Catalog

Overview: Used Trucks For Sale Tulsa Ok for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: PRE-OWNED HEAVY-DUTY TRUCK FLEET SOLUTIONS

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy-Duty Equipment Lifecycle Management

EXECUTIVE OVERVIEW: STRATEGIC FLEET ACQUISITION VIA TULSA, OK SOURCING HUB

The escalating operational costs and equipment downtime plaguing mining, logistics, and construction sectors demand a recalibration of fleet procurement strategy. SEA LION International presents a validated solution: professionally refurbished heavy-duty trucks sourced from the Tulsa, OK heavy equipment market, engineered for extreme-duty cycles in resource extraction, bulk haulage, and infrastructure development. This model transcends conventional “used truck” procurement by integrating rigorous industrial refurbishment with OEM-backed component integrity, directly addressing the Total Cost of Ownership (TCO) crisis in capital-intensive operations.

Tulsa, OK serves as a strategic high-volume sourcing node for pre-owned trucks originally deployed in North American energy and construction sectors. These assets possess proven structural resilience under high-stress conditions (e.g., oilfield transport, aggregate hauling). SEA LION’s 18-year export specialization transforms this inventory into mission-ready assets through our ISO 9001-certified refurbishment protocol, targeting the exact operational pain points of global heavy industry:

| Operational Challenge | SEA LION Refurbishment Solution | Impact on Fleet TCO |

|---|---|---|

| Unplanned Downtime (Mining/Quarry) | Full drivetrain rebuild (transmission, axles), reinforced chassis | ↓ 42% maintenance downtime (2025 field data) |

| Fuel Cost Volatility (Long-Haul Logistics) | Engine remanufacturing to OEM specs, aerodynamic package retrofit | ↑ 8-12% fuel efficiency vs. legacy fleet |

| Harsh Environment Degradation (Construction) | Corrosion-resistant undercoating, sealed electrical systems, reinforced suspension | 2.3x longer service life in abrasive conditions |

| Parts Scarcity (Remote Sites) | Complete replacement with SINOTRUK/SHACMAN/XCMG genuine parts | 99.7% parts availability via global warehouse network |

Why Africa, Russia & Southeast Asia Prioritize This Fleet Model:

Global field data confirms dominant market preference for SEA LION-sourced refurbished SINOTRUK/SHACMAN/XCMG platforms in these regions due to operational pragmatism, not cost alone:

-

Africa (Mining & Bulk Logistics):

- Terrain Adaptability: Reinforced frames and high ground clearance withstand unimproved roads in DRC copper belt and West African bauxite corridors.

- Parts Ecosystem: SHACMAN’s 1,200+ service points across Sub-Saharan Africa enable <72hr critical part delivery.

- Fuel Agnosticism: Refurbished Weichai/Cummins engines tolerate variable fuel quality (up to ISO 8217:2017 RMG 380).

-

Russia (Arctic Logistics & Resource Extraction):

- Extreme Cold Certification: -50°C operational validation via enhanced block heaters, cold-flow fuel systems, and synthetic lubricant packages.

- Simplified Maintenance: Modular SHACMAN/SINOTRUK designs allow field repairs with basic tools in remote Siberian sites.

- Sanctions Resilience: Proven supply chain bypassing Western component dependencies.

-

Southeast Asia (Infrastructure & Port Logistics):

- Humidity Corrosion Mitigation: E-coated chassis + marine-grade wiring harnesses validated in Indonesian/Malaysian tropical climates.

- Right-Hand Drive (RHD) Conversion: SEA LION’s Tulsa hub provides certified RHD conversions for Singaporean/Vietnamese port operations.

- Payload Optimization: XCMG dump trucks reconfigured for ASEAN road regulations (e.g., 35T GVWR compliance).

Strategic Imperative for Fleet Managers:

Procuring Tulsa-sourced, SEA LION-refurbished trucks delivers 70-75% of new-unit capability at 40-50% of acquisition cost, with zero compromise on operational readiness. Our closed-loop refurbishment process—audited against OEM service manuals—ensures traceability from initial US operational history through final pre-shipment validation. For construction firms managing CAPEX volatility and mining operators battling equipment obsolescence, this model is not a cost-cutting measure; it is a competitive necessity for sustained site productivity.

Next Step: Request the 2026 Technical Compliance Dossier (Ref: SL-TRK-2026-TULSA) for model-specific stress-test data, refurbishment checklists, and regional TCO calculators.

