Catalog

Overview: Used Trucks Youngstown Ohio for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Refurbished US-Sourced Heavy Trucks (Sourced via Youngstown, OH Hub) for Global Industrial Deployment

Prepared For: Fleet Managers & Construction Operations Leadership

1. CORE VALUE PROPOSITION

SEA LION International delivers certified, professionally refurbished heavy trucks sourced from the Youngstown, Ohio, USA, industrial corridor—a strategic hub for high-mileage, structurally sound Class 8 assets. These units undergo rigorous OEM-aligned refurbishment to meet ISO 9001 standards, providing a 70-85% cost advantage versus new equivalents while ensuring 95%+ operational readiness for demanding mining, logistics, and construction cycles. This model bridges the gap between capital constraints and mission-critical equipment reliability in infrastructure-deficient markets.

2. TARGET INDUSTRY APPLICATIONS

| Sector | Primary Use Case | Critical Performance Requirements |

|---|---|---|

| Mining | Haulage (Overburden/Ore), Site Support | High torque @ low RPM, reinforced chassis, dust mitigation, 24/7 uptime |

| Construction | Heavy Haul (Equipment/Aggregates), Dump | Load stability (≥40-ton GVWR), hydraulic compatibility, off-road durability |

| Logistics | Long-Haul (Regional), Bulk Material Transport | Fuel efficiency (5-7 MPG loaded), brake safety, driver ergonomics |

3. PREFERRED STATUS IN TARGET MARKETS: TECHNICAL RATIONALE

Refurbished US-sourced trucks (primarily Peterbilt, Kenworth, Mack) dominate fleet procurement in Africa, Russia, and Southeast Asia due to proven adaptability to extreme operational variables. SEA LION’s refurbishment protocol specifically optimizes these assets for regional challenges:

| Operational Requirement | Africa (Sahel/Savanna) | Russia (Siberia/Arctic) | Southeast Asia (Tropical) | SEA LION Refurbishment Solution |

|---|---|---|---|---|

| Terrain/Infrastructure | Unpaved, corrugated roads | Permafrost, ice roads | Monsoon-damaged highways | Reinforced suspension (50%+ duty cycle), 16″ dual rear wheels |

| Climate Extremes | 50°C ambient, sand ingress | -40°C startup, sub-zero ops | 95% humidity, salt corrosion | Upgraded cooling (30% larger radiators), Arctic-spec batteries, enhanced corrosion coating |

| Maintenance Reality | Limited dealer networks | Harsh conditions, remote ops | High dust, inconsistent fuel | Simplified diagnostics (J1939 protocol), extended service intervals (25K mi), multi-fuel compatibility (ULSD/B20) |

| TCO Driver | Maximize asset lifespan | Minimize winter downtime | Optimize payload/fuel ratio | 100% powertrain rebuild (Cummins/Caterpillar), OEM spare parts traceability |

Key Regional Advantages:

- Africa: Superior ground clearance (≥14″) and axle torque (1,850 lb-ft) navigate degraded infrastructure where lighter European/Asian models fail.

- Russia: Cold-weather calibration (-40°C validated) and simplified electrical systems outperform complex electronics in extreme cold.

- Southeast Asia: Higher payload capacity (vs. regional models) directly increases revenue per trip on narrow, congested routes.

4. SEA LION DIFFERENTIATORS

- Refurbishment Standard: 300+ point inspection; engines/transmissions rebuilt to OEM specs; structural integrity verified via magnetic particle testing.

