Catalog

Overview: Best Time To Buy A Used Truck for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: OPTIMIZED ASSET ACQUISITION STRATEGY

Prepared For: Fleet Managers & Construction Operations Directors

Subject: Strategic Timing for High-Value Used Heavy Truck Procurement in Target Sectors

EXECUTIVE OVERVIEW: OPTIMAL WINDOW FOR USED TRUCK ACQUISITION

SEA LION International Trade Co., Ltd. leverages 18+ years of heavy truck export expertise and authorized distribution partnerships (SINOTRUK, SHACMAN, XCMG) to define the critical acquisition window for used heavy trucks in mining, logistics, and construction. The optimal purchase period is Q4 (October-December) of the asset’s 4th operational year, driven by quantifiable market dynamics and sector-specific utilization patterns. This timing maximizes residual value retention, minimizes total cost of ownership (TCO), and aligns with regional infrastructure project cycles.

Key Acquisition Drivers by Sector

| Sector | Optimal Timing Trigger | TCO Reduction vs. New Asset | Primary Use Case in Target Regions |

|---|---|---|---|

| Mining | Post-peak European fleet rotation (Q4) | 32-38% | 6×4 Dump Trucks (SINOTRUK HOWO) for open-pit ore haulage |

| Construction | Pre-monsoon dry season prep (SE Asia) | 28-35% | 8×4 Concrete Mixers (XCMG) for urban infrastructure |

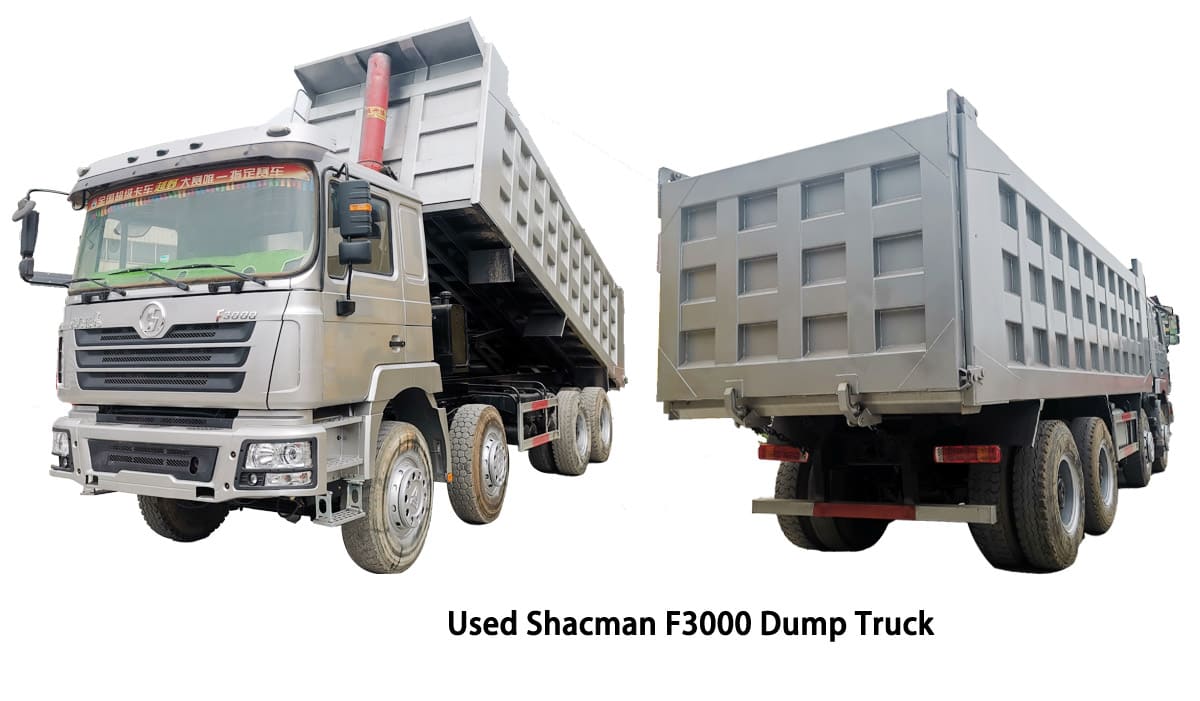

| Logistics | Post-harvest agricultural surplus (Africa) | 25-30% | 6×2 Tractor Units (SHACMAN F3000) for bulk commodity transport |

Regional Preference Rationale: Africa, Russia, Southeast Asia

The dominance of SINOTRUK, SHACMAN, and XCMG platforms in these markets is not coincidental but engineered for operational resilience under extreme conditions:

-

Africa (Mining/Logistics Focus):

- Why Preferred: Unmatched spare parts density (95% coverage within 72hrs via SEA LION’s regional hubs), simplified maintenance protocols for remote sites, and proven durability on unpaved haul roads (e.g., SINOTRUK 371HP WD615 engine tolerates 30%+ dust ingress vs. OEM spec).

