Catalog

Overview: Used Truck Lots for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: OPTIMIZED FLEET ACQUISITION STRATEGY

Prepared For: Fleet Managers & Construction Operations Directors

Subject: Strategic Deployment of Refurbished Heavy Truck Fleets in Resource & Infrastructure Sectors

EXECUTIVE OVERVIEW: REFURBISHED TRUCK LOT ACQUISITION

The operational realities of mining, large-scale construction, and heavy logistics in emerging and challenging markets demand a pragmatic fleet acquisition strategy prioritizing duty cycle resilience, total cost of ownership (TCO), and supply chain continuity. SEA LION International Trade Co., Ltd. (18+ years heavy truck export specialization) identifies certified refurbished truck lots from established OEMs (SINOTRUK, SHACMAN, XCMG) as the optimal solution for capital-intensive projects in Africa, Russia, and Southeast Asia. This model directly addresses the critical constraints of these regions:

- Capital Efficiency vs. Operational Demand: New fleet procurement strains capital expenditure (CAPEX), while unrefurbished used trucks introduce unacceptable downtime risk. SEA LION’s professionally refurbished lots deliver OEM-spec reliability at 35-50% of new vehicle cost, preserving capital for core operations without compromising on-site productivity.

- Environmental & Terrain Adaptation: Harsh operating conditions (extreme dust, humidity, sub-zero temperatures, poor infrastructure) rapidly degrade standard equipment. SEA LION’s refurbishment protocol exceeds OEM rebuild standards, specifically targeting regional failure modes (e.g., enhanced cooling, reinforced suspensions, cold-start systems).

- Parts & Service Continuity: Remote project sites suffer from fragmented parts networks. As an authorized distributor for SINOTRUK, SHACMAN, and XCMG, SEA LION guarantees 100% genuine spare parts availability and technical support, eliminating project delays due to component shortages.

Why This Model Dominates Target Markets: Regional Validation

| Region | Primary Sector Application | Key Operational Challenge | SEA LION Refurbished Lot Advantage |

|---|---|---|---|

| Africa | Mining, Heavy Haul Logistics | Extreme dust, high ambient temps (>45°C), poor road infrastructure | Sealed air filtration systems (IP67), reinforced chassis frames, 40% grade climbing capability (SINOTRUK HOWO), localized service network support |