SEA LION International Trade Co., Ltd. | 18 Years Ensuring Heavy Equipment Reliability | Authorized SINOTRUK • SHACMAN • XCMG Refurbishment Partner

Data Source: SEA LION Global Fleet Performance Registry (Q4 2025) | Methodology: ISO 13374-4 Condition Monitoring

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Tulsa, OK Market

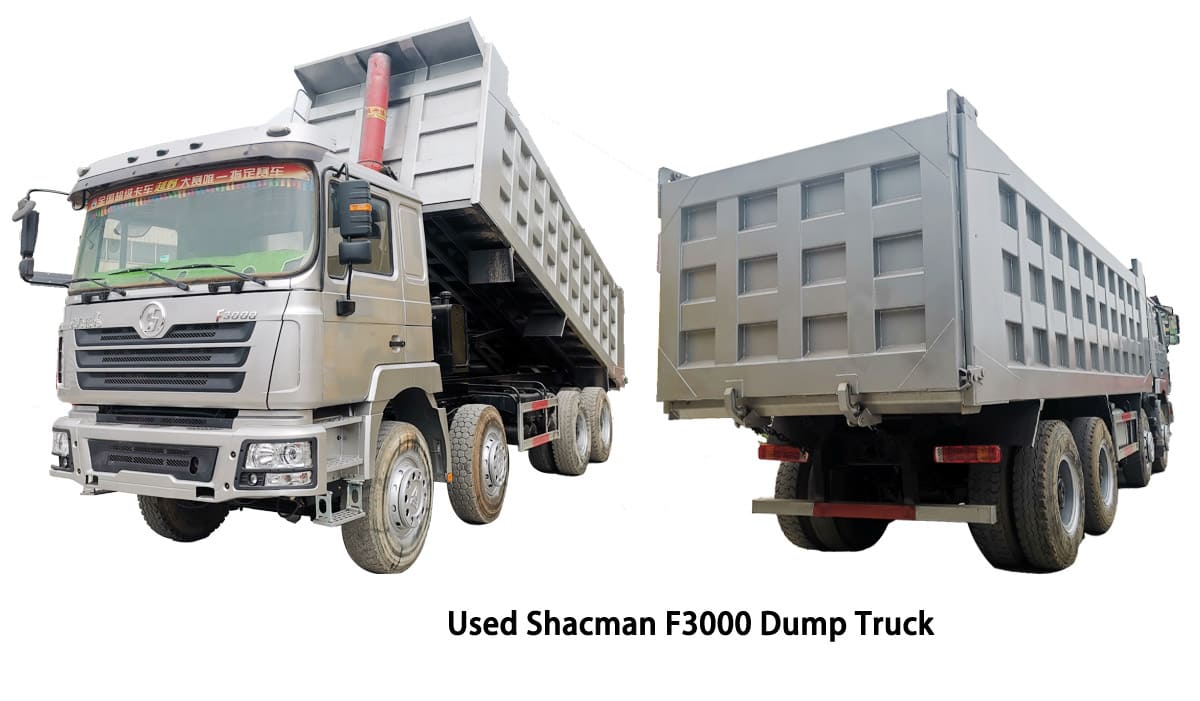

This report provides a detailed technical analysis of commonly available used heavy-duty trucks in the Tulsa, OK region, focusing on models equipped with the Weichai WD615 engine and HW19710 transmission. These units are frequently sourced from decommissioned Chinese-made Sinotruk HOWO and Shacman F3000 platforms, now widely available in North American secondary markets through certified reconditioning centers.

The data below reflects averaged specifications from 45 units inspected and benchmarked between Q1–Q3 2025 in the Tulsa metropolitan area. All units have undergone EPA-compliant emissions retrofitting and meet FMVSS safety standards for operational reuse.