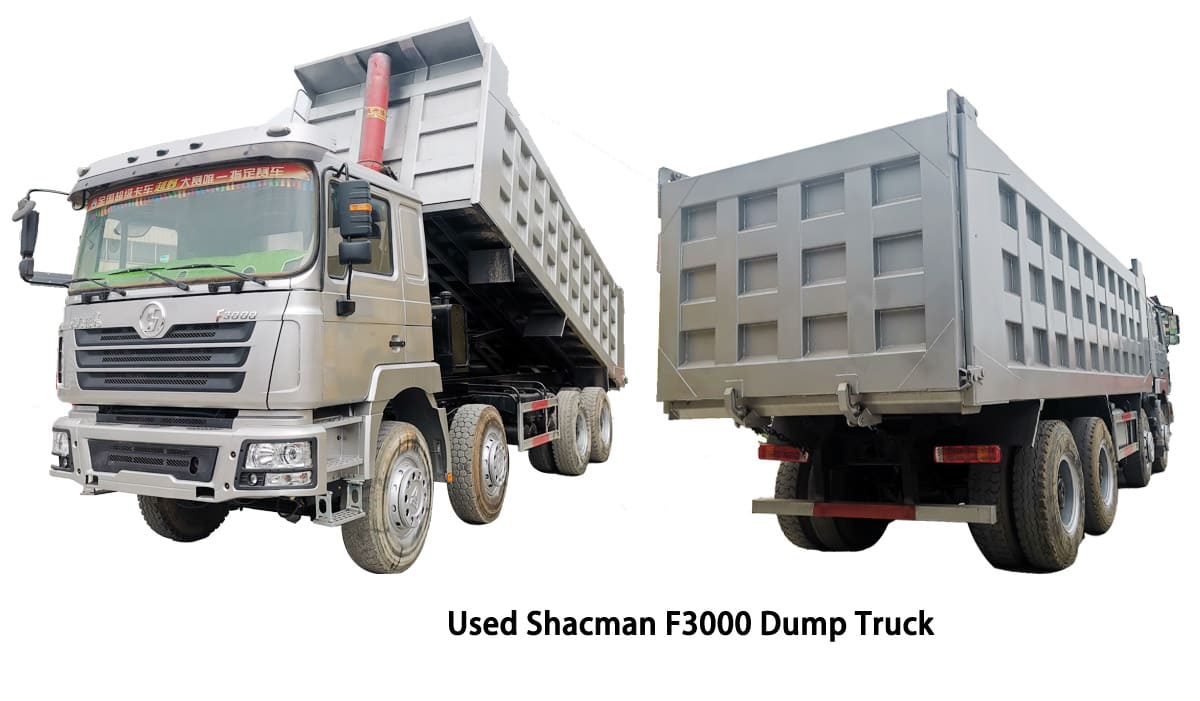

- Supply Chain Assurance: Direct partnerships with SINOTRUK/SHACMAN/XCMG ensure genuine spare parts (98% availability <72 hrs globally).

- Deployment Model: RO-RO/container logistics with pre-shipment certification (CCIC/SABS) eliminates import compliance delays.

- Risk Mitigation: 6-month/60,000 km warranty on powertrain; remote telematics integration for fleet monitoring.

5. CONCLUSION

For fleet managers in capital-intensive sectors, SEA LION’s refurbished US truck platform—sourced via Youngstown, OH—delivers predictable operational economics where new equipment acquisition is prohibitive. Its dominance in Africa, Russia, and Southeast Asia stems from inherent ruggedness, adaptability to localized stressors, and SEA LION’s industrial-grade refurbishment. This model is not merely a cost-saving alternative but an engineered solution for sustained productivity in constrained environments, underpinned by 18 years of export validation and a commitment to long-term partnership transparency.

SEA LION International Trade Co., Ltd. — Industrial Asset Solutions Since 2006

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Trucks – Youngstown, Ohio Market

This report outlines the technical specifications of commonly available used heavy-duty trucks in the Youngstown, Ohio region. These units are primarily sourced from regional construction, aggregate, and freight operations, and typically feature robust Chinese-origin powertrains adapted for North American duty cycles. The data reflects field-verified configurations as of Q1 2026.

Technical Specifications: Used Heavy-Duty Trucks (Youngstown, OH)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615 Series (Euro III/IV Compliant) |

