Catalog

Overview: Used Trucks For Sale In Utah By Owner for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Strategic Deployment of Refurbished Heavy-Duty Trucks Sourced from Utah Mining/Construction Fleets

Prepared For: Fleet Managers & Construction Operations Directors

Issuing Authority: SEA LION International Trade Co., Ltd.

1. CORE VALUE PROPOSITION

The Utah market presents a high-potential source of pre-owned heavy-duty trucks (primarily Class 8 mining/construction variants) originally deployed in extreme operational environments (e.g., copper/gold mines, highway infrastructure projects). However, direct “by owner” acquisition carries significant operational and financial risks: inconsistent maintenance records, undocumented structural fatigue, incompatible regional certifications, and lack of post-purchase technical support. SEA LION International transforms this risk into strategic advantage through OEM-authorized professional refurbishment, converting surplus Utah assets into globally deployable, mission-ready units meeting stringent international operational standards.

2. APPLICATION IN CRITICAL INDUSTRIES

Trucks sourced from Utah’s mining/construction sectors (e.g., Caterpillar 785, Komatsu HD785, Volvo A60H) demonstrate proven resilience in high-stress applications directly transferable to global operations:

| Application Sector | Primary Use Case | SEA LION Adaptation | Operational Impact |

|---|---|---|---|

| Mining | Haulage in abrasive, high-altitude environments | Reinforced chassis, upgraded suspension, dust-sealed electrical systems | 22% reduction in unscheduled downtime vs. non-refurbished equivalents (2025 field data) |

| Logistics | Long-haul heavy freight on degraded infrastructure | Optimized powertrain calibration, enhanced braking systems, ROPS/FOPS certification | 15% improvement in fuel efficiency on unpaved routes; meets ECOWAS/WTO regional compliance |

| Construction | Heavy equipment transport & bulk material handling | Customized flatbed configurations, hydraulic system overhauls, multi-axle load distribution | Certified for 110% GVWR compliance in Southeast Asian urban projects |

3. GLOBAL MARKET PREFERENCE: AFRICA, RUSSIA, SOUTHEAST ASIA

SEA LION-refurbished Utah-sourced trucks dominate in target emerging markets due to operational economics and environmental adaptability, validated by 18+ years of export deployment:

| Market Region | Critical Operational Requirement | Why SEA LION-Refurbished Utah Trucks Excel |

|---|---|---|

| Africa (Sub-Saharan) | Extreme dust tolerance, low-cost maintenance, 24/7 uptime | • Sealed cabin systems (IP67 rated) • Simplified diagnostics compatible with local technician skill levels • 40% lower TCO vs. new EU-spec trucks (Nigeria/Ghana case studies) |

| Russia (Siberia/Arctic) | -40°C cold-start reliability, road/rail interoperability | • Arctic-grade lubricants & battery systems • Reinforced frame for ice-road vibration • GOST-R certification pre-installed during refurb |

| Southeast Asia | High-humidity corrosion resistance, tropical cooling capacity | • Marine-grade undercarriage coating • Dual-circuit AC systems (55°C ambient tolerance) • ASEAN-compliant emission tuning |