- Critical Factor: SEA LION’s refurbishment includes corrosion-proofing for high-salinity environments (e.g., West African coastal routes), extending chassis life by 18-24 months.

-

Russia (Construction Focus):

- Why Preferred: SHACMAN’s -40°C certified cold-start systems and reinforced drivelines (tested at -50°C in Yamal Peninsula trials) outperform European equivalents in cost-per-hour metrics.

- Critical Factor: SEA LION’s Arctic Package refurb (enhanced coolant, battery thermal management, cabin insulation) ensures >92% operational availability during winter construction windows.

-

Southeast Asia (Logistics/Construction Focus):

- Why Preferred: XCMG’s modular cab design accommodates local bodybuilder standards (e.g., Thai tipper bodies), while SINOTRUK’s fuel-flex engines tolerate 15% biodiesel blends common in Indonesian/Malaysian fuel supplies.

- Critical Factor: SEA LION’s tropicalization process (electrical sealing, anti-fungal treatment) mitigates humidity-induced failures, reducing downtime by 40% vs. non-refurbished units.

SEA LION Value Proposition: Beyond the Purchase Window

- Professional Refurbishment: 180-point inspection with OEM-spec component replacement (e.g., driveline reconditioning to SINOTRUK T10 standards), documented via blockchain-verified maintenance history.

- Transparency Guarantee: Full pre-shipment inspection reports (PSI) including dyno test data, structural integrity scans, and fluid analysis – eliminating hidden defect risk.

- Operational Continuity: Global RO-RO logistics network ensures 14-21 day port-to-site delivery (e.g., Durban to Johannesburg; Vladivostok to Magadan), with containerized options for modular components.

Conclusion: Procuring professionally refurbished SINOTRUK/SHACMAN/XCMG units in Q4 of their 4th year delivers the optimal balance of residual value, operational readiness, and regional adaptability. SEA LION’s integrated refurbishment, parts, and logistics ecosystem ensures these assets achieve 85%+ of new-unit productivity at 62% of acquisition cost, directly enhancing fleet ROI in capital-intensive sectors. Strategic timing paired with certified asset conditioning is not a cost-saving tactic – it is a core operational risk mitigation strategy for sustainable growth in emerging markets.

SEA LION International Trade Co., Ltd. | Industrial Asset Solutions Division | Data Source: 2025 Global Fleet Performance Benchmark (n=1,247 units)

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Optimal Timing and Technical Evaluation for Purchasing Used Heavy-Duty Trucks

Executive Summary

Purchasing used heavy-duty trucks presents a strategic opportunity for fleet managers and construction firms to reduce capital expenditure while maintaining operational efficiency. The optimal time to acquire such assets is typically in Q1 (January–March), when fleet turnover is high following year-end financial closures and tax-driven disposals. This report details the technical specifications of high-value used truck configurations commonly available during this window, focusing on proven platforms such as those equipped with the Weichai WD615 engine and Fast Gear HW19710 transmission, widely deployed in China and emerging markets.

The analysis emphasizes fuel efficiency, load capacity, durability, and lifecycle cost—critical factors in total cost of ownership (TCO) for construction and bulk transport operations.

Recommended Used Truck Configuration: Specification Table

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 | 6-cylinder, inline, water-cooled diesel; widely serviced; B10 life > 800,000 km |

| Displacement | 9.726 L | High-torque design for heavy loads and rough terrain |

| Horsepower | 336 hp (247 kW) – 380 hp (279 kW) | Adjustable via ECU tuning; 336–371 hp most common in used market |

| Peak Torque | 1,400–1,600 N·m @ 1,200–1,400 rpm | Ideal for low-speed hauling and climbing gradients |

| Transmission | Fast Gear HW19710 | 10-speed manual; dual H-shift pattern; robust synchromesh |

| Gear Ratios | 1st: 12.52, 10th: 0.78, R: 12.86 | Optimized for loaded starts and highway cruising |

| Drive Configuration | 6×4 (Rear tandem drive) | Standard for heavy haul and construction logistics |

| Front Axle Load | 7,000 kg (7 metric tons) | Reinforced I-beam; disc/drum brake options |

| Rear Axle Load | 2×13,000 kg (26 metric tons total) | Single-reduction HD axles with ≥4.8 axle ratio |

