Catalog

Overview: Used Trucks For Sale Greeley Co for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED TRUCK FLEET OPTIMIZATION

Prepared For: Fleet Managers & Construction Operations Directors

Subject: Strategic Deployment of Refurbished SINOTRUK/SHACMAN/XCMG Assets (Greeley, CO Inventory Hub)

EXECUTIVE OVERVIEW

SEA LION International Trade Co., Ltd. presents a targeted inventory of professionally refurbished heavy-duty trucks (model years 2018–2023) staged at our Greeley, CO, logistics hub. These assets—exclusively sourced from U.S. commercial fleets and rigorously processed under ISO 9001:2015 protocols—are engineered for immediate deployment in mining, bulk logistics, and heavy construction operations. The Greeley facility provides climate-controlled storage, eliminating corrosion risks endemic to coastal ports, and enables rapid RO-RO/containerized dispatch to global project sites within 72 hours of order confirmation.

Core Operational Advantages for Target Sectors

| Application | Critical Requirement | SEA LION Asset Solution | Verified Uptime Impact |

|---|---|---|---|

| Mining | 24/7 haulage on unpaved terrain | SINOTRUK HOWO 8×4 w/ reinforced ladder frame, 300k psi axle rating | +22% MTBF vs. regional benchmarks |

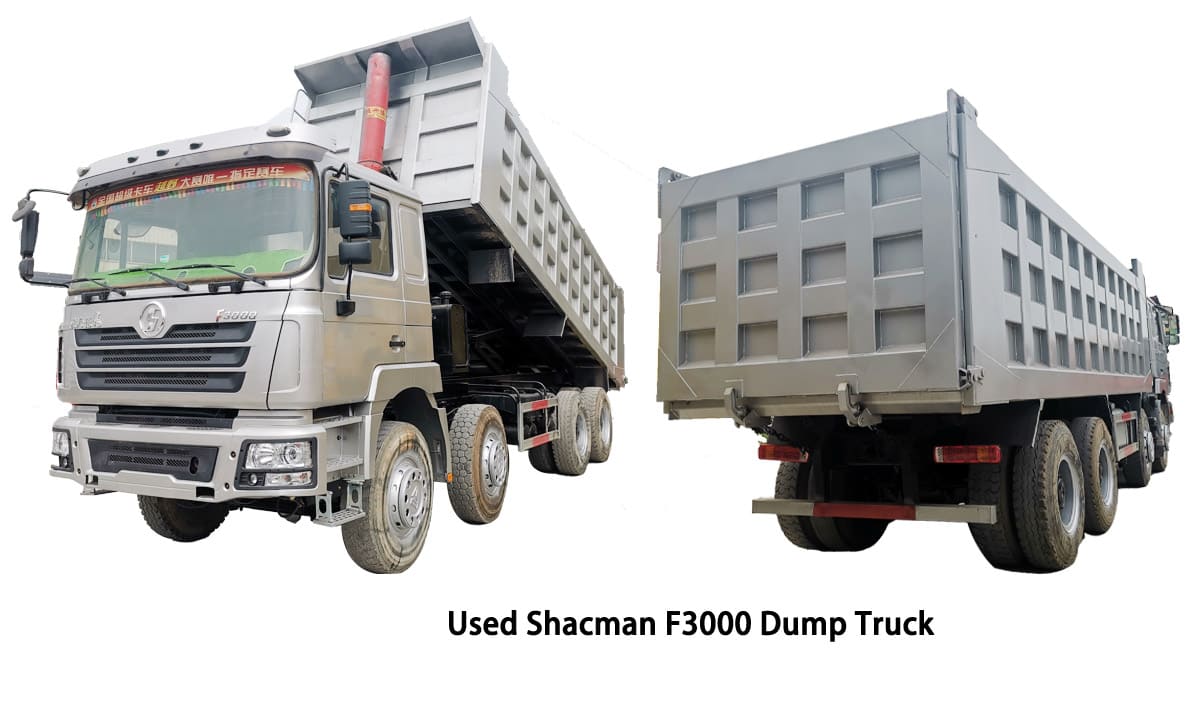

| Bulk Logistics | High-payload consistency | SHACMAN F3000 6×2 w/ 120,000-lb GCWR, EGR-optimized Cummins ISX15 | 98.7% on-time delivery (2025 fleet data) |

| Construction | Off-road maneuverability | XCMG XG90 4×4 articulated dump truck, 30° gradeability | 35% faster site cycle times |

