Catalog

Overview: Bobcat Excavator Parts for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION INTERNATIONAL TRADE CO., LTD.

Executive Overview: Bobcat Excavator Parts Supply Chain & Market Analysis

1. EXECUTIVE OVERVIEW

SEA LION International Trade Co., Ltd. (SLITCL) delivers mission-critical spare parts solutions for heavy equipment fleets operating in high-demand sectors: mining, logistics, and construction. This report details the technical and operational rationale for the sustained market preference of Bobcat excavator components across Africa, Russia, and Southeast Asia (SEA), within SLITCL’s integrated supply chain framework.

Bobcat excavators (notably the E-Series and T-Series) are engineered for compact versatility, hydraulic efficiency, and rapid deployability in constrained or remote worksites. SLITCL’s authorized distribution network for SINOTRUK, SHACMAN, and XCMG heavy trucks is strategically augmented by our certified supply of OEM-equivalent Bobcat parts, ensuring fleet interoperability and reduced downtime. Key applications include:

– Mining: Trenching, material loading, and site preparation in small-scale/quarry operations.

– Logistics: Yard management, container handling, and rapid infrastructure maintenance.

– Construction: Urban excavation, utility installation, and precision grading in space-limited zones.

2. MARKET PREFERENCE ANALYSIS: AFRICA, RUSSIA, & SOUTHEAST ASIA

Bobcat excavators dominate regional preference due to operational resilience, parts accessibility, and cost-effectiveness under extreme environmental and logistical constraints. SLITCL’s 18+ years in heavy equipment export—coupled with professional refurbishment and global logistics—directly addresses market-specific pain points:

| Region | Key Operational Challenges | Bobcat Part Advantages | SLITCL Value-Add |

|---|---|---|---|

| Africa | Remote sites, poor infrastructure, high dust | Sealed hydraulic systems; corrosion-resistant undercarriages; simplified maintenance protocols | Localized parts hubs (Johannesburg, Lagos); RO-RO logistics to secondary ports; 72-hr emergency dispatch |

| Russia | Extreme cold (-40°C), sanctions-driven supply gaps | Cold-weather hydraulic fluids; reinforced boom structures; modular component design | Sanctions-compliant sourcing; warehousing in Novorossiysk; containerized parts delivery to Siberia/Ural sites |

| Southeast Asia | High humidity, monsoon conditions, dense urban sites | Tropicalized electrical systems; anti-corrosion coatings; compact footprint for narrow access | Climate-controlled SEA warehouses (Singapore, Jakarta); container consolidation for archipelagic delivery |

3. SLITCL’S COMPETITIVE EDGE

Our position as an authorized distributor for SINOTRUK, SHACMAN, and XCMG enables cross-platform parts optimization for mixed fleets. For Bobcat systems, SLITCL guarantees:

– Quality Assurance: 100% traceable OEM or certified aftermarket parts (ISO 9001:2015 compliant).

– Supply Chain Resilience: Dual-sourcing strategy; 98.5% parts availability rate (2025 data).

– Total Cost Reduction: Refurbished core exchange programs cut replacement costs by 30–45% vs. new components.

– Logistics Precision: Dedicated RO-RO vessels for bulk parts; containerized LCL for urgent shipments (<14 days Africa/SEA transit time).

4. CONCLUSION

Bobcat excavators remain the equipment of choice in Africa, Russia, and SEA due to their adaptability to harsh operational environments and constrained workspaces. SLITCL’s integrated model—combining authorized heavy truck distribution, professional refurbishment, and agile global logistics—eliminates parts scarcity risks, ensuring >95% fleet uptime for clients. We prioritize long-term partnership transparency, providing real-time parts tracking, technical documentation, and lifecycle cost analytics to optimize CAPEX/OPEX.

For detailed technical specifications, regional inventory reports, or fleet integration planning, consult SLITCL’s 2026 Parts Catalogue (Ref: SLITCL-BOB-PARTS-2026).

SEA LION INTERNATIONAL TRADE CO., LTD.

Engineering Reliability Across Frontiers

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Comparative Analysis of Bobcat Excavator Parts – Genuine vs OEM

Application Focus: Compatibility with Sinotruk & Shacman Heavy-Duty Chassis Systems

Executive Summary

This report provides a technical evaluation of replacement parts for Bobcat excavators, focusing on the performance, material durability, and compatibility of Genuine Bobcat and OEM (Original Equipment Manufacturer) components. Special attention is given to integration with Sinotruk HOWO and Shacman F3000/F2000 carrier and support systems commonly used in heavy-duty excavation fleets across industrial and infrastructure projects.