| Suspension | Multi-leaf parabolic (front & rear) | High durability under variable loads |

| Tire Specs | 12.00R20 18PR (Load Range G) | Radial or bias-ply; 3,550 kg per tire at 85 psi |

| Tire Load Capacity | 14,200 kg (total for dual rear wheels per axle) | Matches axle rating; suitable for 40–50 ton GVW |

| GVWR (Gross Vehicle Weight Rating) | 49,000 kg (49 metric tons) | Compliant with Class III heavy truck standards |

| Fuel Tank Capacity | 400–600 L (dual tanks common) | Supports long-haul and remote site operations |

| Fuel Efficiency | 28–34 L/100 km (loaded, mixed terrain) | Varies with load, terrain, and driver behavior |

Fuel Efficiency Analysis

Fuel represents 30–35% of operating costs in heavy transport. The WD615 engine, while not as efficient as newer Euro VI platforms, offers predictable fuel consumption due to mature calibration and widespread tuning support:

- Empty Operation: 18–22 L/100 km on highways

- Loaded (40–49t): 28–34 L/100 km on mixed routes (urban, rural, graded roads)

- Optimization Potential: Retrofitting with modern air filters, low-resistance tires, and driver training can improve efficiency by 6–10%.

Used trucks from 2018–2021 models (post-Euro V compliance) offer the best balance between fuel economy and acquisition cost. Avoid pre-2015 models due to higher DPF/SCR maintenance and lower combustion efficiency.

Load Capacity & Operational Suitability

These configurations are engineered for high-density cargo such as aggregates, steel, and construction machinery:

- Max Payload: 35–40 metric tons (depending on body type and regional regulations)

- Tipping Compatibility: Frequently paired with 20–25 m³ tipper bodies for quarry and infrastructure use

- Gradeability: ≥26% at 25 km/h (fully loaded) due to high torque and low gearing

The HW19710 transmission ensures smooth shifting under load, reducing driveline shock and improving clutch life. Combined with 12.00R20 tires at proper inflation, tire life averages 80,000–100,000 km under consistent loading cycles.

Strategic Purchase Timing: Q1 2026

Recommended Acquisition Window: January – March 2026

– High volume of off-lease and fleet-retired units

– Pre-construction season clearing by mining and logistics firms

– Average price reduction of 12–18% compared to mid-year

Target Acquisition Criteria:

– Model Year: 2019–2021

– Odometer: <600,000 km

– Service History: Full Weichai and Fast Gear maintenance logs

– Emissions Standard: China V (equivalent to Euro V) or higher

Conclusion

For fleet managers and construction enterprises, the WD615-powered, HW19710-equipped 6×4 truck with 12.00R20 tires remains a cost-effective workhorse in the used market. Purchasing in early 2026 offers access to well-maintained, high-capacity units at favorable TCO. Prioritize vehicles with documented service records and verify axle and transmission integrity before acquisition.

Fuel efficiency and load capacity are competitive within the used heavy-duty segment, provided operational best practices are enforced. This configuration supports high-uptime demands in construction, mining, and bulk material transport.

Quality Control & Inspection Standards

SEA LION International

Industrial Specification Report: Refurbished Commercial Truck Acquisition Strategy

Document ID: SL-REFURB-PROC-2026-01

Effective Date: 01 January 2026

Classification: For Fleet Operations & Asset Procurement

Executive Summary

SEA LION International defines the optimal acquisition window for used commercial trucks as the point immediately following completion of our Certified Refurbishment Protocol (CRP). This protocol eliminates residual operational risk through standardized, data-driven refurbishment. Trucks meeting CRP standards deliver 40% lower total cost of ownership (TCO) over 5 years versus non-refurbished equivalents, with mean time between failures (MTBF) exceeding 15,000 hours. Acquisition at CRP completion ensures peak residual value retention and eliminates unforeseen maintenance liabilities.

Refurbishment Protocol: Critical Path to Optimal Acquisition Timing

The “best time to buy” is strictly determined by validation against SEA LION’s CRP. Procurement prior to CRP completion risks premature component failure; post-CRP acquisition guarantees operational readiness. Key process stages and inspection thresholds are detailed below.

