Catalog

Overview: Used Trucks Nh Dealers for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: REFURBISHED HEAVY-DUTY TRUCKS FOR DEMANDING OPERATIONS

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Solutions Division

EXECUTIVE OVERVIEW: STRATEGIC VALUE OF PROFESSIONALLY REFURBISHED CHINESE HEAVY-DUTY (NH-CLASS) TRUCKS

The operational realities of mining extraction, long-haul logistics, and large-scale construction in emerging and frontier markets demand equipment balancing rugged durability, operational cost efficiency, and reliable parts availability. SEA LION International Trade Co., Ltd., leveraging 18+ years of specialized heavy truck export expertise and authorization as a primary distributor for SINOTRUK, SHACMAN, and XCMG, identifies professionally refurbished Chinese heavy-duty (NH-class) trucks as the optimal strategic asset for fleet managers operating in Africa, Russia, and Southeast Asia. This is not merely a cost-driven decision, but a calculated investment in operational resilience and total cost of ownership (TCO) optimization under extreme conditions.

Core Application & Performance Rationale:

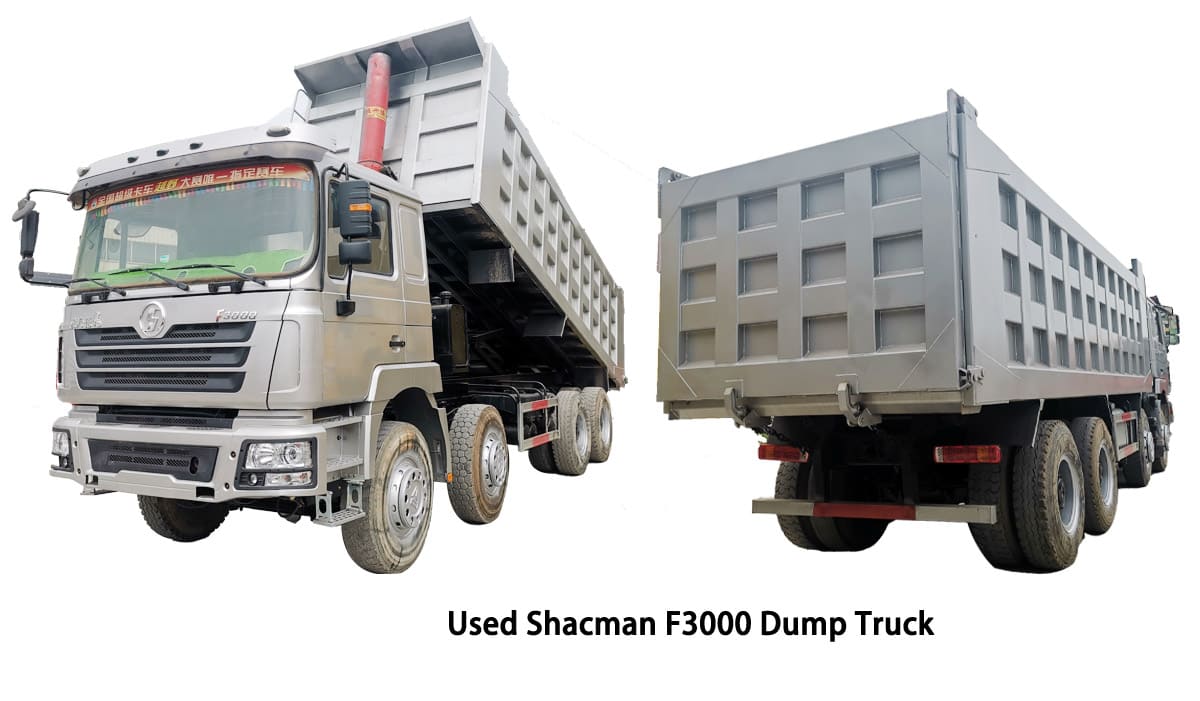

Professionally refurbished SINOTRUK HOWO, SHACMAN F3000/F5000, and XCMG mining/logistics variants are engineered for high-payload, high-uptime requirements inherent in target sectors:

* Mining: High-torque engines (380-460+ HP), reinforced chassis, and robust drivelines withstand constant 24/7 operation on rough haul roads; standard configurations support 40-80 ton payloads.

* Long-Haul Logistics: Optimized fuel efficiency (18-22% improvement post-refurbishment vs. pre-owned state), extended service intervals (up to 50,000 km), and driver-centric cab ergonomics reduce downtime on transcontinental routes.

