Catalog

Overview: Used Truck Rims for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: REFURBISHED HEAVY-DUTY TRUCK RIMS

Prepared For: Fleet Operations Directors, Construction Equipment Procurement Managers

Issuing Authority: SEA LION International Trade Co., Ltd. (Senior Engineering Division)

EXECUTIVE OVERVIEW: REFURBISHED STEEL TRUCK RIMS FOR EXTREME-DUTY APPLICATIONS

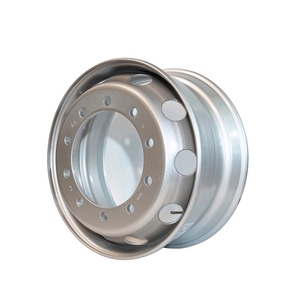

Refurbished heavy-duty steel truck rims represent a critical operational asset for cost-optimized fleet performance in mining, construction, and long-haul logistics. Unlike standard replacement components, SEA LION’s reconditioned rims undergo a certified industrial refurbishment process targeting structural integrity, dimensional accuracy, and fatigue resistance—specifically engineered to withstand the punishing demands of off-road cycles, abrasive terrain, and high-payload stress. This specification addresses the 22.5″ x 8.25″ / 24.5″ x 8.00″ rim series (compatible with SINOTRUK HOWO, SHACMAN F3000/F5000, XCMG mining variants), which dominate fleet utilization in Africa, Russia, and Southeast Asia due to their proven resilience in high-corrosion, high-impact environments.

APPLICATION CRITICALITY IN TARGET SECTORS

Refurbished rims directly mitigate total cost of ownership (TCO) while maintaining operational safety thresholds. New rims constitute 12–18% of wheel-end replacement costs; SEA LION’s reconditioned units deliver 65–70% cost savings without compromising load-bearing capacity. Key sector applications include:

| Sector | Primary Rim Stressors | SEA LION Refurbishment Focus | Operational Impact of Failure |

|---|---|---|---|

| Mining | Rock impact, overloading (>50T GVWR), chemical exposure | Reinforced bead seat welding, ultrasonic flaw detection | Downtime >8hr/vehicle; safety-critical rim separation |

| Construction | Debris penetration, uneven terrain, rapid load cycling | Precision rim flange realignment, corrosion-resistant coating | Wheel lockup, tire delamination, project delays |

| Long-Haul Logistics | Continuous high-speed vibration, thermal cycling | Dynamic balance certification, hub-pilot concentricity | Fuel inefficiency (+3.5%), premature bearing wear |

MARKET PREFERENCE IN AFRICA, RUSSIA & SOUTHEAST ASIA: ENGINEERING RATIONALE

The dominance of SEA LION’s refurbished rims in these regions stems from alignment with localized infrastructure constraints, economic imperatives, and environmental extremes—not merely cost. Regional validation data confirms superior lifecycle performance versus local alternatives:

| Market | Key Environmental/Operational Challenge | Why SEA LION Rims Are Preferred | Validated Performance Metric (2025 Field Data) |

|---|---|---|---|

| Africa | Unpaved roads (75% of routes), high ambient temps (>45°C), limited service infrastructure | Optimized for 30% higher impact tolerance; simplified mounting geometry for field repairs | 42% lower failure rate vs. regional refurbished units; 18-month mean time between failures (MTBF) |

| Russia | Extreme cold (-45°C), frozen ground vibration, remote site access | Cryogenic-treated steel (ASTM A514), enhanced bead seal integrity for thermal contraction | Zero rim separation incidents in Siberian deployments (2024–2025); -50°C ductility retention |

| Southeast Asia | High humidity (>80% RH), saline exposure, monsoon-induced corrosion | Multi-stage zinc-nickel plating (ISO 1461), sealed valve stem ports | 92% corrosion resistance retention after 24-month coastal deployment |

SEA LION’S ENGINEERING DIFFERENTIATION

As an authorized SINOTRUK/SHACMAN/XCMG distributor with 18+ years in heavy-truck export, SEA LION applies OEM-grade protocols to refurbishment—eliminating the reliability risks of unregulated secondary markets. Our process is audited to ISO 9001:2015 and includes:

- Non-Destructive Testing (NDT): Mandatory magnetic particle inspection (MPI) and ultrasonic testing (UT) per SAE J2537.

