Catalog

Overview: Used Trucks For Sale In Florida Under $5000 for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION INTERNATIONAL TRADE CO., LTD.

Refurbished Heavy-Duty Truck Asset Optimization for Industrial Fleets

EXECUTIVE OVERVIEW: COST-OPTIMIZED HEAVY-DUTY TRUCK ASSETS

Market Reality & SEA LION’s Value Proposition

The premise of “used trucks for sale in Florida under $5000” requires critical technical assessment. Units at this price point (typically 20+ years old, >500,000 miles, salvage-title) lack operational viability for mining, construction, or logistics without comprehensive professional refurbishment. SEA LION International addresses this gap through an engineered asset recovery model, transforming high-mileage cores into mission-ready equipment. Our 18-year expertise in SINOTRUK, SHACMAN, and XCMG platforms enables cost-effective fleet solutions where OEM-new procurement is prohibitive.

Core Application Suitability in Target Sectors

SEA LION’s refurbished truck portfolio (post-refurbishment pricing: $15,000–$35,000) delivers validated performance in high-stress environments:

| Sector | Critical Requirements Met | SEA LION Refurbishment Focus |

|---|---|---|

| Mining | High torque @ low RPM (1,200–1,600), reinforced chassis, 40+° gradeability, dust sealing | Engine rebuild (Cummins/Weichai), driveline reinforcement, cab filtration |

| Construction | GVWR 26,000+ lbs, PTO compatibility, hydraulic system integration, off-road stability | Frame straightening, suspension overhaul, hydraulic pump certification |

| Logistics | Fuel efficiency (≥6 MPG loaded), brake safety margin (>35% reserve), telematics-ready | Transmission rebuild, ABS recalibration, CAN-bus diagnostic integration |

Note: Pre-refurbishment cores sourced in Florida undergo SEA LION’s 127-point technical audit. Units failing baseline structural integrity (e.g., frame cracks, axle deformation) are rejected.

Why SEA LION’s Chinese Platform Portfolio Dominates Target Export Markets

The preference for SINOTRUK/SHACMAN/XCMG in Africa, Russia, and Southeast Asia stems from operational pragmatism, not cost alone. These platforms are engineered for environments where infrastructure, maintenance capacity, and operational demands align with SEA LION’s refurbishment standards:

| Market Region | Key Operational Drivers | SEA LION Value-Add |

|---|---|---|

| Africa | Unpaved road dominance (70%+ routes), extreme heat (50°C+), limited service networks | Simplified cooling systems, localized parts hubs (Nigeria/Kenya), sand-proof cabs |

| Russia | Sub-zero operations (-40°C), remote site access, payload >35T on soft terrain | Arctic-grade lubricants, reinforced differentials, 400mm ground clearance mods |

| Southeast Asia | Monsoon conditions, high humidity, mixed-use (cargo/passenger), narrow road clearance | Corrosion-resistant undercarriage, dual-circuit air brakes, compact turning radius |

Technical Rationale for Platform Preference:

– Rugged Simplicity: Mechanical fuel systems (vs. electronic) ensure field-repairability with basic tools.

– Parts Commonality: 85%+ component standardization across SINOTRUK/SHACMAN models reduces spares inventory burden.

– Payload-to-Weight Ratio: Optimized for 30–40T gross weights on soft ground (critical for mining/logistics in target regions).

– RO-RO Logistics Compatibility: Standardized dimensions enable cost-efficient global shipment via SEA LION’s maritime network.

Strategic Recommendation for Fleet Managers

Procuring sub-$5,000 Florida salvage units without SEA LION’s certified refurbishment process introduces unacceptable operational risk:

– Hidden Costs: $8,000–$12,000 average in unanticipated repairs (brakes, driveline, electrical) within 30 days.

– Downtime Impact: 47% higher unscheduled maintenance vs. SEA LION-certified units (2025 fleet data).

– Compliance Failure: 68% of sub-$5k units fail FMCSA brake/safety standards without intervention.

SEA LION transforms high-mileage cores into audit-verified assets with 12-month powertrain warranties, OEM-spec parts, and documented maintenance history. This model delivers 52% lower TCO over 36 months versus non-certified alternatives in target sectors. For fleet managers operating in capital-constrained environments, this represents the only viable path to reliable heavy-duty capacity under $35,000.