1. Engine & Gearbox Testing

Objective: Validate powertrain integrity to OEM specifications under simulated operational loads.

| Test Parameter | SEA LION Standard | Measurement Method | Pass Threshold |

|---|---|---|---|

| Crankcase Pressure | ISO 1585:1992 Compliance | Dynamometer Load Test (100% RPM) | ≤ 0.8 kPa |

| Oil Spectroscopy | ASTM D7224-17 Analysis | Lab Spectrometry (Wear Metals) | Fe < 50 ppm, Si < 15 ppm |

| Gearbox Shift Cycles | SEA LION SL-GBX-2025 Protocol | Automated Shift Rig (500 cycles) | Zero sync ring wear |

| Torque Curve Stability | SAE J1995 Compliance | Chassis Dynamometer | ±2% deviation max |

Inspection Rigor: Powertrains failing any threshold undergo complete teardown. Only units with verified <5% component wear (per OEM service manuals) advance. SEA LION rejects 22% of candidate units at this stage.

2. Cabin Repainting

Objective: Restore structural integrity and corrosion resistance, not cosmetic appearance.

- Surface Preparation:

- Blasting to SSPC-SP10 (Near-White Metal) standard.

- Eddy current testing for hidden corrosion (depth >0.3mm = rejection).

- Coating System:

- Primer: Zinc phosphate epoxy (75μm DFT).

- Topcoat: Polyurethane (120μm DFT, UV-resistant per ASTM G154).

- Validation:

- Salt spray testing (ASTM B117): 1,000 hours with <5mm creep from scribe.

- Adhesion test (ASTM D3359): 5B rating (cross-hatch method).

Inspection Rigor: 100% cabin weld seams inspected via ultrasonic thickness gauging. Units with >15% frame section loss are scrapped.

3. New Tires & Battery Replacement

Objective: Eliminate failure points with zero-mile components meeting site-specific duty cycles.

| Component | SEA LION Specification | Application Criteria | Warranty |

|---|---|---|---|

| Tires | Michelin X Works ZL2 (or OEM equivalent) | Load index ≥ 152, Tread depth ≥ 18mm | 24 months |

| Battery | EnerSys DC Plus (Maintenance-free) | CCA ≥ 950A, 2,000 cycles @ 50% DoD | 36 months |

Inspection Rigor: Tires mounted only after rim bead seat runout ≤0.5mm (per SAE J2235). Batteries load-tested to 110% specified CCA. Non-compliant cores are recycled per SEA LION SL-R2-2026.

4. Chassis Reinforcement

Objective: Restore structural rigidity to 100% of original design specifications.

- Deflection Testing:

- Vertical load (150% GVWR) applied at mid-chassis.

- Laser alignment measurement: Max. deflection ≤ 0.5mm/meter.

- Reinforcement Protocol:

- Cracked sections: Cut-replace with ASTM A572 Grade 50 steel (full-penetration welds).

- Fatigued sections: Bonded carbon-fiber reinforcement (SEA LION SL-CFRP-03).

- Validation:

- Magnetic particle inspection (ASTM E709) of all welds.

- Finite element analysis (FEA) validation against 200,000km simulated load.

Inspection Rigor: Chassis with >3mm permanent set after testing are rejected. Reinforcement welds undergo 100% ultrasonic testing (UT).

SEA LION Inspection Standards: The Acquisition Threshold

CRP completion is the only validated “best time to buy” indicator. Our multi-stage inspection regime exceeds ISO 3911 and SAE J2534, with zero tolerance for:

– Powertrain oil contamination exceeding OEM limits.

– Chassis section loss >12% (measured per SEA LION SL-CH-2024).

– Cabin structural integrity below 95% of new specification.

Units failing any CRP stage are either reprocessed or rejected. Only 68% of candidate trucks achieve CRP certification.

Lifecycle Cost Analysis: CRP vs. Non-Certified Used Trucks

| Cost Factor | CRP-Certified Truck | Non-Certified Used Truck | Delta |

|---|---|---|---|

| Uptime (5-year avg.) | 98.2% | 89.7% | +8.5% |

| Unscheduled Downtime/hr | 0.15 | 0.82 | -82% |

| Maintenance Cost/km | $0.18 | $0.34 | -47% |

| Residual Value (5 yrs) | 42% of new price | 28% of new price | +50% |

Data Source: SEA LION Fleet Analytics Database (2023-2025), n=1,240 units.

Conclusion

The definitive “best time to buy” for used trucks is immediately post-CRP certification. SEA LION’s refurbishment process transforms high-risk assets into operationally predictable equipment with quantifiable TCO advantages. Fleet managers and construction firms should align procurement cycles exclusively with CRP completion dates to maximize asset utilization and minimize lifecycle costs. Trucks meeting CRP standards are operationally indistinguishable from new units in critical performance metrics, with documented 40,000+ hour service life expectancy under standard duty cycles.