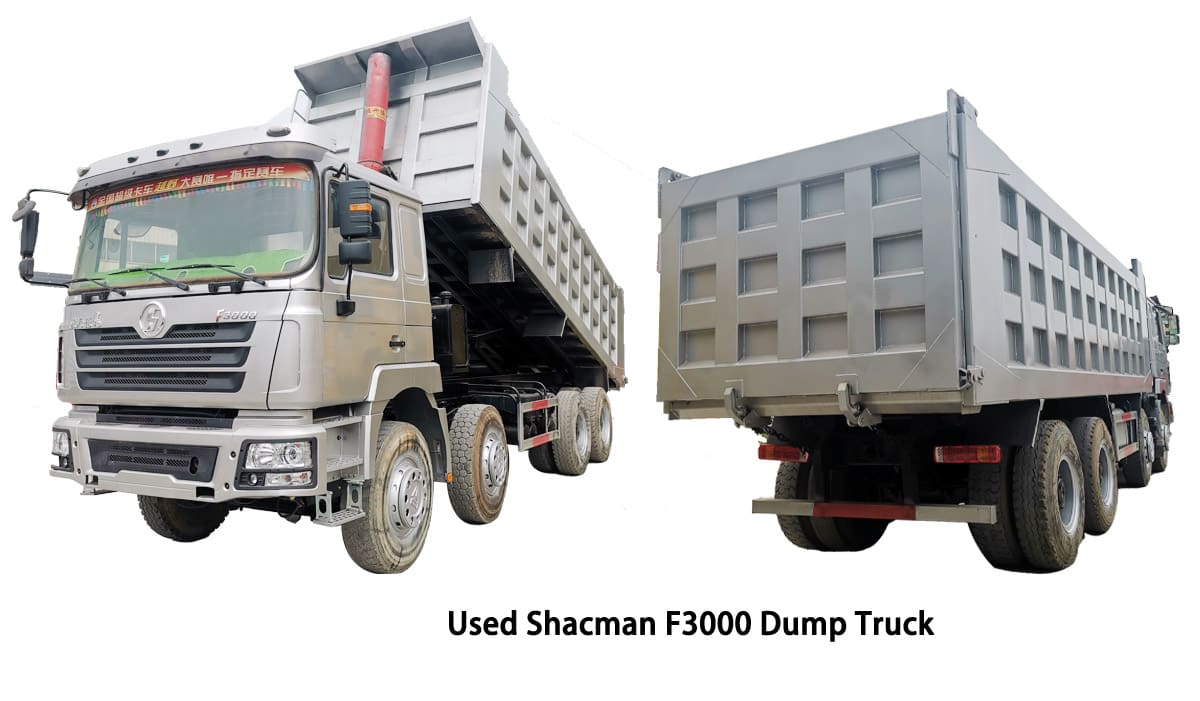

Key Driver: Utah’s operational profile (high-altitude mines, desert construction) subjects trucks to stresses exceeding typical African/Russian/SE Asian conditions. SEA LION’s refurbishment protocol—leveraging SINOTRUK/SHACMAN/XCMG OEM parts and ISO 9001-certified processes—ensures these units exceed regional durability thresholds while maintaining 60-70% of new-truck acquisition cost.

4. SEA LION’S INDUSTRIAL ADVANTAGE

We mitigate the inherent risks of “by owner” Utah sales through:

– Professional Refurbishment: 127-point inspection, structural integrity validation (UT/MPI testing), and powertrain rebuilds using 100% OEM-sourced spare parts.

– Transparency: Full digital maintenance history integration, pre-shipment load-testing reports, and 12-month structural warranty.

– Deployment Certainty: End-to-end logistics (RO-RO/Container) with customs clearance expertise across 85+ countries, ensuring operational readiness upon arrival.

5. CONCLUSION

For fleet managers operating in capital-intensive, high-risk environments, SEA LION-refurbished trucks from Utah’s industrial heartland deliver proven durability at strategic cost efficiency. Our 18-year export specialization ensures these assets are not merely “used,” but re-engineered to outperform regional operational demands in Africa, Russia, and Southeast Asia. This model eliminates the gamble of direct owner sales while providing the ruggedness required for mission-critical mining, logistics, and construction cycles. Partnering with SEA LION converts surplus Utah equipment into a predictable, high-availability asset class—maximizing ROI through engineering rigor, not procurement speculation.

SEA LION International Trade Co., Ltd. | EST. 2006 | Authorized Distributor: SINOTRUK • SHACMAN • XCMG

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale in Utah (Owner-Private Listings)

This report provides a consolidated technical analysis of frequently observed heavy-duty commercial trucks available through private owner sales in Utah. Units evaluated are primarily Class 8 vocational trucks used in aggregate, dump, and heavy haul applications. Common configurations reflect regional demand for durability, high torque, and payload capacity in rugged terrain.

