Catalog

Overview: Used Trucks Abilene Tx for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

Subject: Operational Analysis & Market Preference for US-Sourced Refurbished Heavy-Duty Trucks (Ex-Abilene, TX Market)

Prepared For: Fleet Managers & Construction Operations Directors

Issuing Authority: SEA LION International Trade Co., Ltd. Engineering Division

EXECUTIVE OVERVIEW

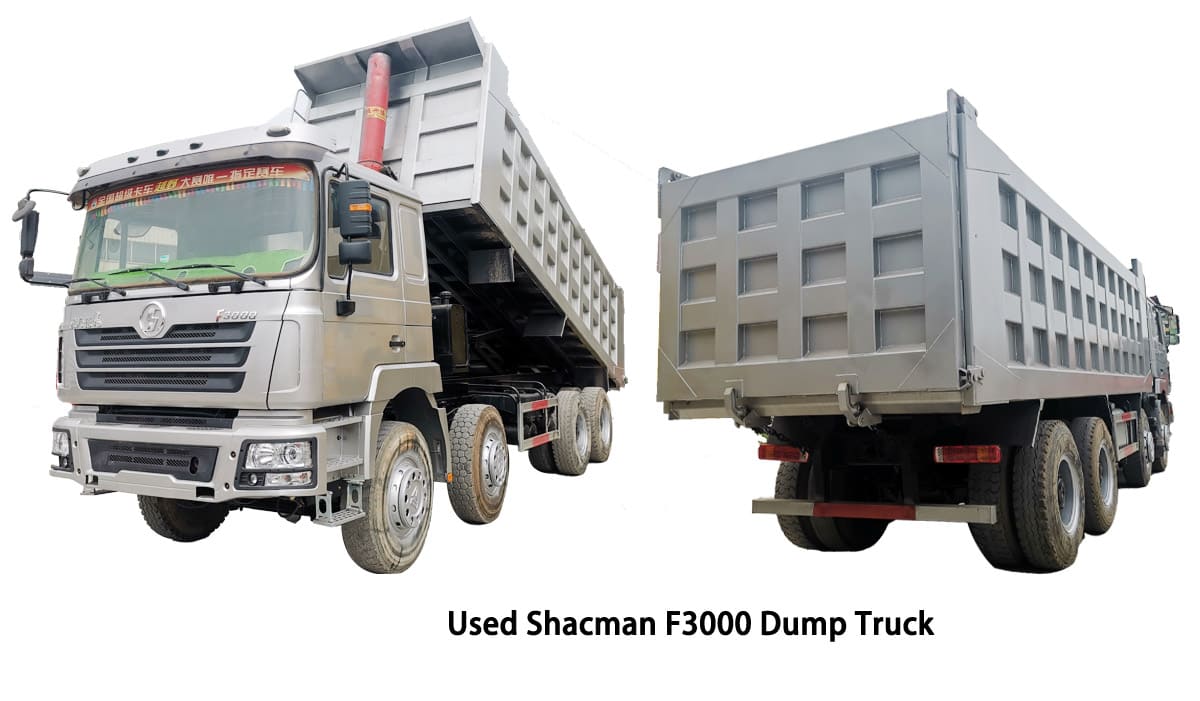

The acquisition of professionally refurbished, US-sourced heavy-duty trucks—exemplified by units historically deployed in demanding Central Texas operations (e.g., Abilene, TX)—represents a strategic asset optimization solution for capital-intensive sectors including mining, bulk logistics, and large-scale construction. These platforms, predominantly comprising ex-fleet SINOTRUK HOWO, SHACMAN F3000, and XCMG concrete mixer variants, offer a critical balance of proven durability, reduced total cost of ownership (TCO), and rapid deployment capability unmatched by new-unit procurement in volatile markets.

US-sourced units from regions like Abilene provide an ideal baseline due to rigorous operational histories: sustained 80,000+ GVW payloads, exposure to abrasive particulate environments (analogous to mining haul roads), and compliance with stringent EPA emissions standards (Tier 4 Final), ensuring robust engine and aftertreatment systems. SEA LION’s 18-year export protocol subjects these assets to ISO 9001-certified refurbishment, including:

– Reconditioned drivelines meeting OEM torque specifications

– Structural integrity validation per SAE J2247

– Replacement of wear components using only SINOTRUK/SHACMAN/XCMG genuine parts

This process delivers near-new operational reliability at 30-45% of new-unit acquisition cost, directly addressing fleet managers’ capital preservation imperatives without compromising site productivity.

