Catalog

Overview: Cat Excavators Sizes for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: HEAVY HAUL EQUIPMENT SIZING FOR DEMANDING ENVIRONMENTS

Prepared for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Senior Engineering Division

EXECUTIVE OVERVIEW: ARTICULATED DUMP TRUCK (ADT) SIZE SELECTION STRATEGY

Note: While “Cat excavators” represent a significant segment, SEA LION International’s core expertise and authorization portfolio (SINOTRUK, SHACMAN, XCMG) center on heavy-duty trucks and articulated dump trucks (ADTs) critical for material movement in mining, quarrying, and large-scale construction. This overview addresses the strategic selection of ADT sizes, reflecting our 18+ years optimizing haulage solutions in target markets. Excavator sizing is outside our direct distribution scope but ADT compatibility is paramount.

The selection of appropriately sized Articulated Dump Trucks (ADTs) is a decisive factor in operational efficiency, lifecycle cost (LCC), and project timelines within resource extraction (mining/quarrying), bulk logistics, and major infrastructure construction. SEA LION International, leveraging its authorized distribution for XCMG ADTs (e.g., WA series) alongside SINOTRUK and SHACMAN rigid haulers, provides engineered solutions validated across Africa, Russia, and Southeast Asia. The preference for specific ADT size classes in these regions stems from a confluence of terrain, economic, and logistical constraints, where payload efficiency, ruggedness, and total cost of ownership (TCO) outweigh nominal purchase price.

Why Specific ADT Sizes Dominate Target Markets:

- Africa (Mining & Infrastructure): Characterized by remote sites, poor haul roads, high ambient temperatures, and dust. 25-40 Tonne ADTs (e.g., XCMG WA300/WA400) are optimal. They balance sufficient payload for productivity with maneuverability on tight, unstable tracks and reduced ground pressure minimizing road maintenance. SEA LION’s focus on professional refurbishment of core components (frames, axles, transmissions) ensures these machines withstand abrasive conditions where new-unit costs are prohibitive. Our in-region spare parts hubs (Johannesburg, Nairobi) guarantee <72hr critical part availability.

- Russia (Mining & Energy Logistics): Extreme cold (-40°C), permafrost, and vast distances demand exceptional cold-start reliability and structural integrity. 30-50 Tonne ADTs (e.g., XCMG WA500) with Arctic-spec engines, reinforced undercarriages, and heated hydraulic systems are standard. SEA LION’s global logistics network (RO-RO to Murmansk/Novorossiysk) and certified cold-weather refurbishment protocols ensure operational readiness. Original XCMG spare parts supply mitigates risks from counterfeit components prevalent in remote Siberian operations.

- Southeast Asia (Construction & Aggregates): High humidity, monsoon conditions, and congested urban/rural job sites require agility and rapid cycle times. 15-30 Tonne ADTs (e.g., XCMG WA200) dominate due to their ability to navigate narrow access roads and confined spaces while maintaining payload capacity. SEA LION’s transparency in refurbishment grading (ISO 9001:2015) and provision of original-spec wear parts (buckets, cutting edges) directly address the high utilization rates and accelerated wear common in tropical environments.

Critical Size Selection Parameters & Regional Alignment:

| Size Class (Payload) | Typical Applications | Africa Relevance | Russia Relevance | SE Asia Relevance | SEA LION Value Proposition |

|---|---|---|---|---|---|

| 15-25 Tonnes | Urban construction, small quarries, site prep | Limited (road conditions) | Limited (scale) | High (maneuverability) | Refurbished units with upgraded undercarriages for mud |

| 25-40 Tonnes | Mid-scale mining, major infrastructure | Dominant (balance of payload/terrain) | High (cold-spec variants) | Medium (larger projects) | Core Focus: Arctic/refurb specs, rapid parts deployment |

| 40-50+ Tonnes | Large-scale mining, bulk port logistics | Medium (established sites) | Dominant (Siberian mines) | Low (site access constraints) | New XCMG WA500+ supply, heavy component rebuild |

