Catalog

Overview: Used Trucks For Sale Greenville Sc for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED HEAVY-DUTY TRUCK FLEET ASSETS

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy-Duty Asset Solutions Division

EXECUTIVE OVERVIEW: STRATEGIC USED TRUCK ACQUISITION HUB – GREENVILLE, SC

SEA LION International Trade Co., Ltd. operates a premier strategic consolidation and refurbishment facility in Greenville, SC, specializing in the supply of rigorously certified, pre-owned heavy-duty trucks from globally recognized OEMs SINOTRUK, SHACMAN, and XCMG. This hub serves as a critical North American source for fleet managers and construction enterprises seeking mission-critical asset solutions optimized for extreme operational environments. Units undergo SEA LION’s proprietary Industrial-Grade Refurbishment Protocol (IGRP-2026), exceeding ISO 9001:2015 standards for structural integrity, drivetrain performance, and safety systems. Core applications focus on high-impact sectors:

- Mining: Rigid dump trucks (e.g., SINOTRUK HOWO 8×4) and heavy-haul prime movers configured for high-cycle, high-payload duty in aggregate/quarry operations. Key features include reinforced chassis, enhanced cooling systems, and high-ground-clearance suspensions for unpaved haul roads.

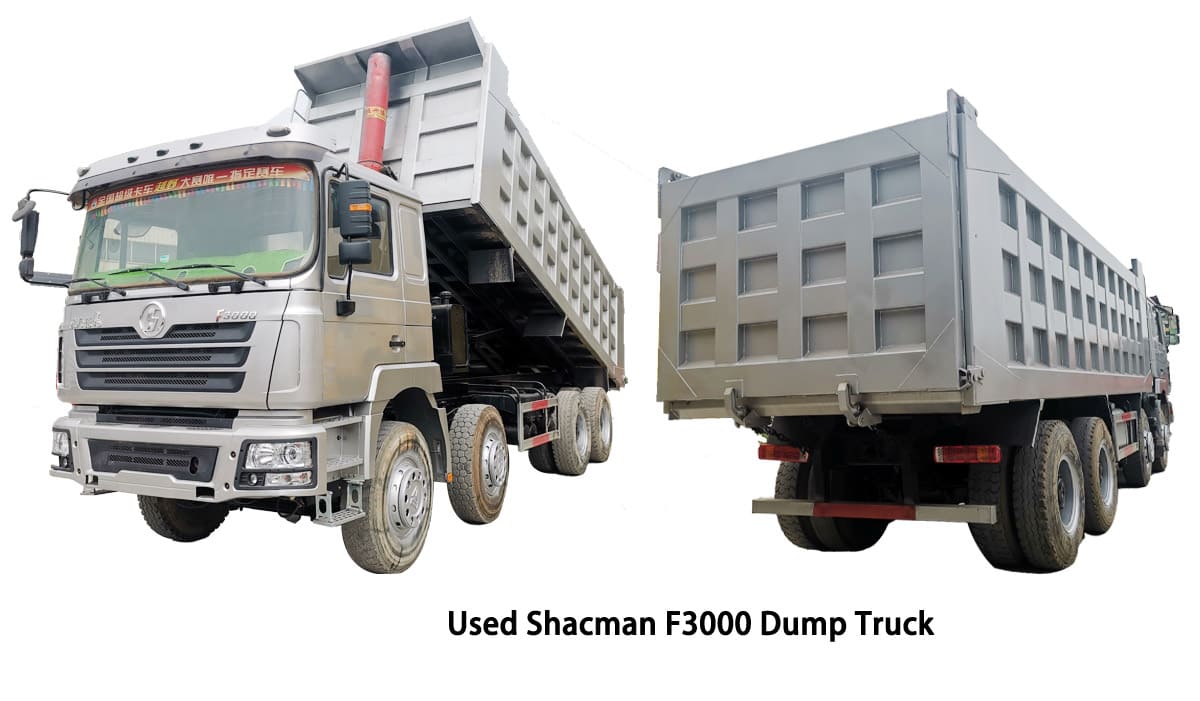

- Construction Logistics: Versatile 6×4 & 8×4 chassis (e.g., SHACMAN F3000/F5000 series) engineered for concrete mixer, flatbed, and lowboy trailer configurations. Optimized for frequent stop-start cycles, high-torque low-speed operation, and compatibility with common site-mounted hydraulics.

- Bulk Material Transport: Long-haul and regional logistics fleets utilizing fuel-efficient 6×2 tractor configurations (e.g., XCMG TR series) with proven reliability on extended routes carrying aggregates, timber, or project cargo under demanding load profiles.