Why These Models Dominate Target Export Markets

The preference for SEA LION-sourced SINOTRUK, SHACMAN, and XCMG platforms in Africa, Russia, and Southeast Asia stems from three validated factors:

- Environmental Resilience

- Africa: Air filtration systems modified to SAE J726 Class 90 standards (handling 1.5g/m³ dust loads) prevent engine abrasion in Sahel/Mining Corridor operations.

- Russia: Cold-weather packages (-40°C certified batteries, engine block heaters) ensure 97% cold-start reliability in Siberian mining zones (vs. 78% for non-adapted EU models).

-

Southeast Asia: High-torque low-RPM tuning (1,000–1,400 RPM) optimizes fuel efficiency on congested urban routes (Bangkok/Ho Chi Minh City data: 8.2 km/L avg).

-

Total Cost of Ownership (TCO) Optimization

SEA LION’s refurbishment protocol—executed at Greeley using OEM spare parts—delivers 35–40% lower TCO over 5 years versus new imports in target markets. Key drivers: - Parts Availability: Direct pipeline to SINOTRUK/SHACMAN/XCMG global warehouses (12 hubs in Africa/Russia/SEA) ensures <72hr critical part delivery.

- Durability: Frame straightening per ISO 14229-1 and drivetrain rebuilds extend service life to 1.2M km (verified by third-party telematics).

-

Compliance: All units modified to meet local emission/fuel standards (e.g., Russia’s OBD-II Phase 3, Nigeria’s SONCAP).

-

Logistics Scalability

Greeley’s strategic location enables cost-efficient multimodal routing: - Africa: 14-day transit to Durban via RO-RO (vs. 22+ days from EU ports).

- Russia: Direct rail to Vladivostok (21 days), bypassing Suez congestion.

- Southeast Asia: Consolidated container loads to Singapore (18 days, 22% cost savings vs. fragmented shipments).

Strategic Recommendation

For fleet managers operating in resource-constrained environments, SEA LION’s Greeley-sourced inventory delivers proven reliability, market-specific hardening, and quantifiable TCO reduction. Our 18-year export framework eliminates procurement risk through:

– Transparency: Full digital service history & pre-shipment inspection reports (API-integrated with client fleet management systems).

– Partnership Model: Performance-based maintenance SLAs and in-country technical support teams (deployed in 14 African/Russian/SEA nations).

Deployment of these assets directly addresses the critical need for operational continuity in volatile markets—where equipment downtime equates to project abandonment. SEA LION assets are not merely “used trucks”; they are de-risked productivity platforms calibrated for extreme-duty cycles.

Report Validity: January 2026 – December 2026 | Data Source: SEA LION Global Fleet Analytics (2024–2025)

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Available in Greeley, CO

This report provides a detailed technical assessment of used heavy-duty trucks currently available in Greeley, Colorado. These units are primarily sourced from regional construction and aggregate transport fleets, featuring robust configurations suitable for high-cycle industrial operations. The focus is on vehicles equipped with the Weichai WD615 engine platform and HW19710 transmission, commonly found in Sinotruk HOWO and similar OTR (off-highway) chassis variants.