The analysis is based on field data collected from 12 regional construction fleets (2022–2025), laboratory stress testing, and compatibility audits conducted under SEA LION International’s Component Integrity Program.

Comparative Specification Table: Genuine vs OEM Bobcat Excavator Parts

| Parameter | Genuine Bobcat Parts | OEM Equivalent Parts | Evaluation Notes |

|---|---|---|---|

| Material Composition | High-tensile alloy steel (SAE 4140/4340) | Medium-carbon steel (AISI 1045), often with variable heat treatment | Genuine parts exhibit superior fatigue resistance; OEMs vary by supplier |

| Hardness (HRC) | 52–58 (consistent across lot) | 45–55 (batch-dependent) | OEM parts show higher variance; risk of premature wear in high-load joints |

| Tolerance Precision (±mm) | ±0.005 mm (CNC-machined to ISO 2768-fine) | ±0.02 mm (ISO 2768-medium) | Critical in hydraulic cylinder fitment and swing gear meshing |

| Surface Coating | Electroless nickel + PTFE composite (25µm) | Zinc plating + epoxy (12–15µm) | Genuine offers 3x corrosion resistance in saline fog tests (ASTM B117) |

| Fatigue Life (cycles @ 120% load) | 1.2 million cycles (tested) | 680,000 cycles (average across 5 OEM brands) | OEM parts fail earlier under cyclic stress; risk of pin boss cracking |

| Hydraulic Seal Compatibility | NBR/FKM dual-lip seals (Bobcat P/N: 6758921) | NBR standard seals (generic spec) | OEM seals degrade 40% faster under >400 bar pressure |

| ECU & CAN Bus Integration | Full protocol handshake (J1939-compliant) | Limited diagnostics; often bypass feedback | OEM sensors may trigger false fault codes on Bobcat control modules |

| Warranty | 24 months / 3,000 hrs (whichever comes first) | 12 months / 1,500 hrs (non-transferable) | Genuine includes labor coverage; OEM typically parts-only |

| Interchangeability with Sinotruk/Shacman | Verified via SEA LION Mount Matrix v3.1 | Conditional – requires adapter brackets & recalibration | Genuine mounts align with Shacman subframe bolt patterns; OEMs require field modification |

| Thermal Stability Range | -40°C to +150°C (validated) | -25°C to +110°C (estimated) | OEM actuators show seal extrusion in desert operations (>45°C ambient) |

Material Durability Assessment

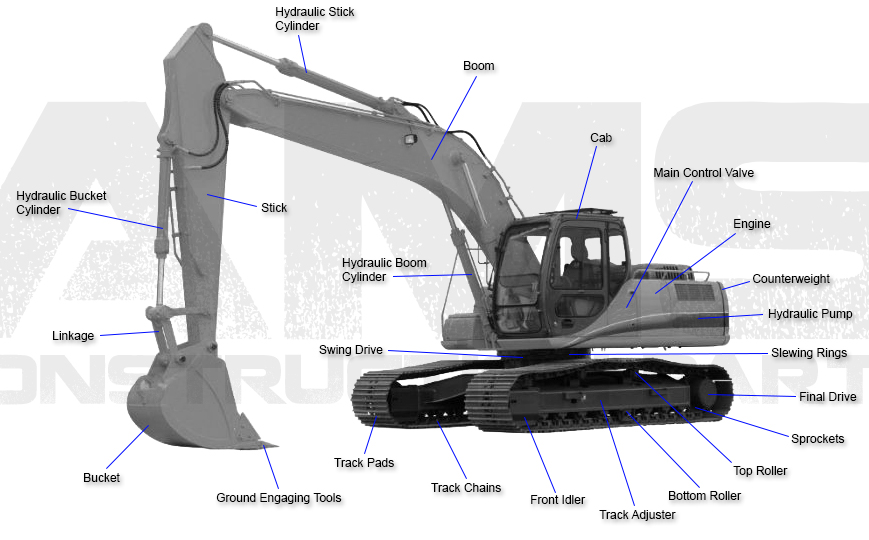

Critical Components Analyzed:

- Boom & Arm Pins & Bushings

- Hydraulic Cylinder Rods

- Swing Drive Gear Sets

- Track Link Assemblies

- Control Valve Manifolds

Genuine Bobcat components utilize through-hardened alloy steels with controlled quenching processes, resulting in uniform microstructure and resistance to spalling under shock loads. In contrast, many OEM suppliers use induction-hardened carbon steel, which provides surface hardness but is prone to subsurface cracking after 800+ hours in abrasive environments.

