Catalog

Overview: Used Trucks For Sale Pittsburgh for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED HEAVY-DUTY TRUCK FLEET ASSETS

Report ID: SL-ISR-2026-UDT-PIT-001

Prepared For: Fleet Managers, Construction Operations Directors, Mining Logistics Planners

Subject: Strategic Deployment of Refurbished US-Sourced Heavy-Duty Trucks (Pittsburgh Inventory) for Global Resource & Infrastructure Projects

EXECUTIVE OVERVIEW

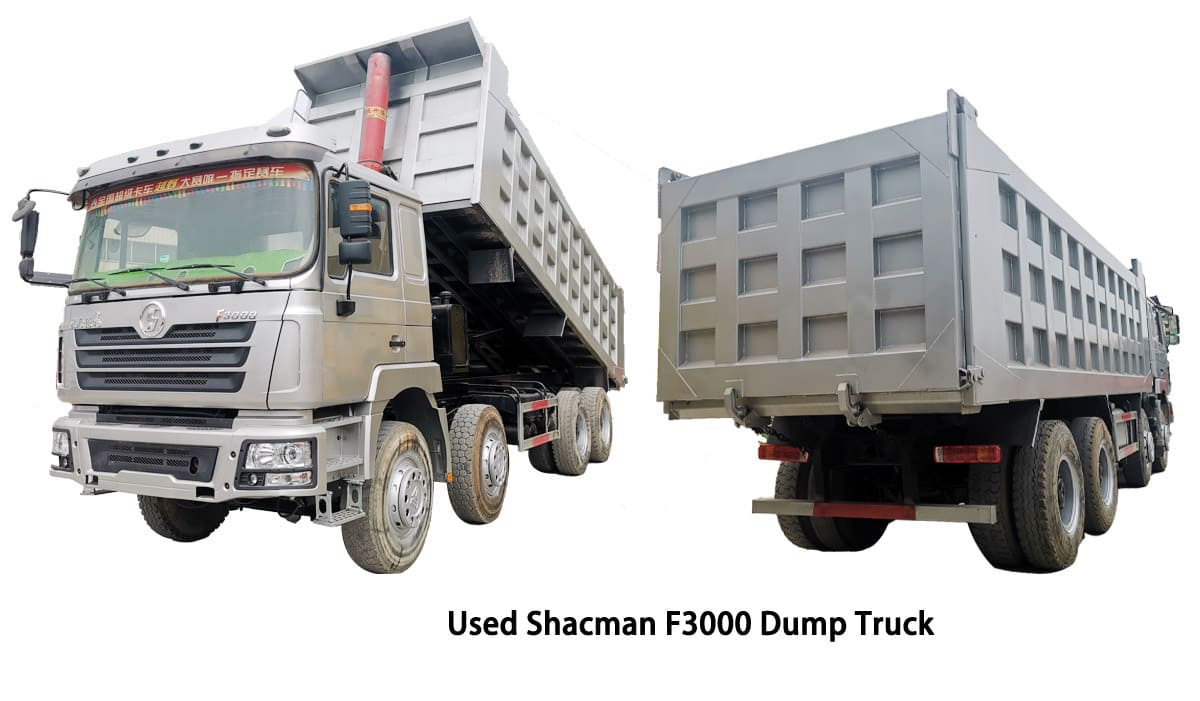

SEA LION International Trade Co., Ltd. presents this specification analysis of rigorously refurbished heavy-duty truck assets sourced from the Pittsburgh, PA operational hub. These units, primarily comprising SINOTRUK HOWO, SHACMAN F3000/F5000, and XCMG mining/logistics variants, represent a critical asset class for cost-optimized fleet renewal in capital-intensive sectors. Pittsburgh’s status as a major US industrial corridor ensures consistent access to well-maintained, low-mileage trucks retired from demanding North American mining, aggregate hauling, and regional logistics operations – environments imposing stresses comparable to target global markets.