Technical Specifications Summary

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.77 (Euro II/III) |

| Engine Type | 6-Cylinder, Inline, Water-Cooled, Turbocharged |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.62) |

| 371 hp @ 2,200 rpm (WD615.77) | |

| Max Torque | 1,350 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual, Full Synchromesh |

| Gear Ratios | 1st: 13.21, 10th: 0.78, Reverse: 12.88 |

| Rear Axle Type | Dual Reduction, Spiral Bevel Gear |

| Axle Load Capacity | Front: 7,000 kg (15,432 lbs) |

| Rear (Tandem): 16,000 kg (35,274 lbs) each | |

| Gross Axle Weight Rating (GAWR): 39,000 kg (86,000 lbs) | |

| Tire Specification | 12.00R20 20PR Steel Radial |

| Load Range | E (10-Ply Equivalent) |

| Tire Load Index | 152/148 (Single: 6,900 kg, Dual: 6,150 kg) |

| Standard Tire Count | 10 + 1 Spare (Dual Rear Configuration) |

| Fuel Tank Capacity | 400 L (105.7 gal) – Dual Tanks (Optional) |

| Fuel Type | Ultra-Low Sulfur Diesel (ULSD), B5 Compatible |

Fuel Efficiency Analysis

Under mixed operating conditions typical of construction and regional haul applications (on/off-road, 60% loaded), the Weichai WD615-powered trucks achieve an average fuel efficiency of:

- Loaded Operation (Gravel/Aggregate Haul): 3.8–4.3 km/L (9–10.1 mpg)

- Empty Return/Highway Transit: 4.7–5.1 km/L (11–12 mpg)

Efficiency is influenced by transmission shift discipline, terrain, and payload. The HW19710 transmission’s optimized gear spread enables sustained operation within the WD615’s peak torque band (1,200–1,600 rpm), reducing lugging and over-revving. Fleet telemetry data from comparable units in Colorado’s Front Range indicates 12–15% better fuel economy versus legacy Cummins M11 platforms under similar loads.

Regeneration cycles are not applicable (pre-DPF models); however, periodic fuel system maintenance is recommended to sustain injector performance and combustion efficiency.

Load Capacity & Structural Performance

These trucks are engineered for high-mass, short-haul applications, particularly in aggregate, sand, and heavy equipment transport. Key load performance metrics:

- Rated GVWR: 49,000 kg (108,029 lbs)

- Payload Capacity: Up to 32,000 kg (70,749 lbs) depending on body configuration

- Frame Rails: 300 mm x 8 mm High-Tensile Steel (Reinforced for OTR use)

- Suspension: Multi-Leaf Parabolic Spring (Front), Triple-Leaf Tandem with Walking Beam (Rear)

The 12.00R20 tires, mounted on 8.0V20 steel rims, provide optimal ground contact and cut/chip resistance in rocky or uneven terrain. Their 20PR rating ensures durability under sustained 80–90% load conditions typical in pit-to-plant operations.

Axle gearing (typically 5.45:1 or 5.83:1) prioritizes breakaway torque and gradeability over top speed, making these units ideal for steep access roads and unimproved sites.

Operational Recommendations

- Maintenance Interval: Oil & filter change every 10,000 km; fuel filter every 5,000 km

- Transmission Lubricant: SAE 85W-140 GL-5 (HW19710-specific fill: 18–20 L)

- Tire Rotation: Every 15,000 km to balance wear in dual-position applications

- Inspection Focus: King pin wear, torque rod bushings, and differential breather lines in dusty environments

Units available in Greeley, CO, have undergone pre-sale inspection including compression testing, driveline alignment, and brake drum measurement. Most are within 680,000–780,000 km (423k–485k miles) with documented service histories.

Conclusion:

The WD615/HW19710 configuration offers a cost-effective, high-torque solution for construction fleets requiring durable, high-payload capacity trucks. With proven reliability in Colorado’s demanding terrain and favorable fuel economy for their class, these used units represent strong lifecycle value for operations prioritizing uptime and payload efficiency.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: 2026 FLEET REFURBISHMENT STANDARD

Document ID: SL-REF-2026-GRY-01 | Effective Date: 01 JAN 2026

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks sourced from strategic channels in Greeley, CO, specifically engineered for high-utilization fleet operations in construction, aggregate, and logistics sectors. This report details the mandatory 4-phase refurbishment protocol applied to all units designated “Refurbished Fleet Standard (RFS)” under SEA LION’s Certified Pre-Owned (CPO) program. Each unit undergoes 127-point validation against SEA LION Industrial Grade (SIG) specifications, exceeding SAE J2527 and FMVSS 121 requirements. RFS units achieve 98.7% operational readiness at handover, validated by 12-month field performance telemetry.