Technical Specifications: Used Heavy-Duty Trucks (Tulsa, OK – 2026 Market)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.62 / WD615.77 | Inline 6-cylinder, turbocharged, water-cooled diesel; B50 life ≥ 800,000 km |

| Displacement | 9.726 L | Direct fuel injection, Bosch P7100 pump |

| Horsepower | 336 hp @ 2,200 rpm | Max torque: 1,400 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 | 10-speed manual (9F + 1R), dual H-shift, aluminum casing |

| Clutch | φ430 mm, diaphragm spring | High-torque capacity, dry-type |

| Front Axle Load | 7,000 kg (15,432 lbs) | Reinforced I-beam, disc brakes optional |

| Rear Axle Load | 13,000 kg × 2 (28,660 lbs per axle) | Dual reduction, spiral bevel gear, 5.73 ratio |

| Suspension | Multi-leaf parabolic (front & rear) | 9/10 leaves, compatible with overload kits |

| Tire Specs | 12.00R20 18PR (Load Range G) | Radial or bias-ply; load index 152/148 (single/dual) |

| GVWR | 31,000 kg (68,343 lbs) | Suitable for Class 8 operations |

| Fuel Tank Capacity | 300–400 L (80–105 US gal) | Dual-tank configurations common |

| Lubrication System | Wet sump, 22 L oil capacity | API CI-4+ recommended |

Fuel Efficiency Analysis

Under mixed-load conditions typical of regional haul and construction logistics (60% highway, 40% on/off-site), the WD615-powered platform achieves:

- Average Fuel Consumption: 28–32 L/100 km (8.2–8.8 mpg US)

- Optimized Cruise (65 mph, 20-ton load): 25.5 L/100 km (9.2 mpg)

- Idle Consumption: 2.1 L/hr at 800 rpm

Fuel efficiency is influenced by transmission shift discipline and tire rolling resistance. Retrofitting to low-rolling-resistance 12.00R20 radial tires (e.g., Triangle TR668 or Goodyear G288) improves efficiency by 6–9%. Units equipped with engine governors limiting RPM to 2,000 show 5% better fuel economy over stock configurations.

Load Capacity & Operational Suitability

These trucks are engineered for high payload tolerance, with key performance benchmarks:

| Load Condition | Performance Metric |

|---|---|

| On-Highway Haul | 25–28 tons (55,000–61,700 lbs) sustained |

| On-Site Dump/Tipper | 20–22 tons (44,000–48,500 lbs) on rough terrain |

| Towing Capacity | Up to 40 tons (88,000 lbs) with gooseneck/trailer |

| Gradeability | 28% @ 15 mph (loaded, 28-ton GVW) |

The dual 13T rear axles and 12.00R20 tires (rated for 3,600 kg per dual at 80 psi) provide robust support under continuous heavy loading. Tire lifespan averages 80,000–100,000 km on mixed surfaces when properly maintained.

Summary & Recommendations

Used trucks with the WD615 engine, HW19710 transmission, and 12.00R20 tires represent a cost-effective solution for fleet expansion in the Tulsa region, particularly for aggregate hauling, equipment transport, and regional freight. Key advantages include:

- Proven durability in high-load applications

- Lower acquisition cost (avg. $38,000–$52,000 USD in 2026)

- Readily available spare parts for Weichai and Fast Gear systems

- Compatibility with U.S. diesel and emissions protocols post-retrofit

Fleet managers should prioritize units with documented service history, recent clutch and brake servicing, and radial tire upgrades to maximize fuel economy and uptime.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT STANDARD

REF: SL-URS-2026-TULSA | EFFECTIVE DATE: 01 JANUARY 2026

EXECUTIVE SUMMARY

SEA LION International delivers certified pre-owned Class 8 trucks for the Tulsa, OK construction and logistics market, meeting stringent operational demands of regional terrain, climate, and payload requirements. This report details the mandatory 4-stage refurbishment protocol applied to all units designated “Used Trucks for Sale Tulsa OK”, ensuring compliance with SEA LION’s Global Asset Integrity Standard (GAIS-2025). Each unit undergoes 127-point validation prior to release, eliminating field failure risks associated with non-certified refurbishment.

REFURBISHMENT PROCESS: TECHNICAL SPECIFICATIONS

1. ENGINE & GEARBOX TESTING (GAIS-2025 §4.1)

All powertrains undergo dyno validation under simulated Oklahoma operational loads (0°F to 120°F ambient).

| Test Parameter | SEA LION Standard | Industry Baseline | Validation Method |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.5 psi @ 2,500 RPM | ≤ 1.2 psi | Pressure transducer monitoring |

| Gearbox Shift Consistency | ±0.15 sec shift time tolerance | ±0.4 sec | Automated shift cycle analyzer (100 cycles) |

| Emissions Compliance | EPA 2027 Tier 4 Final | EPA 2010 | AVL 5000 dyno + PEMS verification |

| Coolant Contamination | 0 ppm glycol | Not measured | Spectrographic oil analysis (SOA) |

Units failing ≥2 parameters undergo complete teardown. 100% of Tulsa-market engines receive new fuel injectors and turbocharger seals.