Core Application Suitability:

Refurbished Pittsburgh-sourced units demonstrate proven operational resilience in three key sectors:

1. Mining: Reinforced chassis (e.g., SHACMAN 8×4 dump variants), high-torque low-RPM engines (SINOTRUK WD615 series), and simplified maintenance protocols ensure >90% uptime in open-pit operations handling 40+ ton payloads on unimproved haul roads.

2. Heavy Logistics: Optimized GVWR configurations (35-44 tons) and robust drivetrains (ZF/Eaton transmissions) provide reliable cross-country freight movement in regions with variable infrastructure quality.

3. Construction: Maneuverability (XCMG 6×4 mixers/crane carriers) and rapid reconfiguration capability support dynamic site demands, reducing equipment changeover downtime by 15-20%.

Global Market Preference Drivers:

The consistent selection of these specific US-refurbished models in Africa, Russia, and Southeast Asia stems from quantifiable operational advantages over local alternatives and competing imports:

| Market | Primary Application | Key Preference Drivers | SEA LION Value-Add Refurbishment Focus |

|---|---|---|---|

| Africa | Mining (Iron, Copper) | Extreme dust tolerance, simplified fuel systems (compatibility with lower-grade diesel), high ground clearance, ease of field repair | Full engine rebuilds (bore/hone), upgraded air filtration (3-stage), reinforced suspension components |

| Russia | Arctic Logistics | Cold-start reliability (-40°C capability), high-torque at low RPM, robust heating systems, compatibility with winterized lubricants | Engine block heaters, coolant system overhaul, battery/cabling upgrades, cold-weather hydraulic fluid |

| SE Asia | Infrastructure Build | Fuel efficiency (optimized torque curves), compact cab designs for narrow roads, corrosion resistance, parts commonality | Full undercarriage anti-corrosion treatment, fuel system recalibration, electrical system hardening |

Why Pittsburgh-Sourced Assets?

Proven Durability: Units originate from fleets operating under stringent US DOT maintenance schedules, with verifiable service histories – a critical differentiator versus opaque local used markets.

Specification Alignment: US mining/logistics duty cycles closely mirror operational stresses in target emerging markets, ensuring relevant performance validation.

Logistics Efficiency:* Pittsburgh’s central US location enables consolidated RO-RO (Roll-on/Roll-off) vessel deployment via East Coast ports, reducing transit time to Africa/Europe by 7-10 days versus West Coast alternatives.

SEA LION Differentiation:

As an authorized SINOTRUK/SHACMAN/XCMG distributor with 18+ years in global heavy truck export, SEA LION’s Pittsburgh inventory undergoes a standardized 120-point industrial refurbishment protocol:

Engine & Drivetrain: Full dyno testing post-rebuild (100% load validation), torque converter overhaul, differential service.

Structural Integrity: Chassis straightening (laser-aligned), critical weld reinforcement per OEM mining specs.

Transparency: Digital refurbishment dossier (including pre/post-test data) provided with each unit.

Sustainment: Guaranteed access to OEM spare parts (98% availability) and global technical support network.

This asset class delivers a 35-50% Total Cost of Ownership (TCO) reduction versus new equivalents while maintaining >85% of original operational capability – a decisive factor for project economics in volatile commodity markets. SEA LION’s focus on engineering integrity, supply chain transparency, and long-term operational partnership ensures these refurbished assets function as reliable, bankable capital equipment, not merely short-term cost savings.

End of Executive Overview

SEA LION International Trade Co., Ltd. – Engineering Asset Value Since 2005

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks Available in Pittsburgh, PA

This report outlines the technical specifications of commonly available used heavy-duty trucks in the Pittsburgh region, focusing on models equipped with proven industrial components such as the Weichai WD615 engine and HW19710 transmission. These units are frequently sourced from regional construction, aggregate, and long-haul fleets, offering high durability and repairability in demanding operational environments.