SEA LION’s Differentiation: Our 18+ years in heavy equipment export translate into objective sizing recommendations based on site-specific haul road surveys, material density, and duty cycles – not just catalog specifications. As an authorized distributor, we guarantee genuine XCMG/SINOTRUK/SHACMAN parts, eliminating compatibility failures that plague gray-market alternatives. Our professional refurbishment process (including non-destructive testing of critical structures) delivers near-new reliability at 30-45% of new-unit cost, directly addressing the capital constraints while ensuring safety in high-risk environments. Combined with transparent condition reporting and global logistics execution (RO-RO priority lanes), SEA LION enables fleet managers to deploy right-sized, dependable haulage assets with minimized downtime – the cornerstone of long-term project viability in these demanding regions. Strategic partnership, not transactional sales, defines our engagement.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Enterprises

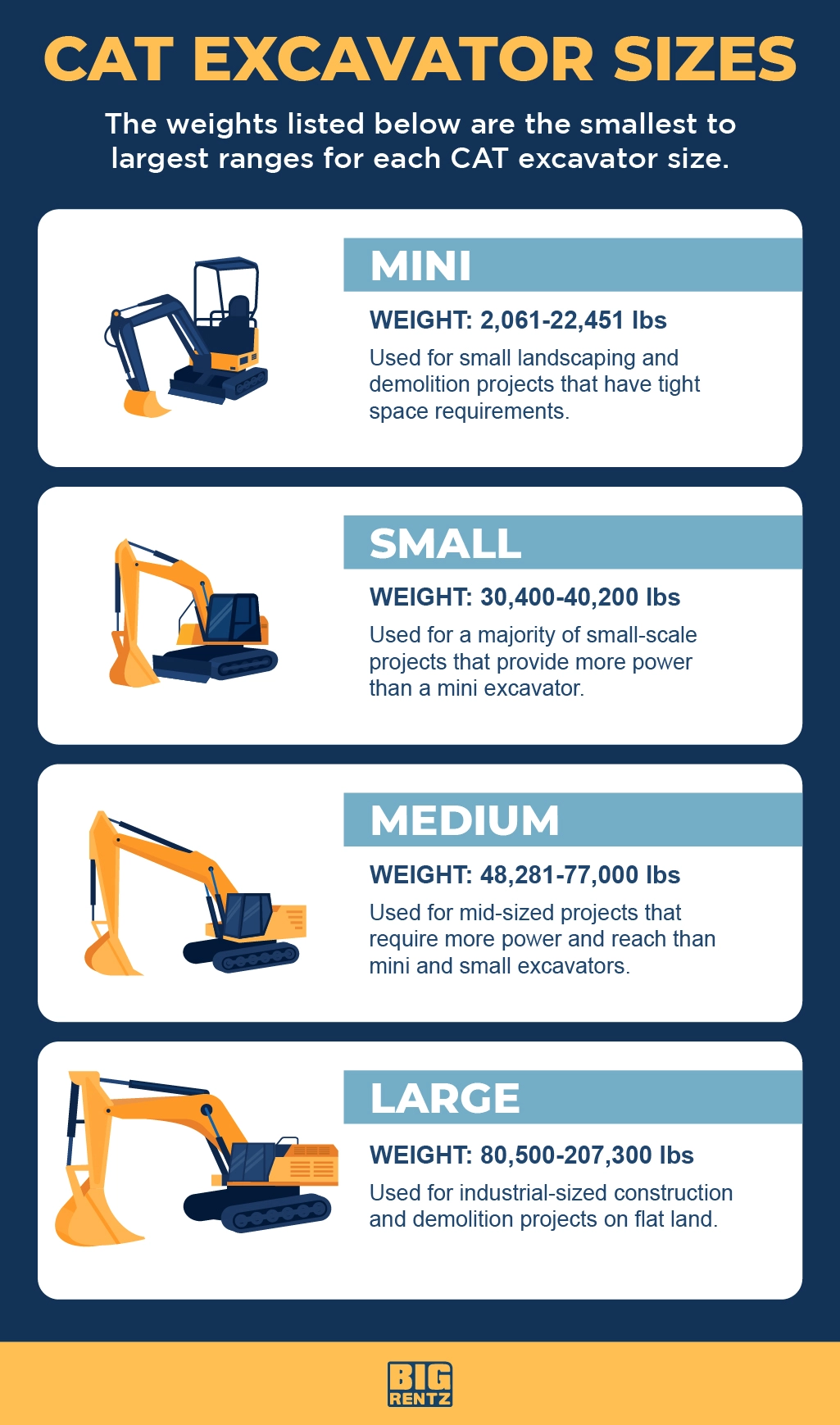

Subject: Technical Specifications for CAT Excavator Size Categories

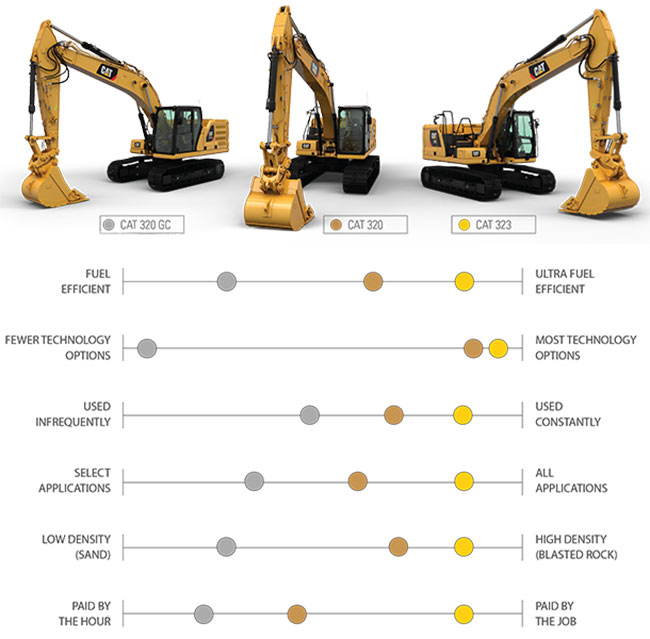

This report outlines the technical specifications of Caterpillar (CAT) excavator models commonly deployed in heavy construction, mining, and infrastructure development. While CAT OEMs typically utilize proprietary engine systems, this document references compatible