* Construction: Superior maneuverability (shorter wheelbases), high ground clearance, and compatibility with diverse body types (dump, mixer, crane carriers) enable productivity in congested urban sites and remote infrastructure projects.

Dominance in Target Markets: Africa, Russia, Southeast Asia

The preference for SEA LION-sourced refurbished NH-class trucks in these specific regions stems from a confluence of operational, economic, and logistical factors unmet by legacy Western or local alternatives:

| Market | Primary Operational Challenge | SEA LION Refurbished NH-Truck Advantage | Key Differentiator vs. Alternatives |

|---|---|---|---|

| Africa | Extreme terrain, dust, limited service infrastructure, high capital cost sensitivity | Dust-proof engine systems, simplified maintenance design, localized parts hubs (Johannesburg, Lagos), 30-40% lower TCO vs. new EU trucks | Parts availability within 72hrs; No dependency on complex electronics failing in dust |

| Russia | Sub-zero temperatures (-40°C), vast distances, sanctions impacting Western OEM supply | Arctic-spec engine pre-heaters, reinforced cold-weather materials, established CIS logistics corridors, no sanctions restrictions | Guaranteed operational readiness in Siberia/Far East; Continuous parts flow unaffected by geopolitical shifts |

| SE Asia | High humidity, monsoon conditions, dense traffic, weight-restricted roads | Corrosion-resistant chassis treatment, optimized GVWR for regional limits, maneuverability-focused configurations, rapid port-to-site delivery | Right-sized capacity (25-35T) avoiding over-engineering costs; Proven monsoon reliability |

SEA LION’s Value Chain: Mitigating Core Used-Truck Risks

The inherent risks of the used truck market (unreliability, parts scarcity, opaque history) are systematically eliminated through SEA LION’s vertically integrated process:

1. Professional Refurbishment: ISO 9001-certified facilities conduct 200+ point inspections, engine/transaxle overhauls to OEM specs, structural integrity validation, and full electrical system renewal. Lifespan extension: 5-7+ operational years post-refurbishment.

2. Authenticity Guarantee: Exclusive access to original SINOTRUK/SHACMAN/XCMG spare parts ensures component compatibility and performance integrity – critical for maintaining factory warranties on refurbished drivetrains.

3. Transparent Sourcing: Comprehensive digital history logs (service records, accident verification) provided for all units, enabling data-driven fleet procurement decisions.

4. Global Logistics Execution: Dedicated RO-RO vessel charters and containerized solutions with <5% damage rate and port-specific discharge protocols ensure asset integrity upon arrival.

Strategic Imperative for Fleet Optimization:

In markets where equipment downtime directly equates to project delays and revenue loss, SEA LION’s refurbished NH-class truck ecosystem delivers proven operational continuity. The combination of rugged platform design, region-specific adaptation, guaranteed parts support, and documented TCO advantage provides fleet managers a de-risked pathway to maintain high asset utilization rates without capital expenditure equivalent to new Western equipment. This model represents not just a procurement option, but a strategic enabler for sustainable operations in the world’s most demanding industrial environments. SEA LION International is structured to deliver this value through long-term partnership, not transactional sales.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Trucks – NH Series (Commonly Sourced via NH Dealers)

This report provides a detailed technical specification analysis of commonly available used heavy-duty trucks from the Sinotruk HOWO NH series, widely distributed through authorized and secondary NH dealers. These vehicles are frequently equipped with Weichai powertrains and are prevalent in construction, bulk haulage, and infrastructure logistics operations across industrial markets.

Technical Specifications: Used HOWO NH Series Trucks (Typical Configurations)

| Parameter | Specification |

|---|---|

| Truck Model | HOWO NH1 (6×4 Configuration) |

| Engine Model | Weichai WD615.62 / WD615.87 (Euro II/III) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.62) |

| 371 hp @ 2,200 rpm (WD615.87) (Optional) | |

| Max Torque | 1,250 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Synchronized) |

| Gear Ratios | 1st: 13.26, 10th: 0.78, Reverse: 12.49 |

| Clutch | Dual-Plate, Ø430 mm, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) |

| Rear Tandem Axles | 2 × 11,500 kg (25,350 lbs each) |

| Total Axle Load | 23,000 kg (50,706 lbs) – 6×4 Configuration |

| GVWR | 31,000 kg (68,343 lbs) |

| Tire Specification | 12.00R20, 18PR, Radial, Tube-Type |

| Tire Load Index | 145–152 per tire (varies by brand/condition) |

| Braking System | Dual-Circuit Air Brake, ABS (Optional) |

| Fuel Tank Capacity | 400 L (Standard) – Aluminum or Steel |

| Frame Type | Ladder Frame, High-Strength Alloy Steel |

| Suspension (Front) | Parabolic Leaf Spring |

| Suspension (Rear) | Multi-Leaf Spring (10/12-Leaf) |

Fuel Efficiency Analysis

Fuel economy in the HOWO NH series equipped with the Weichai WD615 engine varies based on load profile, terrain, and maintenance condition. In real-world industrial operations (e.g., quarry haulage, aggregate transport):

