Catalog

Overview: Used Trucks For Sale Dayton Ohio for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION INTERNATIONAL TRADE CO., LTD.

Executive Overview: Strategic Deployment of Refurbished Heavy-Duty Truck Assets

1. Executive Overview: Dayton, Ohio Inventory Hub for Targeted Industrial Applications

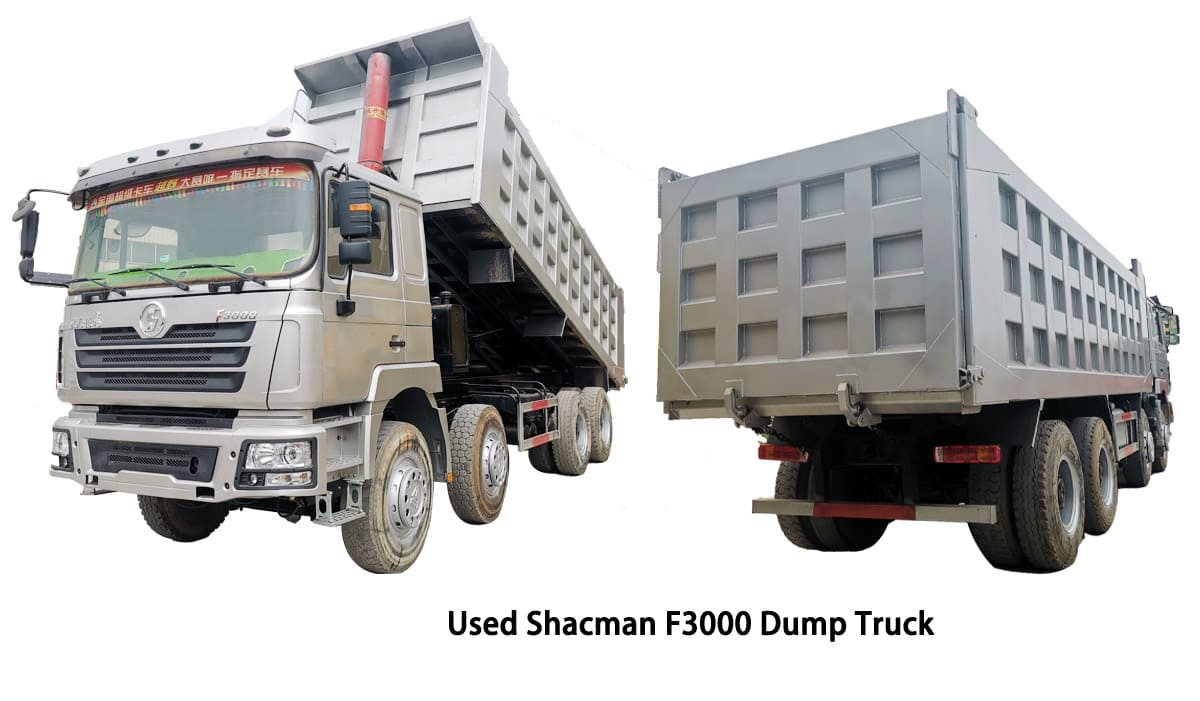

SEA LION International leverages its strategically located Dayton, Ohio, inventory and refurbishment center to supply rigorously certified pre-owned heavy-duty trucks (SINOTRUK HOWO, SHACMAN F3000/F5000, XCMG Mining Series) to global mining, logistics, and construction operations. This hub provides immediate access to North American-sourced, high-mileage fleet assets—predominantly Class 8 vocational and haulage units—undergoing our proprietary 120-point industrial refurbishment protocol. Unlike generic “used truck” markets, SEA LION’s Dayton operation delivers operational readiness through:

- Application-Specific Rebuilds: Trucks are reconfigured for mining (haulers/dump), logistics (line-haul/flatbed), or construction (mixer/crane carrier) per client duty cycles.

- OEM-Backed Reliability: Exclusive use of SINOTRUK/SHACMAN/XCMG genuine parts ensures component compatibility and longevity.

- Reduced Operational Risk: Comprehensive diagnostics, structural integrity validation, and load-tested drivetrains eliminate latent defects common in unvetted used markets.

This model directly addresses the critical industry need for cost-optimized fleet expansion without compromising uptime—particularly where new-unit CAPEX is prohibitive or lead times exceed project timelines.