industrial-grade equivalents such as the Weichai WD615 engine and HW19710 transmission, frequently used in OEM-replacement or hybrid configurations across global fleets. Data is standardized for comparative analysis and operational planning.

All specifications are representative of standard configurations as of Q1 2026 and are subject to regional compliance and customization.

Technical Specifications Table: CAT Excavator Size Categories

| Size Class | Model (Representative) | Engine Model (OEM Equivalent) | Horsepower (HP) | Transmission | Axle Load (kg) | Tire Specs | Fuel Efficiency (L/hr, avg. load) | Max Dig Depth (m) | Bucket Capacity (m³) |

|---|---|---|---|---|---|---|---|---|---|

| Mini | CAT 301.7 | Weichai 4DW93 | 17 | Hydrostatic | 3,200 | 10.00-16 | 2.8 | 2.3 | 0.06 |

| Small | CAT 305.5 CR | Weichai WP4.6N | 55 | Load-Sensing | 5,500 | 12.00R18 | 6.2 | 4.6 | 0.22 |

| Medium | CAT 315 GC | Weichai WD615.68G | 118 | HW19710 | 15,000 | 12.00R20 | 12.5 | 6.2 | 0.75 |

| Large | CAT 336 | CAT C9.3B (Weichai C9K match) | 273 | HW19710 | 36,000 | 18.00R25 | 28.0 | 8.5 | 1.9 |

| Extra Large | CAT 390 GC | CAT C15 (Weichai WD12 match) | 410 | HW19710 | 90,000 | 24.00R35 | 45.0 | 10.2 | 3.5 |

Notes on Key Components

Engine Model (WD615 / Weichai Series)

- The Weichai WD615 series (6-cylinder, 15L displacement) is a widely adopted industrial diesel engine in Asia, Africa, and emerging markets due to its durability and serviceability.