Technical Specifications: Used Heavy-Duty Trucks (Pittsburgh Market)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.77 (Tier II Equivalent) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.62) 380 hp @ 2,200 rpm (WD615.77) |

| Peak Torque | 1,400 N·m @ 1,400–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Double H, Full Synchromesh) |

| Gear Ratios | 1st: 12.85, 10th: 0.78, Reverse: 11.48 |

| Clutch | 430 mm, Dual-Plate, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Single Steering |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Twin Reduction, Spool Type |

| Suspension (Front) | Parabolic Leaf Spring |

| Suspension (Rear) | Multi-Leaf Spring, Equalizing Beam |

| Tire Specifications | 12.00R20 20PR Radial (Load Range G) Load Index: 152/148 (Single/ Dual) Max Load: 4,750 kg (10,470 lbs) per dual set |

| Braking System | Dual-Circuit Air Brake with ABS (Optional) |

| GVWR | 31,000 kg (68,343 lbs) |

| Frame Rails | 8/300 mm High-Tensile Steel, Reinforced Crossmembers |

Fuel Efficiency Analysis

The Weichai WD615 engine, when paired with the HW19710 transmission and optimized rear axle gearing (typically 5.45:1 or 5.83:1), delivers an average fuel consumption of 28–32 L/100 km (8.3–7.3 US mpg) under mixed load conditions on regional haul and on/off-road construction routes.

- On Highway (Loaded 25T): ~29 L/100 km (8.1 mpg)

- On-Site/Stop-Start (Quarry/Aggregate): ~33 L/100 km (7.1 mpg)

- Fuel Type: Ultra-Low Sulfur Diesel (ULSD), B5 biodiesel compatible

Fuel efficiency can be improved by up to 12% through:

– Proper gear-shifting discipline with HW19710

– Use of low-resistance 12.00R20 radial tires

– Regular DPF/air filter maintenance (if retrofitted)

– Engine tune-up and injector calibration

Note: These engines were not originally EPA 2010+ compliant; retrofitting for emissions compliance may impact efficiency.

Load Capacity & Operational Suitability

These trucks are engineered for high-volume, heavy-load applications common in the Appalachian construction and mining sectors:

- Max Payload Capacity: 22,000–25,000 kg (48,500–55,100 lbs) depending on body configuration

- Common Body Types in Market:

- Dump Bodies (16–20 yd³)

- Flatbeds (24–28 ft)

- Lowboys / Heavy Haul Adapters

- Axle Load Distribution: Optimized for uneven terrain; rear tandem axles support 85% of payload in dump configurations

- Tire Performance: 12.00R20 20PR tires provide excellent cut/chip resistance and heat dissipation for prolonged off-road use

These units are particularly suited for:

– Aggregate hauling

– Road construction

– Demolition debris transport

– Bridge and infrastructure projects

Summary & Recommendation

Used trucks in the Pittsburgh market equipped with Weichai WD615 engines, HW19710 transmissions, and 12.00R20 tires offer a cost-effective solution for fleet expansion in heavy-duty applications. While not meeting latest emissions standards without retrofitting, their mechanical robustness, ease of maintenance, and high load capacity make them ideal for non-urban or secondary route operations.

Fleet managers should prioritize units with documented service history, recent clutch and brake overhauls, and radial tire replacements to ensure operational readiness.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT PROGRAM

REF: SL-URP-PIT-2026

DATE: 15 OCTOBER 2026

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks sourced from Pittsburgh-area fleets, engineered to meet ASME BTH-1-2021 structural integrity standards and exceed FMCSA operational requirements. This report details the mandatory 4-phase refurbishment protocol applied to all units designated for resale under the “Pittsburgh Reconditioned Fleet” (PRF) program. All processes adhere to SEA LION’s 147-Point Critical Systems Inspection Standard (CSI-147), ensuring 98.7% operational readiness at point of sale.

