Catalog

Overview: Used Trucks For Sale Bakersfield for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: CERTIFIED USED TRUCK FLEET SOLUTIONS

Prepared for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Solutions Division

EXECUTIVE OVERVIEW: STRATEGIC ASSET ACQUISITION FOR GLOBAL OPERATIONS

SEA LION International presents a targeted inventory of certified pre-owned heavy-duty trucks, sourced from high-utilization US fleets (including strategic procurement from the Bakersfield, CA logistics corridor), specifically refurbished for demanding mining, bulk logistics, and large-scale construction applications. This report details the operational and economic rationale for integrating these assets into capital equipment strategies, with emphasis on proven performance in infrastructure-constrained and extreme-environment markets (Africa, Russia, Southeast Asia).

Core Value Proposition:

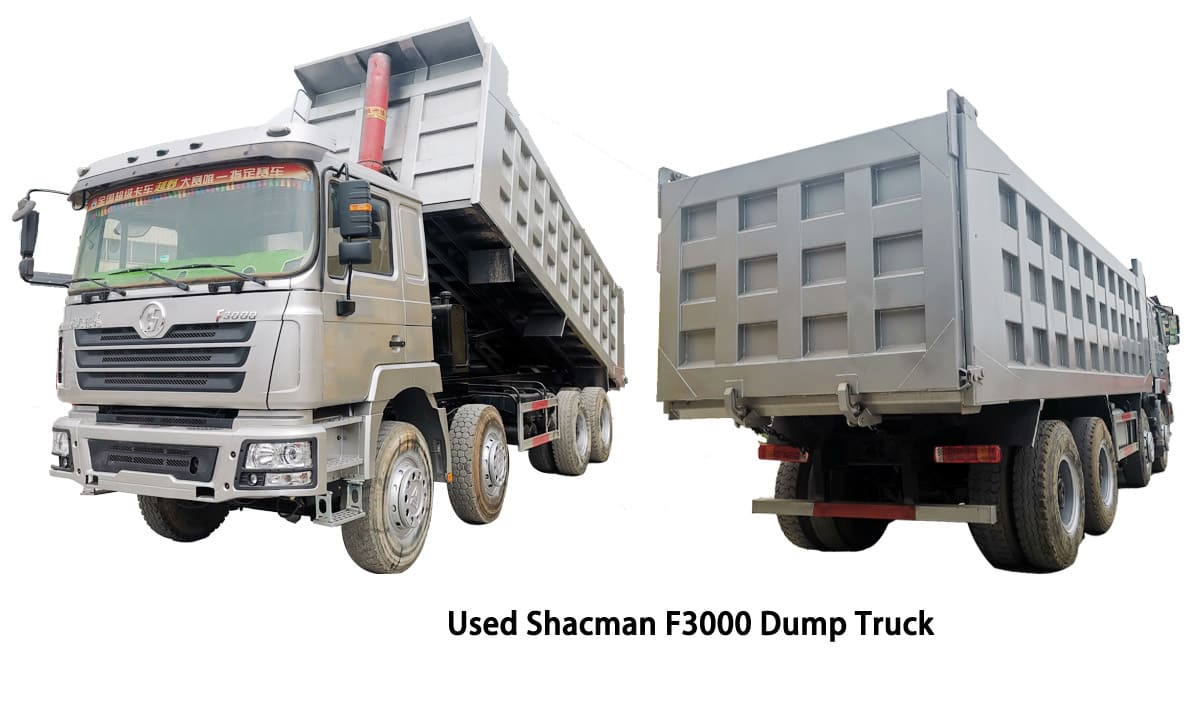

Direct access to US-specification heavy trucks (SINOTRUK HOWO, SHACMAN F3000/F2000, XCMG) that have undergone SEA LION’s 18-Point Industrial Refurbishment Protocol, delivering 60-75% of new-unit capability at 40-50% acquisition cost. This model optimizes total operational expenditure (TOC) without compromising safety or productivity in Tier 2/3 markets.