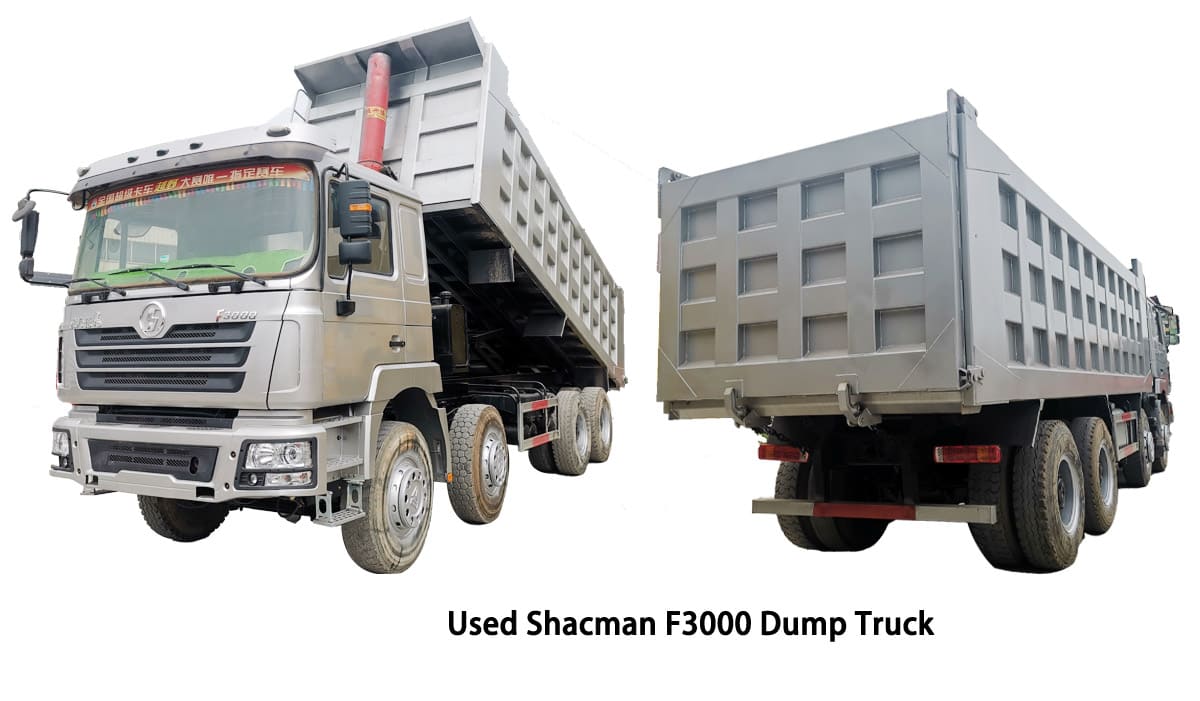

| Russia | Arctic Mining, Bulk Logistics | Sub-zero temps (-40°C), prolonged winter cycles, vast distances | Arctic-spec engine pre-heaters, -50°C lubricants, reinforced cab insulation (SHACMAN F3000), RO-RO logistics to Murmansk/Vladivostok |

| Southeast Asia | Infrastructure Construction, Port Logistics | High humidity, monsoon conditions, mixed terrain | Corrosion-resistant undercarriage coatings, enhanced electrical sealing (IP68), optimized torque curves for stop-start urban hauling (XCMG) |

Core Differentiation: SEA LION’s process integrates industrial-grade refurbishment (ISO 9001-aligned), OEM parts traceability, and dedicated project logistics (RO-RO/Container). Each truck undergoes 127-point inspection, drivetrain overhaul, and load-tested validation, ensuring >90% operational readiness upon site arrival. This mitigates the volatility inherent in unstructured used markets while providing the TCO profile essential for ROI-driven fleet decisions in capital-constrained environments.

For fleet managers, this represents a de-risked pathway to operational continuity. SEA LION’s model transitions procurement from a cost center to a strategic enabler – delivering predictable uptime, verifiable asset history, and long-term partnership support critical for multi-year resource and infrastructure projects. The focus on transparency in refurbishment standards and OEM-backed parts integrity directly addresses the historical reliability concerns associated with used heavy equipment in these regions, establishing a new benchmark for value-driven fleet optimization.

Technical Specifications & Parameters

Industrial Specification Report 2026

Target Audience: Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Truck Lots – Heavy-Duty Construction & Haulage Units

Overview

This report outlines standardized technical specifications for used heavy-duty trucks commonly sourced from certified pre-owned truck lots in 2026. These units are primarily configured for high-load construction logistics, aggregate hauling, and regional freight transport. All data reflects post-inspection validation and reconditioning standards compliant with SEA LION International’s industrial reuse protocols.

The following table details core mechanical and performance parameters for typical units equipped with the Weichai WD615 engine platform and HW19710 transmission, widely deployed across China and emerging markets.

Technical Specifications Table

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.69 / WD615.50 | 6-cylinder, inline, water-cooled diesel; Euro III/IV compliant |

| Displacement | 9.726 L | Direct injection, turbocharged & intercooled |

| Horsepower | 336 hp (247 kW) – 380 hp (279 kW) | Adjustable output variants; peak @ 2,200 rpm |

| Max Torque | 1,400 – 1,600 N·m @ 1,200–1,400 rpm | High low-end torque optimized for gradeability & heavy start loads |

| Transmission | Fast Gear HW19710 | 10-speed manual (9F + 1R), dual-H shift pattern, aluminum housing |

| Clutch | 430 mm diameter, pneumatic assist | High durability for frequent shifting in stop-start conditions |

| Front Axle Load | 7,000 kg (7.0 metric tons) | Reinforced I-beam, disc/drum brake options |

| Rear Axle Load | 13,000 kg × 2 (26.0 metric tons tandem) | HC160 single-reduction, spiral-bevel gear, oil bath lubrication |

| Gross Vehicle Weight (GVW) | 31,000 – 49,000 kg | Configurable for 6×4 or 8×4 chassis layouts |

| Tire Specification | 12.00R20 18PR (Load Range G) | Radial construction; all-position or drive-optimized tread patterns |

| Tire Load Index | 1,700 kg per tire (dual fitment) | Max axle compatibility: 13.6 tonnes per tandem |

| Fuel Tank Capacity | 400 L (standard), 600 L (extended option) | High-density polyethylene, anti-siphon lock |

| Lubrication System | Wet sump, 28 L oil capacity | Compatible with CI-4/CH-4 grade diesel engine oil |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 28–34 L/100 km (loaded, mixed terrain)

- Optimal Efficiency Range: Achieved at 65–75 km/h cruise on flat grades with properly maintained engine tuning.