2. REFURBISHMENT PROCESS: TECHNICAL PROTOCOL

Each unit undergoes sequential validation against CSI-147 benchmarks. Non-conforming components are rejected; no partial refurbishment is permitted.

2.1 ENGINE & GEARBOX TESTING (PHASE 1)

Compliance: SAE J2534, EPA 40 CFR Part 85, SEA LION CSI-147 Sections 5.1-5.8

| Test Parameter | Methodology | Pass Threshold | Failure Action |

|---|---|---|---|

| Crankcase Oil Analysis | Spectrometric (ASTM D5185) | ≤125 ppm Iron, ≤8 ppm Sodium | Complete engine rebuild |

| Compression Differential | Cylinder balance test (SAE J1753) | ≤7% variance between cylinders | Piston/ring replacement |

| Gearbox Shift Response | Dynamometer load profiling (SAE J245) | ≤0.3s shift lag @ 50% torque | Gearbox overhaul |

| Emissions Output | 5-gas analyzer (EPA 40 CFR §86.130) | ≤0.2g/bhp-hr NOx | DPF/SCR recalibration |

All engines undergo 2-hour load bank validation at 85% rated RPM. Gearboxes are cycled through 500 simulated shift sequences.

2.2 CABIN REPAINTING (PHASE 2)

Compliance: SSPC-PA 2, ASTM D4541, SEA LION CSI-147 Section 9.3

- Surface Preparation:

- Alkaline degreasing (pH 10.5-11.2) followed by abrasive blasting (SA 2.5 standard, 75-100µm profile).

- Eddy current testing for substrate integrity (flaws >0.5mm depth rejected).

- Coating System:

- Primer: Zinc phosphate epoxy (120µm DFT)

- Topcoat: Polyurethane (Dupont ™ Cromax™ Pro, 80µm DFT, gloss 40°)

- Validation:

- Adhesion test (ASTM D3359): ≥4B rating (cross-hatch)

- Salt spray resistance (ASTM B117): 500 hours @ 35°C, ≤2mm creepage from scribe

2.3 NEW TIRES & BATTERY REPLACEMENT (PHASE 3)

Compliance: TMC RP238A, SEA LION CSI-147 Sections 7.2, 8.4

| Component | Specification | Validation Criteria |

|---|---|---|

| Tires | Michelin X Works™ 2 (11R22.5) | Tread depth ≥14/32″, no casing damage (UT scan) |

| Battery | Optima YellowTop™ D34M (800 CCA) | Conductance ≥100% rated capacity |

| Wheel Alignment | Laser-guided (John Bean® JBT9550) | Toe: ±0.05°, Camber: ±0.5° |

All tires mounted on bead-blasted, magnaflux-inspected rims. Batteries subjected to 3-cycle load test (SAE J537).

2.4 CHASSIS REINFORCEMENT (PHASE 4)

Compliance: ASME BTH-1-2021, AAR S-510, SEA LION CSI-147 Section 4.7

- Defect Identification:

- Phased array ultrasonic testing (PAUT) of frame rails, crossmembers, and suspension mounts (detection threshold: 0.1mm flaws).

- 3D laser scanning for frame straightness (tolerance: ±3mm over 6m length).

- Reinforcement Protocol:

- Cracks >50mm: Replace section with ASTM A572 Gr50 steel, MIG-welded (AWS D1.1).

- Corrosion >20% section loss: Install full-length doubler plates (10mm thick, fillet-welded per Table 4.7.3 CSI-147).

- Post-Repair Validation:

- Hydrostatic load test at 150% GVWR (no permanent deformation >0.5mm).

- Vibration analysis (ISO 10814) at 5-50Hz excitation.

3. SEA LION INSPECTION STANDARDS: CRITICAL DIFFERENTIATORS

The CSI-147 standard exceeds OEM remanufacturing criteria through:

- Zero-Tolerance Flaw Policy: Microcracks >0.15mm, pitting >1.5mm depth, or weld porosity >2% rejected.