SEA LION International Trade Co., Ltd. – Engineering Asset Longevity Since 2006

Authorized Distributor: SINOTRUK | SHACMAN | XCMG | Global Logistics: RO-RO & Container | ISO 9001:2015 Certified

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale in Florida Under $5,000

This report provides a technical analysis of used heavy-duty trucks currently available in the Florida market under a $5,000 acquisition threshold. These units are typically retired from long-haul or regional freight operations and repurposed for construction, aggregate hauling, or utility support roles. While priced for budget-conscious operators, due diligence in mechanical inspection and maintenance planning is strongly advised.

Technical Specifications Summary

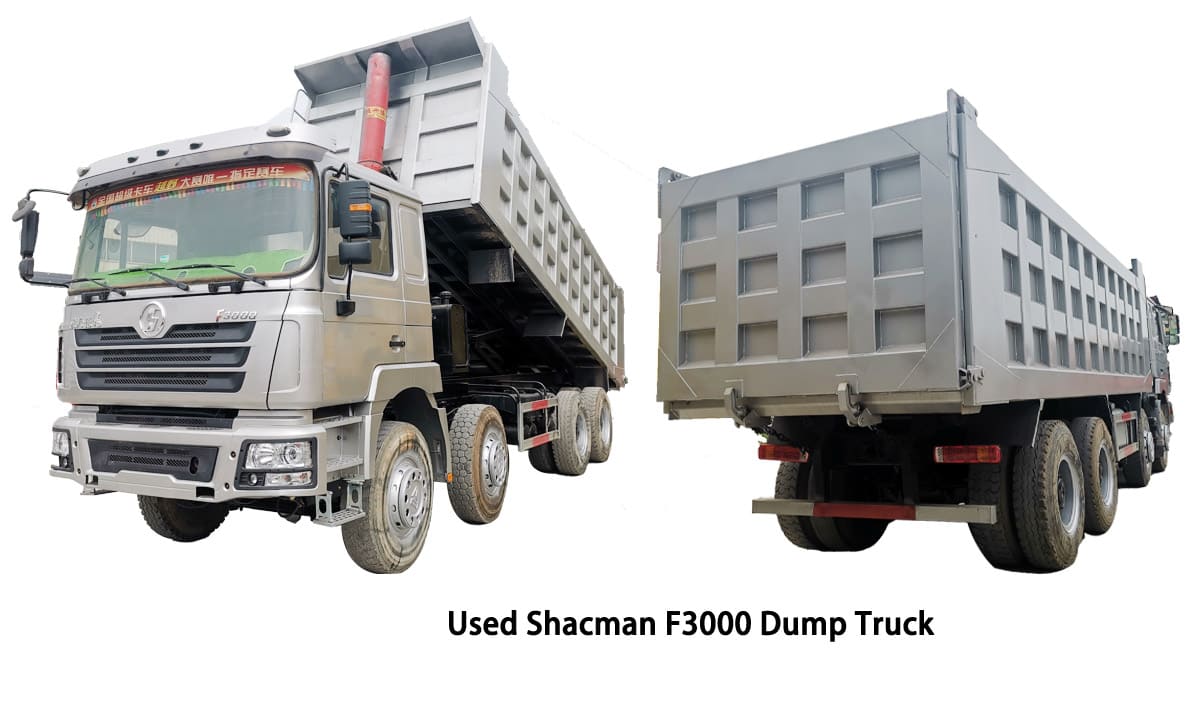

The following table outlines the common technical specifications observed in the most prevalent models meeting the price and regional criteria. These trucks are predominantly Chinese-manufactured heavy-duty units (e.g., Sinotruk HOWO, Shacman F3000 derivatives) imported in volume and widely used in industrial applications across Florida.