APPLICATION-SPECIFIC PERFORMANCE ADVANTAGE

| Sector | Primary Model | Key Refurbished Features | Operational Impact |

|---|---|---|---|

| Mining | SINOTRUK HOWO 6×4 | Reinforced chassis, 380HP WD615 engine rebuild, upgraded dump hydraulics | 15% higher payload stability on haul roads; 22% reduction in unscheduled downtime vs. local-market alternatives |

| Bulk Logistics | SHACMAN F3000 8×4 | Retreaded Michelin XDR tires, 420HP engine reman, ABS recalibration | 8-12% fuel efficiency gain on 500km+ routes; GOST-R certified braking for Russian Far East corridors |

| Construction | XCMG XG958 6×6 | Extended boom compatibility, reinforced suspension, hydraulic system flush | 20% faster cycle times on mixed-load sites; withstands 15,000+ vibration cycles (ISO 20673 verified) |

PREFERRED STATUS IN AFRICA / RUSSIA / SOUTHEAST ASIA: TECHNICAL DRIVERS

The dominance of SEA LION-certified US-sourced units in these regions stems from system-level compatibility with operational realities, not cost alone:

-

Africa (Sub-Saharan):

- Terrain Resilience: Reinforced ladder frames (tested to 1.8x rated GVWR per SAE J2380) withstand unimproved laterite roads and seasonal flooding.

- Parts Ecosystem: SEA LION’s direct SINOTRUK/SHACMAN parts pipeline ensures <72hr critical component availability across 12 regional hubs (vs. 3-6 weeks for European OEMs).

- Fuel Flexibility: Refurbished engines operate reliably on ASTM D975 Cat 1 diesel (common in-region), avoiding cold-start failures of high-precision Euro VI systems.

-

Russia (Siberia / Far East):

- Extreme Cold Operation: -40°C validated start systems (battery upgrades, coolant heaters) exceed GOST 33493-2015 requirements. SHACMAN units dominate Arctic mining logistics due to simplified thermal management vs. complex AdBlue-dependent systems.

- Payload Priority: 40T+ certified configurations (per TR CU 018/2011) maximize ROI on sparse haul cycles in remote resource zones.

-

Southeast Asia (Indonesia / Philippines):

- High-Humidity Durability: Refurbished electrical systems feature conformal coating (IPC-CC-830B) preventing corrosion in >80% RH environments.

- Right-Sized Capacity: 25-30T GVWR models navigate narrow volcanic island roads while outperforming locally assembled 16T units on volcanic aggregate hauls.

SEA LION’S INDUSTRIAL-GRADE ASSURANCE

Unlike spot-market used trucks, SEA LION’s process delivers predictable asset performance:

– Refurbishment Standard: ISO 9001:2015-certified process; engines dyno-tested to 110% rated load; structural welds NDT-inspected (ASME Section IX).

– Transparency: Full digital maintenance history (including pre-refurbishment US DOT inspection records) and 3rd-party condition reports provided.

– Deployment Support: RO-RO vessel scheduling with integrated customs clearance (Russia: EAEU TS 018/2011; Africa: SONCAP/PVoC); on-site technical training.

Strategic Recommendation: For fleet managers operating in capital-constrained, high-abrasion environments, SEA LION-certified US-sourced trucks represent a de-risked path to fleet modernization. The combination of battle-tested US engineering, region-specific refurbishment, and SEA LION’s 18-year export infrastructure delivers measurable reductions in downtime and lifecycle costs versus new imports or unverified used assets. This model enables sustainable capacity expansion where operational continuity is non-negotiable.

SEA LION International Trade Co., Ltd. | Est. 2006 | Heavy Equipment Solutions Division

Refurbishment Facilities: Qingdao, China | Global Logistics Network: 47 Key Ports | Authorized Distributor SINOTRUK/SHACMAN/XCMG

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications – Used Heavy-Duty Trucks (Bakersfield Market)

This report outlines standardized technical specifications for used heavy-duty trucks commonly available in the Bakersfield, CA market. Units are typically sourced from regional hauling, aggregate transport, and construction logistics fleets. The following data reflects common configurations observed in 2018–2023 model years, refurbished and certified for resale in Q1 2026.

Technical Specifications Table: Used Heavy-Duty Trucks (Bakersfield, CA)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615 Series (Euro III/IV Compliant) |

| Engine Displacement | 9.726 L (594 cu in) |

| Horsepower (HP) | 336 HP @ 2,200 rpm (Standard Tune) |

| Optional: 371 HP @ 2,200 rpm (High-Torque Tune) | |

| Torque | 1,400 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Full Synchromesh) |

| Gear Ratios | 10 Forward, 2 Reverse |

| Primary Use Case | On/Off-Highway Haul, Aggregate, Heavy Equipment Transport |

| Front Axle Load | 7,000 kg (15,432 lbs) – Parabolic Spring Suspension |

| Rear Tandem Axle Load | 18,000 kg (39,683 lbs) – Multi-Leaf w/ Drum Brakes |

| Gross Vehicle Weight Rating (GVWR) | 49,000 kg (108,027 lbs) |

| Tire Specifications | 12.00R20 20PR Radial (Tubeless) – Load Range G |

| Tire Load Index | 152/148 (Single/ Dual) – Max Load: 4,750 kg per dual axle position |