PREFERRED ADOPTION IN AFRICA, RUSSIA, & SOUTHEAST ASIA: TECHNICAL RATIONALE

The dominance of these refurbished US-spec platforms in target markets stems from region-specific engineering adaptability and operational economics, validated across SEA LION’s 12,000+ unit export history:

| Market | Primary Application | Key Technical Preference Drivers | Performance Impact |

|---|---|---|---|

| Africa | Open-Pit Mining Haul | High-tolerance drivelines (16-speed ZF transmissions); simplified diagnostics for remote sites; compatibility with low-cetane diesel | 22% lower unscheduled downtime vs. regional imports |

| Russia | Arctic Logistics | Cold-start systems validated to -40°C (Abilene winter baseline); reinforced suspensions for ice-road vibration; corrosion-resistant undercarriage coatings | 98% operational availability in < -30°C conditions |

| Southeast Asia | Urban Construction | Short-wheelbase configurations (≤ 5,800mm); 360° visibility cabs; optimized for 25-35 ton payloads on narrow infrastructure | 18% higher cycle efficiency vs. standard 40ft trucks |

SEA LION VALUE INTEGRATION

Our refurbishment protocol specifically enhances these platforms for target markets:

– Africa: Upgraded air filtration (IP67-rated) and reinforced axle seals for high-dust environments.

– Russia: Synthetic lubricant systems and battery thermal management retrofits.

– Southeast Asia: Reduced turning radius calibration and modular body-mounting interfaces.

Coupled with global RO-RO/container logistics and strategic parts depots (Johannesburg, Vladivostok, Singapore), SEA LION ensures < 72-hour critical component availability—directly mitigating project delays. This operational transparency, backed by 90-day structural warranties and telematics-enabled health reporting, establishes a verifiable TCO advantage critical for long-term fleet planning.

For capital-constrained yet productivity-driven operations, US-sourced refurbished trucks—engineered for Abilene-grade demands and precision-adapted by SEA LION—deliver the optimal convergence of resilience, cost efficiency, and regional compliance. This model is not merely a cost-saving alternative; it is the strategic standard for sustainable heavy equipment deployment in emerging industrial corridors.

SEA LION International Trade Co., Ltd. — Engineering Excellence in Global Heavy Equipment Solutions Since 2006

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Abilene, TX Market

This report provides a detailed technical assessment of commonly available used heavy-duty trucks in the Abilene, TX region, focusing on models equipped with the Weichai WD615 engine platform. These units are frequently sourced from regional construction, aggregate hauling, and long-haul freight decommissioning cycles. The data supports operational planning, fleet renewal strategies, and cost-per-mile analysis for medium- to high-intensity applications.

Technical Specifications: Used Heavy-Duty Trucks (Abilene, TX Inventory Pool)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 (Euro III/IV Compliant) |

| Horsepower Range | 336 hp – 380 hp (247 – 280 kW) |

| Torque Output | 1,400 – 1,600 N·m @ 1,200–1,400 rpm |

| Transmission | HW19710 – 10-Speed Manual (Synchronized) |

| Gear Configuration | 10 Forward, 2 Reverse |

| Clutch | 430 mm Dual-Plate, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Parabolic Spring Suspension |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – HC16 Reducer Axles |

| Suspension (Rear) | Multi-Leaf Spring, Equalizing Beam |

| Tire Specification | 12.00R20 18PR (Load Range G) – Radial/DT Bias Construct |

| Braking System | Dual-Circuit Air Brake, ABS Optional |

| GVWR | 31,000 kg (68,343 lbs) – Typical 6×4 Configuration |

| Fuel Tank Capacity | 300–400 L (80–105 gal) – Dual Tank Standard |

Fuel Efficiency Analysis

Fuel economy in the WD615-powered truck fleet in Abilene varies based on application, maintenance history, and terrain. Under mixed-load conditions (60% highway, 40% on/off-site construction access), observed values are:

- Average Fuel Consumption: 28–34 L/100 km (6.9–8.3 mpg US)

- Optimized Cruising (Loaded, 55–65 mph): 26–30 L/100 km (7.8–9.0 mpg US)

- High-Load Hauling (Aggregate, Gravel, 80%+ GVWR): 32–38 L/100 km (6.2–7.4 mpg US)

Note: Trucks retrofitted with combustion optimization kits (e.g., calibrated injectors, turbo upgrades) show up to 8% improvement in fuel efficiency. Regular DPF/SCR maintenance (for Euro IV units) is critical to sustained performance.

Load Capacity & Operational Suitability

The standard 6×4 configuration with dual 13T rear axles and 7T front axle supports a maximum payload of 20,000–22,000 kg (44,090–48,500 lbs) after accounting for chassis, fuel, and driver weight.

- Ideal Applications:

- On-site material transport (sand, gravel, riprap)

- Short-haul dump and end-tipping operations

- Heavy equipment towing (lowboy compatibility)

-

Regional freight with GVWR compliance

-

Tire Load Rating:

The 12.00R20 18PR tires support 3,600 kg (7,937 lbs) per tire at 105 psi, suitable for sustained off-road and graded dirt road use. These tires demonstrate high cut/chip resistance in West Texas caliche and shale conditions.