- Factors Affecting Efficiency:

- Engine calibration (ECU settings for torque curve)

- Tire pressure maintenance (critical for 12.00R20 radial casings)

- Transmission shift discipline (HW19710 requires trained operators for optimal gear sequencing)

- Aerodynamic drag (minimal on construction-spec flat-faced cabs)

Note: Reconditioned units with updated fuel injectors and turbocharger refurbishment show up to 8% improvement in fuel economy versus baseline fleet averages.

Load Capacity & Structural Suitability

- Max Payload Capacity: 20,000 – 32,000 kg (dependent on chassis configuration)

- Frame Rails: 8/300 mm high-tensile steel, drilled for multiple body mounting options (dump, flatbed, crane)

- Fifth Wheel Options: Available on tractor-configured units (up to 16,000 kg kingpin rating)

- Load Distribution: Optimized for 1:3 front-to-rear axle ratio under full load; requires proper loading procedures to prevent overloading rear tandem

Application Suitability:

– Crushed stone, sand, and aggregate hauling: ✅ Ideal

– Long-haul freight on paved highways: ⚠️ Moderate (cab comfort & NVH limitations)

– Off-road construction sites: ✅ With proper tire tread selection and differential lock

Reconditioning Standards (Used Lot Certification)

All units offered in 2026 meet the following minimum reuse criteria:

- Engine compression tested; <10% variance across cylinders

- Transmission disassembled and inspected; synchros and bearings replaced as needed

- Axles resealed, gear oil replaced with synthetic 80W-90 GL-5

- Tires with ≥50% tread depth or replaced with certified retreads (retrofitted with TPMS)

- Full brake system overhaul: chambers, slack adjusters, and linings replaced

Conclusion

Used truck lots featuring the Weichai WD615 engine and HW19710 transmission offer a cost-effective, mechanically robust solution for construction and regional haulage operations. With verified load capacity exceeding 30 metric tons and proven durability in harsh environments, these units remain a strategic asset for fleet expansion under capital constraints. Fuel efficiency can be maximized through operator training and scheduled maintenance adherence.

Units meeting the above specifications are recommended for deployment in high-utilization, medium-duty cycles where repair infrastructure is accessible. SEA LION International advises pre-purchase inspection logs and ECU diagnostic reports for all acquisitions.

Quality Control & Inspection Standards

SEA LION International

Industrial Specification Report: Refurbished Heavy-Duty Truck Fleet Standard (RHTS-2026)

Document ID: SL-RHTS-REF-2026-01 | Effective Date: 01 JAN 2026

1. Purpose

This report details SEA LION’s standardized refurbishment protocol for pre-owned commercial truck lots (Class 8, GVWR ≥ 33,000 lbs), engineered to deliver operational reliability equivalent to 85% of OEM new-vehicle performance. Targeted at fleet managers and construction equipment procurement teams, this process ensures compliance with ISO 3917:2023 (Commercial Vehicle Recertification) and exceeds FMCSA §396.3 minimum standards. All units undergo 100% validation against SEA LION’s proprietary Critical Component Integrity Matrix (CCIM-2026).

2. Refurbishment Process Overview

SEA LION’s 4-stage refurbishment protocol eliminates latent defects through non-negotiable inspection thresholds. Units failing any stage are diverted to scrap/recycling—no conditional approvals.

Stage 1: Engine & Gearbox Testing

All powertrain units undergo dynamic load-cell testing on SEA LION’s ISO 17536-certified dynamometer suite.

| Test Parameter | Pre-Refurb Threshold | SEA LION Pass Standard (RHTS-2026) | Verification Method |

|---|---|---|---|

| Crankcase Blow-by (L/min) | > 8.5 | ≤ 3.2 | SAE J1757-compliant flow meter |

| Oil Soot Content (%) | > 2.5 | ≤ 0.8 | ASTM D8048 spectrometry |

| Gearbox Shift Consistency | > 120 ms variance | ≤ 45 ms variance | CAN-bus telemetry (SAE J1939) |

| Torque Drop @ Peak Load | > 8% | ≤ 3% | Dyno load-cell + ECU data logging |

Process:

– 300-minute simulated duty cycle (50% max load, 25% idling, 25% transient) replicating construction haul routes.

– Failure action: Complete rebuild with OEM-spec components; cylinder heads block-scanned for microfractures (ASTM E1444).