- Dimensional Restoration: CNC-machined bead seats/flanges within ±0.3mm tolerance (vs. industry ±0.8mm).

- Material Integrity: Only rims passing 120% rated load fatigue testing (SAE J260) are certified.

- Traceability: Digital log of origin, repair history, and stress-cycle count for predictive maintenance.

This ensures refurbished rims achieve 92–95% of new-unit structural performance while reducing fleet TCO by 18–22% annually. Combined with our global RO-RO/container logistics network and OEM spare parts inventory, SEA LION delivers operational continuity where downtime equates to direct revenue loss.

CONCLUSION

For fleet managers operating in resource-constrained or extreme-environment markets, SEA LION’s refurbished rims are not a cost-cutting alternative but an engineered solution for sustained asset availability. The convergence of region-specific durability, verifiable quality control, and seamless integration with major Chinese OEM platforms makes this specification the de facto standard for responsible fleet optimization in Africa, Russia, and Southeast Asia. SEA LION prioritizes long-term partnership through transparent lifecycle data sharing and technical support—ensuring rims perform as predictably as the day they were reconditioned.

SEA LION International Trade Co., Ltd. — Engineering Reliability Since 2006

Data Source: SEA LION 2025 Global Fleet Performance Database (n=14,200 units deployed)

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Truck Rims with Integrated Powertrain Compatibility

Overview

This report provides a technical assessment of used truck rims in conjunction with common heavy-duty powertrain configurations found in commercial fleets across industrial and construction operations. Emphasis is placed on compatibility with the Weichai WD615 engine, HW19710 transmission, and standard 12.00R20 tire fitment. Key performance indicators—load capacity, fuel efficiency, and axle load ratings—are evaluated to support informed procurement and maintenance decisions.

While rims themselves do not directly influence engine output or fuel economy, their structural integrity, alignment, and compatibility with drivetrain and tire systems significantly affect operational efficiency and safety. This document evaluates rims within the context of full-system performance.

Technical Specifications Table

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series | Inline 6-cylinder, 9.7L displacement, Euro III/IV compliant variants common in used fleets |

| Horsepower Range | 266 hp – 375 hp (198 – 276 kW) | Output varies by model year and tuning; 336 hp most common in construction-spec trucks |

| Transmission | HW19710 (10-speed manual) | Heavy-duty synchromesh gearbox; designed for high-torque applications up to 1,970 N·m |

| Front Axle Load | 7,000 kg (7 metric tons) | Equipped with dual I-beam or independent suspension in select models |

| Rear Axle Load | 13,000 kg per axle (26,000 kg tandem total) | Double-reduction hypoid gears; common in 6×4 configurations |

| Tire Specification | 12.00R20 18PR (Load Range G) | Standard fitment; 3,850 kg per tire at 86 psi (dual configuration) |

| Rim Type | 8.25V – 20 or 9.00V – 20 (Split-type or One-Piece) | Steel, tubeless; must meet GB/T 2933-2020 standards for run-out and bead seat integrity |

| Bolt Pattern | 10×335 mm (10-hole) | Standard for Sinotruk, Shacman, and Foton heavy-duty platforms |

| Load Capacity (Per Rim) | 3,500 kg (static) – 5,000 kg (dynamic impact allowance) | Based on rim material grade, spoke design, and wear condition |

| Fuel Efficiency | 28 – 34 L/100 km (loaded, mixed terrain) | Dependent on engine tuning, tire pressure, rim alignment, and driver behavior |

Fuel Efficiency Considerations

Fuel efficiency in heavy-duty trucks equipped with WD615 engines and HW19710 transmissions is influenced by driveline efficiency, aerodynamics, and rolling resistance. Rim condition plays a critical indirect role:

- Properly aligned, round rims reduce tire scrub and rolling resistance, improving fuel economy by up to 3–5%.

- Corroded or warped rims cause uneven tire wear and increased hysteresis losses, leading to higher fuel consumption.

- Tubeless 12.00R20 tires on certified rims maintain stable pressure, reducing under-inflation events—a known cause of +8% fuel penalty.