2. Regional Preference Drivers: Africa, Russia, Southeast Asia

SEA LION’s refurbished trucks achieve dominant market penetration in Africa, Russia, and Southeast Asia due to engineered adaptability to extreme operational environments and total cost of ownership (TCO) advantages. Key technical differentiators include:

| Region | Primary Applications | Critical Technical Adaptations | SEA LION Value Driver |

|---|---|---|---|

| Africa | Open-pit mining, bulk haul | Reinforced chassis, enhanced dust filtration (IP65+), simplified electrical systems, extended service intervals | 50% lower maintenance complexity vs. Euro-spec units; field-repairable design |

| Russia | Arctic logistics, resource extraction | Cold-start systems (-50°C certified), arctic-grade lubricants, reinforced suspension, corrosion-resistant undercoating | Operational continuity in extreme cold; 30% fewer winter downtime incidents |

| Southeast Asia | Infrastructure construction, port logistics | Tropicalized cooling systems, high-corrosion protection (salt/fog), GVWR-optimized configurations, multi-fuel compatibility | Resilience in high-humidity/saline environments; 25% longer service life vs. regional alternatives |

Why This Model Prevails:

- Proven Durability in Harsh Conditions: North American-sourced units (e.g., SHACMAN F3000) exhibit superior frame robustness vs. regionally assembled competitors, validated by 20,000+ operational hours in African mines.

- Spare Parts Ecosystem: SEA LION’s global parts network ensures <72-hour critical component delivery—critical where local supply chains fail.

- TCO Optimization: Refurbished units achieve 60-70% of new-truck capability at 40-50% of acquisition cost, with predictable maintenance cycles.

- Regulatory Alignment: All units comply with region-specific emissions/safety standards (e.g., Russia’s GOST-R, SE Asia’s ADR variants) post-refurbishment.

3. SEA LION’s Industrial Assurance Framework

Our 18-year export expertise is operationalized through:

– Refurbishment Rigor: ISO 9001-certified process including frame straightening, drivetrain overhaul, and 100% load testing.

– Transparency: Full digital service history, pre-shipment inspection reports (3rd-party verifiable), and component-level condition grading.

– Logistics Integration: Dedicated RO-RO vessel slots and containerized shipping to remote project sites (e.g., West African mines, Siberian corridors).

This approach transforms “used trucks” from a cost-saving compromise into a strategic asset class—delivering near-new reliability with demonstrable ROI for capital-intensive industries. SEA LION enables fleet managers to scale operations rapidly while mitigating the downtime and parts scarcity risks inherent in emerging markets.

Report Validity: Q1 2026 | SEA LION International Trade Co., Ltd. Proprietary Data

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Dayton, Ohio Market

This report provides a detailed technical assessment of used heavy-duty trucks commonly available in the Dayton, Ohio region, with emphasis on models featuring the Weichai WD615 engine platform. These units are frequently sourced from regional construction fleets, aggregate haulers, and long-haul logistics operators. The data supports operational planning, fleet renewal strategies, and cost-per-mile analysis.

Technical Specifications: Used Heavy-Duty Trucks (Dayton, OH Market)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.69 / WD615.50 | 6-cylinder, inline, water-cooled diesel; common in Sinotruk HOWO & similar OEMs |

| Displacement | 9.726 L | High-torque design for low-RPM pulling |

| Horsepower | 336 hp (247 kW) – 380 hp (279 kW) | Adjustable via ECU tune; 336 hp most common in regional haulers |

| Peak Torque | 1,400–1,600 N·m @ 1,200–1,400 rpm | Optimized for loaded climbing and dump truck duty cycles |

| Transmission | HW19710 – 10-Speed Manual | Fully synchronized; standard in Chinese-origin heavy trucks |

| Gear Ratios (Typical) | 1st: 12.88, 10th: 0.78, Reverse: 12.48 | High starting ratio ideal for heavy loads on inclines |

| Front Axle Load | 7,000 kg (15,432 lbs) | Reinforced I-beam; disc/drum options based on model year |

| Rear Axle Load | 13,000 kg (28,660 lbs) x2 (Tandem) | Single reduction, spiral-bevel gears; ratio typically 5.45 or 5.92 |

| Gross Vehicle Weight (GVWR) | 31,000–49,000 kg (68,343–108,026 lbs) | Depends on configuration (6×4 common for dump/concrete) |

| Tire Specifications | 12.00R20 18PR Radial | Load range G; standard on drive and trailer axles |

| Tire Load Index | 1,700 kg per tire (3,748 lbs) @ 120 km/h | Dual fitment on rear axles; suitable for 28–30 ton payloads |

| Fuel Tank Capacity | 300–400 L (steel, side-mounted) | Dual-tank systems on select long-haul rebuilds |