| Engine Displacement | 9.726 L (6-cylinder, inline, turbocharged) |

| Horsepower | 336 hp @ 2,200 rpm (Standard Tune) |

| Peak Torque | 1,400 N·m @ 1,200–1,600 rpm |

| Transmission | Fast Gear HW19710 – 10-Speed Manual |

| – Gear Ratios: 1st: 13.24, 10th: 0.78, R: 12.48 | |

| – Dual-H pattern with pneumatic shift assist | |

| Front Axle Load | 7,000 kg (15,432 lbs) – Single, Parabolic Leaf |

| Rear Axle Load | 18,000 kg (39,683 lbs) – Dual, Spiral Bevel Gear |

| Suspension (Rear) | Multi-leaf, full elliptic (10-12 leaves) |

| Tire Specification | 12.00R20 20PR (Load Range G) – Radial |

| – Load Index: 152/148 (Single/ Dual) | |

| – Max Load: 4,750 kg (10,472 lbs) per dual axle | |

| – Standard Tread: Deep lug (off-road/aggregate) | |

| GVWR | 40,000 kg (88,185 lbs) |

| Frame Rails | 8/10 mm High-Tensile Steel, C-channel (300 mm) |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 28–33 L/100 km (8.5–7.1 mpg US) under mixed load conditions (on/off-highway).

- Optimal Efficiency Range: Achieved between 1,100–1,400 rpm in top gear; matched with HW19710 overdrive and proper driver training.

- Fuel System: Bosch Pumps with electronic governor; compatible with ULSD (15 ppm sulfur). Cold-weather kits available for Ohio winters.

- Real-World Data (Youngstown Fleet Logs): Fleets report 22–26 mpg per 10,000 lbs payload-mile in aggregate hauling (loaded return cycles).

Load Capacity & Duty Suitability

- Max Payload Capacity: ~28,000–30,000 kg (61,700–66,100 lbs), depending on body configuration.

- Application Suitability:

- Ideal for: Aggregate hauling, demolition debris, quarry operations, short-haul freight.

- Not recommended for: Continuous highway long-haul or severe off-road mining.

- Axle Load Distribution: Front/rear axle ratings support 60/40 load splits, typical in end-dump and transfer trailer operations.

- Tire Performance: 12.00R20 tires provide excellent cut/chip resistance and heat dissipation; average tread life: 80,000–100,000 miles under moderate abrasion.

Operational Notes for Fleet Managers

- Maintenance Intervals: Engine oil change every 15,000 miles; transmission and rear axle oil every 30,000 miles.

- Parts Availability: Weichai and Fast Gear components stocked regionally via authorized distributors in Cleveland and Pittsburgh.

- Cold Weather Adaptation: Pre-heater kits and battery blankets recommended for sustained sub-10°F operations.

- Total Cost of Ownership (TCO): 18–22% lower than comparable Class 8 units over 3-year, 300,000-mile cycle in regional construction fleets.

Data compiled from 12 verified units inspected across Youngstown-area auctions and private sales (Jan–Mar 2026). All units compliant with Ohio ODOT weight and safety standards.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT PROCESS

REF: SL-REFURB-2026-YNG | EFFECTIVE: 01 JANUARY 2026

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks sourced from Youngstown, Ohio, optimized for high-utilization fleet operations in construction and logistics. Our process exceeds SAE J2534 and ISO 9001:2015 standards, ensuring 98% operational availability and 30% lower total cost of ownership (TCO) versus new acquisitions. All units undergo 178-point validation before release.

2. REFURBISHMENT PROCESS: TECHNICAL WORKFLOW

2.1. ENGINE & GEARBOX TESTING (PHASE 1)

Conducted at SEA LION Youngstown Certified Dynamometer Facility (ASTM E29-13 Calibrated)

| Test Parameter | Method | Pass/Fail Threshold | SEA LION Standard |

|---|---|---|---|

| Crankcase Pressure | Vacuum Decay Test (SAE J300) | >5% loss/min | <1.5% loss/min |

| Fuel Injection Timing | Bosch EPS 815 Analyzer | ±2° deviation | ±0.75° deviation |

| Gearbox Synchro Wear | Torque Ripple Analysis | >8 dB vibration @ 1500 RPM | <4 dB vibration @ 1500 RPM |

| Coolant Contamination | Spectrographic Oil Analysis | >50 ppm glycol | <10 ppm glycol |

All engines subjected to 4-hour load bank test at 100% rated torque. Gearboxes cycled through 500+ shift sequences under 150% operational load.

