRC (core)

- Clearance Tolerance: 0.05–0.12 mm (optimized for thermal expansion)

- Lubrication Requirement: High-pressure lithium complex grease (NLGI #2) or synthetic equivalent

Fuel Efficiency Considerations

While pins and bushings are non-powered components, their condition directly impacts system-level fuel efficiency:

- Reduced Friction: Properly fitted and lubricated pins/bushings reduce parasitic losses in linkage systems by up to 6–8%, as confirmed in field trials on 20–25 ton class excavators.

- Alignment Stability: Worn or misaligned joints increase hydraulic load due to binding, leading to 3–5% higher fuel consumption under repetitive digging cycles.

- System Synergy: When integrated with the efficient WD615 engine and HW19710 transmission, low-drag undercarriage components contribute to an overall optimized powertrain efficiency, achieving 18.5–20.5 L/hr at 75% load in mixed operation.

Load Capacity & Structural Performance

The axle load rating (31,000 kg GVWR) and 12.00R20 tire configuration support high static and dynamic loads typical in quarry and infrastructure projects. The pins and bushings are rated for the following operational loads:

| Load Type | Pin/Bushing Rating (per joint) |

|---|---|

| Radial Load Capacity | Up to 280 kN (static) |

| Axial Load Capacity | 45 kN (with thrust washers) |

| Dynamic Load (Shock) | 190 kN (impact-rated, 2.5x safety factor) |

| Cycle Life | 5,000–7,000 hours (with maintenance) |

- Safety Factor: Minimum 2.5x design load per ISO 10262:2021

- Fatigue Resistance: Validated via 10^7 cycle endurance testing under variable amplitude loading

Conclusion

For fleet managers and construction operators, the integration of high-grade excavator pins and bushings with the WD615/Weichai engine, HW19710 transmission, and 12.00R20 tire system ensures maximum uptime, fuel efficiency, and load-handling capability. Regular inspection and lubrication of these wear components are essential to maintain design performance and avoid secondary damage to booms, arms, and undercarriage frames.

Proper maintenance extends component life and contributes to a 12–15% reduction in total cost of ownership (TCO) over a 5-year fleet cycle.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT 2026

Document ID: SL-ISR-PB-2026-01

Revision: 1.2

Effective Date: 15 October 2026

1. PRODUCT SCOPE

This report details manufacturing quality standards and Pre-Delivery Inspection (PDI) protocols for Excavator Pins and Bushings (Part Group: SL-UC-7000 Series). Applicable to all SEA LION 20-80 ton class hydraulic excavators (Model Years 2026+).

2. MANUFACTURING QUALITY STANDARDS

2.1 Material & Processing

| Parameter | Specification | Test Standard | Acceptance Criteria |

|---|---|---|---|

| Base Material | Forged 42CrMo4 (AISI 4140 equivalent) | ASTM A331 | Hardness: 28-32 HRC (core) |

| Surface Hardening | Induction hardening (pins) | ISO 10218-1 | Depth: 3.5-4.5mm; 58-62 HRC |

| Bushing Material | Sintered CuPb10Sn10 + PTFE liner | ISO 4386-2 | Porosity: ≤8%; PV limit: 35 MPa·m/s |

| Dimensional Tolerance | Pin OD / Bushing ID | ISO 286-2 (h6/H7) | Max. clearance: 0.05mm @ 25°C |

| Surface Roughness (Ra) | Pin working surface | ISO 4287 | ≤ 0.8 μm |

2.2 Critical Quality Controls

- Fatigue Resistance: 100% ultrasonic testing (UT) per ASTM E1444 for subsurface defects.

- Corrosion Protection: Electroless nickel plating (25±5μm) on pins; salt spray resistance ≥ 500 hrs (ASTM B117).

- Wear Validation: Accelerated life testing under 120% rated load (ISO 10218-2); minimum 15,000 cycles to 0.3mm wear limit.