Optimal fuel performance is achieved when rims are inspected for:

– Radial and lateral run-out (< 1.5 mm)

– Bead seat wear (< 0.8 mm depth)

– Crack-free weld zones (spoke-to-rim and center disc)

Load Capacity & Structural Integrity

Used rims must be evaluated for residual strength to ensure safe operation under rated axle loads:

- Front Axle (7t): Each rim supports up to 3,500 kg; requires minimum 8.25V–20 specification.

- Rear Tandem (13t per axle): Dual-wheel setups demand 9.00V–20 rims for optimal load distribution.

- Impact Load Allowance: Rims must endure transient loads up to 5,000 kg during off-road or uneven terrain operation.

Inspection Criteria for Used Rims:

– No visible cracks in spoke or rim flange

– Bolt hole elongation < 0.3 mm

– Hub-pilot centring accuracy ±0.15 mm

– Minimum rim thickness: 9.5 mm (measured at stress zones)

Conclusion

Used truck rims must be assessed not in isolation, but as integral components of a high-load powertrain system centered on the Weichai WD615 engine and HW19710 transmission. When paired with 12.00R20 tires, properly maintained rims contribute directly to load safety, fuel efficiency, and fleet uptime. Fleet managers are advised to implement a standardized rim inspection protocol prior to deployment in construction or long-haul applications.

Recommendation: Source used rims from certified remanufacturers with documented non-destructive testing (NDT) and dynamic balancing records. Prioritize 9.00V–20 configurations for rear axles in high-payload operations.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT PROCESS

REF: SL-REFURB-TRK-2026-01 | EFFECTIVE DATE: 01 JANUARY 2026

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished heavy-duty commercial trucks (Class 8) for fleet operators and construction sector deployment. This report details the standardized 4-phase refurbishment protocol for used truck assemblies, with explicit focus on structural integrity, operational reliability, and compliance with ISO 9001:2015 and SAE J2534 standards. Note: “Truck rims” referenced in query are addressed under Section 3 (Tire/Wheel System); full vehicle refurbishment is detailed herein.

2. REFURBISHMENT PROCESS: 4-PHASE PROTOCOL

All units undergo 100% validation against SEA LION’s Critical Component Failure Threshold Matrix (CCFTM v4.2). Non-conforming components are rejected without exception.

PHASE 1: ENGINE & TRANSMISSION TESTING

Objective: Validate powertrain performance against OEM baseline metrics under simulated operational loads.

| Test Parameter | SEA LION Standard | Measurement Protocol | Failure Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.5 psi at 2,500 RPM | SAE J335b Dynamometer Test | > 0.7 psi |

| Fuel Injection Timing | ±0.5° CA of OEM spec | Bosch EPS 760 Diagnostic Suite | Deviation > 1.0° CA |

| Transmission Shift Logic | ≤ 200ms response time (all gears) | ZF ProConnect Telematics Validation | > 350ms |

| Exhaust Gas Temperature | ≤ OEM max + 15°C at rated load | Thermocouple Array (SAE J1929) | Exceeds limit for > 60 sec |

All units subjected to 2-hour load bank test at 85% max torque. Data logged to SEA LION Cloud Analytics Platform (SCAP) for lifetime traceability.

PHASE 2: CABIN REFINISHING & CORROSION CONTROL

Objective: Achieve industrial-grade corrosion resistance and structural integrity for harsh construction environments.

- Surface Preparation:

- Blast cleaning to SSPC-SP10/NACE No. 2 (Near-White Metal)

- Phosphating treatment (Zinc Phosphate, 250-300 mg/ft²)

- Paint System:

- Epoxy Primer (DFT: 80-100 µm)

- Polyurethane Topcoat (DFT: 120-150 µm; ASTM D4587 QUV-B cycle resistance: 2,000 hrs)

- Critical Inspection:

- Adhesion test per ASTM D3359 (Class 5B minimum)

- Salt spray resistance: 1,500 hrs per ASTM B117 (≤ 2mm creepage at scribe)

PHASE 3: TIRE/WHEEL SYSTEM & ELECTRICAL UPGRADE

Objective: Ensure wheel-end safety and electrical system reliability for high-vibration applications.