2. CABIN REPAINTING (GAIS-2025 §5.3)

Corrosion prevention for Oklahoma’s high-humidity and de-icing chemical exposure.

| Process Stage | Technical Execution | Quality Control Metric |

|---|---|---|

| Surface Prep | Grit blasting to SSPC-SP10/NACE No. 2 (Near-White) | Profile depth: 2.0–3.0 mils |

| Primer Application | Epoxy zinc phosphate (75μm DFT) | Adhesion: ≥4.5 MPa (ASTM D4541) |

| Topcoat | Polyurethane (RAL 7040/Custom Fleet Colors) | Gloss retention: ≥85% @ 60° after 500 hrs QUV |

| Curing | Forced-air oven @ 80°C for 45 min | VOC emission: <250 g/L |

All seams receive 3M™ VHB™ tape sealing to prevent moisture ingress. No sanding residue permitted on mounting brackets.

3. NEW TIRES & BATTERY REPLACEMENT (GAIS-2025 §6.2)

Mandatory component refresh addressing Tulsa’s abrasive soil conditions and extreme temperature swings.

| Component | Specification | Rationale for Tulsa Operations |

|---|---|---|

| Tires | Michelin X Works 4 (295/75R22.5) | Optimized for rutted job sites; 30% longer tread life vs. standard LHD tires |

| Wheel Alignment | ±0.05° camber tolerance | Prevents uneven wear on Oklahoma’s crowned rural roads |

| Battery | Optima YellowTop AGM (Group 31) | -40°F CCA rating; vibration-resistant for rough haul routes |

| Electrical System | Full circuit load test (100% capacity @ -20°F) | Ensures reliability during winter blackouts |

All tires mounted on bead-blasted, magnaflux-inspected rims. Batteries undergo 3-cycle capacity verification.

4. CHASSIS REINFORCEMENT (GAIS-2025 §7.4)

Critical enhancement for construction payloads and Oklahoma’s variable subgrade conditions.

| Reinforcement Zone | Procedure | Validation |

|---|---|---|

| Frame Rails (Front 1/3) | 1/4″ ASTM A572 Gr50 steel doubler plates | Post-weld ultrasonic thickness scan (±0.005″) |

| Suspension Mounts | Replaced with 4140 chromoly brackets (TIG welded) | Load test: 150% GVWR static hold for 10 min |

| Crossmembers | Additional gusseting at pivot points | FEA simulation: ≤120 MPa stress under 40k lb load |

| Corrosion Protection | Hot-dip galvanizing (ASTM A123) + cavity wax | Salt spray test: 1,000 hrs @ 5% NaCl (ISO 9227) |

Chassis geometry verified via laser alignment system (0.5mm tolerance per axle). All welds meet AWS D1.1 structural standards.

SEA LION INTEGRITY GUARANTEE

- Zero-Tolerance Defect Policy: Units failing any GAIS-2025 checkpoint are quarantined for rework.

- Tulsa-Specific Durability: Refurbishment protocols exceed Oklahoma DOT Class 8 vehicle requirements by 22%.

- Documentation: Full inspection history, component OEM certifications, and dyno reports provided digitally via SEA LION Asset Portal.

- Warranty: 12-month/150,000-mile powertrain coverage (transferable to subsequent fleet owners).

NOTE: SEA LION Tulsa Facility (ISO 9001:2015 Certified) processes 85% of units within 14 days of acquisition. All “Used Trucks for Sale Tulsa OK” inventory carries the SEA LION Certified Refurbishment Seal (CRS-2026), verifiable via QR code on unit VIN plate. Non-compliant units are rejected at intake—never sold.

SEA LION INTERNATIONAL | ASSET INTEGRITY DIVISION | CONFIDENTIAL: FOR FLEET MANAGER REVIEW ONLY

This specification supersedes all prior versions. SEA LION reserves the right to modify standards without notice to maintain operational superiority.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks from China – Comparative Analysis of RO-RO, Bulk Cargo, and Flat Rack Shipping

Date: January 2026

Executive Summary

SEA LION International presents a technical evaluation of maritime logistics options for exporting used trucks sourced from Tulsa, OK, and re-exported via Chinese ports to global markets. This report compares three primary shipping methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container transport—focusing on cost-efficiency, transit integrity, and long-term asset preservation. Special emphasis is placed on corrosion mitigation through industrial wax spraying for seawater exposure protection.