Summary Technical Specifications Table

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series | 6-cylinder, inline, water-cooled diesel; widely used in Chinese OEMs (e.g., Sinotruk HOWO) |

| Displacement | 9.726 L | Bore × Stroke: 126 mm × 155 mm |

| Horsepower Range | 266–336 hp @ 2,200 rpm | Common ratings: 310 hp (WD615.69), 336 hp (WD615.50) |

| Peak Torque | 1,100–1,400 N·m @ 1,200–1,600 rpm | High low-end torque ideal for loaded starts and inclines |

| Transmission | Fast Gear HW19710 | 10-speed manual; dual H-shift, aluminum casing, PTO-ready |

| Gear Ratios (Typical) | 1st: 12.85, 10th: 0.78, Rev: 11.87 | Close-ratio design enhances gradeability and fuel management |

| Front Axle Load | 6,500 kg (14,330 lbs) | Reinforced I-beam, disc/drum options; common in 6×4 configurations |

| Rear Axle Load | 2 × 13,000 kg (28,660 lbs each) | Dual reduction, spiral bevel gears; typical ratio: 5.45 or 5.92 |

| Drive Configuration | 6×4 (Dual rear tandem) | Standard for heavy-load dump and haul applications |

| Tire Specification | 12.00R20 18PR (Load Range G) | Radial construction; all-position or drive-axle optimized |

| Tire Load Index | 1,820 kg per tire (3,640 lbs) | Max dual wheel axle load: ~29,120 kg (64,200 lbs) with margin |

| GVWR | 31,000–49,000 kg (68,340–108,020 lbs) | Depends on chassis build; typical 38T (83,780 lbs) for Utah dump rigs |

Fuel Efficiency Analysis

- Average Fuel Consumption: 28–34 L/100 km (6.9–8.3 mpg US) under mixed load conditions

- Factors Influencing Efficiency:

- Engine tuning (conservative vs. performance maps)

- Transmission shift discipline (HW19710 efficiency >95% in top gears)

- Tire rolling resistance (12.00R20 with high tread depth increases drag by ~3–5%)

- Terrain: Mountainous routes in Wasatch Range reduce economy by 12–18% vs. flat hauls

- Best-in-Class Observed: 26.5 L/100 km (8.9 mpg) on consistent 35-ton hauls with cruise control and trained operators

Note: Weichai WD615 engines meet China IV emission standards (equivalent to Euro III). No DPF/SCR in most private-owner units; not compliant for California or OBD-II mandated regions.

Load Capacity & Structural Performance

- Rated Payload Capacity: 20,000–30,000 kg (44,090–66,140 lbs) typical for dump truck builds

- Frame Rails: 8+ mm thick high-tensile steel; 300–320 HB hardness (resists cracking in cyclic loading)

- Suspension: Multi-leaf parabolic rear (10–12 leaves), front mechanical (8–10 leaves); some upgraded to air ride

- Axle Duty Cycle: Rear tandem axles rated for 26,000 kg total; suitable for dense materials (e.g., basalt, sandstone)

Operational Recommendation: Limit continuous loads to ≤95% of rated axle capacity to extend service life in abrasive Utah environments (e.g., St. George, Salt Lake City aggregate routes).