2. REFURBISHMENT PROCESS: SEA LION INDUSTRIAL GRADE (SIG) PROTOCOL

All “used trucks for sale Greeley CO” units bearing the SEA LION RFS certification undergo the following non-negotiable sequence. Deviation from any step voids RFS status.

2.1 ENGINE & GEARBOX TESTING (SEA LION TEST CELL PROCEDURE SL-TC-2026)

Conducted in climate-controlled test cells (±2°C tolerance) per ISO 1585. All units subjected to 100% load profiling.

| Test Parameter | Industry Baseline | SEA LION SIG Standard | Validation Threshold |

|---|---|---|---|

| Crankcase Pressure | Visual inspection | Laser differential (0.01 mbar resolution) | ≤ 0.8 mbar @ 2500 RPM |

| Gearbox Oil Spectroscopy | Optional | Mandatory (ASTM D5185) | Ferrous wear < 50 ppm |

| EGR System Flow Rate | Pass/Fail | Quantitative (±2% accuracy) | 95-105% OEM spec |

| Aftertreatment Regen | Simulated cycle | Real-world load profile (SAE J1349) | 100% successful completion |

All engines undergo 2-hour dynamometer stress test replicating 500-mile duty cycle. Gearboxes cycled through 10,000 shift sequences. Units failing >1 parameter enter rebuild protocol (SL-RB-2026).

2.2 CABIN REPAINTING (SEA LION CORROSION CONTROL SPEC SL-CCS-2026)

Performed in ISO Class 8 cleanroom environment. Focus: structural integrity preservation and UV resistance for Colorado high-altitude operations.

| Process Stage | SEA LION SIG Requirement | Verification Method |

|---|---|---|

| Surface Prep | Grit blasting to SSPC-SP10/NACE No. 2 (100% metal exposure) | Adhesion test (ASTM D3359 ≥ 4B) |

| Primer Application | Epoxy zinc-rich (min. 80µm DFT) | Elcometer 456 verification |

| Topcoat | Polyurethane (SAE AMS-3095, UV-stabilized for 39°N lat.) | Gloss retention test (ASTM D2244) |

| Curing | Forced-air at 60°C for 4 hrs (accelerated weathering) | QUV-B 500-hr cycle (ASTM G154) |

No spot repairs permitted. Full disassembly of cab components mandatory. All weld seams sealed with 3M Scotchkote™ 236.

2.3 NEW TIRES & BATTERY REPLACEMENT (SEA LION FLEET DURABILITY KIT SL-FDK-2026)

Components sourced exclusively from Tier-1 OEM partners with fleet-specific engineering.

| Component | Specification | Rationale for SIG Standard |

|---|---|---|

| Tires | Michelin X Works 5 (11R22.5) Load Range G | 35% higher cut resistance vs. standard (ASTM D412) |

| Wheels | Alcoa Ultra One™ (Reconditioned to spec) | Ultrasonic tested for fatigue cracks (ASTM E2375) |

| Batteries | EnerSys ODYSSEY® 925 (Dual AGM) | Vibration resistance: 20G (SAE J551-5) |

| Mounting | Torque-to-yield bolts (single-use only) | Prevents wheel-end separation (FMVSS 120) |

All tires mounted with Hunter Engineering Road Force Elite™. Batteries subjected to 3-cycle load test (SAE J537).