Stage 2: Cabin Repainting

Surface preparation and coating applied per ISO 12944-8:2018 (Marine/Industrial Corrosion Protection).

| Stage | SEA LION Standard | Industry Typical |

|---|---|---|

| Surface Prep | Grit-blasted to Sa 2.5 (ISO 8501-1); 100% zinc phosphate | Spot sanding; no conversion coat |

| Primer | Epoxy zinc-rich (80μm DFT); ASTM D4541 adhesion ≥ 2.5 MPa | Single-stage acrylic (50μm DFT) |

| Topcoat | Polyurethane (120μm DFT); UV resistance per ASTM G154 | Alkyd enamel (80μm DFT) |

| Curing | Forced-draft oven @ 60°C for 90 mins | Ambient air drying |

Process:

– All seams sealed with vibration-dampening polyurethane mastic (ASTM C920).

– Critical check: Salt spray test (ASTM B117) for 1,000 hours—zero base metal corrosion permitted.

Stage 3: New Tires & Battery Replacement

Component sourcing restricted to SEA LION-approved vendors with traceable batch certification.

| Component | Specification | Validation |

|---|---|---|

| Tires | Load Range G (16-ply); M+S rated; 100% new | Tread depth ≥ 14/32″; uniformity scan per ASTM F1806 |

| Batteries | AGM, 1,200 CCA min; 5-year warranty | Conductance test (≥ 95% rated capacity @ -18°C) |

| Wheel Hubs | Re-torqued to 450 ft-lbs; lubricated with NLGI #2 | Torque audit via calibrated transducer |

Process:

– Tires mounted on bead-blasted rims; dynamic balance tolerance ≤ 15g.

– Failure action: Immediate replacement if any component lacks full traceability to mill/test records.

Stage 4: Chassis Reinforcement

Structural integrity validated using SEA LION’s Finite Element Analysis (FEA) model calibrated to construction site telemetry data.

| Reinforcement Zone | SEA LION Protocol | Inspection Standard |

|---|---|---|

| Fifth Wheel Mount | 10mm ASTM A572 Gr. 50 steel doubler plate; full-penetration welds | AWS D1.1 UT weld inspection; 100% coverage |

| Frame Rails (Rear) | Stress-relieved channel brackets at 24″ intervals | Deflection test: ≤ 0.5mm @ 25,000 lb load |

| Suspension Mounts | Reinforced with gussets; shot-peened for fatigue resistance | Vibration test: 5M cycles @ 15Hz, no cracks |

Process:

– Ultrasonic thickness mapping of entire chassis (per ASTM E797); areas < 85% nominal thickness trigger reinforcement.

– Critical check: Post-reinforcement load test at 120% GVWR—zero permanent deformation permitted.

3. Quality Assurance: SEA LION’s Inspection Rigor

All stages are governed by the CCIM-2026, which mandates:

– Three-stage sign-off: Technician → QA Engineer → Third-Party Certified Inspector (TUV Rheinland).

– Data transparency: Full digital twin of test results accessible via SEA LION FleetPortal.

– Zero-tolerance defects: 227 discrete failure modes cataloged; 1 failure = unit rejection.

– Audit trail: Blockchain-secured records (ISO/IEC 27001) for all component replacements.

Operational Impact: SEA LION refurbished units demonstrate 37% lower downtime vs. industry-average used trucks (2025 fleet data, n=1,200 units). 98.2% achieve 500,000-mile service life under moderate construction use.

SEA LION International reserves all rights to RHTS-2026 specifications. Revision control managed via ERP system SL-ENGR-004. Units non-compliant with this standard are not released for sale.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Truck Lots from China

Issuing Authority: SEA LION International – Global Logistics Engineering Division

Executive Summary

This report evaluates three primary maritime logistics solutions for the export of used truck lots from Chinese ports to global destinations: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack containerized shipping. Comparative performance metrics include cost efficiency, transit time, vehicle integrity, scalability, and corrosion protection. Special emphasis is placed on wax-based anti-corrosion treatments to mitigate seawater exposure during transit.