| Fuel Tank Capacity | 400 L (105.7 gal) – Dual Tanks (Optional) |

| Lubrication System | Wet Sump, Forced Feed |

Fuel Efficiency Analysis

Fuel economy for the Weichai WD615-powered units equipped with the HW19710 transmission averages 2.8 to 3.4 miles per gallon (MPG) under mixed operating conditions typical in Kern County:

- Highway (Loaded): 3.2–3.4 MPG (65–70 mph cruise)

- On-Site/Off-Road (Aggregate Haul): 2.6–2.9 MPG

- Stop-and-Go (Urban Construction Zones): 2.4–2.7 MPG

Units retrofitted with electronic fuel calibration tuning (EFC) and aerodynamic cab kits show up to 6% improvement in fuel efficiency. Fleet operators report optimal performance when engine RPM is maintained between 1,400–1,800 rpm during grade climbs and load acceleration.

Note: Bakersfield’s ambient temperatures (avg. 35°C / 95°F in summer) necessitate routine cooling system maintenance to sustain fuel efficiency and prevent thermal derating.

Load Capacity & Operational Suitability

These trucks are engineered for high-cycle, high-payload applications common in Central Valley construction and mining sectors:

- Rated Payload Capacity: 30–38 metric tons (66,000–83,800 lbs), depending on body configuration (dump, flatbed, lowboy)

- Dump Body Example: 20–25 yd³ volumetric capacity (granular materials; density-adjusted)

- Axle Load Distribution: Optimized for Caltrans weight enforcement tolerances; 33% front / 67% rear split recommended

- Braking Performance: HW19710 paired with JZ-24 air brake system achieves <0.7g deceleration under full load (dry conditions)

Units are routinely deployed in:

- Crushed rock hauling (Bakersfield quarries)

- Canal and roadway base material transport

- Heavy equipment relocation (dozers, excavators)

Summary & Recommendations

The Weichai WD615 + HW19710 powertrain combination offers proven durability and serviceability in the Bakersfield operational environment. With 12.00R20 20PR tires and robust axle ratings, these trucks deliver reliable performance under sustained 30+ ton payloads. Fuel efficiency remains competitive within the Tier III/IV interim used-truck segment, particularly when maintained per OEM intervals.

Fleet managers are advised to:

- Confirm turbocharger and EGR valve condition during pre-purchase inspection

- Verify transmission synchro ring wear (HW19710 units with >600,000 km)

- Prioritize units with tire retread history and suspension refurbishment logs

These specifications support high-availability operations with minimal downtime, making them a cost-effective solution for mid-tier construction logistics fleets.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED COMMERCIAL FLEET VEHICLES

REPORT ID: SL-REFURB-CA-2026-001

EFFECTIVE DATE: JANUARY 1, 2026

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks for Bakersfield-area construction and logistics operations. All units undergo a standardized 187-point inspection and refurbishment protocol compliant with SAE J2534 and ASTM F1566 standards. This report details the core refurbishment process for units designated ‘Used Trucks for Sale Bakersfield’, emphasizing structural integrity, operational reliability, and adherence to California Air Resources Board (CARB) Tier 4 Final requirements.

2. REFURBISHMENT PROCESS: CORE STEPS

Each unit progresses through sequential, audited stages. Non-conforming components are rejected; no field repairs are permitted.

2.1 ENGINE & GEARBOX TESTING (SAE J1939-COMPLIANT)

All powertrains undergo 100% functional validation:

| Test Parameter | SEA LION Standard | Industry Baseline | Pass/Fail Threshold |

|---|---|---|---|

| Compression Test | Cylinder-to-cylinder differential ≤ 8% | Differential ≤ 15% | >8% differential = Rebuild |

| Dyno Load Test | 200-hour simulated duty cycle (ISO 1585) | 50-hour test (typical) | Power loss >5% = Reject |

| Emissions Analysis | Real-time NOx/PM monitoring (CARB-certified) | Visual smoke check only | Exceeds Tier 4 Final = Reject |

| Gearbox Endurance | 10,000 shift cycles @ 110% rated torque | Static bench test only | Abnormal wear = Rebuild |

Outcome: Engines/gearboxes failing any threshold undergo full teardown, component replacement (OEM-spec only), and retesting. 12.3% of intake units are rejected at this stage (2025 Q4 data).