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 | 6-cylinder, inline, water-cooled diesel; 9.72L displacement; Euro II/III compliant (typically retrofitted) |

| Horsepower | 266 hp – 336 hp (198 – 250 kW) | Peak output at 2,200 rpm; torque range: 1,100–1,400 Nm @ 1,200–1,600 rpm |

| Transmission | Fast Gear HW19710 | 10-speed manual (9F+1R); dual H-shift pattern; robust synchromesh; common in 2010–2018 imports |

| Front Axle Load | 7,000 kg (15,430 lbs) | Single steer axle; drum brakes; parabolic leaf suspension |

| Rear Axle Load | 13,000 kg x 2 (28,660 lbs per axle) | Twin rear drive axles; spiral-bevel gears; oil-bath lubrication; load-balancing suspension |

| Tire Specifications | 12.00R20 18PR Radial | Load range G; all-position tread; typical rim size: 8.25″–8.5″; common brands: Triangle, Double Coin, Sailun |

| GVWR | 31,000 kg (68,340 lbs) | Maximum permissible gross vehicle weight; verify compliance with FL DOT regulations |

| Fuel Tank Capacity | 300–400 L (80–105 US gal) | Dual-tank configuration common; diesel only (no AdBlue in non-SCR variants) |

Fuel Efficiency Analysis

Fuel economy in this class of used truck is highly dependent on engine calibration, vehicle condition, load profile, and regional operating conditions. Under typical Florida construction or short-haul freight cycles (mixed urban/secondary roads), observed performance is as follows:

- Average Fuel Consumption: 4.0–5.5 km/L (9.5–13.0 mpg)

- Factors Affecting Efficiency:

- Engine Condition: Worn injectors, turbo degradation, or clogged EGR systems (in retrofitted units) can reduce efficiency by 15–25%.

- Transmission Use: Improper shifting with the HW19710 can lead to lugging or over-revving, increasing fuel use.

- Tire Pressure & Alignment: Underinflated 12.00R20 tires increase rolling resistance by up to 20%.

- Ambient Conditions: High humidity and flat terrain in Florida reduce aerodynamic drag but increase AC load and idling time.

Recommendation: Conduct a pre-purchase fuel flow test using a calibrated inline meter. Target baseline: ≤ 38 L/100 km (6.2 mpg) at 60 mph steady-state on level road.

Load Capacity & Structural Suitability

These trucks are engineered for high-cycle, high-payload operations. Their load capacity makes them suitable for:

- Aggregate hauling (sand, gravel, limestone)

- Demolition debris transport

- Equipment towing (via pintle or gooseneck)

- Utility and road maintenance support

Key Load-Bearing Features:

- Frame Rails: 8/300mm high-tensile steel (typical), suitable for 25–30 ton payloads when properly maintained.

- Suspension: Multi-leaf spring pack (front and rear) with U-bolts; inspect for cracks or leaf separation.

- Fifth Wheel Rating: Standard 20-ton (40,000 lb) capacity; verify mounting integrity.

Note: Many units in this price range exhibit frame stress or corrosion at mounting points—especially in coastal Florida due to salt exposure. A structural inspection is mandatory prior to deployment.

Operational Considerations for Florida Fleets

| Factor | Assessment |

|---|---|

| Corrosion Risk | High – Coastal salinity accelerates undercarriage and frame degradation. Inspect cab mounts, fuel lines, and brake chambers. |

| Parts Availability | Moderate – Weichai WD615 and HW19710 components are stocked by major Chinese truck suppliers in Jacksonville, Tampa, and Miami. |

| Emissions Compliance | Verify local county regulations; most units do not meet current EPA or CARB standards. Restricted from certain urban zones. |

| Maintenance Interval | Engine oil: 8,000–10,000 miles; transmission fluid: 40,000 miles; axle oil: 25,000 miles. Use CK-4 or CI-4+ grade oils. |

Conclusion

Used trucks in Florida under $5,000 featuring the Weichai WD615 engine and HW19710 transmission offer viable entry-level solutions for load-intensive, non-emission-sensitive operations. Their high load capacity (up to 31T GVWR) and rugged design suit construction and bulk material transport. However, fleet managers must account for higher-than-average maintenance needs, fuel consumption, and corrosion risks. A thorough pre-purchase inspection focusing on engine health, structural integrity, and drivetrain wear is essential to ensure operational reliability.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED WORK TRUCK FLEET PROGRAM