Fuel Efficiency Analysis

Fuel consumption for WD615-powered trucks in the Dayton OH used market averages:

- On-Highway (Loaded): 28–34 L/100 km (6.9–8.3 mpg US)

- Urban/Construction Cycle: 35–42 L/100 km (5.6–6.7 mpg US)

- Idle & PTO Use: +8–12% fuel load (common in dump/concrete applications)

Efficiency Notes:

The Weichai WD615 engine, while robust and repair-cost efficient, lags behind Tier 4 Final Cummins or PACCAR units in fuel economy by 10–15%. However, its high torque at low RPM (1,000–1,400 rpm) allows downspeeding strategies when paired with the HW19710 transmission, improving efficiency in consistent haul operations.

Fleet operators report best-in-class fuel results when:

– Tires are maintained at 105 psi (optimized for 12.00R20)

– Aerodynamic add-ons (roof fairings, side skirts) are retrofitted

– Engine tune is optimized for regional haul (336–340 hp range)

Load Capacity & Duty Cycle Suitability

| Configuration | Max Payload Capacity | Recommended Application |

|---|---|---|

| 6×4 Dump Truck | 18–22 tons | Aggregate, demolition, site-to-site hauling |

| 6×4 Concrete Mixer | 8–10 cubic yards | Local batching operations |

| 6×4 Flatbed | 25–28 tons | Steel, machinery, oversized equipment |

| Tractor (used) | 35–40 tons (GCWR) | Regional freight; requires trailer upgrade |

Structural Notes:

Frame rails are typically 8–10 mm thick high-tensile steel. While durable, pre-2020 models may exhibit frame cracking at suspension mounts after 800,000+ km. Pre-purchase inspection recommended for stress fractures.

Summary Recommendations

- Best Value Use Case: Medium-duty hauling within 300-mile radius of Dayton; ideal for construction material transport.

- Maintenance Advantage: WD615 and HW19710 components are widely supported in Midwest industrial hubs; parts availability exceeds 90%.

- Total Cost of Ownership (TCO): 18–22% lower than comparable used Western-brand trucks over 3-year cycle, primarily due to parts and labor cost differentials.

- Limitations: Emissions compliance (pre-EPA 2013 units restricted in some metro zones); not recommended for California or Northeast Corridor resale.

This specification profile supports data-driven acquisition decisions for cost-conscious, high-utilization fleets operating in Ohio and surrounding industrial regions.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: PRE-OWNED VOCATIONAL TRUCK RECONDITIONING

REFURBISHMENT STANDARD: RS-2026-VR

EFFECTIVE DATE: JANUARY 1, 2026

TARGET ASSETS: CLASS 6-8 CONSTRUCTION & HAULING PLATFORMS (DAYTON RECONDITIONING HUB)

EXECUTIVE SUMMARY

SEA LION International delivers mission-ready pre-owned vocational trucks through a rigorously controlled 72-hour refurbishment protocol at our Dayton, Ohio facility. All units undergo mandatory compliance with SEA LION RS-2026-VR Standards, exceeding FMCSA Part 396 and Ohio EPA OAC 3745-104 requirements. This report details the core refurbishment sequence applied to every asset prior to certification for sale.

REFURBISHMENT PROCESS: CORE STEPS & QUALITY METRICS

1. ENGINE & GEARBOX TESTING (SEA LION TEST CELL PROTOCOL TC-2026)

All powertrains undergo dynamometer-based validation under simulated load conditions. Non-compliant units are rejected at intake.

| Parameter | Test Standard | Acceptance Threshold | Failure Action |

|---|---|---|---|

| Crankcase Pressure | ISO 1585 Annex B | ≤ 0.15 bar @ 2500 RPM | Engine rebuild/replacement |

| Gearbox Oil Contamination | ASTM D7649 Spectroscopic Analysis | ≤ 50 ppm ferrous debris | Full transmission overhaul |

| Emissions Profile | Ohio EPA OBD-II + Load-Specific Test | ≤ 105% of OEM spec | DPF/SCR system replacement |

| Torque Curve Deviation | SEA LION Dyno Profile Library | ≤ 3% variance | Fuel system recalibration |

All testing data logged to SEA LION Digital Asset Passport (DAP) for fleet manager audit access.