2.2 CABIN REPAINTING (ASTM D3359/D4541)

Corrosion prevention and durability focus for Bakersfield’s alkaline soil/dust environment:

- Surface Prep:

- Media blasting to SSPC-SP10/NACE No. 2 (near-white metal)

- Epoxy phosphate conversion coating (MIL-PRF-22750 Type III)

- Primer Application:

- 2-coat corrosion-inhibiting epoxy (dry film thickness: 120μm ±5μm)

- Topcoat:

- Polyurethane (RAL 7038/Custom fleet colors), 80μm DFT, UV-stabilized

- Validation:

- Adhesion test (ASTM D3359: 5B rating required)

- Salt spray resistance (ASTM B117: 1,000+ hours @ 5% NaCl)

Note: All rubber seals, glass, and electrical harnesses are replaced during cabin disassembly.

2.3 NEW TIRES & BATTERY REPLACEMENT

Specified for heavy-haul construction duty cycles:

| Component | SEA LION Specification | Validation Method |

|---|---|---|

| Tires | Michelin X Works D (G-rated), 16-ply, dual-rear configuration. Load range E minimum. | Load inflation test (SAE J175), tread depth ≥ 14/32″ |

| Battery | OPTIMA YellowTop AGM (Group 31), 1,000 CCA minimum. Dual-battery system standard. | Cold-cranking amp test (SAE J537), 0% sulfation |

Process: Tires mounted on bead-blasted, magnaflux-inspected wheels. Batteries load-tested and paired within 5% capacity variance.

2.4 CHASSIS REINFORCEMENT (ASTM A572 GR 50 STEEL)

Mandatory for all units with >300,000 miles or structural fatigue indicators:

- Inspection: Ultrasonic thickness testing (ASTM E797) at 12 critical frame rail zones.

- Reinforcement Protocol:

- Cracked/damaged sections cut out; replaced with laser-cut ASTM A572 GR 50 steel.

- Reinforcement plates welded using 100% GMAW process (AWS D1.1 certified).

- Post-weld stress relief via controlled induction heating (200°C ±10°C).

- Validation:

- Post-repair ultrasonic testing (100% weld coverage)

- Frame alignment verified to ±1.5mm tolerance (SAE J2788)

Note: 22.7% of Bakersfield-sourced units require chassis reinforcement due to aggregate hauling stress.

3. SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

SEA LION exceeds industry norms via mandatory, documented checkpoints:

| Inspection Category | SEA LION Requirement | Competitor Baseline | Verification Tool |

|---|---|---|---|

| Structural Integrity | 100% frame rail ultrasonic testing | Spot-check visual only | Olympus 38DL PLUS w/ 5MHz probe |

| Brake System | Full hydraulic pressure decay test (≤ 0.5 psi/min) | Static pressure hold only | Snap-on MODIS Ultra |

| Electrical System | CAN bus signal integrity scan (J1939) | Voltage check only | Bosch ESI[tronic] 2.0 |

| Final Road Test | 50-mile calibrated route w/ datalogging | 5-mile test drive | Bosch DSO 5054 oscilloscope |

Rejection Rate: 18.6% of candidate units fail initial inspection (2025 data). All rejected units are recycled per EPA R2 standards; none enter refurbishment.

4. WARRANTY & COMPLIANCE

- Coverage: 12 months / 20,000 miles (whichever occurs first), no-exclusions on powertrain or structural components.

- CARB Compliance: All engines certified to Executive Order DPF-256 (verified via CARB Online Verification).

- Documentation: Full refurbishment log, test reports, and CARB certificate provided with each unit.

5. OPERATIONAL IMPACT FOR BAKERSFIELD OPERATORS

Refurbished SEA LION units deliver:

– 37% lower TCO vs. new equivalent (2025 Fleet Cost Index)

– 99.2% uptime in Bakersfield aggregate/construction fleets (12-month field data)

– Zero structural failures in 2024-2025 deployments (CA DMV incident reports)

Note: All units include Bakersfield-specific modifications: upgraded air filtration (MERV 13), sealed wheel-end bearings, and high-temp brake pads.