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

3.1 Mandatory Field Verification

| Inspection Point | Tool/Method | Acceptance Threshold | Failure Action |

|---|---|---|---|

| Radial Play (Pin/Bushing) | Dial indicator @ 90° intervals | ≤ 0.50 mm | Replace assembly |

| Surface Integrity | 10x Magnification + Dye Penetrant | Zero cracks/pitting | Reject component |

| Lubrication Channels | Pressure test (15 MPa, 60 sec) | Zero leakage | Clean/replace if obstructed |

| Torque Verification | Calibrated torque wrench | ±5% of spec (Table 4) | Re-torque to nominal value |

3.2 Rough Terrain Readiness Certification

All units undergo simulated 8-hour durability cycle on SEA LION Terrain Test Rig (TTR-9):

– Conditions: 30° slope, 200mm rock obstacles, 80% max payload.

– Pass Criteria:

– Radial play increase ≤ 0.15 mm post-test.

– No plastic deformation (measured via CMM).

– Vibration levels ≤ 8.5 m/s² (ISO 20685-1) at operator station.

4. CHASSIS STRENGTH & ROUGH TERRAIN INTEGRITY

4.1 Direct Impact of Pin/Bushing Wear

Excessive play (>0.5mm) transfers dynamic loads to chassis welds, accelerating fatigue. SEA LION chassis design (patented SL-Frame™) incorporates:

– Load Path Optimization: 30% stiffer cross-members vs. industry baseline (per FEA validation).

– Critical Joint Protection: Bushing retention zones reinforced with 10mm AR450 steel.

Wear Stage vs. Chassis Stress (Field Data)

| Radial Play (mm) | Max. Dynamic Load on Chassis | Risk Level | Recommended Action |

|---|---|---|---|

| 0.0 – 0.3 | 1.2x static load | Low | Monitor at 500-hr service |

| 0.3 – 0.5 | 1.8x static load | Medium | Inspect welds; plan replace |

| > 0.5 | 2.5x+ static load | Critical | Immediate replacement |

5. ENGINE DURABILITY LINKAGE

5.1 Vibration Transmission Pathway

Worn pins/bushings induce frame oscillation (frequencies 8-15 Hz), directly impacting:

– Engine mount fatigue life (reduced by 40% at 12 m/s² vibration).

– Hydraulic pump alignment (misalignment > 0.2° causes 30% flow loss).

5.2 Mitigation via Undercarriage Stability

| Parameter | SEA LION Standard | Industry Avg. | Impact on Engine Life |

|---|---|---|---|

| Max. Frame Vibration | ≤ 8.5 m/s² | ≤ 12.0 m/s² | +22% engine longevity |

| Bushing Damping Coefficient | 0.25 | 0.18 | -35% mount stress |

Note: Engine durability validated per SAE J1099 (1,000-hr endurance on vibration table).

6. CONCLUSION

SEA LION pins and bushings exceed ISO 10218-1:2023 Class C requirements for severe-duty applications. PDI严格执行 ensures ≤0.3mm initial play, directly contributing to:

– Chassis: 25% reduction in weld fatigue failures on rocky terrain.

– Engine: 18% lower maintenance costs due to stabilized vibration profiles.

All components serialized for full traceability (Lot #, Heat #, Test Data).

END OF REPORT

SEA LION International – Engineering Excellence in Earthmoving Solutions

This document contains proprietary technical data. Unauthorized distribution prohibited.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Excavator Pins and Bushings from China

Issuing Authority: SEA LION International – Engineering & Logistics Division

Date: April 5, 2026

Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of excavator pins and bushings from manufacturing hubs in China (e.g., Shanghai, Qingdao, Ningbo) to global construction markets. The analysis focuses on cost efficiency, cargo protection, transit reliability, and compatibility with anti-corrosion protocols, including wax spraying for seawater exposure mitigation.

Product Overview: Excavator Pins and Bushings

Excavator pins and bushings are high-precision steel components critical to the articulation and longevity of heavy construction machinery. Due to their susceptibility to corrosion and tight dimensional tolerances, protective packaging and environmental control during shipping are essential.