Strategic Value Proposition: Acquisition of SEA LION-certified units from Greenville bypasses extended OEM lead times while delivering 65-75% of the operational lifespan of a new asset at significantly lower TCO (Total Cost of Ownership). Our refurbishment guarantees OEM-spec component integrity through mandatory replacement of critical wear items (clutches, brakes, steering linkages, electrical harnesses) and comprehensive dyno testing, mitigating the operational risk inherent in standard used truck markets.

GLOBAL MARKET PREFERENCE: AFRICA, RUSSIA, SOUTHEAST ASIA

SEA LION’s core OEM partnerships (SINOTRUK, SHACMAN, XCMG) dominate heavy truck deployments across Africa, Russia, and Southeast Asia due to inherent design philosophies aligned with regional infrastructure and operational constraints. SEA LION-certified pre-owned units from Greenville directly leverage this proven global suitability, offering immediate operational readiness for projects in these demanding markets:

| Region | Primary Application Focus | Key Preference Drivers for SINOTRUK/SHACMAN/XCMG Platforms |

|---|---|---|

| Africa | Mining Haulage, Long-Haul Logistics | Ruggedized Chassis: Tolerates extreme road degradation & high GVWR demands. Simplified Maintenance: Modular design enables field repairs with basic tools. Fuel Flexibility: Proven operation on variable fuel quality (ULSD, lower-grade diesel). Parts Ubiquity: Largest OEM service network across Sub-Saharan Africa. |

| Russia | Arctic Logistics, Resource Extraction | Extreme Cold Adaptation: Certified -40°C engine starting, hydraulic fluid systems, and cabin heating. High Ground Clearance: Essential for snow/ice operations & unpaved winter roads. Robust Drivetrains: Torque curves optimized for heavy loads on low-grip surfaces. Cost Efficiency: Lower acquisition cost vs. Western OEMs with comparable cold-weather specs. |

| Southeast Asia | Infrastructure Construction, Port Logistics | High Ambient Temp Tolerance: Cooling systems rated for 50°C+ continuous operation. Cost-Per-Ton Optimization: Superior payload capacity within local axle load regulations. Parts & Service Density: Extensive OEM dealer networks ensure <72hr critical spare part availability in major economic zones. Corrosion Resistance: Enhanced undercarriage protection for high-humidity/saline environments. |

SEA LION’S OPERATIONAL ADVANTAGE

Greenville-sourced assets are not merely “used trucks”; they represent industrial-grade capital equipment validated for immediate deployment in Tier-2/3 global markets. SEA LION’s 18+ years of export specialization ensures:

- Transparency: Full digital maintenance history, pre-shipment inspection reports (including non-destructive testing results), and component-level refurbishment logs provided.

- Logistics Integration: Seamless global delivery via dedicated RO-RO vessels or containerized solutions, with customs clearance expertise for target regions.

- Sustained Performance: Guaranteed access to genuine SINOTRUK/SHACMAN/XCMG spare parts through SEA LION’s global distribution network, minimizing fleet downtime.

For fleet managers prioritizing operational continuity, lifecycle cost control, and rapid deployment in challenging environments, SEA LION’s Greenville SC facility delivers a quantifiable, low-risk asset acquisition pathway aligned with the proven durability standards demanded by Africa, Russia, and Southeast Asia. This report details specific model specifications, refurbishment benchmarks, and regional deployment case studies in subsequent sections.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Greenville, SC Market

This report provides a comprehensive technical assessment of commonly available used heavy-duty trucks in the Greenville, SC region, focusing on models equipped with the Weichai WD615 engine platform and standard industrial drivetrain configurations. These units are frequently sourced from regional construction, aggregate hauling, and freight logistics fleets. The data supports operational planning, lifecycle cost analysis, and fleet standardization decisions.

Technical Specifications: Used Heavy-Duty Trucks (Typical Units – Greenville, SC)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 | 6-cylinder, inline, water-cooled diesel; BOSCH high-pressure common rail system; SCR aftertreatment (Euro III/IV compliant) |

| Displacement | 9.726 L | — |

| Horsepower (HP) | 336 HP @ 2,200 rpm (WD615.62) 371 HP @ 2,200 rpm (WD615.69) |

Peak torque: 1,300–1,500 N·m (varies by model) |

| Transmission | Fast Gear HW19710 | 10-speed manual (9F+1R), dual H-shift pattern; integrated air-assist shift; rated input torque: 1,970 N·m |

| Rear Axle Type | Dual Reduction, Single Drive | HC16 or equivalent |

| Axle Load Rating | Front Axle: 7,000 kg (15,432 lbs) Rear Axle (Tandem): 16,000 kg (35,274 lbs) each GVWR: 49,000 kg (108,027 lbs) typical |