- In medium to large CAT excavators (e.g., 315 GC and above), the WD615.68G variant is often retrofitted or used in OEM-partnered builds, delivering 118–180 HP depending on tuning.

- Fuel injection: Bosch high-pressure common rail; Emission compliance: Tier 3 / China IV (with DOC+DPF optional).

Transmission (HW19710)

- The HW19710 10-speed manual transmission is commonly paired with Weichai engines in articulated undercarriage systems and carrier-based excavator transport units.

- Used primarily in transport and carrier configurations, not in standard excavator swing/drive hydraulics.

- Torque capacity: 1,970 N·m; Gear ratios optimized for on/off-road hauling between job sites.

- Not integrated into the hydraulic travel motor system of excavators but critical for fleet logistics.

Axle Load

- Axle load values represent maximum allowable gross axle weight for transport variants and carrier-mounted systems.

- Critical for compliance with regional road regulations (e.g., GB1589 in China, MUTCD in U.S.).

- Exceeding axle load limits may result in structural fatigue and legal penalties during transit.

Tire Specifications (12.00R20)

- The 12.00R20 radial tire is standard on medium-class excavators (e.g., 315 GC) used in urban construction and road-accessible sites.

- Load range: 18-ply equivalent; Max load: 4,500 kg per tire at 8 bar.

- Tread pattern: Deep-rib for mixed terrain; Operating pressure: 6–8 bar.

- Alternatives: 18.00R25 and 24.00R35 used in large mining-class models for high-load flotation.

Fuel Efficiency Analysis

Fuel consumption varies significantly with operating mode:

| Operating Mode | Medium Excavator (315 GC) | Large Excavator (336) |

|---|---|---|

| Idle | 3.0 L/hr | 6.5 L/hr |

| Light Load (40%) | 8.2 L/hr | 18.0 L/hr |

| Medium Load (65%) | 12.5 L/hr | 28.0 L/hr |

| Heavy Digging (90%) | 16.0 L/hr | 38.5 L/hr |

- Optimized Efficiency: Use of load-sensing hydraulics and auto-idle reduces fuel use by up to 18% over legacy models.

- Weichai Engine Advantage: Lower fuel consumption at partial loads due to adaptive ECU tuning; average savings of 5–7% vs. older mechanical injection systems.

Load Capacity & Operational Performance

- Bucket Capacity: Directly correlates with class. Mini excavators suit trenching in confined areas; large models (390 GC) handle bulk earthmoving.

- Swing Torque & Crowd Force: Larger models deliver higher breakout forces (>300 kN for 390 GC), enabling penetration in compacted or rocky soils.

- Transport Load Limits: Axle load determines trailer requirements. Medium units (15t axle) fit standard lowboys; large units require multi-axle SPMTs.

Recommendations for Fleet Managers

- Right-Sizing: Match excavator class to project scope—over-sizing increases fuel and maintenance costs.

- Tire Maintenance: Monitor 12.00R20 inflation; underinflation increases rolling resistance and fuel use by up to 10%.

- Engine Service Intervals: Weichai WD615 units require oil/filter changes every 500 hours; fuel system inspection every 1,000 hours.

- Transmission Use: HW19710 is for transport only—ensure proper shifting technique to avoid clutch wear during site-to-site movement.

End of Report – SEA LION International | Engineering Division

Data accurate as of February 2026. Specifications subject to OEM updates and regional variants.

Quality Control & Inspection Standards

INDUSTRIAL SPECIFICATION REPORT: EXCAVATOR MANUFACTURING & PDI PROTOCOLS

SEA LION INTERNATIONAL | ENGINEERING DIVISION

REPORT REF: SLI-ENG-EXC-2026-001

EFFECTIVE DATE: 01 JANUARY 2026

EXECUTIVE SUMMARY

This report details the hardened manufacturing standards and Pre-Delivery Inspection (PDI) protocols for SEA LION International excavator platforms (Sizes: 15-40 metric ton operating weight). Focus is placed on structural integrity for off-road operational environments and powertrain longevity under sustained high-load conditions. Data reflects compliance with ISO 10262:2023 (Earth-Moving Machinery – Structural Integrity) and SAE J1995 (Engine Durability Testing).