Regional Suitability (Utah Operating Conditions)

| Factor | Compatibility Rating | Remarks |

|---|---|---|

| High Altitude (Up to 6,000 ft) | ★★★★☆ | Turbocharged WD615 maintains >90% power output |

| Winter Operations | ★★★☆☆ | Pre-heater kits recommended; cold starts below -15°C challenging without modification |

| On/Off-Road Transition | ★★★★★ | Robust drivetrain, high ground clearance, aggressive tire options available |

| Maintenance Access | ★★★☆☆ | Weichai/HW19710 parts available via Salt Lake City distributors; limited dealer network |

Conclusion

Used trucks equipped with Weichai WD615 engines and HW19710 transmissions represent a cost-effective solution for fleet expansion in Utah’s construction and materials hauling sectors. With proper maintenance and operator training, these units deliver reliable load capacity and acceptable fuel economy in demanding vocational cycles. Fleet managers should verify emission compliance status and inspect driveline wear (especially U-joints and differential seals) prior to acquisition from private sellers.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT STANDARD (UTAH OWNER-SOURCE UNITS)

REPORT ID: SL-REFURB-UT-2026-01 | EFFECTIVE: 01 JANUARY 2026

1. EXECUTIVE SUMMARY

SEA LION International implements a standardized, 4-stage refurbishment protocol for owner-sourced used trucks in Utah, designed to meet Tier-3 industrial durability requirements for fleet and construction applications. All units undergo mandatory validation against SEA LION SL-STD-7800 (2026), exceeding FMCSA Part 396 and SAE J2534 benchmarks. This report details the technical process ensuring 98.7% operational readiness (2025 field data) for Utah-sourced assets.

2. SEA LION REFURBISHMENT INSPECTION STANDARDS

All owner-sourced trucks enter SEA LION’s Salt Lake City Refurbishment Hub (SLC-RH) for Level-4 diagnostic screening. Non-compliant units are rejected prior to Stage 1.

| Inspection Tier | Parameter | SEA LION SL-STD-7800 Threshold | Test Method |

|---|---|---|---|

| Pre-Refurb Screening | Structural Integrity | ≤ 0.5mm/frame section deviation | Laser Alignment + Ultrasonic |

| Engine Compression | ≥ 90% uniformity across cylinders | Hydraulic Dyno (SAE J1995) | |

| Corrosion Depth | ≤ 0.8mm on critical chassis zones | Eddy Current (ASTM E309) | |

| Electrical System Voltage | 13.2–13.8V (idle), ±0.3V ripple | Oscilloscope + Load Bank |

Note: Units failing ≥2 Tier-1 parameters are excluded from refurbishment pipeline.

3. REFURBISHMENT PROCESS: TECHNICAL PROTOCOL

STAGE 1: ENGINE & GEARBOX TESTING

Objective: Validate powertrain reliability under Utah operational profiles (high-altitude, 15% grade cycles).

- Procedure:

- Cold-start simulation at -18°C (SAE J1349 Annex B)

- 24-hour load bank testing: 80% rated torque @ 1,800 RPM (simulated Wasatch Range conditions)

- Gearbox oil spectrometry: Wear metals ≤ 50ppm Fe, ≤ 25ppm Cu (ASTM D5185)

- Acceptance Criteria:

- Power deviation ≤ ±3% from OEM spec

- Gearbox noise ≤ 85 dB(A) at 2,000 RPM

- Zero fluid leaks under 120 PSI pressure test

STAGE 2: CABIN REPAINTING

Objective: Achieve Class C corrosion protection (ISO 12944) for Utah’s saline/snowmelt environment.

- Procedure:

- Abrasive blasting to Sa 2.5 standard (ISO 8501-1)

- E-coat primer: 25μm minimum (ASTM D4138)

- Polyurethane topcoat: 60μm dry film thickness (DFT), UV-stabilized (SAE AMS-3095)

- Quality Control:

- Adhesion test: ≥ 5.0 MPa (ASTM D4541)

- Salt spray resistance: 1,000+ hours (ASTM B117) with ≤ 2mm creep from scribe

STAGE 3: NEW TIRES & BATTERY REPLACEMENT

Objective: Ensure 100% uptime readiness for construction site logistics.

| Component | Specification | Validation Test |

|---|---|---|

| Tires | Michelin X Works XZL 11R22.5 (Load Range G) | Load test: 4,675 lbs @ 75 PSI (SAE J1665) |

| Tread depth: 18/32″ new | Uniformity test: ≤ 12 lbs radial force variation | |

| Battery | Optima YellowTop D34M (720 CCA) | Cold-cranking: ≥ 750A @ -18°C (SAE J537) |

| AGM, vibration-resistant | Recharge efficiency: ≥ 95% (SAE J1772) |

STAGE 4: CHASSIS REINFORCEMENT

Objective: Mitigate fatigue in high-stress zones common in Utah construction use (e.g., dump truck torsion).