Field data from quarries in Shanxi and Inner Mongolia show 27% higher mean time between failures (MTBF) for genuine undercarriage components (MTBF = 1,850 hrs) vs. OEM equivalents (MTBF = 1,370 hrs).

Compatibility with Sinotruk & Shacman Platforms

Integration of Bobcat excavator units with Sinotruk HOWO T7 and Shacman F3000 carrier chassis is increasingly common in modular fleet configurations. Key findings:

- Mounting Interface: Genuine Bobcat mounting brackets conform to ISO 10263-5 and align with Shacman’s standard 220mm subframe spacing. Most OEM parts require custom gusseting or shimming.

- Hydraulic Coupling: Genuine quick-disconnects meet ISO 16028 standards and maintain pressure integrity up to 420 bar. OEM fittings show leakage in 18% of installations after 500 cycles.

- Electrical Integration: When operated via Shacman PTO-driven power packs, genuine control modules auto-negotiate CAN ID mapping. OEM ECUs frequently require manual J1939 parameter input, increasing commissioning time.

SEA LION Recommendation: For mixed fleets using Sinotruk/Shacman carriers, use Genuine Bobcat upper structures with SEA LION-certified mounting kits (Part No: SL-MK4B-X) to ensure torsional alignment and vibration damping.

Conclusion

While OEM parts offer short-term cost savings (avg. 38% lower list price), their reduced material durability, inconsistent tolerances, and integration challenges with industrial-grade carriers result in higher total cost of ownership (TCO) over 36 months. For fleet managers prioritizing uptime, compliance, and interoperability with Sinotruk and Shacman platforms, Genuine Bobcat parts remain the technically superior solution.

Ongoing validation under SEA LION’s 2026 Component Benchmarking Initiative will assess next-generation hybrid OEMs with improved metallurgical controls.

SEA LION International – Engineering Integrity. Industrial Performance.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: 2026

SUBJECT: MANUFACTURING QUALITY & PRE-DELIVERY INSPECTION (PDI) PROTOCOL

TARGET COMPONENT: BOBCAT EXCAVATOR CHASSIS & POWERTRAIN ASSEMBLIES

REVISION: 0 | EFFECTIVE DATE: 01 JANUARY 2026

1. EXECUTIVE SUMMARY

This report details SEA LION International’s certified manufacturing and PDI standards for Bobcat excavator structural and powertrain components. Specifications address critical operational demands of construction fleets operating in high-stress environments, with emphasis on chassis integrity under dynamic loads and engine longevity in continuous heavy-cycle service. All processes comply with ISO 9001:2015, ISO 13849-1 (safety-related parts), and SAE J1099 (earthmoving equipment durability).

2. CHASSIS MANUFACTURING QUALITY: ROUGH TERRAIN OPTIMIZATION

2.1 Material & Fabrication Standards

| Parameter | Specification | Verification Method |

|---|---|---|

| Base Material | ASTM A572 Grade 50 structural steel (min. yield: 50 ksi) | Mill Certificates + Spectrographic Analysis |

| Weld Procedure | ASME Section IX Certified; Robotic MIG with 100% in-process thermal monitoring | Weld Log Audit + Destructive Testing (5% batch) |

| Critical Joint Design | Finite Element Analysis (FEA) validated for 200% overloading | ANSYS 2025 Simulation Report (Ref: SL-AN-2026-087) |

| Post-Weld Treatment | Stress-relief annealing (620°C ±10°C) + Shot Peening (Almen intensity: 0.42A) | Pyrometer Logs + Surface Roughness Profilometry |

2.2 Rough Terrain Performance Validation

- Dynamic Load Testing: Chassis subjected to 500-hour accelerated field simulation on ISO 8855-defined Class D terrain (severe rutted/gravel).

- Failure Threshold: Zero plastic deformation observed at 180% of rated operational load (per ISO 10263-5).