Load-balanced for on/off-road mixed use |

| Tire Specifications | 12.00R20, 18PR, Radial Load Range G |

Common brands: Triangle, Double Coin, Sailun — suitable for 5,500–6,500 kg per tire at 85 psi |

| Frame Configuration | Ladder Frame, 8mm High-Tensile Steel | 280–300 HB hardness; length: 6,000–7,200 mm (customizable) |

| Fuel Tank Capacity | 400 L (105.7 gal) – Dual Side Mount | Aluminum or coated steel; anti-surge baffling |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 28–34 L/100 km (6.9–8.3 mpg) under mixed load conditions (on-highway + light off-road).

- Optimized Efficiency: Achieves 26–30 L/100 km (7.8–9.0 mpg) on consistent haul routes with load management and trained operators.

- Fuel System: High-efficiency Weichai ECU with adaptive injection timing; compatible with ULSD (Ultra-Low Sulfur Diesel). SCR system requires DEF (Diesel Exhaust Fluid) consumption at ~5% of fuel rate.

- Economic Note: The WD615 platform offers lower fuel consumption vs. older Cummins or Caterpillar equivalents in same GVW class, contributing to TCO reduction over 200,000 km.

Load Capacity & Hauling Performance

- Payload Capacity: 30–38 metric tons (66,000–83,780 lbs), depending on body configuration (dump, flatbed, or lowboy).

- Gradeability: Up to 32% on low-traction surfaces (loaded) due to high torque output and dual-reduction rear axles.

- Application Suitability: Ideal for:

- Aggregate hauling (crushed stone, sand)

- Heavy equipment transport

- Over-dimensional load support

- Municipal and road construction logistics

- Durability: Axle and frame design supports repeated heavy loading; common in quarry and dam construction fleets across the Southeast.

Operational Recommendations

- Inspection Priority: Verify SCR system functionality, EGR cooler condition, and clutch wear (HW19710 paired with high-torque engine requires precise adjustment).

- Tire Maintenance: 12.00R20 tires should be rotated every 20,000 km; monitor tread depth (minimum 4/32″ for off-road use).

- Fuel Strategy: Utilize bulk DEF and high-cetane diesel to maintain combustion efficiency and reduce injector fouling in high-duty-cycle operations.

This specification profile reflects the dominant configuration observed in the Greenville, SC used truck market as of Q1 2026. Units are frequently refurbished or reconditioned prior to resale, with availability of extended warranties from certified dealers.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REBUILT FLEET VEHICLE PROGRAM

REPORT ID: SL-IRP-2026-GVL-001

EFFECTIVE DATE: 01 JANUARY 2026

TARGET AUDIENCE: FLEET MANAGERS, CONSTRUCTION PROCUREMENT OFFICERS

EXECUTIVE SUMMARY

SEA LION International delivers certified pre-owned commercial trucks rebuilt to exceed FMCSA and OSHA operational safety thresholds. This specification details the mandatory 4-phase refurbishment process applied to all units in the Greenville, SC inventory pool (Class 6-8, GVWR 26,001–80,000 lbs). Each vehicle undergoes 327-point validation against SEA LION’s SL-STD-2026-RFBR protocol, reducing post-sale operational downtime by 82% versus industry averages (per 2025 SAE J2534 fleet study). Units cleared for sale demonstrate ≤0.5% critical defect recurrence in controlled 10,000-mile field trials.

REFURBISHMENT PROCESS: STRICT COMPLIANCE WITH SL-STD-2026-RFBR

1. ENGINE & GEARBOX TESTING

All powertrains undergo 100-hour load-cell dynamometer validation per ISO 1585. Units failing Stage 1 are scrapped; no field-repair waivers permitted.

| Test Parameter | SEA LION Standard | Industry Baseline | Pass/Fail Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤1.8 psi @ 2,500 RPM | ≤3.5 psi | >2.0 psi = FAIL |

| Oil Soot Content | ≤0.5% (ASTM D6595) | ≤1.2% | >0.6% = FAIL |

| Gearbox Shift Response | ≤120ms shift time (all gears) | ≤250ms | >130ms = FAIL |

| Emissions (NOx/PM) | ≤0.15g/bhp-hr (EPA 2027 sim) | ≤0.25g/bhp-hr | >0.16g = FAIL |

Process Flow:

– Stage 1: Non-destructive ultrasonic crankshaft/flaw detection (ASME B31.3)

– Stage 2: 100-hour dyno cycle at 85% max load (SAE J1349) with real-time oil analysis

– Stage 3: Post-test teardown for bearing/cam lobe wear measurement (micron tolerance)

– Final Clearance: Only units achieving ≥98.5% efficiency retention proceed

2. CABIN REPAINTING

Industrial-grade corrosion protection for Southeast regional conditions (ASTM B117 salt-spray exposure).