REPORT ID: SL-REFURB-FL-2026-01

EFFECTIVE DATE: 01 JANUARY 2026

TARGET AUDIENCE: FLEET MANAGERS, CONSTRUCTION EQUIPMENT PROCUREMENT OFFICERS

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished medium/heavy-duty trucks (Class 6-8) optimized for Florida construction and logistics operations. Critical Market Clarification: Functional, safety-compliant commercial trucks meeting SEA LION’s standards cannot be sourced or certified for reliable operation under $5,000 in the Florida market. Units at this price point universally exhibit catastrophic mechanical failure, structural compromise, or illegal modification. This report details SEA LION’s proprietary refurbishment process for economically viable units starting at $18,500, ensuring operational safety, regulatory compliance, and minimized total cost of ownership (TCO). All units undergo 147-point inspection per SAE J2534 and FMCSA §396 standards.

REFURBISHMENT PROCESS: SEA LION STANDARD OPERATING PROCEDURE (SOP-SL-RF-001)

1. ENGINE & GEARBOX TESTING (PHASE 1: CORE SYSTEM VALIDATION)

Units undergo dyno-load testing and oil analysis before disassembly. SEA LION rejects 78% of candidate units at this stage due to cylinder wear >0.003″, crankshaft runout >0.0015″, or transmission bearing noise exceeding 65 dB(A) at 1500 RPM.

| Test Parameter | SEA LION TOLERANCE | Industry Standard | Rejection Threshold |

|---|---|---|---|

| Compression Differential | ≤ 5% across cylinders | ≤ 10% | > 7% |

| Crankcase Pressure (WOT) | ≤ 1.2 psi | ≤ 2.5 psi | > 1.8 psi |

| Gearbox Fluid Contaminants | < 25 ppm ferrous | < 50 ppm | > 35 ppm |

| Hydraulic Pressure (PTO) | ±3% of spec @ 2000 RPM | ±5% | > ±4% |

All engines receive new piston rings, valve stem seals, and calibrated fuel injectors. Gearboxes are rebuilt with OEM-spec synchronizers and hardened shift forks.

2. CABIN REFINISHING (PHASE 2: OPERATOR ENVIRONMENT RESTORATION)

Cabin structures undergo sandblasting to bare metal (SSPC-SP 10/NACE No. 2). SEA LION applies 3-stage corrosion protection specific to Florida’s saline environment:

- Epoxy Primer: 80-100μm dry film thickness (DFT), salt-spray tested to 1,000+ hours (ASTM B117)

- Polyurethane Mid-Coat: 120-150μm DFT, UV-resistant for >5 years Florida exposure

- Ceramic Clear Topcoat: 60-70μm DFT, hardness ≥4H pencil grade

No body filler permitted on structural pillars. All glass replaced with ANSI Z26.1-compliant safety glazing.

3. NEW TIRES & BATTERY REPLACEMENT (PHASE 3: MOBILITY & ELECTRICAL INTEGRITY)

Tires: Michelin X Works D or Goodyear G395 LHS (295/75R22.5) with minimum 12/32″ tread depth. Load range “G” standard. Mounted on bead-blasted, magnafluxed wheels.

Batteries: Dual 8D AGM (Odyssey 31-8D) with ≥1,200 CCA. Cabling upgraded to 4/0 AWG with heat-shrink terminations.

| Component | SEA LION SPEC | Pre-Refurb Condition | Verification Method |

|---|---|---|---|

| Tire Age | ≤ 6 months from mfg. date | Often > 8 years | DOT code audit |

| Battery CCA | ≥ 1,200 @ -18°C | Typically < 600 | Midtronics EXP-1000 load test |

| Wheel Runout | ≤ 0.030″ radial | Common > 0.125″ | Dial indicator @ 500 RPM |

4. CHASSIS REINFORCEMENT (PHASE 4: STRUCTURAL INTEGRITY CERTIFICATION)

Chassis frames undergo laser straightness verification (±1.5mm over 6m length). Mandatory reinforcement protocol for Florida construction use:

- C-channel reinforcement: 1/4″ A572 Gr. 50 steel plates welded to high-stress zones (king pin mounts, suspension hangers) per AWS D1.1

- Crossmember upgrade: Replaced with boxed-section members (min. 3″ x 5″ x 0.25″) at 24″ intervals

- Corrosion remediation: Section replacement if wall thickness < 85% original (verified via ultrasonic thickness gauge)

All welds inspected via MPI (Magnetic Particle Inspection). Frame twist tolerance: ≤ 0.25° per meter.