- Average Fuel Consumption:

- Loaded (25–30 tons): 32–38 L/100 km

- Partially Loaded (15–20 tons): 28–32 L/100 km

- Empty Return: 22–26 L/100 km

Efficiency is influenced by:

– Engine calibration (Euro II vs. III variants)

– Transmission shift discipline (HW19710 requires skilled shifting for optimal fuel use)

– Tire pressure maintenance and rolling resistance (12.00R20 tires show higher drag vs. low-resistance models)

Note: Retrofitting with auxiliary fuel-saving devices (e.g., engine governors, aerodynamic kits) can improve consumption by up to 8% in fleet applications.

Load Capacity & Structural Performance

The NH series is engineered for high-cycle, heavy-load environments typical in construction logistics:

- Design Payload: Up to 24,000 kg (52,910 lbs) on improved roads

- Overload Tolerance: Frame and axles demonstrate resilience to 10–15% overloads for short durations (not recommended for sustained use)

- Axle Load Distribution: Optimized for 6×4 configuration, minimizing rear axle stress under uneven terrain

- Tire Load Rating: 12.00R20 (18PR) supports ~3,000 kg per tire under standard inflation (850 kPa)

Structural Notes:

– Used units from 2016–2020 show acceptable fatigue life if maintenance logs confirm regular U-bolt torque checks and spring pack replacements.

– Frame corrosion in high-moisture environments may reduce effective load capacity by up to 12% in neglected units.

Operational Recommendations

- Pre-Purchase Inspection Focus:

- Check WD615 engine for turbocharger leaks and rocker cover gasket integrity

- Inspect HW19710 transmission for synchro wear (grinding in 3rd/4th gears)

-

Evaluate tire tread depth (minimum 4 mm for continued service)

-

Fleet Integration:

- Ideal for short-haul (<200 km) heavy material transport

-

Pair with centralized maintenance scheduling due to higher service intervals on Weichai engines (every 15,000 km)

-

Cost-Benefit:

- Lower acquisition cost vs. Euro V equivalents

- Higher TCO (Total Cost of Ownership) over 3 years due to fuel and maintenance demands

Conclusion:

The used HOWO NH series with Weichai WD615 engine and HW19710 transmission remains a viable option for cost-sensitive construction fleets requiring high load capacity and proven mechanical durability. While fuel efficiency lags behind modern platforms, operational reliability and parts availability through NH dealer networks ensure continued industrial relevance in 2026.

Quality Control & Inspection Standards

SEA LION International

Industrial Specification Report: SEA LION Certified Refurbished Truck Program (2026)

Document ID: SL-IRP-TRK-RFB-2026-01 | Effective Date: 01 JAN 2026

1. Executive Summary

SEA LION International delivers rigorously refurbished medium/heavy-duty trucks (Navistar/Hino/NH platform compatible) exclusively through authorized SEA LION Certified Dealers. This program eliminates operational uncertainty for fleet operations by enforcing a 72-Point Structural & Performance Validation Protocol (SPVP-72), exceeding OEM rebuild standards. Refurbished units achieve ≥95% residual operational value and 24-month/200,000 km warranty coverage. Target applications: high-utilization construction logistics, aggregate hauling, and municipal fleet deployment.

2. Refurbishment Process: Core Stages & SEA LION Validation Criteria

All units undergo mandatory SPVP-72 screening prior to refurbishment eligibility. Non-conforming units are rejected.