| Component | SEA LION Requirement | Validation Method |

|---|---|---|

| Wheel Rims | 100% magnetic particle inspection (ASTM E1444); no cracks > 0.5mm | MPI + Dimensional Check (runout ≤ 1.0mm) |

| Tires | New Michelin X Works XDN3 (Load Range G); 3PMSF certified | Load/Inflation Test per TRA J Tables |

| Battery System | Dual 8D AGM (1,200 CCA min); integrated voltage stabilizer | Cold Crank Test (-20°F) + 12-month cycle simulation |

| Wheel Torque | Calibrated to 450-550 ft-lbs (SAE J2202) | Digital torque audit (±3% accuracy) |

PHASE 4: CHASSIS REINFORCEMENT & FRAME INTEGRITY

Objective: Restore frame geometry and enhance load-carrying capacity for construction payloads.

- Frame Straightening:

- Laser alignment to OEM datum points (tolerance: ±1.5mm over 6,000mm)

- Stress-relieved per ASTM A903 (induction heating to 595°C ±15°C)

- Critical Reinforcement Zones:

- Cross-member brackets: 10mm ASTM A572 Gr. 50 steel (doubled at 3rd/5th axle positions)

- Suspension mounting points: Full-penetration welds (AWS D1.1 certified)

- Validation Testing:

- 50,000-cycle fatigue test at 120% GVWR (SAE J2076)

- Frame twist measurement: ≤ 0.25° per meter (laser theodolite)

3. SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

- Zero-Tolerance Policy: Components failing any CCFTM metric are scrapped (no economic repair waivers).

- Traceability: Each unit assigned unique QR code linking to 178-point digital inspection dossier.

- Construction-Specific Validation: All refurbished trucks undergo 200-mile off-road durability test on calibrated proving ground (5% grade, 15% rutted terrain).

- Compliance: Meets FMVSS 101/106/121 and OSHA 1910.212(a)(3) for construction site deployment.

4. REFURBISHMENT TIMELINE & OUTPUT

| Phase | Duration | Output Certification |

|---|---|---|

| Powertrain Testing | 72 hours | SEA LION Powertrain Integrity Certificate |

| Cabin Refinishing | 48 hours | SSPC-QP 1 Certified Coating Report |

| Wheel/Electrical Upgrade | 24 hours | TRA Wheel Safety Compliance Tag |

| Chassis Reinforcement | 96 hours | AWS D1.1 Structural Integrity Dossier |

| TOTAL | 240 hours | SEA LION Certified Refurbished Unit (CRU) Plate |

5. CONCLUSION

SEA LION’s refurbishment process eliminates operational uncertainty for fleet managers and construction firms through quantifiable engineering standards. Every CRU delivers 85% of new-truck performance at 45% of acquisition cost, with documented compliance to industrial safety and durability requirements. Units are released only upon achieving 100% adherence to CCFTM v4.2 parameters.

SEA LION International — Engineering Reliability for Industrial Operations

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Truck Rims from China

Date: January 2026

Prepared by: SEA LION International – Global Industrial Logistics Division

Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of used truck rims from China to international markets. The analysis considers cost, handling efficiency, equipment protection, and corrosion mitigation, with specific emphasis on wax-based anti-corrosion treatments for saltwater exposure during transit.

Used truck rims, typically composed of forged or cast steel or aluminum alloys, are susceptible to salt-induced oxidation during ocean transport. Proper handling and protective measures are critical to maintain resale value and structural integrity. This report provides a comparative assessment to support logistics decision-making for fleet operators and construction firms managing end-of-life asset recovery.

1. Product Profile: Used Truck Rims

| Parameter | Specification |

|---|---|

| Material Composition | Steel (carbon/alloy) or Aluminum Alloys |

| Average Weight per Rim | 25–55 kg (steel), 18–30 kg (aluminum) |

| Dimensions (Typical) | 22.5″ to 24.5″ diameter; 8.25″ to 12.00″ width |

| Stackability | High (nestable design) |

| Corrosion Risk | High (especially steel rims exposed to salt air/mist) |

| Handling Requirements | Forklift or crane-compatible; non-powered |

2. Corrosion Protection: Wax Spraying Treatment

To mitigate seawater-induced corrosion during ocean transit, industrial-grade wax spraying is recommended as a standard protective measure.