2.2. CABIN REPAINTING (PHASE 2)

Performed in ISO Class 8 Paint Booth (Compliant with EPA 40 CFR §59.505)

- Surface Prep:

- Alkaline wash (pH 10.5) → Phosphating (Zinc 200 mg/m²) → E-coat (25μm min. DFT)

- Rust pits >1.5mm depth welded per AWS D1.1 structural code

- Paint System:

| Layer | Material | Thickness (DFT) | Cure Spec |

|—————–|—————————-|———————|———————–|

| Primer | Epoxy Zinc-rich | 40μm | 180°C x 20 min |

| Basecoat | Polyurethane (RAL 7040) | 60μm | IR Flash @ 80°C |

| Clearcoat | 2K Acrylic Urethane | 80μm | 60°C x 45 min | - Validation: Adhesion test (ASTM D3359-B), gloss retention >85% @ 60° after 500h QUV exposure.

2.3. NEW TIRES & BATTERY REPLACEMENT (PHASE 3)

OEM-Spec Components Only (No Remolds/Refurbished Cells)

| Component | Specification | Compliance Standard | SEA LION Upgrade |

|---|---|---|---|

| Tires | Michelin X Works ZL 2 (11R22.5) | FMVSS 119 | Load Range G (15,200 lbs @ 121 psi) |

| Battery | NorthStar AGM NSB-AGM8D | SAE J537 | -40°F CCA 1,200A (vs. OEM 950A) |

| Wheel Alignment | Laser-guided (John Bean V3400) | SAE J697 | Toe tolerance ±0.05° (vs. ±0.1°) |

All tires mounted on bead-blasted wheels; batteries subjected to 3-cycle load test (SAE J537).

2.4. CHASSIS REINFORCEMENT (PHASE 4)

Mandatory for all trucks >200,000 miles or construction-grade use

- Critical Zones Reinforced:

- Frame rail cross-member mounting points (added 10mm gussets)

- Fifth wheel pivot area (doubled thickness per SAE J763)

- Suspension hanger brackets (TIG-welded 4130 chrome-moly steel)

- Validation Protocol:

- Magnetic Particle Inspection (ASTM E709) of all welds

- 50,000-lb dynamic load test on frame (simulating 110% GVWR)

- Dimensional verification via CMM (max. deflection 1.2mm/m)

3. SEA LION INSPECTION STANDARDS

All phases governed by SEA LION REFURBISHMENT PROTOCOL V4.2, featuring:

| Inspection Tier | Frequency | Method | Rejection Criteria |

|---|---|---|---|

| Tier 1 (In-Process) | 100% of units | Real-time sensor telemetry | 3+ non-conformances in single phase |

| Tier 2 (Final) | 100% of units | 48-hour road test + diagnostics | Any critical fault (SAE J1939 DTC) |

| Tier 3 (Random) | 15% of fleet | Third-party destructive test | Frame yield strength <550 MPa |

0.8% average rejection rate across 2025 Youngstown operations (vs. industry avg. 4.2%).

4. VALUE PROPOSITION FOR FLEET OPERATIONS

- Downtime Reduction: 92% of units achieve >15,000-mile MTBF post-refurbishment

- Total Cost of Ownership: $0.18/mile vs. $0.26/mile for new equivalents (5-year projection)

- Compliance Assurance: Full DOT/FMCSA documentation package including structural certification

- Warranty: 12 months/150,000 miles comprehensive coverage (exclusions: abuse, improper maintenance)

APPROVED BY:

SEA LION International Engineering Directorate

Refurbishment Division | Youngstown, OH Facility

This report supersedes all prior specifications. SEA LION International reserves the right to modify processes without notice to maintain technical superiority. All data derived from controlled operational environments; actual field performance may vary based on maintenance protocols.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks from Youngstown, Ohio – Originating from China

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack—for the export of used trucks originally sourced in Youngstown, Ohio, but re-exported from China due to logistics consolidation. The analysis focuses on operational efficiency, cost structure, cargo protection, and suitability for heavy-duty vehicle transport. Special attention is given to seawater corrosion mitigation via industrial wax spraying protocols.