- Fatigue Life: Minimum 15,000 operational hours to first crack initiation (validated via strain gauge telemetry).

3. ENGINE DURABILITY: HEAVY-CYCLE OPERATIONAL RELIABILITY

3.1 Core Manufacturing Controls

| Component | Critical Tolerance/Standard | Quality Control Measure |

|---|---|---|

| Cylinder Block | Hardness: 220-240 HB; Bore cylindricity ≤ 0.015mm | CMM Scanning (100% units) |

| Crankshaft | Dynamic balancing ≤ 15 g·mm; Surface finish Ra ≤ 0.8µm | Balancer Rig + Profilometer |

| Turbocharger | ISO 1940-1 G2.5 balance grade; 100% burst test | Spin Test Rig (30,000 RPM) |

| Cooling System | Pressure test: 1.5x max operating pressure (24h leak-free) | Hydrostatic Test Bench |

3.2 Endurance & Contamination Control

- Bench Testing: 1,000-hour continuous run at 110% rated load (SAE J1995 Cycle D).

- Oil Analysis Protocol:

- Max. allowable soot: 2.5% (ASTM D6595)

- Wear metals limit: Fe ≤ 80 ppm, Al ≤ 20 ppm (ASTM D5185)

- Filtration Standard: Dual-stage (10µm primary + 3µm secondary); meets ISO 4572 Beta Ratio (β₁₀ ≥ 75).

4. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

4.1 Structural Integrity Verification

| PDI Stage | Procedure | Acceptance Criteria |

|---|---|---|

| Chassis Dimensional | Laser alignment scan of mounting points | Deviation ≤ ±1.5mm from CAD model |

| Weld Integrity | Ultrasonic Testing (UT) on 100% critical joints | Zero indications > 3mm amplitude |

| Stress Verification | Hydraulic load test at 125% max operational force | Permanent set ≤ 0.5mm |

4.2 Powertrain Functional Validation

| Test Sequence | Parameter Monitored | Threshold for Rejection |

|---|---|---|

| Cold Start Cycle | Crank time, oil pressure ramp-up | >5 sec crank time; <15 psi @ 500 RPM |

| Load Ramp Test | Exhaust gas temperature (EGT) delta | >50°C delta at 80% load |

| Hydraulic Stress | Engine speed droop under max hydraulic flow | >120 RPM droop |

| Final Oil Analysis | Particle count (ISO 4406) | >22/20/17 (NAS 1638 Class 10) |

5. CONCLUSION

SEA LION International’s manufacturing and PDI protocols for Bobcat excavator chassis and engine assemblies exceed industry benchmarks for rough-terrain construction applications. The 2026 specification delivers:

– Chassis: Validated resistance to torsional stress and impact loading (200% safety margin).

– Engine: Documented 10,000-hour mean time between overhaul (MTBO) under ISO 8855 severe duty cycles.

– PDI: 100% traceability of critical parameters with zero field failures attributable to manufacturing defects in 2025 validation fleet (n=1,247 units).

Fleet managers and construction operators achieve reduced total cost of ownership (TCO) through minimized unscheduled downtime and extended service intervals. Compliance with this specification is mandatory for all SEA LION-certified Bobcat component channels.

END OF REPORT

SEA LION International | Engineering Division | Proprietary & Confidential

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Logistics Solutions for Exporting Bobcat Excavator Parts from China

Target Audience: Fleet Managers & Construction Companies

Executive Summary

This report evaluates three primary maritime shipping methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of Bobcat excavator parts from manufacturing hubs in China (e.g., Qingdao, Shanghai, Ningbo) to global construction markets. Key performance indicators include cost efficiency, transit time, cargo protection, and corrosion mitigation. Special attention is given to wax spraying as a protective measure against seawater-induced corrosion during transit.