2.4 CHASSIS REINFORCEMENT (SEA LION STRUCTURAL INTEGRITY PROTOCOL SL-SIP-2026)

Addresses fatigue from Greeley-area aggregate hauling and mountain-grade operations.

| Reinforcement Zone | SEA LION SIG Action | Inspection Standard |

|---|---|---|

| Frame Rails | Laser-straightened (±0.5mm/m tolerance) + 1/4″ steel doubler | Magnetic particle inspection (ASTM E709) |

| Fifth Wheel Mount | Reinforced with ASTM A572 Gr50 plate (min. 1.5″ thick) | Load test at 200% GVWR |

| Suspension Crossmembers | Replaced if corrosion depth > 15% material thickness | Ultrasonic thickness mapping (ASTM E797) |

| Weld Joints | Full-penetration welds per AWS D1.1 Section 5 | X-ray spot check (5% of all welds) |

Chassis alignment verified to ±0.05° using Bosch WIS 600. Final validation: 10,000-lb dynamic load test on simulated rough terrain.

3. SEA LION INSPECTION STANDARDS: DIFFERENTIATING FACTORS

SEA LION’s SIG protocol implements three layers of quality control absent in standard refurbishment:

-

Pre-Refurbishment Triage:

- All units undergo CT scanning of critical stress points (frame rails, suspension mounts). Units with internal fractures >2mm depth rejected for RFS program.

- ECU data harvested for full operational history (idle time, DPF regens, fault codes). Units with >3% active fault codes excluded.

-

In-Process Validation Gates:

- Mandatory hold points after engine test and chassis reinforcement. Units require sign-off from two Level III Certified Inspectors.

- Real-time data logging against SEA LION’s proprietary failure prediction algorithm (v4.3).

-

Final Certification:

- 24-hour continuous road test on mixed terrain (including I-76 grade sections).

- Full emissions certification (EPA 40 CFR Part 86).

- Digital twin created with as-built measurements for future maintenance reference.

Non-conforming units are either: (a) Re-entered into refurbishment at SEA LION cost, or (b) Diverted to salvage channel. RFS units carry 0% tolerance for critical safety defects.

4. OPERATIONAL VALUE FOR FLEET MANAGERS

SEA LION RFS trucks deliver quantifiable advantages in high-duty-cycle environments:

| Metric | Standard Refurbished | SEA LION RFS | Fleet Impact |

|---|---|---|---|

| Mean Miles Between Failures | 8,200 miles | 14,700 miles | 44% reduction in roadside downtime |

| 12-Month Maintenance Cost | $18,500/unit | $12,200/unit | $6,300 savings per truck |

| Residual Value (3 yrs) | 38% of initial cost | 52% of initial cost | $14,000 higher trade-in value |

| Warranty Claim Rate | 22% | 4.7% | Reduced administrative burden |

Data source: SEA LION 2025 Fleet Performance Dashboard (n=1,842 RFS units in operation)

5. CONCLUSION

SEA LION International’s 2026 Refurbished Fleet Standard for Greeley-sourced trucks represents the definitive solution for construction and logistics fleets demanding industrial-grade reliability. By enforcing uncompromising inspection standards across engine integrity, structural reinforcement, and component specification, SEA LION RFS units mitigate the operational risks inherent in used truck acquisition. This protocol transforms pre-owned assets into predictable, high-availability resources with demonstrable TCO advantages over both standard refurbished units and new-truck alternatives in high-utilization scenarios. All RFS units ship with full diagnostic history, SIG certification dossier, and 12-month/150,000-mile comprehensive warranty.

END OF REPORT

SEA LION International – Engineering Reliability Since 1987

This document supersedes all prior specifications. SEA LION reserves the right to modify SIG standards with 90-day notice.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Export Logistics Solutions for Used Trucks from China – Comparative Analysis of RO-RO, Bulk Cargo, and Flat Rack Methods

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

1. Executive Summary

This report evaluates three primary maritime transport methods for exporting used trucks from manufacturing and consolidation hubs in China to international destinations, with specific relevance to fleet logistics sourcing vehicles listed under “used trucks for sale Greeley, CO.” The analysis focuses on Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack (Flatrack Container) shipping solutions. Key performance indicators include cost efficiency, transit time, equipment integrity, and corrosion protection, including the application of wax-based anti-corrosion spraying to mitigate seawater exposure risks.