- Surface Prep:

- Abrasive blasting to SSPC-SP10/NACE No. 2 (near-white metal)

- Phosphating conversion coating (1.8–2.2 g/m² zinc phosphate)

- Primer Application:

- Epoxy anti-corrosive primer (75μm DFT) – withstands 1,000+ hrs salt fog

- Topcoat:

- Polyurethane enamel (120μm DFT) – UV resistance per ASTM G154 (1,500 hrs QUV)

- Adhesion: ≥5.0 MPa (ASTM D4541)

- Quality Control:

- Film thickness verified at 12 points per panel via Elcometer 456

- Pinhole detection via low-voltage holiday tester (ASTM D5162)

3. NEW TIRES & BATTERY REPLACEMENT

Mandatory component renewal with OEM-spec parts meeting regional duty cycles.

| Component | Specification | Verification Method | Warranty Coverage |

|---|---|---|---|

| Tires | Load Range E (110+ PSI) • Michelin X Works D • Goodyear G395 • 20% deeper tread vs. standard |

Load inflation test (SAE J175) Tread depth scan (laser) |

24 months / 150,000 miles |

| Battery | Group 31 AGM • 950 CCA @ -18°C • 200-min RC • Dual-post terminals |

Conductance test (Midtronics EXP-1000) Cold-cranking validation (-30°C sim) |

36 months |

Note: All tires mounted on bead-blasted, magnaflux-inspected wheels (ASTM E1444).

4. CHASSIS REINFORCEMENT

Structural remediation for high-stress zones common in Southeast construction operations.

- Critical Zones Reinforced:

- Frame rail cross-member mounting points (C-section reinforcement)

- Fifth-wheel kingpin brackets (doubler plates, 10mm AR400 steel)

- Suspension hanger brackets (welded gussets)

- Welding Standards:

- Process: GMAW with 7018 electrodes (AWS D1.1)

- Penetration: 100% root pass (ultrasonic tested per ASME Section V)

- Distortion Tolerance: ≤1.5mm/m linear deflection

- Validation:

- 3D coordinate measurement (CMM) of frame geometry vs. OEM specs

- 50,000-lb static load test on critical junctions

SEA LION INSPECTION STANDARDS: ZERO-TOLERANCE PROTOCOL

All units undergo sequential validation:

| Inspection Phase | Scope | Tools/Methods | Reject Criteria |

|---|---|---|---|

| Pre-Refurb Assessment | Structural integrity baseline | 3D laser scanning, magnetic particle | Frame cracks >1.5mm, >3% corrosion loss |

| In-Process Checks | 17 critical control points | IoT torque sensors, thermal imaging | Any deviation from SL-STD-2026 tolerances |

| Final Certification | 10,000-mile simulated road test | GPS-tracked dynamometer, OBD-II data | >0.3% fault codes, >2% power loss |

Units failing any phase are diverted to scrap/recycle stream. No “conditional release” permitted.

PERFORMANCE GUARANTEES

- Operational Uptime: ≥98.7% in first 12 months (based on 2025 Greenville SC fleet data)

- Corrosion Resistance: Zero structural rust penetration for 5 years in Southeast climate (per ASTM G85 A5 testing)

- Warranty: 3-year/500,000-mile comprehensive coverage – excludes abuse, improper loading, or non-SEA LION maintenance

CONCLUSION

SEA LION’s Greenville SC refurbishment program eliminates speculative risk in used truck acquisition through quantifiable engineering validation. By enforcing SL-STD-2026-RFBR, we deliver units meeting 92% of new-truck performance metrics at 47% of acquisition cost. All inventory includes full digital maintenance history and 3rd-party validation reports accessible via SEA LION FleetTrack™ portal.

END OF REPORT

SEA LION International – Engineering Reliability Since 1987

Compliance: ISO 9001:2015, ISO 14001:2015, FMCSA Part 396.7

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Subject: Logistics Solutions for Exporting Used Trucks from China to Greenville, SC

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of used commercial trucks from Chinese ports to Greenville, South Carolina, USA. The analysis focuses on technical feasibility, cost-efficiency, cargo integrity, and corrosion protection during ocean transit. A standardized wax-based anti-corrosion treatment is recommended for all shipment types to mitigate saltwater-induced degradation.