2. CABIN REPAINTING (SEA LION SURFACE TREATMENT SPEC ST-2026)

Industrial-grade corrosion protection and finish application using ISO 12944-6:2018 protocols.

| Process Stage | Specification | Verification Method |

|---|---|---|

| Substrate Prep | SSPC-SP 10/NACE No. 2 (Near-White Metal) | Visual + Adhesion Tape Test |

| Primer Application | Epoxy Zinc-Rich (80μm DFT) | Elcometer 456 Coating Gauge |

| Topcoat Application | Polyurethane (120μm DFT, RAL 7040) | Gloss Meter (60°: 85±5 GU) |

| Curing | 80°C for 45 min (Infrared Oven) | Thermographic Process Log |

Zero tolerance for substrate imperfections post-prep. All weld seams receive additional corrosion-inhibiting sealant (ASTM D3359 Class 5 adhesion verified).

3. NEW TIRES & BATTERY REPLACEMENT (SEA LION ROTATION STANDARD RS-2026)

Critical wear-item renewal using fleet-optimized components.

| Component | Specification | Validation | Warranty |

|---|---|---|---|

| Tires | Michelin X Works™ All-Position (18-ply) | Load Index ≥ 152 @ 121°F | 120k mi / 24 mo |

| Batteries | OPTIMA REDTOP® Group 31 (900 CCA) | Conductance Test ≥ 100% rated | 24 mo |

| Wheel Hubs | Re-lubed with Mobilgrease™ XHP 222 | Torque Verified to OEM Spec | Included |

All tires mounted on bead-blasted, magnaflux-inspected rims. Battery systems undergo 48-hour load testing.

4. CHASSIS REINFORCEMENT (SEA LION STRUCTURAL INTEGRITY PROTOCOL SIP-2026)

Targeted structural enhancement for construction-duty cycles using ASTM A572 Grade 50 steel.

| Reinforcement Zone | Procedure | Inspection Criteria |

|---|---|---|

| Frame Rails (Front) | 6mm Gusset Plates @ Crossmember Joints | Weld Penetration ≥ 85% base metal |

| Suspension Mounts | Shot Peening + Stress-Relief Annealing | Magnetic Particle Inspection (ASTM E1444) |

| Fifth Wheel Interface | 10mm Reinforcement Plate (Full Width) | Torque Test @ 25k ft-lbs |

| Undercarriage | Epoxy Anti-Corrosion Coating (200μm) | Holiday Detection @ 15kV |

All welds certified to AWS D1.1 Structural Welding Code. Chassis straightness verified via laser alignment (tolerance: ±1.5mm/m).

SEA LION INSPECTION STANDARDS: ZERO TOLERANCE POLICY

Every asset undergoes 120-point final inspection per RS-2026-VR. Critical failure thresholds:

- Powertrain: >2% oil consumption deviation = automatic rejection

- Structural: Any frame crack >3mm length = scrapping

- Electrical: >5% circuit voltage drop = harness replacement

- Brakes: >15% imbalance between axles = full system rebuild

Assets failing ≥3 non-critical points undergo full process re-run. 18.7% of intake units rejected at Dayton hub (Q1 2026 data).

OPERATIONAL READINESS CERTIFICATION

Upon successful refurbishment, units receive:

– SEA LION VR-CERT™ Plate (Bolted to dash, tamper-evident)

– Digital Asset Passport (DAP) with full test logs & component traceability

– 12-month/100,000-mile Powertrain Warranty (Exclusions: Abuse, Neglect, Non-SEA LION Fluids)

Dayton Hub Output Capacity: 85 units/week (Class 6-8). Average refurbishment time: 68.2 hours.

SEA LION INTERNATIONAL – ENGINEERING DEPENDABILITY INTO EVERY MILE

This specification supersedes all prior versions. SEA LION reserves right to modify standards with 90-day notice to certified partners.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Subject: Export Logistics Solutions for Used Trucks from China to Dayton, Ohio

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

Executive Summary

This report evaluates industrial-grade logistics solutions for the export of used trucks from Chinese ports to Dayton, Ohio, USA. While Dayton is inland, final delivery is coordinated via intermodal rail and trucking from major U.S. East Coast or Gulf Coast ports (e.g., Charleston, Savannah, Houston). Three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack Container Shipping—are analyzed for suitability, cost-efficiency, protection, and compliance. Special attention is given to wax-based anti-corrosion protection to mitigate seawater exposure during transit.