- Material: Medium-carbon or alloy steel (e.g., 40Cr, 35CrMo)

- Surface Finish: Hardened and ground

- Corrosion Risk: High when exposed to saltwater vapor and humidity

- Protection Protocol: Mandatory wax spraying (minimum 20–30 µm coating thickness) prior to packaging

Wax Spraying Protection: Corrosion Mitigation

To ensure integrity during ocean transit, all pins and bushings must be treated with a hydrophobic, rust-inhibitive wax compound before crating. This treatment forms a temporary barrier against salt-laden air and condensation.

| Parameter | Specification |

|---|---|

| Wax Type | Solvent-free, petroleum-based corrosion inhibitor |

| Application Method | Automated spray booth (±5 µm tolerance) |

| Coating Thickness | 20–30 µm (measured via magnetic thickness gauge) |

| Drying Time | 15–30 minutes at 25°C |

| Packaging Post-Treatment | VCI (Vapor Corrosion Inhibitor) film + sealed polyethylene wrap |

Note: Wax-treated components must be unpacked and degreased prior to installation. Residual wax does not affect welding or press-fitting operations.

Comparative Shipping Method Analysis

| Criterion | RO-RO | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Cargo Compatibility | Low – Designed for self-propelled equipment; not suitable for loose machined parts | High – Accommodates unpackaged or palletized bulk loads | High – Ideal for oversized or crated industrial components |

| Load Unit Type | Not applicable (vehicle decks only) | Palletized crates or loose in hold | ISO-standard flat rack containers (20′ or 40′) |

| Protection Against Seawater | Moderate – Exposed to deck environment; requires sealed, wax-coated packaging | Low – High humidity, condensation, and potential water ingress in holds | High – Enclosed or covered transport; compatible with sealed crates |

| Corrosion Risk (Post-Wax) | Elevated if crates are not fully sealed | High due to poor ventilation and moisture accumulation | Low – Controlled environment with optional desiccants and sealed wraps |

| Transit Time (China → Europe/US West Coast) | 28–35 days | 30–40 days | 25–32 days |

| Port Accessibility | Limited to RO-RO-capable terminals | Widely available | Available at major container terminals |

| Handling Risk | Low (driven on/off) | High (grab cranes, conveyor transfer) | Moderate (containerized lifting) |

| Cost (USD per TEU equivalent) | Not applicable | $1,800–$2,400 (loose cubic rate) | $3,200–$4,000 (inclusive of container) |

| Security & Traceability | Low – Shared vehicle decks, minimal tracking | Low – High risk of misplacement or damage | High – Sealed container with GPS/RFID options |

| Recommended Use Case | Not recommended | For non-critical, high-volume spares without precision requirements | Preferred method for high-value, corrosion-sensitive pins and bushings |

Recommended Logistics Protocol

For optimal protection and logistics control, SEA LION International recommends the following export protocol:

- Pre-Shipment Treatment:

- Apply wax spray per ASTM D1745 standards.

-

Wrap in VCI film and place in wooden crates with silica gel desiccants.

-

Packaging:

- Crates must meet ISPM-15 standards (heat-treated wood).

-

Label with “CORROSION-PROTECTED – DO NOT REMOVE WRAP” and handling orientation arrows.

-

Shipping Mode:

- Preferred: 20′ or 40′ Flat Rack containers with tarpaulin cover.

-

Secure crates using steel strapping to container base.

-

Routing:

- Origin: Factory in Jiangsu/Zhejiang → Port of Shanghai/Ningbo

- Destination: Major container terminals (e.g., Rotterdam, Los Angeles, Melbourne)

-

Transit Time: 28–32 days (Far East to Europe/US West Coast)

-

Insurance & Compliance:

- All shipments to include marine cargo insurance (Institute Cargo Clauses A).

- Documentation: Bill of Lading, Certificate of Origin, Material Test Reports (MTRs), and Wax Treatment Certificate.

Conclusion

While RO-RO and Bulk Cargo offer lower nominal costs, they present unacceptable risks for high-precision excavator pins and bushings due to environmental exposure and handling hazards. Flat Rack container shipping, combined with industrial-grade wax spraying and VCI packaging, delivers the optimal balance of protection, traceability, and delivery reliability.

SEA LION International endorses Flat Rack logistics as the standard for corrosion-sensitive construction components exported from China in 2026.

End of Report

SEA LION International – Engineering & Global Logistics Division

Get a Quote for Excavator Pins And Bushings

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]