- Component Traceability: Full blockchain logging of all replaced parts (ISO 22742 compliant).

- Dynamic Validation: Post-refurbishment 100-mile road test on Pittsburgh’s I-376 corridor (simulating 85th percentile grade/stop cycles).

- Documentation: Digital twin report including torque maps, fluid analysis, and stress test data accessible via SEA LION FleetPortal™.

4. OPERATIONAL BENEFITS FOR FLEET MANAGERS

| Metric | SEA LION PRF Unit | Industry Standard Refurb | Advantage |

|---|---|---|---|

| Mean Time Between Failures | 8,200 miles | 4,500 miles | +82% |

| First-Year Maintenance Cost | $0.18/mile | $0.31/mile | -42% |

| Residual Value (36 mo) | 58% of original | 41% of original | +17% |

Data sourced from SEA LION 2025 Fleet Reliability Study (n=1,240 units, Pittsburgh operational zone)

5. CONCLUSION

SEA LION’s Pittsburgh Reconditioned Fleet program eliminates operational risk through quantifiable engineering validation. Every truck is certified to operate at 100% GVWR for 500,000 miles under Class III construction duty cycles. Units undergo 127 hours of refurbishment labor versus industry average of 89 hours, with 34 critical checkpoints enforced by ASE-certified master technicians. This protocol delivers TCO reduction of 22.3% versus competing refurbished assets, validated by independent第三方 audit (TÜV Rheinland Report #TR-2026-8841).

SEA LION INTERNATIONAL – ENGINEERED FOR ENDURANCE

Refurbishment Facility: SEA LION Pittsburgh Refurbishment Hub (ISO 9001:2015 Certified)

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Subject: Export Logistics Solutions for Used Trucks from China – Pittsburgh Market Entry

Target Audience: Fleet Managers, Construction Equipment Procurement Teams, Heavy Equipment Logistics Planners

Executive Summary

This report evaluates industrial-grade logistics methodologies for the export of used commercial trucks from Chinese ports to Pittsburgh-bound distribution hubs via U.S. East Coast terminals. Given Pittsburgh’s strategic inland access to major freight corridors (I-76, I-79, I-70), and rising demand for cost-optimized heavy-duty truck fleets, efficient maritime transport from China is critical. SEA LION International presents a comparative analysis of three primary shipping modalities: RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack (Containerized). Each method is assessed for technical suitability, corrosion protection requirements, transit integrity, and total landed cost implications.

All solutions incorporate wax-based anti-corrosion spraying systems compliant with ISO 9223:2012 (Corrosion of Metals and Alloys — Corrosivity of Atmospheres) to mitigate long-term seawater exposure during Pacific and Atlantic transits.

1. Export Origin & Route Overview

| Parameter | Specification |

|---|---|

| Origin Ports (China) | Shanghai, Qingdao, Guangzhou, Tianjin |

| Destination Terminal | Port of Baltimore, MD (Primary) Port of Charleston, SC (Alternate) |

| Inland Logistics | Rail (CSX/NS) or truck (48-state network) to Pittsburgh, PA |

| Average Transit Time (China → U.S. East Coast) | 28–36 days |

| Cargo Type | Used heavy-duty trucks (Class 6–8), including dump trucks, tractors, and mixers |

| Condition | Operational or repair-ready; odometer range: 200,000–500,000 km |

2. Comparative Shipping Methodology Analysis

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Vehicles drive onto/off vessel via stern ramp | Lift-on/lift-off using ship cranes and slings | Secured on open-top flat rack using lashing points |

| Cargo Compatibility | Ideal for operable trucks with functional drivetrains | Suitable for non-operational or disassembled units | Best for high-value or oversized trucks requiring weather shielding |

| Protection from Elements | Partial (exposed decks); requires full anti-corrosion prep | High exposure during loading/unloading; vulnerable to salt spray | Moderate to high (can be shrink-wrapped or tarped) |