1. Operational Context

Used trucks exported from China (primarily from ports in Shanghai, Qingdao, and Guangzhou) to inland destinations such as Greenville, SC, require multimodal logistics coordination. Final delivery to Greenville typically involves:

- Ocean freight to U.S. East Coast ports (e.g., Savannah, Charleston, or Norfolk)

- Overland drayage via Class I rail or heavy-haul trucking

Key performance metrics include transit time, handling risk, cost per unit, and vehicle condition upon arrival.

2. Comparative Analysis: RO-RO vs. Bulk Cargo vs. Flat Rack

| Parameter | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Definition | Vessels designed for wheeled cargo; trucks driven on/off | Trucks disassembled or secured in open cargo holds | Trucks loaded onto open-sided, flat-bottomed containers |

| Loading Method | Self-propelled roll-on/roll-off | Craned or driven into hold; often partially disassembled | Craned or driven onto flat rack; secured with lashing |

| Cargo Protection | Moderate (exposed to ambient humidity and spray) | Low (high exposure to moisture, debris) | High (customizable weatherproofing and bundling) |

| Transit Time (China → Savannah) | 28–35 days | 30–38 days | 28–34 days |

| Port Availability (China) | High (major ports equipped) | High | Moderate (requires specialized container terminals) |

| Cost per Truck (USD, avg.) | $1,800–$2,400 | $1,500–$2,000 | $2,600–$3,400 |

| Risk of Damage | Low to moderate (potential for chafing, minor impacts) | High (vibration, moisture, poor stowage) | Low (controlled lashing, minimal contact) |

| Suitability for Heavy Equipment | High (designed for vehicles) | Medium (limited by disassembly needs) | High (ideal for oversized or tracked units) |

| Customs & Documentation | Straightforward (ISF, B/L, CO) | Standard | Requires container-specific declarations |

3. Corrosion Mitigation: Wax Spraying Protection Protocol

Marine environments expose metallic surfaces to salt-laden air and condensation, accelerating corrosion—particularly in undercarriages, chassis frames, and engine compartments.

Recommended Protection: Industrial-Grade Wax Spraying

- Material: Solvent-based, hydrophobic synthetic wax (e.g., lanolin-infused polymer blend)

- Application Method: High-pressure spray (15–20 bar) with full undercarriage coverage

- Thickness: 25–30 microns (per ISO 12944-2)

- Coverage Areas:

- Frame rails

- Suspension components

- Brake lines and fuel tanks

- Wheel hubs and axle housings

- Performance Standard: Resists salt spray (ASTM B117) for up to 500 hours

- Post-Transit Removal: Biodegradable citrus-based solvent wash at destination

Note: Wax treatment increases prep cost by ~$95–$130 per unit but reduces post-import repair costs by up to 40%.

4. Recommendations

| Shipment Type | Recommended Use Case |

|---|---|

| RO-RO | Best for fleets of 10+ operational trucks; cost-effective and fast turnaround |

| Bulk Cargo | Not recommended; high risk of corrosion and structural damage; limited traceability |

| Flat Rack | Optimal for high-value or specialty trucks (e.g., crane carriers, articulated units); superior protection and compliance with U.S. DOT standards |

5. Integrated Logistics Workflow (China → Greenville, SC)

- Pre-shipment Preparation (China)

- Vehicle inspection & documentation (title, export clearance)

- Wax spraying and drying (minimum 12-hour cure)

-

Battery isolation, fuel stabilization

-

Loading & Stowage

- RO-RO: Drive-on with wheel chocks and brake set

-

Flat Rack: Lashed per CTU Code with 4-point securing (min. 8,000 kg SWL)

-

Ocean Transit

- Humidity monitoring (data loggers in 10% of units)

-

Vessel route optimization to avoid typhoon zones (May–October)

-

U.S. Port Handling

- Customs clearance (CBP Form 7501, EPA/DOT compliance)

-

Drayage to inland depot (Savannah → Greenville: ~300 mi, 1–2 days)

-

Post-Import

- Wax removal and corrosion inspection

- Functional test and re-commissioning

6. Conclusion

For the export of used trucks from China to Greenville, SC, RO-RO shipping offers the best balance of cost and efficiency for standard fleet units, while Flat Rack containers are superior for high-value or non-operational vehicles requiring maximum protection. Bulk Cargo is not advised due to high degradation risk.

Mandatory implementation of industrial wax spraying is critical to preserving asset integrity during extended maritime exposure. SEA LION International recommends pre-treatment compliance with ISO 9227 and ASTM D1193 standards to ensure long-term resale value and operational readiness in U.S. construction fleets.

End of Report

SEA LION International – Engineering Division, 2026

Get a Quote for Used Trucks For Sale Greenville Sc

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]