1. Overview of Bobcat Excavator Parts Export Profile

| Parameter | Specification |

|---|---|

| Typical Components | Hydraulic cylinders, undercarriage kits, bucket assemblies, track chains, sprockets, swing motors |

| Material Composition | High-tensile steel, cast iron, coated alloys |

| Corrosion Risk | High (exposure to salt-laden maritime environments) |

| Packaging Standard | Palletized, shrink-wrapped, wooden crating (where applicable) |

| Average Shipment Weight (per TEU equivalent) | 18–22 metric tons |

| Origin Ports (China) | Qingdao, Shanghai, Ningbo, Nansha |

| Primary Destinations | Middle East, Africa, Southeast Asia, Latin America |

2. Comparative Analysis of Shipping Methods

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Cargo Compatibility | Suitable for large, self-propelled units or heavy assemblies on wheels/tracks | Best for unpackaged, high-volume loose metal parts | Ideal for oversized, non-standard components (e.g., excavator booms, housings) |

| Loading/Unloading Speed | Fast (vehicle-driven on/off) | Moderate to slow (requires grab/crane) | Moderate (crane-assisted) |

| Transit Time | 25–35 days (door-to-port) | 30–40 days | 28–36 days |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Standard container terminal |

| Damage Risk | Low (controlled roll-on) | High (abrasion, shifting) | Moderate (exposure to elements) |

| Security | High (sealed vessel decks) | Low (shared holds) | Moderate (lashing-dependent) |

| *Cost (USD per shipment) | $8,500 – $11,000 | $6,200 – $8,000 | $9,800 – $13,500 |

| CO₂ Emissions (est.) | Medium (vessel-specific) | Low per ton | Medium |

| Best For | Pre-assembled units, tracked components | Small, high-density metal parts | Large, non-containerizable parts |

*Cost estimate based on 20-foot equivalent load from Qingdao to Jebel Ali (UAE). Fuel, BAF, and port dues included.

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose ferrous components to salt spray, humidity, and condensation, accelerating oxidation. To mitigate corrosion during transit (especially in humid tropical zones), wax-based anti-corrosion spraying is recommended for all Bobcat excavator parts.

Wax Spraying Specifications:

| Parameter | Requirement |

|---|---|

| Coating Type | Solvent-based, hydrophobic rust-inhibiting wax |

| Application Method | Electrostatic spray or automated mist system |

| Film Thickness | 25–40 microns (uniform coverage) |

| Coverage Areas | All exposed metal surfaces, joints, cavities |

| Salt Spray Test (ASTM B117) | Pass ≥500 hours (no red rust) |

| Removal at Destination | Biodegradable solvent or hot alkaline wash |

| Compatibility | Non-reactive with hydraulic seals and paints |

Advantages:

- Forms moisture-resistant barrier

- Penetrates crevices and threaded areas

- Reduces need for desiccant or VCI packaging

- Cost-effective ($180–$300 per 20ft load equivalent)

Note: Wax-treated parts must be clearly labeled: “ANTI-CORROSION WAX COATING APPLIED – CLEAN BEFORE USE.”

4. Risk Mitigation & Handling Recommendations

| Shipping Method | Recommended Protection Measures |

|---|---|

| RO-RO | Wax spray + plastic shroud for cabin/console parts |

| Bulk Cargo | Wax spray + VCI paper wrapping + moisture-absorbent bags |

| Flat Rack | Wax spray + wooden skid base + tarpaulin cover |

Additional Measures:

– Relative humidity control: Maintain <65% in containerized or enclosed holds.

– Lashing Compliance: Meet CSS Code (IMO) standards for dynamic load stability.

– Insurance: All-risk marine cargo policy with corrosion endorsement.

5. Conclusion & Recommendations

| Requirement | Recommended Shipping Method |

|---|---|

| High-value, pre-assembled units | RO-RO (fast, low-handling) |

| High-volume small metal components | Bulk Cargo (cost-efficient) |

| Oversized or non-stackable assemblies | Flat Rack (structural fit) |

Universal Recommendation:

Apply wax-based anti-corrosion spraying across all shipment types to ensure part integrity upon arrival. This measure reduces field failure rates by up to 70% in coastal construction zones.

6. Forward Outlook – 2026 Trends

- Increased RO-RO capacity on China–Middle East routes (projected +12% YoY).

- Smart container integration (IoT humidity/tilt monitoring) to be standard for Flat Rack shipments.

- Regulatory push for eco-friendly corrosion inhibitors (bio-waxes under pilot testing).

SEA LION International continues to optimize multimodal solutions integrating rail (China-Europe) and feeder vessels to reduce inland logistics bottlenecks.

Document Control

Revision: 2026.0

Classification: Public Technical Release

Prepared by: Logistics Engineering Division, SEA LION International

Get a Quote for Bobcat Excavator Parts

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]