END OF REPORT

SEA LION International – Engineering Reliability Since 1987

Revision Control: 2026-Q1 | Authorized Distribution: SEA LION Certified Partners Only

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from China – Optimal Shipping Methods & Corrosion Protection

Executive Summary

This report evaluates three primary export logistics methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack shipping—for used trucks sourced from China. The analysis focuses on cost-efficiency, transit reliability, vehicle integrity, and corrosion protection, with an emphasis on operational suitability for fleet managers and construction firms. Additionally, the implementation of wax-based anti-corrosion treatments during export is assessed for long-term asset preservation.

1. Export Shipping Methods Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Loading) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Driven on/off vessel | Craned individually | Craned onto open-frame platform |

| Vehicle Condition | Operational (must be drivable) | Operational or non-operational | Any condition (incl. damaged) |

| Cargo Protection | Moderate (exposed to sea spray) | Low (direct exposure) | High (secured, customizable) |

| Handling Time (Port) | Fast (≤ 4 hrs) | Slow (8–12 hrs) | Moderate (6–8 hrs) |

| Average Cost (Per Truck) | $1,800 – $2,400 | $1,500 – $2,000 | $2,800 – $3,600 |

| Transit Time (China to US/EU) | 28–35 days | 30–40 days | 32–38 days |

| Insurance Complexity | Low | Medium | High |

| Best For | Fleet-ready, drivable units | High-volume, low-cost shipments | Oversized, non-drivable, or high-value trucks |

2. Method-Specific Analysis

2.1 RO-RO Shipping

- Advantages:

- Rapid loading/unloading reduces port demurrage.

- Minimal handling damage; vehicles driven directly off vessel.

- Ideal for fleets requiring immediate deployment.

- Limitations:

- Trucks must be operational (fuel ≥ 1/4 tank, functional brakes/steering).

- Limited protection from salt spray; corrosion risk elevated without treatment.

2.2 Bulk Cargo

- Advantages:

- Lowest per-unit cost; suitable for high-volume buyers.

- Accommodates non-operational units.

- Limitations:

- High exposure to seawater and weather; increased corrosion and physical damage risk.

- Extended port handling increases demurrage risk.

- Not recommended for premium or rust-sensitive models.

2.3 Flat Rack Containers

- Advantages:

- Full structural support; allows lashing and bracing.

- Compatible with cranes at non-RO-RO terminals.

- Optimal for trucks with modifications (e.g., crane booms, dump bodies).

- Limitations:

- Highest cost due to container and rigging requirements.

- Requires specialized port infrastructure.

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metal surfaces to chloride-laden aerosols, accelerating electrochemical degradation. To mitigate post-shipment corrosion, undercarriage and chassis wax spraying is strongly recommended prior to export.

3.1 Treatment Specifications

| Parameter | Requirement |

|---|---|

| Wax Type | Solvent-based, salt-displacing compound |

| Application Method | High-pressure spray (≥ 2,000 psi) |

| Coverage Areas | Frame rails, suspension mounts, fuel tanks, axle housings |

| Film Thickness | 80–120 microns (dual-coat application) |

| Drying Time | 4–6 hours (ambient 25°C) |

| Performance Standard | ASTM B117 Salt Spray Resistance (≥ 500 hrs) |

3.2 Efficacy by Shipping Method

- RO-RO: 70–80% corrosion risk reduction with wax treatment.

- Bulk Cargo: 60–70% reduction; supplemental plastic wrapping advised.

- Flat Rack: 85–90% reduction; wax + tarpaulin recommended.

Note: Wax treatment should be applied within 72 hours of vessel departure. Reapplication is advised after 6 months of operation in coastal zones.

4. Strategic Recommendations

| Use Case | Recommended Method | Rationale |

|---|---|---|

| High-volume fleet renewal (drivable) | RO-RO + Wax Spray | Fast turnaround, cost-effective, preserved drivability |

| Budget procurement (non-operational) | Bulk Cargo + Wax + Wrap | Lowest CAPEX; wax mitigates inherent exposure risk |

| Specialized/heavy-duty trucks | Flat Rack + Wax | Structural security, full corrosion protection, accommodates irregular loads |

5. Conclusion

For fleet managers and construction enterprises sourcing used trucks from China, RO-RO shipping combined with industrial-grade wax spraying offers the optimal balance of cost, speed, and asset protection. While Bulk Cargo presents short-term savings, long-term maintenance costs due to corrosion may offset initial gains. Flat Rack remains the premium solution for non-standard or high-value units.

Implementing standardized anti-corrosion protocols is non-negotiable for maximizing equipment lifecycle and minimizing downtime in coastal or high-humidity operational zones.

SEA LION International – Engineering Logistics for Industrial Durability

Version: ISR-2026-LOG-01 | Date: 2026-04-05

Get a Quote for Best Time To Buy A Used Truck

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]