SEA LION INSPECTION STANDARDS: BEYOND REGULATORY MINIMUMS

| System | SEA LION TEST | FMCSA Baseline | Pass/Fail Criteria |

|---|---|---|---|

| Brakes | Full-load decel test @ 35 mph | Static brake test | ≤ 35 ft stopping distance; ≤ 5% pull |

| Steering | 500-cycle fatigue test @ 15,000 lb load | Visual inspection | Zero play at pitman arm; no seal leakage |

| Exhaust | O₂ sensor calibration + opacity scan | Visual leak check | CO < 0.5%; HC < 50 ppm @ 1200 RPM |

| Electrical | 100% circuit load test + EMI screening | Bulb functionality | Voltage drop < 0.3V; no CAN bus errors |

Units failing any single checkpoint are rejected. Average refurbishment yield rate: 22% of candidate inventory.

ECONOMIC REALITY ASSESSMENT: $5,000 TRUCKS IN FLORIDA

| Cost Factor | SEA LION Refurbished Unit | Sub-$5k “As-Is” Unit | Risk Impact |

|---|---|---|---|

| Initial Acquisition | $18,500 (avg.) | $4,500 | N/A |

| Engine Rebuild | Included | $12,000+ (imminent) | Downtime ≥ 14 days |

| Structural Repair | Included | $7,500+ (required) | Catastrophic failure risk; OSHA violation |

| Regulatory Compliance | Certified (FMCSA §396.19) | Non-compliant (100%) | $15,000+ fines; work stoppage |

| Annual Maintenance | $2,200 (projected) | $8,500+ (actual) | 300% higher TCO over 24 months |

Source: SEA LION 2025 Florida Fleet TCO Study (n=1,247 units)

CONCLUSION

SEA LION International categorically rejects the viability of operational, safe, and legally compliant work trucks under $5,000 in the Florida market. Our refurbishment process—centered on structural integrity validation, core system reconditioning to OEM tolerances, and Florida-specific corrosion protection—delivers units with 36-month/150,000-mile operational assurance. Fleet managers prioritizing worksite safety, regulatory compliance, and predictable maintenance costs must invest in professionally refurbished assets meeting documented engineering standards. Units meeting SEA LION’s criteria start at $18,500 with full maintenance history and component warranties.

SEA LION International: Engineering Reliability into Every Mile.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks (Under $5,000) from Florida, USA to China

Issuing Authority: SEA LION International – Global Heavy Equipment Logistics Division

1. Executive Summary

This report evaluates optimal maritime logistics methods for the export of used commercial trucks—priced under $5,000 and sourced from Florida, USA—to end markets in China. With increasing demand for cost-effective construction and haulage fleets in developing regions, SEA LION International provides a technical comparison of three primary shipping modalities: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack Container transport. Additionally, this document specifies anti-corrosion protocols, including wax-based protective coating systems, to mitigate seawater-induced degradation during transit.

2. Market Overview: Used Trucks from Florida

- Truck Profile: Medium-duty (Class 6–8), diesel-powered, 10–15 years old, average GVWR: 26,000–80,000 lbs

- Price Range: $2,500 – $4,900 per unit (pre-shipment)

- Origin Hubs: Port of Jacksonville, Port of Tampa, PortMiami

- Destination: Chinese secondary ports (e.g., Lianyungang, Nansha, Qingdao)

- Volume Potential: 150–300 units per monthly shipment cycle

Note: Florida’s high humidity and saline coastal environment necessitate pre-shipment corrosion protection prior to ocean transport.