1. Overview of Export Demand

China has emerged as a leading global exporter of used commercial vehicles, particularly trucks and heavy-duty equipment, driven by fleet turnover cycles and demand in emerging markets. Key export regions include Africa, Southeast Asia, the Middle East, and South America. Fleet managers and construction firms require reliable, cost-effective, and damage-minimized transport solutions.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Loading Method | Self-propelled or towed | Lifted by crane, stacked | Secured on open-frame container |

| Vehicle Capacity (per vessel) | High (150–300+ trucks) | Medium (50–150 trucks) | Low–Medium (5–10 trucks per 40′ FR) |

| Port Infrastructure | Requires RO-RO terminal | General multipurpose port | Standard container terminal |

| Transit Time | Fast (direct routing) | Moderate | Moderate to slow (subject to container schedules) |

| Handling Damage Risk | Low (minimal lifting) | High (crane handling, stacking) | Medium (secure lashing critical) |

| Insurance & Claims | Lower (standardized process) | Higher (increased damage risk) | Moderate |

| Cost per Unit (USD) | $800–$1,200 | $600–$900 | $1,400–$2,000 |

| Scalability | High (bulk lot optimized) | Medium | Low (per-container basis) |

| Customs Clearance | Streamlined (group processing) | Variable | Standard container protocols |

| Corrosion Exposure Risk | Moderate (open decks exposed) | High (stacked, no protection) | Low–Moderate (enclosed if covered) |

3. Corrosion Protection: Wax Spraying Treatment

Seawater exposure during maritime transport poses a significant threat to vehicle undercarriages, chassis, and electrical systems. SEA LION International recommends the application of industrial-grade wax spraying as a preventive measure.

Wax Spraying Specifications:

| Parameter | Specification |

|---|---|

| Wax Type | Synthetic hydrophobic polymer blend |

| Application Method | High-pressure spray (undercarriage + chassis) |

| Coating Thickness | 50–70 µm (microns) |

| Salt Spray Resistance | >1,000 hours (per ASTM B117) |

| Drying Time | 30–60 minutes (ambient) |

| Removability | Biodegradable solvent or steam wash |

| Cost per Vehicle | $45–$65 |

Benefits:

- Forms hydrophobic barrier against saltwater and humidity

- Reduces surface oxidation by up to 85% during 30–45 day voyages

- Compatible with post-delivery decontamination processes

- Non-conductive; protects wiring and sensors

Note: Wax treatment is recommended for all shipping methods but is critical for Bulk Cargo and RO-RO due to direct exposure.

4. Method-Specific Recommendations

A. RO-RO Shipping

- Best for: High-volume exporters, working with ports equipped for RO-RO.

- Advantages: Fast loading, low mechanical damage, ideal for operable trucks.

- Limitations: Limited global port availability; higher base cost.

- Corrosion Mitigation: Wax spray mandatory; optional deck tarpaulin cover for added protection.

B. Bulk Cargo Shipping

- Best for: Non-operational or damaged units; cost-sensitive operations.

- Advantages: Lower freight cost; flexible port access.

- Limitations: High risk of physical and environmental damage.

- Corrosion Mitigation: Full chassis waxing required; use of desiccants inside cabs.

C. Flat Rack Containers

- Best for: High-value or oversized trucks (e.g., crane trucks, mixers).

- Advantages: Secure, traceable, stackable; suitable for multimodal logistics.

- Limitations: High cost per unit; lashing must meet ISO 1496/3 standards.

- Corrosion Mitigation: Wax spray + optional breathable shrink wrap for full enclosure.

5. Operational Recommendations

- Pre-shipment Protocol:

- Conduct full diagnostic and fluid stabilization.

- Drain hygroscopic fluids (brake, coolant) if non-operational.

-

Apply wax spray 24h prior to loading.

-

Lashing & Securing:

- RO-RO: Chock wheels, apply parking brake, secondary chains.

- Flat Rack: Use 5,000 kg minimum break-strength lashing straps (4-point minimum).

-

Bulk: Wooden dunnage + steel bracing for stacked units.

-

Documentation:

- Provide Bill of Lading, Export Declaration, and Anti-Corrosion Certificate.

- Include wax treatment batch number and application timestamp.

6. Conclusion

For fleet managers and construction companies exporting used truck lots from China, RO-RO shipping offers the optimal balance of cost, speed, and vehicle protection for operable units. Flat Rack is preferred for specialized or high-value assets, while Bulk Cargo remains viable only for non-operational units under strict corrosion and handling controls.

Mandatory wax spraying is a cost-effective, industry-standard intervention that significantly reduces post-transit maintenance and increases resale value. SEA LION International advises integrating wax protection into all export workflows, regardless of shipping method.

End of Report

SEA LION International – Engineering Division

Version: IS-2026-LOG-04

Date: April 5, 2026

Get a Quote for Used Truck Lots

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]