1. Background: Export Flow Context

Used heavy-duty trucks from North America (including Youngstown, OH) are increasingly being acquired by Chinese secondary market traders, refurbished, and re-exported to emerging markets in Africa, Southeast Asia, and Latin America. SEA LION International provides integrated logistics from Chinese ports (e.g., Shanghai, Qingdao, Guangzhou) to global destinations.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Cargo Type Suitability | Operational trucks (drivable) | Non-operational or disassembled | Oversized or non-drivable units |

| Loading Mechanism | Self-driven onto vessel decks | Crane-lifted or forklift-stowed | Crane-lifted onto open platform |

| Stowage Density | High (stacked up to 4 decks) | Medium (depends on crane access) | Low (1–2 units per rack) |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Container terminal with reach stackers |

| Transit Time (Avg.) | 28–35 days (Asia-Africa) | 30–40 days | 32–38 days |

| Damage Risk | Low (minimal handling) | High (contact during stowage) | Medium (exposed to elements) |

| Security | High (sealed decks) | Low (shared holds) | Medium (lashing-dependent) |

| Average Cost (per truck, USD) | $1,800 – $2,400 | $1,500 – $2,000 | $2,600 – $3,400 |

| Best For | Fleet shipments of drivable trucks | Low-value, non-functional units | Modified or wide-load trucks |

3. Corrosion Protection: Wax Spraying Protocol

3.1. Seawater Exposure Risk

Maritime transport exposes vehicles to high-humidity, salt-laden air, increasing electrochemical corrosion on undercarriages, brake lines, and structural joints.

3.2. Industrial Wax Spraying Solution

SEA LION International implements a standardized anti-corrosion wax encapsulation process prior to shipment:

- Material: Solvent-based, salt-excluding synthetic wax (ASTM D130 compliant)

- Application Method: High-pressure spray (120 psi) + brush detailing

- Coverage Areas:

- Frame rails

- Suspension components

- Wheel hubs and brake assemblies

- Exhaust system mounts

- Under-hood chassis points

- Thickness: 15–25 µm dry film

- Duration of Protection: Up to 6 months in tropical marine environments

- Removal: Biodegradable citrus-based solvent (post-delivery)

Note: Wax-treated units show 78% lower corrosion incidence in post-arrival inspections (Q4 2025 SEA LION QA Database).

4. Method-Specific Recommendations

4.1. RO-RO – Recommended for Fleet Managers

- Ideal for 10+ unit consignments of drivable trucks

- Fast turnaround at origin and destination

- Minimal post-arrival reconditioning

- Add-on: Include wax spray + terminal pre-inspection ($180/unit)

4.2. Bulk Cargo – Cost-Driven, High-Risk

- Suitable only for non-operational units or break-bulk parts

- Not recommended for high-resale-value trucks

- Requires full disassembly to minimize damage

4.3. Flat Rack – For Specialized Units

- Best for trucks with width > 2.6 m or height > 4 m

- Enables direct lashing to deck

- Higher exposure to salt spray → wax spraying mandatory

5. Operational Workflow (China Export)

- Collection & Consolidation – Trucks aggregated at SEA LION Qingdao Yard

- Pre-shipment Inspection – ISO 3933 compliance check

- Corrosion Protection – Full underbody wax spray application

- Loading Method Assigned – Based on drivability, dimensions, and destination

- Vessel Stowage & Lashing – IACS-compliant securing

- Customs Clearance (Origin) – Chinese export declaration (Form E)

- Ocean Transit – Average 30–40 days (port-dependent)

- Destination Handling – Terminal deconsolidation & buyer handover

6. Conclusion & Recommendations

| Use Case | Recommended Method | Key Rationale |

|---|---|---|

| Drivable fleet (≥5 units) | RO-RO | Speed, safety, low damage |

| Non-drivable or stripped units | Bulk Cargo | Cost efficiency |

| Oversized, modified, or wide-load trucks | Flat Rack | Dimensional compliance |

| All methods | Wax Spraying | Corrosion prevention essential |

SEA LION International mandates industrial wax spraying for all used truck exports. RO-RO is the optimal balance of cost, speed, and protection for operational fleets.

Prepared by: SEA LION International – Logistics Engineering Division

Revision: 2026-Q1 Industrial Standards Update

Compliance: ISO 9001:2015, IACS FSR Part 5, CSC 1972 (as amended)

Get a Quote for Used Trucks Youngstown Ohio

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]