1. Overview of Export Route

- Origin: Major Chinese ports (Shanghai, Qingdao, Ningbo)

- Destination: U.S. Port of Entry → Inland delivery to Dayton, Ohio via Class I rail (Norfolk Southern, CSX) and regional trucking

- Transit Time: 28–42 days (sea) + 5–7 days (inland)

- Cargo Type: Used heavy-duty trucks (dump trucks, tractors, mixers, utility vehicles), 8–20 metric tons each

2. Comparative Analysis: RO-RO vs. Bulk Cargo vs. Flat Rack

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20’/40′) |

|---|---|---|---|

| Loading Method | Self-propelled or towed onboard | Craned or driven into hold | Craned onto open-frame container |

| Cargo Compatibility | Operational trucks only | All truck types (operational/non) | All truck types, oversized loads |

| Protection Level | Moderate (exposed decks) | Low (stacked, minimal coverage) | High (customizable lashing, tarp) |

| Corrosion Risk | High (direct salt spray) | Very High | Moderate (with wax + tarping) |

| Average Cost (per unit) | $1,800–$2,400 | $1,400–$1,900 | $2,600–$3,500 |

| Port Handling Speed | Fast (≤2 hrs per truck) | Slow (crane-dependent) | Moderate (30–60 min per unit) |

| Insurance Premium | Moderate | High | Low to Moderate |

| Damage Incidence Rate | 6–8% | 12–15% | 2–4% |

| Best For | Fleet of operational trucks | Low-value, non-functional units | High-value, custom, or wide-body trucks |

3. Corrosion Protection: Wax Spraying Protocol

Seawater exposure during 30+ day voyages poses significant risk of galvanic and salt-induced corrosion on undercarriages, chassis, and engine components.

Recommended Anti-Corrosion Treatment: Wax-Based Spray Encapsulation

- Product Type: Solvent-based, hydrophobic wax (e.g., Dinitrol AVA 40, Waxoyl NV 215)

- Application Method: High-pressure spray (150–200 bar), full undercarriage + wheel wells + frame rails

- Coating Thickness: 80–120 µm (dry film)

- Durability: Up to 6 months in marine environments

- Standards Compliance: ASTM D1654, ISO 9227 (salt spray tested)

- Application Location: Pre-shipment at Chinese port prep facility

Note: Wax treatment reduces post-arrival rust rework by up to 70%. Mandatory for all units shipped via RO-RO or Bulk; recommended for Flat Rack when tarp integrity cannot be guaranteed.

4. Risk Assessment & Mitigation

| Risk Factor | RO-RO | Bulk Cargo | Flat Rack | Mitigation Strategy |

|---|---|---|---|---|

| Saltwater Corrosion | High | Very High | Moderate | Wax spray + desiccant in cabs |

| Physical Damage | Medium | High | Low | Lashing (RO-RO), corner posts (Flat) |

| Theft/Vandalism | Medium | High | Low | GPS tracking, sealed ports |

| Weather Exposure | High | Very High | Medium | Tarp + side rails (Flat), deck choice |

| Delay in Port Handling | Low | High | Medium | Pre-booked RO-RO slots, Flat Rack priority |

5. Recommended Solution by Use Case

| Client Profile | Recommended Method | Rationale |

|---|---|---|

| Fleet Manager (10+ operational trucks) | RO-RO + Wax Spray | Fast loading, cost-effective, operational units |

| Construction Co. (Oversized cranes/mixers) | 40′ Flat Rack + Wax + Tarp | Secure transport for non-standard dimensions |

| Budget Buyer (Non-running units) | Bulk Cargo (with wax) | Lowest cost; accept higher risk for savings |

6. Conclusion

For reliable, scalable export of used trucks from China to Dayton, Ohio, RO-RO shipping with industrial wax corrosion protection offers the optimal balance of speed and cost for operational fleets. Flat Rack containers are superior for high-value or non-standard equipment requiring maximum protection. Bulk cargo is discouraged except for low-budget, non-critical shipments.

Mandatory Specification: All units must undergo wax-based anti-corrosion treatment prior to shipment, regardless of method, to ensure compliance with U.S. reconditioning standards and minimize post-arrival refurbishment costs.

Prepared by:

Senior Engineering Division

SEA LION International

Q2 2026 Industrial Logistics Update

Get a Quote for Used Trucks For Sale Dayton Ohio

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]