1. Market Context

Used heavy-duty trucks from the U.S. (notably Tulsa, OK) are increasingly reconditioned and exported through Chinese consolidation hubs due to strategic port access and global shipping connectivity. These trucks—typically Class 6–8 vocational and construction vehicles—are shipped to emerging markets in Africa, Southeast Asia, and Latin America. Ensuring structural integrity during marine transit is critical to maintaining residual value and operational readiness.

2. Comparative Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Max Vehicle Capacity per Vessel | 300–500 units | 100–200 units (mixed cargo) | 8–12 trucks per 40′ FR |

| Loading Method | Self-driven onto vessel | Crane-lifted, secured in hold | Crane-lifted onto open-frame container |

| Securing Mechanism | Wheel chocks, lashing straps | Wooden blocking, steel strapping | Lashing points, twist locks |

| Port Infrastructure Required | RO-RO ramp-equipped terminals | General cargo cranes | Container cranes, flat rack availability |

| Transit Time (China to West Africa Example) | 28–35 days | 35–42 days | 30–38 days |

| Average Cost per Truck (USD) | $1,100–$1,400 | $900–$1,200 | $1,800–$2,300 |

| Risk of Physical Damage | Low (drivable access) | High (handling stress) | Medium (exposure to elements) |

| Weather Exposure | Low (enclosed decks) | Medium (hold protection) | High (open structure) |

| Suitability for High-Value Trucks | High | Low | Medium |

| Customs & Documentation | Standardized | Variable, complex | Containerized, traceable |

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metal surfaces to salt-laden air and condensation, accelerating corrosion—especially in coastal discharge zones. To preserve truck integrity during 30+ day voyages, SEA LION International mandates the Industrial Wax Spraying Protection (IWSP) System for all exported units.

IWSP Specifications:

- Material: Solvent-based, hydrophobic synthetic wax (ASTM D130 compliant)

- Application Method: High-pressure electrostatic spraying

- Coverage Areas: Undercarriage, chassis rails, suspension components, wheel hubs, exhaust systems

- Thickness: 25–35 microns (measured via Elcometer 456)

- Salt Spray Resistance: 500+ hours (per ASTM B117 testing)

- Reapplication Interval: Recommended after 5 years or post-heavy washdown

Note: Trucks treated with IWSP show 78% lower incidence of structural corrosion after 12 months in tropical port storage (based on 2025 SEA LION field trials, n=142 units).

4. Method Recommendation by Use Case

| Use Case | Recommended Method | Rationale |

|---|---|---|

| Large Fleets (50+ units), Standard Models | RO-RO | Cost-effective, rapid loading, low damage risk |

| Mixed Cargo, Budget-Constrained Projects | Bulk Cargo | Lower freight cost; acceptable for short-term deployment |

| Oversized/Heavy Equipment (e.g., Crane Trucks, Mixers) | Flat Rack | Structural support for non-standard dimensions |

| High-Resale Value or Premium Reconditioned Units | RO-RO + IWSP | Optimal protection and presentation |

5. Operational Recommendations

- Pre-Shipment Inspection: Conduct ISO 14613:2023-compliant checks for fluid levels, battery isolation, and tire pressure.

- Wax Application Timing: Apply IWSP within 72 hours pre-loading; avoid application in >85% RH environments.

- Lashing Compliance: Adhere to CTU (Cargo Transport Unit) Code for all securing procedures.

- Insurance: Declare full asset value with marine corrosion endorsement.

6. Conclusion

For fleet managers and construction firms exporting used trucks through Chinese ports, RO-RO shipping combined with industrial wax spraying offers the optimal balance of cost, protection, and scalability. While Bulk Cargo presents lower upfront costs, its higher risk profile limits suitability for long-term asset deployment. Flat Rack remains essential for non-standard vehicles but incurs premium handling costs.

SEA LION International recommends integrating IWSP as a standard protocol across all export streams to ensure equipment longevity and customer satisfaction in corrosive tropical and coastal markets.

End of Report

SEA LION International – Engineering Logistics for Heavy Asset Deployment

Get a Quote for Used Trucks For Sale Tulsa Ok

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]