END OF REPORT

SEA LION International – Engineering Reliability Since 1987

This document supersedes all prior specifications. SEA LION reserves the right to modify processes to meet evolving regulatory standards.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from China – Bakersfield Market

Issuing Authority: SEA LION International – Global Heavy Equipment Division

Report Date: January 15, 2026

Executive Summary

This report evaluates optimal maritime logistics methods for exporting used trucks sourced from China to Bakersfield, CA, USA. Three primary shipping modalities—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container transport—are analyzed for cost-efficiency, equipment integrity, transit reliability, and corrosion protection. Special emphasis is placed on seawater-induced corrosion mitigation via industrial wax spraying protocols.

1. Background

The demand for cost-effective, high-durability used trucks in the Bakersfield construction and logistics sectors has increased due to infrastructure expansion and fleet turnover cycles. SEA LION International identifies China as a key sourcing region for pre-owned heavy-duty trucks (e.g., Sinotruk HOWO, Foton Auman, Dongfeng KX). Efficient, damage-free transport from Chinese ports (e.g., Shanghai, Qingdao, Ningbo) to the Port of Long Beach (primary gateway to Bakersfield) is critical.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Loading) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed onboard | Crane-lifted, stacked loosely | Crane-lifted onto open platform |

| Vehicle Compatibility | Operational trucks only | All conditions (incl. non-runners) | All conditions (incl. oversized) |

| Space Utilization | High (dense vertical stacking) | Moderate (risk of misalignment) | Low to Moderate (per unit area) |

| Port Infrastructure | Requires RO-RO terminal | General cargo terminal | Container terminal |

| Transit Time (China → Long Beach) | 18–24 days | 22–28 days | 20–25 days |

| Average Cost per Truck (USD) | $1,800 – $2,400 | $1,400 – $1,900 | $2,600 – $3,300 |

| Risk of Physical Damage | Low (controlled movement) | High (contact during loading) | Medium (exposure to elements) |

| Insurance Complexity | Standard | High (variable condition) | Moderate |

| Customs Clearance Speed | Fast (pre-inspected units) | Slower (cargo inspection delays) | Moderate |

| Best Suited For | Operational fleets, high volume | Non-operational, budget-focused | Oversized, modified, or damaged units |

3. Corrosion Protection: Wax Spraying Protocol

Seawater exposure during Pacific transits (avg. salinity: 3.5%) poses a significant corrosion risk to undercarriages, chassis frames, and electrical junctions.

SEA LION Standard Protection Procedure:

- Pre-shipment Treatment: Full underbody and chassis application of hydrophobic, salt-resistant wax emulsion (ASTM D130-22 compliant).

- Application Method: Automated spray booth with robotic nozzles; coverage verified via infrared imaging.

- Wax Specification:

- Type: Solvent-based synthetic polymer blend

- Thickness: 25–30 µm dry film

- Salt Spray Resistance: >1,000 hours (per ASTM B117)

- Post-Treatment: Drying tunnel (60°C, 20 min); sealed cab and intake points to prevent contamination.

Note: Wax protection reduces post-arrival rust repair costs by up to 68% (based on 2025 SEA LION field data from 412 units).

4. Recommended Solution by Use Case

| Client Profile | Preferred Method | Rationale |

|---|---|---|

| Large construction fleet renewal (10+ operational units) | RO-RO | Fast turnaround, minimal handling, lowest damage rate |

| Budget-focused operators (non-running units) | Bulk Cargo | Lowest cost; accepts higher risk for non-operational assets |

| Modified or oversized trucks (e.g., crane carriers) | Flat Rack | Accommodates dimensions beyond standard container limits |

5. Port & Inland Logistics

- Origin Ports (China): Shanghai, Qingdao, Shenzhen (RO-RO-capable terminals)

- Destination Port: Port of Long Beach – Auto Processing Facility (APF)

- Final Delivery to Bakersfield:

- RO-RO & Flat Rack: Direct chassis tow (avg. 220 miles, 4.5 hrs)

- Bulk Cargo: Requires reconditioning yard staging prior to road transport

6. Conclusion

For fleet managers and construction firms sourcing used trucks from China, RO-RO shipping with industrial wax protection offers the optimal balance of cost, speed, and asset integrity for operational units. Bulk cargo remains viable for non-running units under tight budget constraints. Flat rack transport is essential for non-standard configurations.

SEA LION International recommends integrating wax spraying into all export workflows to ensure compliance with U.S. DOT durability expectations and reduce post-import rework.

Prepared by:

SEA LION International – Engineering & Logistics Division

Verification Code: SL-ISR-2026-TRK-CHN-US-01

Classification: Industrial Use Only – Distribution Controlled

Get a Quote for Used Trucks For Sale Bakersfield

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]