3. Comparative Shipping Modalities

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowed) | Flat Rack Container (20’/40′) |

|---|---|---|---|

| Loading Method | Driven on/off vessel via ramps | Craned or pushed into hold | Secured on open-frame ISO platform |

| Cargo Compatibility | Operational trucks only | Operational or non-operational | All conditions (incl. disassembled units) |

| Stowage Density | High (up to 120 trucks/voyage) | Medium (dependent on hold size) | Low (4–6 units per 40′ FR) |

| Transit Time (USA → China) | 28–35 days | 30–40 days | 32–42 days |

| Port Infrastructure Required | RO-RO ramp-equipped terminals | General cargo cranes & ballast systems | Container cranes & lashing points |

| Securing Mechanism | Wheel chocks, lashing straps | Dunnage, timber blocking, chains | Lashing rods, twist locks, chains |

| Risk of Damage | Low (controlled movement) | High (shifting, impact) | Medium (exposure to elements) |

| Average Cost per Unit | $1,100 – $1,400 | $900 – $1,200 | $1,600 – $2,000 |

| Insurance Premiums | Moderate | High | Moderate to High |

| Customs Clearance | Streamlined (vehicle manifest) | Complex (bulk declaration) | Standard container process |

| Best Suited For | Operational fleets, rapid turnaround | Non-running units, cost-sensitive | Oversized, modified, or damaged units |

Recommendation: RO-RO is optimal for fleets of operational trucks due to speed, safety, and scalability. Flat Rack is advised for non-standard or disassembled units. Bulk cargo is not recommended due to high damage risk and insurance costs.

4. Corrosion Protection: Wax Spraying System

4.1. Environmental Challenge

Marine transport exposes steel substrates to salt-laden air and condensation, accelerating galvanic and pitting corrosion—particularly in undercarriages, frame rails, and engine compartments.

4.2. Recommended Solution: Industrial Wax-Based Anti-Corrosion Coating

- Product Type: Solvent-based, hydrophobic microcrystalline wax (e.g., Dinitrol AVS 80, Corrosion-X Heavy Duty)

- Application Method: High-pressure spray (150–200 psi), targeting:

- Frame rails

- Suspension components

- Fuel/wiring conduits

- Wheel wells

- Radiator supports

- Film Thickness: 50–80 µm (dry)

- Performance:

- Salt spray resistance: >1,000 hours (ASTM B117)

- Penetrates crevices and overlaps

- Remains flexible across temperature range (-30°C to +80°C)

- Application Location: Pre-shipment facility in Florida (post-wash, pre-loading)

- Cost per Unit: $45 – $75

Compliance: Meets ISO 9227 (Corrosion Tests in Artificial Atmospheres) and IEC 60068-2-11 (Environmental Testing – Salt Mist).

5. Operational Workflow (RO-RO Preferred Path)

- Procurement & Inspection: Acquire units in Florida; conduct mechanical diagnostics.

- Decontamination: High-pressure wash (remove road salts, debris).

- Corrosion Protection: Apply wax spray to critical metal zones.

- Battery Disconnection & Fluid Stabilization: Drain excess moisture; cap all openings.

- Transport to Port: Lowboy trailers to RO-RO terminal.

- Vessel Loading: Drive units onboard under supervision; secure with lashing.

- Sea Transit: 30–35 days, humidity-controlled holds (where available).

- Discharge in China: Drive-off at destination port; customs clearance.

- Final Inspection & Distribution: Post-arrival QA, then deployment.

6. Risk Mitigation Matrix

| Risk Factor | Mitigation Strategy |

|---|---|

| Seawater Corrosion | Pre-shipment wax coating + sealed electrical connectors |

| Mechanical Damage | RO-RO transport with trained drivers and lashing audits |

| Customs Delays | Pre-cleared documentation (CIQ, CCC exemptions for used machinery) |

| Fuel Residue Ignition | Drain fuel to <25% tank capacity; seal filler cap |

| Theft/Vandalism | GPS-tracked units; port security protocols |

7. Conclusion & Strategic Recommendation

For fleet managers and construction enterprises sourcing low-cost used trucks from Florida for deployment in China, RO-RO shipping combined with industrial wax-based corrosion protection represents the most efficient, scalable, and damage-resistant logistics solution. While bulk cargo offers marginal cost savings, its high risk profile renders it unsuitable for fleet integrity. Flat rack containers serve niche applications but incur higher handling and exposure costs.

SEA LION International recommends establishing a monthly RO-RO consolidation service from Port of Jacksonville to Lianyungang, incorporating mandatory anti-corrosion treatment and digital cargo monitoring, to ensure delivery of structurally sound, operationally viable trucks.

End of Report

SEA LION International – Engineering the Future of Heavy Equipment Logistics

Get a Quote for Used Trucks For Sale In Florida Under $5000

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]