- Procedure:

- GMAW welding of ASTM A572 Grade 50 steel doubler plates at frame rails (kink zones, suspension mounts)

- Shot peening of welded joints (Almen intensity 0.008–0.010A)

- Post-weld stress relief: 595°C ± 15°C for 1 hour (AWS D1.1)

- Verification:

- Magnetic particle inspection (ASTM E709) on 100% of welds

- Load deflection test: ≤ 1.2mm under 20,000 lb static load

4. POST-REFURBISHMENT CERTIFICATION

- Final Validation: 100-mile road test on Utah terrain (I-80 corridor) with telematics monitoring

- Documentation: Digital health report including:

- Engine oil analysis (PQ index ≤ 150)

- Chassis alignment report (toe-in ±0.05°)

- Full electrical system voltage map

- Warranty: 12 months/20,000 miles comprehensive coverage (excludes abuse)

5. CONCLUSION

SEA LION’s Utah owner-source refurbishment protocol eliminates variability in pre-owned truck quality through rigid adherence to SL-STD-7800. Each unit delivers documented parity with new-truck performance metrics for critical systems, reducing fleet downtime by 33% (2025 SEA LION case study). This standard is non-negotiable for all units marketed under the SEA LION Certified Refurbished™ program.

SEA LION International | Engineering Division | Salt Lake City, UT | CONFIDENTIAL: For Fleet Manager & Construction Partner Use Only

© 2026 SEA LION International. All specifications subject to SEA LION SL-STD-7800 (2026) revision control.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Subject: Logistics Solutions for Exporting Used Trucks from China to Utah, USA (Owner-Direct Consignments)

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

Executive Summary

This report evaluates optimal maritime logistics strategies for transporting used commercial trucks sourced from China to end buyers in Utah, USA. As demand for cost-effective, pre-owned heavy-duty vehicles rises in North American construction and logistics sectors, efficient and protective export methodologies are critical. SEA LION International presents a comparative analysis of three primary shipping modalities—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container transport—tailored for owner-direct consignments of used trucks.

Key considerations include transit integrity, corrosion mitigation, handling efficiency, inland logistics integration, and total landed cost. Special emphasis is placed on wax-based anti-corrosion treatments to combat prolonged seawater exposure.

1. Overview of Export Logistics Pathways

Used trucks exported from Chinese ports (e.g., Shanghai, Qingdao, Ningbo) to inland Utah must transit via West Coast U.S. gateways (e.g., Los Angeles, Long Beach, Tacoma), followed by rail or over-the-road (OTR) drayage. The maritime leg is the most critical phase for asset preservation.

| Shipping Method | Description | Typical Use Case |

|---|---|---|

| RO-RO (Roll-on/Roll-off) | Vessels designed for wheeled cargo; trucks driven on/off via ramps | High-volume, operable vehicle shipments |

| Bulk Cargo | Non-containerized loading into cargo holds; trucks secured on deck or in holds | Irregular shipments; limited port infrastructure |

| Flat Rack Container | Open-sided ISO containers; trucks secured using lashing points | High-value or non-operational units requiring enclosed protection |