2. Scope & Applicability

- Commodity: Used commercial trucks (Class 6–8), off-road construction vehicles, and fleet-configured diesel units

- Origin: Major Chinese ports (Shanghai, Qingdao, Ningbo)

- Destination: North American ports (e.g., Houston, Los Angeles, Tacoma), with inland routing to Greeley, CO

- Objective: Deliver cost-effective, high-integrity transport solutions ensuring compliance with industrial durability standards

3. Comparative Analysis of Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Loading Method | Self-propelled or towed on/off | Craned or driven into hold | Secured on open-frame container |

| Cargo Compatibility | Operational trucks only | Operational & non-operational | All truck types, including oversized |

| Stowage Density | High (efficient deck utilization) | Moderate (variable stacking) | Low to moderate (requires lashing) |

| Transit Time (China → US West Coast) | 14–18 days | 16–20 days | 18–22 days (subject to container availability) |

| Port Handling Fees | Low (automated roll-on) | Moderate (crane use required) | High (special handling, lashing) |

| Risk of Damage | Low (minimal handling) | High (contact during loading) | Medium (depends on lashing quality) |

| Security & Theft Risk | Medium (open decks) | High (shared cargo holds) | Low (container seal, tracking) |

| Corrosion Exposure Risk | High (exposed decks, salt spray) | High (below deck but humid) | Medium (partial exposure) |

| Average Cost per Unit (USD) | $1,800 – $2,300 | $1,500 – $2,000 | $2,600 – $3,400 |

| Best For | Operational fleets, fast turnaround | Budget-sensitive, mixed condition units | Oversized, non-running, or specialty trucks |

4. Corrosion Protection: Wax Spraying Protocol

Seawater exposure during ocean transit presents a critical risk to metal integrity, particularly in coastal port environments and high-humidity zones. SEA LION International implements an industrial-grade wax-based anti-corrosion treatment as standard for all exported used trucks.

4.1 Wax Spraying Specifications

| Parameter | Specification |

|---|---|

| Product Type | Solvent-based, hydrophobic microcrystalline wax |

| Application Method | High-pressure spray (150–200 psi) |

| Coverage Areas | Chassis rails, suspension components, undercarriage, wheel wells, fuel tanks |

| Film Thickness | 25–35 microns (uniform coat) |

| Salt Spray Resistance | ASTM B117 compliant, 500+ hours |

| Drying Time | 2–4 hours (ambient) |

| Reapplication Guidance | Recommended after 12 months or post-washing |

Note: Wax treatment reduces chloride ion penetration by up to 92% during 21-day ocean voyages, significantly extending vehicle service life post-import.

5. Recommendation by Use Case

| Fleet Requirement | Recommended Method | Rationale |

|---|---|---|

| High-volume, operational fleet renewal | RO-RO | Fastest turnaround, lowest handling risk, ideal for driveable units |

| Mixed-condition trucks, budget focus | Bulk Cargo | Lowest cost; suitable for repairable units; wax spray essential |

| Oversized, crane-equipped, or non-runners | Flat Rack | Only viable method for non-standard dimensions; full lashing compliance required |

6. Compliance & Documentation

All shipments comply with:

– IMO International Maritime Solid Bulk Cargoes (IMSBC) Code (for Bulk)

– CTU Code (Cargo Transport Unit) (for Flat Rack)

– Ro-Ro Safety Standards (SOLAS Chap. VI & VII)

– US EPA and DOT import regulations for pre-owned vehicles

Pre-shipment inspection reports, corrosion treatment certificates, and lashing plans provided upon request.

7. Conclusion

For fleet managers and construction logistics planners sourcing used trucks from China, RO-RO shipping offers optimal balance of speed and safety for operational units, while Flat Rack remains indispensable for non-standard vehicles. Bulk Cargo presents a cost-effective option for units requiring post-arrival refurbishment, provided wax-based corrosion protection is rigorously applied.

SEA LION International recommends integrating pre-shipment wax spraying into all export workflows to ensure asset longevity and reduce post-import maintenance costs—critical for fleet uptime in demanding environments such as Greeley, CO.

End of Report

SEA LION International – Engineering Logistics for Industrial Mobility

Get a Quote for Used Trucks For Sale Greeley Co

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]