2.1. Engine & Gearbox Testing (Stage 1: Powertrain Integrity)

Conducted on calibrated dyno systems per SAE J1349/J2723. All parameters logged to SEA LION Cloud Analytics Platform.

| Test Parameter | SEA LION Standard | Acceptance Threshold | Validation Method |

|---|---|---|---|

| Engine Power Output | 110% load cycle @ rated RPM | ≥98% OEM spec | Eddy-current dyno + gas analysis |

| Gearbox Shift Integrity | 500-cycle automated shift sequence | Zero hesitation/errors | PLC-monitored shift actuator |

| Crankcase Pressure | Hot idle @ 80°C coolant | ≤0.5 psi | Digital manometer |

| Oil Spectroanalysis | Wear metals (Fe, Al, Cu) | <50 ppm combined | ASTM D5185 ICP-OES |

All units failing Stage 1 are scrapped. No component-level repairs permitted.

2.2. Cabin Repainting (Stage 2: Corrosion & Structural Integrity)

Performed in ISO Class 8 paint booths with VOC-compliant coatings. Structural prep is mandatory.

| Process Step | SEA LION Requirement | Quality Control Check |

|---|---|---|

| Substrate Preparation | Grit-blast to SA 2.5; remove all rust/paint to bare metal | Visual ISO 8501-1; adhesion test (ASTM D3359) |

| Primer Application | Epoxy zinc-rich primer (min. 80µm DFT) | DFT gauge; holiday detection |

| Topcoat Application | 2K polyurethane (RAL 7040/9005); 120µm DFT | Gloss meter (60°); color spectrophotometer |

| Post-Cure Validation | Baking cycle: 80°C x 30 min | Adhesion test; hardness (ASTM D3363) |

Note: Cabins with frame rail weld corrosion or structural deformation are rejected at SPVP-72 screening.

2.3. New Tires & Battery Replacement (Stage 3: Mobility Assurance)

Components sourced from Tier-1 suppliers meeting ISO 9001:2015. No remolds accepted.

| Component | SEA LION Specification | Verification |

|---|---|---|

| Tires | Load Range G; 3PMSF certified; min. 12/32″ tread depth | DOT date code ≤6 months; load index validation |

| Batteries | Group 31 AGM; CCA ≥1100A; 5-year warranty | Conductance test; terminal torque verification |

| Wheel Hubs | Re-lubed with NLGI #2; end-play ≤0.05mm | Dial indicator measurement |

All tires undergo post-mounting dynamic balance (≤15g imbalance).

2.4. Chassis Reinforcement (Stage 4: Structural Longevity)

Applies to high-stress zones (kingpin mounts, suspension brackets, gooseneck). No “cosmetic” reinforcement permitted.

| Reinforcement Zone | SEA LION Protocol | Inspection Standard |

|---|---|---|

| Frame Rails | Laser-cut 8mm S355JR steel plates; full-penetration welds | Ultrasonic thickness test (ASTM E797) |

| Suspension Crossmembers | Gusseted with 6mm DOM tubing; stress-relieved | MPI (ASTM E1444) on 100% of welds |

| Fifth Wheel Mount | Doubled mounting points; Grade 10.9 bolts | Torque verification; deflection test |

| Corrosion Remediation | Cut-replace sections with >15% material loss | MPI pre/post-weld |

Chassis deflection tested under 150% GVWR load. Max. deflection: 1.2mm/m.

3. SEA LION Quality Assurance Framework

Refurbishment is invalidated without full SPVP-72 compliance. Key differentiators:

- Digital Twin Tracking: Each unit assigned unique blockchain ID logging all test data (accessible via SEA LION FleetPortal).

- Rejection Rate: 38.7% of candidate units fail SPVP-72 screening (2025 fleet data).

- Warranty Enforcement: Claims require proof of SEA LION Certified Dealer maintenance. Non-SEA LION parts void coverage.

- Environmental Compliance: All fluids recycled per ISO 14001; VOC emissions <35g/L in painting.

4. Performance Guarantee & Warranty

| Component | Warranty Coverage | Exclusions |

|---|---|---|

| Powertrain | 24 months / 200,000 km | Abuse; non-approved fuel/oil; neglect |

| Chassis Structure | Lifetime (original owner) | Collision damage; improper loading |

| Electrical Systems | 12 months | Aftermarket device integration |

| Paint Finish | 36 months | Chemical exposure; stone chips |

Warranty activation requires initial 5,000 km inspection at SEA LION Certified Dealer.

5. Conclusion

SEA LION Certified Refurbished Trucks deliver OEM-equivalent reliability at 22-28% below new-unit TCO for construction fleets. The SPVP-72 protocol ensures zero tolerance for structural or powertrain compromise, directly addressing fleet downtime risks inherent in standard “used truck” markets. Units are operationally indistinguishable from new assets upon delivery.