2. Comparative Analysis: RO-RO vs. Bulk Cargo vs. Flat Rack

| Parameter | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Cargo Suitability | Operable trucks only (must self-propel) | Operable or inoperable (lift-on/lift-off) | Inoperable or oversized units; secure lashable cargo |

| Loading/Unloading Speed | High (drive-on/drive-off) | Moderate to slow (crane-dependent) | Moderate (requires rigging and securing) |

| Structural Protection | Moderate (exposed deck areas) | Low (direct seawater/salt spray exposure) | High (partial enclosure, customizable bracing) |

| Corrosion Risk | High (prolonged salt air exposure) | Very High (direct wetting, pooling) | Moderate (reduced exposure with wax treatment) |

| Average Transit Time (China → U.S. West Coast) | 14–18 days | 16–20 days | 15–19 days |

| Inland Intermodal Compatibility | Truck → Rail → OTR | Requires crane handling at port | Containerized rail-ready; seamless drayage |

| Cost (USD per unit, avg.) | $1,800 – $2,300 | $1,500 – $2,000 | $2,600 – $3,400 |

| Damage Incidence Rate (Industry Avg.) | 6.2% | 11.8% | 3.1% |

| Best For | High-volume, functional fleet exports | Budget-sensitive, non-critical assets | High-value, restoration, or non-drivable units |

3. Corrosion Mitigation: Wax Spraying Protection Protocol

Seawater-induced corrosion is the leading cause of post-shipment depreciation in exported used trucks. SEA LION International recommends industrial-grade wax spraying as a mandatory pre-shipment treatment.

Wax Spraying Specifications:

| Parameter | Specification |

|---|---|

| Wax Type | Solvent-based, hydrophobic polymer blend (e.g., lanolin-enhanced) |

| Application Method | High-pressure spray (minimum 2,000 psi) |

| Coverage Areas | Undercarriage, frame rails, suspension components, wheel hubs, brake assemblies, exhaust system |

| Coating Thickness | 25–35 microns (measured via DFT gauge) |

| Curing Time | Minimum 4 hours at 20°C prior to shipment |

| Performance Standard | ASTM B117 Salt Spray Resistance: 500+ hours |

| Reapplication Guidance | Required if storage >30 days pre-shipment or post-discharge delay |

Note: Wax treatment reduces corrosion-related warranty claims by up to 74% (per 2024 JOC Fleet Integrity Study). RO-RO and Bulk Cargo shipments benefit most due to exposure.

4. Recommended Shipping Strategy by Use Case

| Procurement Profile | Recommended Method | Rationale |

|---|---|---|

| Fleet of 10+ operable trucks | RO-RO + Wax Spray | Cost-efficient, rapid turnaround, scalable |

| Single high-value vintage truck | Flat Rack + Full Wax + Desiccant | Maximized protection, container integrity |

| Inoperable or damaged units | Flat Rack or Lift-on Bulk (with wax) | Non-negotiable securement and corrosion control |

| Budget-constrained buyer (risk-tolerant) | Bulk Cargo + Wax Spray | Lowest cost; acceptable risk with treatment |

5. Compliance & Documentation (China → USA)

All shipments must adhere to:

– Chinese Customs: Export declaration (General Administration of Customs PRC), title verification

– U.S. EPA & DOT: Import compliance for vehicles (EPA Form 3520-1, DOT HS-7)

– USDA: Undercarriage soil/debris inspection (mandatory for Utah entry)

– Bill of Lading: Clean, non-negotiable, consigned to owner or designated agent

6. Conclusion

For used trucks exported from China to Utah, RO-RO shipping with industrial wax spraying presents the optimal balance of cost and efficiency for operable units. Flat Rack containers are superior for high-value or non-functional trucks requiring maximum environmental protection. Bulk Cargo is discouraged except for lowest-tier assets due to high corrosion and damage rates.

SEA LION International advises all owner-shipments to implement mandatory wax-based undercarriage protection and utilize containerized or RO-RO methods with verified carrier corrosion management protocols.

End of Report

SEA LION International – Engineering Division

February 2026

Get a Quote for Used Trucks For Sale In Utah By Owner

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]