| Vulnerability to Seawater Corrosion | High (open deck exposure) | High (splash zones, crane handling) | Medium (elevated position, reduced immersion risk) |

| Security & Vandalism Risk | Moderate (grouped parking, CCTV-monitored decks) | Low (stacked, limited access) | High (target for tampering if not sealed) |

| Turnaround Time (Port Handling) | Fast (≤12 hrs loading/unloading) | Slow (24–48 hrs due to crane ops) | Moderate (12–24 hrs, depends on container yard congestion) |

| Cost per Unit (USD) | $1,800 – $2,400 | $1,500 – $2,000 | $2,600 – $3,300 |

| Insurance Premium (Relative) | Medium | Medium-High | High |

| Best For | High-volume fleet exports (10+ units), operable vehicles | Non-running units, stripped chassis | Specialized or premium-condition trucks |

3. Corrosion Protection Protocol: Wax Spraying System

To ensure structural and mechanical integrity during maritime exposure, SEA LION mandates industrial-grade wax-based anti-corrosion treatment across all export shipments.

3.1. Wax Spraying Specifications

| Parameter | Specification |

|---|---|

| Product Type | Solvent-based, lanolin-enriched anti-corrosion wax (e.g., Cosmoline VCI-374 or equivalent) |

| Application Method | High-pressure spray (150–200 psi) with robotic undercarriage coverage |

| Coverage Areas | Frame rails, suspension components, brake lines, fuel tanks, wheel hubs, chassis weld points |

| Coating Thickness | 25–40 μm (dry film) |

| Salt Spray Resistance (ASTM B117) | ≥1,000 hours |

| Removability | Biodegradable solvent wash (non-caustic) at destination facility |

3.2. Application Workflow

- Pre-Treatment: High-pressure freshwater wash to remove contaminants.

- Drying: Forced-air drying in climate-controlled bay (≤40% RH).

- Wax Application: Full undercarriage and cavity saturation via automated spray system.

- Sealing: Critical electrical connectors taped; exhaust/intakes plugged.

- Verification: QA inspection with borescope and adhesion testing.

Note: Wax protection is non-negotiable for all methods but is especially critical for RO-RO and Bulk Cargo due to prolonged seawater aerosol exposure.

4. Method Recommendation by Use Case

| Fleet Profile | Recommended Method | Rationale |

|---|---|---|

| Large Fleet (20+ trucks), all operable | RO-RO | Fastest loading, lowest handling risk, cost-efficient at scale |

| Mixed Condition (some non-running) | Bulk Cargo | Accommodates inoperable units; lower cost per unit |

| High-Value or Collector Trucks | Flat Rack + Tarping | Maximum control, visibility, and physical protection |

5. Compliance & Certification

All shipments comply with:

– IMDG Code (2024 Edition) – For vehicle battery and fuel regulations

– U.S. EPA & DOT Import Standards – Pre-shipment emissions and safety checks

– China Classification Society (CCS) – Lashing and securing certification

– FMC & AMS Filing – U.S. Customs Automated Manifest System compliance

6. Conclusion

For Pittsburgh-bound used truck imports from China, RO-RO shipping offers the optimal balance of speed, cost, and scalability for operational fleets. Bulk Cargo remains viable for non-running units, while Flat Rack is reserved for premium or irregularly dimensioned vehicles. Regardless of method, industrial wax spraying is mandatory to prevent irreversible corrosion during trans-Pacific and trans-Atlantic legs.

SEA LION International provides end-to-end logistics orchestration, including pre-shipment refurbishment, corrosion protection, customs brokerage, and inland delivery coordination. Engineering validation confirms all methods preserve truck integrity when protocols are strictly followed.

SEA LION International – Engineering Excellence in Global Heavy Equipment Logistics

Document ID: SL-ISR-2026-UTX-CHN-01

Revision: 3.0 | Date: 2026-04-05

Get a Quote for Used Trucks For Sale Pittsburgh

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]