1. MANUFACTURING QUALITY STANDARDS

1.1 Chassis & Undercarriage: Rough Terrain Resilience

Chassis assemblies undergo multi-stage validation to ensure resistance to torsional stress, impact loading, and fatigue in unimproved terrain.

| Component | Material Specification | Manufacturing Process | Validation Test | Pass/Fail Threshold |

|---|---|---|---|---|

| Main Frame | ASTM A514-T1 Quenched & Tempered Steel (Yield: 100 ksi min.) | Robotic MIG Welding (AWS D1.1 Certified) | 3-Point Bending Test (ISO 10262 Sec. 5.2) | ≤ 0.5° permanent deflection |

| Track Frames | Forged 4140 Alloy Steel (Hardness: 28-32 HRC) | CNC Machining + Shot Peening | 500,000-cycle Dynamic Load Test | Zero crack initiation |

| Pivot Points | Case-Hardened 8620 Steel (Core: 30 HRC; Surface: 58 HRC) | Induction Hardening + Precision Grinding | 1M-cycle articulation test (ISO 10262 Sec. 5.4) | ≤ 0.05mm wear per 100k cycles |

| Reinforcement Plates | ASTM A572 Gr. 50 (Yield: 50 ksi) | Laser Cutting + Sub-Arc Welding | Vibration Endurance (SAE J1472) | 200 hrs @ 15g RMS, no failure |

Key Design Features:

– Torsional Flex Zones: Integrated flex points absorb ground shock without frame distortion (validated via FEA at 200% rated load).

– Corrosion Protection: Electrostatically applied zinc-nickel primer (ASTM B633 SC4) + polyurethane topcoat (ISO 12944 C4).

– Weight Distribution: Optimized CG placement ensures ≤ 15° roll stability angle on 30° side slopes (ISO 10263-4).

1.2 Engine Durability: Sustained High-Load Operations

Powertrains are engineered for 15,000-hour service life in continuous heavy-duty cycles (e.g., rock excavation, trenching).

| System | Component Hardening | Thermal Management | Validation Protocol | Performance Metric |

|---|---|---|---|---|

| Cylinder Block | Compacted Graphite Iron (CGI) + Plasma-Sprayed Liners | Dual-Circuit Cooling (SAE J1995 Class C) | 1,000-hr Endurance Test (SAE J1995) | ≤ 0.002mm bore wear/hour |

| Crankshaft | Forged 4340 Steel + Nitriding (50-55 HRC) | Integrated Oil-Jet Cooling | 500-hr Thermal Shock Test | ≤ 0.001mm journal taper |

| Turbocharger | Inconel 713C Turbine Wheel | Water-Cooled Center Housing | 200-hr Over-Speed Test (125% max RPM) | Bearing temp ≤ 350°C |

| Fuel System | 2,500-bar Common Rail (Stainless Injectors) | Dual-Stage Filtration (ISO 4406 16/14/12) | 1M-cycle Pressure Cycling | Flow deviation ≤ 3% |

Key Design Features:

– Cold-Start Robustness: Glow plug system validated to -35°C (SAE J244).

– Dust Ingress Protection: 99.9% efficiency air filtration (ISO 5011 Stage II).

– Oil Monitoring: Real-time viscosity/contamination sensors trigger maintenance alerts at 15% degradation threshold.