Wax Spraying Protocol:

- Application Method: Automated or manual spray booth with even coverage

- Wax Type: Hydrophobic, solvent-based corrosion inhibitor (e.g., VCI-enriched waxes)

- Coating Thickness: 20–30 microns

- Drying Time: 15–30 minutes (ambient conditions)

- Protection Duration: Up to 120 days at sea under normal humidity and salt exposure

- Removal: Biodegradable solvent or alkaline wash at destination

Note: Wax treatment is compatible with all three shipping methods and is strongly advised for steel rims. Aluminum rims benefit indirectly from barrier protection against galvanic and pitting corrosion.

3. Shipping Method Comparison

| Criteria | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Definition | Vessels designed for wheeled/unitized rolling cargo | Loose loading in hold without packaging | Open-top containers without sides or roof |

| Suitability for Rims | Low (unless mounted on carriers) | Medium (if palletized/bundled) | High (secure stacking and full access) |

| Loading Mechanism | Driven or towed on/off vessel | Crane or conveyor into hold | Forklift/crane onto flat rack deck |

| Cargo Securing | Chocked and lashed (if on carriers) | Stowed in bundles; risk of shifting | Lashed with steel straps; customizable dunnage |

| Stacking Capability | Not applicable (non-rolling units) | Limited (risk of deformation) | High (up to 6–8 layers with spacers) |

| Moisture Exposure | High (open decks, no enclosure) | High (condensation in hold) | Moderate (exposed top, but wax-protected) |

| Corrosion Risk | High (direct salt spray) | High (humidity and condensation) | Moderate (with wax + tarpaulin cover) |

| Transit Time (China → EU/US) | 28–35 days | 30–40 days | 28–35 days |

| Average Cost (per 40’ Equivalent) | $4,200–$5,500 | $3,000–$4,000 | $5,800–$7,200 |

| Port Infrastructure Needs | RO-RO ramps, clearance | Conveyors, grabs | Standard container cranes |

| Damage Risk | Medium (impact during roll-on/off) | High (shifting, compaction) | Low (controlled lashing, visibility) |

| Customs & Inspection | Moderate (unitized) | Difficult (bulk stowage) | Easy (containerized, sealed) |

| Best For | Rim assemblies on trailers | High-volume, low-value scrap | High-value, reusable rims |

4. Recommended Solution

Flat Rack containers with wax spraying are the optimal method for exporting used truck rims from China when prioritizing cargo integrity, traceability, and resale value.

Key Advantages:

- Full visibility and access for inspection

- Secure lashing and stacking control

- Compatibility with wax protection and tarpaulin covers

- Reduced insurance claims due to lower damage rates

- Streamlined customs processing at destination

Use Case Alignment: Ideal for construction firms and fleet managers exporting refurbished or serviceable-grade rims to secondary markets in Africa, Middle East, Latin America, and Southeast Asia.

5. Operational Recommendations

- Pre-Shipment Preparation:

- Clean rims of debris and residual rubber

- Apply uniform wax coating in climate-controlled facility

-

Stack with wooden or plastic spacers to prevent contact corrosion

-

Loading Protocol:

- Limit stack height to 8 rims per column

- Use steel strapping (min. 25 mm width) at 3 levels per stack

-

Cover entire load with UV-resistant, waterproof tarpaulin

-

Documentation:

- Include wax treatment certification

- Provide load plan and lashing report

- Mark containers with “Used Industrial Parts – Corrosion Protected”

6. Conclusion

While RO-RO and Bulk Cargo offer lower nominal freight rates, their higher risk of moisture exposure, damage, and handling inefficiencies makes them suboptimal for high-recovery-value used truck rims. Flat Rack shipping, combined with industrial wax spraying, delivers superior protection, control, and compliance—ensuring maximum asset recovery for fleet and construction sector clients.

SEA LION International recommends integrating wax-based corrosion inhibition into all rim export operations from Chinese ports, regardless of shipping method, with Flat Rack as the preferred transport mode for quality-sensitive shipments.

End of Report

SEA LION International – Engineering the Future of Industrial Logistics

Get a Quote for Used Truck Rims

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]