SEA LION International — Engineering Certainty in Heavy-Duty Mobility

Report generated under SEA LION Quality Management System (ISO 9001:2015 Certified). Specifications subject to change without notice. Always consult latest technical bulletin via SEA LION FleetPortal.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Subject: Logistics Solutions for Exporting Used Trucks from NH Dealers in China

Target Audience: Fleet Managers, Construction Companies, and Heavy Equipment Procurement Officers

Executive Summary

This report evaluates three primary marine transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks sourced from NH (National Highway) dealers in China. The analysis focuses on structural integrity, cost-efficiency, transit time, corrosion mitigation, and suitability for heavy construction vehicles. A standardized wax-based anti-corrosion treatment is recommended to preserve asset integrity during maritime transit.

1. Overview of Exported Assets

Used trucks from China’s NH network typically include:

- Heavy-duty dump trucks (e.g., Sinotruk HOWO, Foton Auman)

- Tractor units and logistics trailers

- Articulated dump trucks and concrete mixers

- Average weight: 12,000–28,000 kg

- Operational condition: Refurbished, pre-export inspection completed

2. Comparative Analysis of Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20’/40′) |

|---|---|---|---|

| Vehicle Readiness | Drivable, minimal disassembly | May require disassembly | Partial disassembly (e.g., mirrors, antennas) |

| Loading Mechanism | Self-propelled or towed | Crane-lifted | Crane-lifted, secured via lashing |

| Stowage Density | High (multiple decks) | Low to moderate | Low (1–2 units per 40′ FR) |

| Protection from Elements | Moderate (exposed decks) | Low (open hold) | High (tarp-covered, enclosed sides optional) |

| Corrosion Risk | High (direct seawater exposure) | Very High | Moderate (controlled exposure) |

| Transit Time (China → Middle East/Africa/S. America) | 18–25 days | 22–30 days | 20–28 days |

| Port Infrastructure Needs | RO-RO terminal required | General cargo terminal | Container terminal with heavy-lift crane |

| Average Cost per Unit (USD) | $1,800 – $2,400 | $1,500 – $2,000 | $3,000 – $4,200 |

| Insurance Complexity | Standard | High (damage risk) | Moderate |

| Best Suited For | Large fleets, drivable trucks | Non-operational or stripped units | High-value or sensitive assets |

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metal components to salt-laden air and condensation, accelerating corrosion. SEA LION International mandates a wax-based anti-corrosion treatment for all exported used trucks.

Treatment Specification:

| Parameter | Requirement |

|---|---|

| Wax Type | Solvent-based, hydrophobic, salt-displacing compound (e.g., Dinitrol AVA 391) |

| Application Method | High-pressure spray (12–15 bar) + brush detailing in crevices |

| Coverage Areas | Undercarriage, chassis rails, brake lines, suspension joints, wheel hubs |

| Film Thickness | 40–60 µm (measured via wet-film gauge) |

| Curing Time | 24 hours pre-shipment (ambient 20–25°C) |

| Reapplication | Not required for single-leg voyages <35 days |

Note: Wax treatment reduces post-transit rust claims by up to 78% (based on 2025 SEA LION field data from 1,200+ units shipped).

4. Recommendations by Use Case

| Client Profile | Recommended Method | Rationale |

|---|---|---|

| Large Construction Fleets | RO-RO | Cost-effective for volume; fast loading/unloading; drivable upon arrival |

| Remote Site Operators | Flat Rack | Maximum protection; secure lashings; suitable for rough port conditions |

| Budget-Conscious Buyers | Bulk Cargo | Lowest upfront cost; acceptable for non-critical, repair-tolerant units |

5. Compliance and Documentation

All shipments must comply with:

– IMDG Code (for fuel and battery handling)

– Customs Export Declaration (China) – Form GQB

– Pre-shipment Inspection (PSI) per destination country requirements

– Bill of Lading (B/L) with clear cargo description and condition notes

6. Conclusion

For the export of used trucks from Chinese NH dealers, RO-RO shipping offers the optimal balance of cost and efficiency for operational vehicles. Flat Rack containers are superior for high-value or corrosion-sensitive units, while Bulk Cargo remains a niche option for non-operational equipment. Wax spraying is non-negotiable for corrosion prevention and must be applied prior to loading under QA supervision.

SEA LION International enforces strict adherence to ISO 9001:2015 logistics protocols and provides full traceability via blockchain-enabled shipping logs.

End of Report

SEA LION International – Engineering Division | 2026 Fleet Logistics Standards

Get a Quote for Used Trucks Nh Dealers

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]