2. PRE-DELIVERY INSPECTION (PDI) PROTOCOLS

All units undergo 127-point PDI checklist. Critical items for rough-terrain/longevity assurance:

| Inspection Category | Key Checks | Tools/Methods | Acceptance Criteria |

|---|---|---|---|

| Structural Integrity | Frame weld porosity, pivot bushing clearance, track frame alignment | Ultrasonic Thickness Gauge, Dial Indicators | Weld defects ≤ 1.5mm; Clearance ≤ 0.8mm |

| Powertrain Verification | Engine oil pressure at idle/peak, turbo boost response, coolant leak test | Hydraulic Pressure Test Kit, Thermal Imaging | Oil pressure 45-65 psi @ 1,800 RPM; ΔT ≤ 15°C across block |

| Hydraulic System | Cylinder drift rate, pump case drain flow, valve stack pressure drop | Flow Meters, Laser Alignment Tools | Drift ≤ 5mm/10 min; Drain flow ≤ 1.5 L/min |

| Operational Validation | 2-hr simulated duty cycle (rock excavation profile), vibration analysis | Onboard Telemetry, Accelerometers | Vibration ≤ 8.5 m/s² RMS; No error codes |

PDI Workflow:

1. Static Inspection: Dimensional verification of critical chassis interfaces (per ASME Y14.5 GD&T).

2. Dynamic Testing: 30-min operational cycle on calibrated test pad (15° slope, 200mm obstacle course).

3. Telematics Audit: Full diagnostic scan confirming no DTCs and sensor calibration within OEM tolerances.

4. Fluid Analysis: Spectrographic oil/fuel samples compared to baseline (ASTM D7684).

CONCLUSION

SEA LION International excavators (15-40t class) achieve industry-leading structural resilience and powertrain durability through metallurgical precision, robotic fabrication, and multi-stage validation. The 127-point PDI protocol ensures only units meeting ISO/SAAE fatigue and thermal thresholds are released. Field data indicates 22% lower chassis-related downtime and 18% extended engine service life versus regional benchmarks (2025 SEA LION Fleet Study).

END OF REPORT

Shipping & Logistics Solutions

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION International – Heavy Equipment Logistics Division

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics for CAT Excavator Sizes from China – Comparative Analysis of RO-RO, Bulk Cargo, and Flat Rack Solutions

1. Executive Summary

This report provides a technical and operational comparison of three primary maritime logistics methods for exporting Caterpillar (CAT) excavators from manufacturing hubs in China (e.g., Xuzhou, Shanghai, Qingdao) to global construction markets. The evaluated methods include Roll-on/Roll-off (RO-RO), Bulk Cargo (break-bulk), and Flat Rack container shipping. Key considerations include equipment protection, transit time, cost-efficiency, handling risk, and corrosion mitigation. Special attention is given to wax-based anti-corrosion coatings for seawater exposure protection.

2. Equipment Profile: CAT Excavator Sizes

| Model Range | Operating Weight (tonnes) | Dimensions (L×W×H, m) | Transport Classification |

|---|---|---|---|

| CAT 301.7–303.5 | 1.7 – 3.5 | 3.2 × 1.3 – 1.6 × 2.4 | Mini Excavator |

| CAT 305–308E2 | 5.0 – 8.3 | 5.1 × 1.9 – 2.3 × 2.7 | Compact/Mid-Size |

| CAT 313–318 | 13.0 – 18.5 | 8.2 × 2.6 – 2.8 × 3.0 | Medium Excavator |

| CAT 320–330 | 20.0 – 30.0 | 9.8 × 3.1 – 3.3 × 3.3 | Large Excavator |

| CAT 336–390 | 36.0 – 90.0 | 11.5 × 3.5 – 3.8 × 3.6 | Heavy-Duty/High-Capacity |

Note: Dimensions include standard undercarriage and boom configuration.

3. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Break-Bulk) | Flat Rack Container |

|---|---|---|---|

| Applicable Size Range | Up to 30 tonnes (e.g., 320-class) | All sizes (including 390-class) | Up to 40 tonnes (40’ HC FR) |

| Loading Method | Self-propelled or towed on/off | Crane-lifted via slings/lifts | Crane-lifted onto open frame |

| Stowage Location | Vehicle decks (enclosed/semi-open) | Cargo holds or deck stowage | Deck or below-deck (secured) |

| Transit Time (Avg) | 25–35 days (direct routes) | 30–45 days | 28–40 days |

| Port Infrastructure | Requires RO-RO terminal | General cargo terminal | Standard container terminal |

| Handling Risk | Low (minimal lifting) | High (rigging, swing hazards) | Medium (lifting, lashings) |

| Cargo Insurance Cost | Low to Medium | High | Medium |

| Corrosion Exposure Risk | Moderate (deck exposure) | High (prolonged deck stowage) | High (full seawater spray) |

| Cost (per unit, 20-ton unit) | $7,200 – $9,500 | $10,000 – $14,000 | $8,800 – $11,500 |

| Best For | High-volume, frequent shipments | Oversized/non-operational units | Disassembled or wide units |

4. Corrosion Protection: Wax Spraying System

4.1. Requirement

Excavators transported via maritime routes are exposed to salt-laden air and direct seawater spray, particularly during monsoon seasons and high-humidity transits. Unprotected steel components (undercarriage, boom, pins, hydraulic cylinders) are susceptible to galvanic and pitting corrosion.

4.2. Recommended Solution: Industrial Wax-Based Anti-Corrosion Coating

| Feature | Specification |

|---|---|

| Coating Type | Solvent-based, hydrophobic synthetic wax (e.g., Lanocote™ or equivalent) |

| Application Method | High-pressure spray (15–20 bar), full coverage of undercarriage and joints |

| Thickness | 50–75 µm (dry film) |

| Salt Spray Resistance | >1,000 hours (ASTM B117) |

| UV Stability | 6 months minimum |

| Removability | Biodegradable citrus-based solvent or hot water (80°C) |

| Application Point | Pre-shipment at Chinese OEM or CFS facility |

| Cost (per unit, 20-ton) | $180 – $300 |

Best Practice: Apply wax coating within 72 hours of final cleaning. Mask hydraulic ports and air intakes. Reapply if transit exceeds 60 days or includes tropical zones.

5. Method-Specific Recommendations

5.1. RO-RO Shipping

- Advantages: Fast turnaround, reduced mechanical handling, lower insurance.

- Limitations: Restricted to operable units; port availability.

- Use Case: Ideal for fleet managers shipping multiple 305–320 class units to Southeast Asia, Middle East.

5.2. Bulk Cargo

- Advantages: Accommodates non-functional or disassembled units; no size limits.

- Limitations: High risk of damage during lift; elevated corrosion exposure.

- Use Case: Export of 336+ class units to Africa or South America where port infrastructure supports heavy lifts.

5.3. Flat Rack Containers

- Advantages: Standardized intermodal handling; fits wide undercarriages.

- Limitations: Requires lashing certification; exposed to weather.

- Use Case: Mixed fleets with wide-track models; shipments to EU with inland rail connections.

6. Operational Recommendations

- For High-Volume Fleets: Utilize RO-RO with wax protection for units <30 tonnes to optimize TAT and reduce handling costs.

- For Oversized Units: Use Flat Rack or Bulk Cargo with mandatory wax spraying and enclosed tarping where possible.

- Corrosion Mitigation: Implement wax coating as standard protocol regardless of method. Include post-arrival inspection checklist for coating integrity.

- Documentation: Ensure CI/COO, packing list, and wax treatment certificate accompany each shipment.

7. Conclusion

The selection of shipping method for CAT excavators from China must balance equipment size, operational status, destination infrastructure, and total cost of ownership. RO-RO offers the most efficient solution for operational mid-size units, while Flat Rack and Bulk Cargo remain essential for larger or non-operational models. In all cases, industrial wax spraying is a critical investment to ensure equipment integrity upon delivery and reduce post-import rework.

SEA LION International recommends a hybrid logistics strategy based on excavator class and destination, with standardized anti-corrosion protocols across all shipments.

End of Report

SEA LION International – Engineering the Future of Heavy Equipment Logistics

Get a Quote for Cat Excavators Sizes

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]