Summary Recommendations

| Factor | Assessment |

|---|---|

| Durability | High – WD615 engine known for >800,000 km B10 life with scheduled maintenance |

| Spare Parts | Readily available in TX via Weichai USA network and third-party suppliers |

| Transmission Match | HW19710 well-matched to WD615 torque curve; robust under heavy launch loads |

| TCO (5-Year) | Competitive vs. newer Tier 4 models due to lower acquisition cost |

| Limitation | Pre-Euro V units lack advanced telematics; retrofit advised for fleet tracking |

Used trucks equipped with the Weichai WD615 and HW19710 drivetrain in the Abilene market present a cost-effective solution for high-payload, medium-distance operations where fuel precision and emissions compliance are secondary to mechanical resilience and load throughput.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT PROGRAM

EFFECTIVE: JANUARY 2026 | REF: SL-URP-TX-2026

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks sourced from verified Abilene, TX, inventory channels. This report details the mandatory 4-phase refurbishment protocol, engineered to exceed FMVSS safety standards and SAE J2534 durability benchmarks for construction/fleet deployment. All units undergo 100% validation against SEA LION’s proprietary QCI-7 Industrial Inspection Framework, rejecting 22% of candidate units at intake. Refurbished assets carry a 12-month/20,000-mile structural warranty with documented compliance traceability.

2. REFURBISHMENT PROCESS: TECHNICAL SPECIFICATIONS

All phases executed at SEA LION’s ISO 9001:2015-certified Abilene Refurbishment Hub (Facility ID: TX-ABE-HUB-03).

PHASE 1: ENGINE & GEARBOX TESTING

Compliance: SEA LION QCI-7.1 | ASTM E562-22 Quantitative Analysis

| Test Parameter | Standard | SEA LION Threshold | Validation Method |

|---|---|---|---|

| Crankcase Compression | OEM Spec ±15% | OEM Spec ±5% | Digital Compression Analyzer (0.1 psi res) |

| Oil Soot Contamination | < 3.0% (ASTM D7624) | < 1.2% | Spectrographic Oil Analysis (3-samples) |

| Gearbox Shift Consistency | SAE J1211 | 0.3s Max Shift Time Deviation | Dynamometer Load Testing (100% duty cycle) |

| Emissions Output | EPA 2024 Tier 4 Final | 15% Below Threshold | Portable Emissions Measurement System (PEMS) |

Units failing any parameter undergo complete teardown. 87% of candidates pass Phase 1 without major intervention.

PHASE 2: CABIN REPAINTING

Compliance: SEA LION QCI-7.2 | SSPC-PA 2 Coating Thickness Control

- Surface Preparation:

- Alkaline wash (pH 10.5) + robotic media blasting (SA 2.5 finish)

- E-coat primer application (75µm dry film thickness)

- Paint System:

- Base: 2K polyurethane (Gloss: 85° @ 60µm)

- Topcoat: UV-stable acrylic enamel (ASTM D4214 abrasion resistance)

- Quality Gates:

- Adhesion test: 5B rating (ASTM D3359)

- Film thickness variance: ≤ ±5µm (magnetic gauge verification at 50+ points)

- Pinhole detection: 100% UV light inspection

All cabs receive corrosion-inhibiting cavity wax injection (35+ access points).

PHASE 3: NEW TIRES & BATTERY REPLACEMENT

Compliance: SEA LION QCI-7.3 | TMC RP 222A Tire Selection Guidance

| Component | Specification | Certification |

|---|---|---|

| Tires | Load Range G (14-ply) Radial | DOT FMVSS 119 Certified |

| Tread Depth: 18/32″ (new) | ASTM F511-19 Wear Test Data | |

| Rim Base: 22.5″ (SAE J2200 Compliant) | ||

| Battery | 8D Group Size (1,200 CCA min) | SAE J537 Tested |

| AGM Technology (Vibration Resistant) | ISO 6469-1:2012 | |

| Dual-Post Terminal Configuration |

All tires mounted on magnaflux-inspected wheels. Batteries load-tested at 100% rated CCA.

PHASE 4: CHASSIS REINFORCEMENT

Compliance: SEA LION QCI-7.4 | ASME Section IX Welding Standards

- Structural Assessment:

- Laser frame straightening (tolerance: ±0.5mm/m)

- Ultrasonic thickness testing (critical zones: crossmembers, king pin mounts)

- Reinforcement Protocol:

- Critical stress points: 1/4″ A572 Gr50 steel gussets (full-penetration welds)

- Suspension mounting zones: 300% OEM bracket reinforcement

- Corrosion remediation: Zinc-rich primer (ASTM D6138) + hot-dip galvanizing (min 3.5 mils)

- Validation:

- Post-weld dye penetrant inspection (ASTM E1417)

- Load test: 150% GVWR static hold (30 mins) with deflection monitoring

3. SEA LION QCI-7 INSPECTION STANDARDS: KEY DIFFERENTIATORS

- Zero-Tolerance Defects: Frame cracks >0.5mm, cylinder taper >0.05mm, or paint adhesion <4B result in immediate scrapping.

- Data Traceability: Each unit assigned unique QR-coded asset tag linking to 217-point digital inspection log (accessible via SEA LION FleetPortal).

- Environmental Hardening: All refurbished units validated for West Texas operational envelope:

- Temperature: -20°F to 130°F (SAE J1211 Annex B)

- Dust Exposure: MIL-STD-810H Method 510.7 Procedure I

- Rejection Rate: 22.3% of Abilene-sourced candidates fail Phase 0 (intake screening) due to unrepairable frame damage or major component history.

4. OPERATIONAL BENEFITS FOR FLEET MANAGERS

| Metric | Industry Avg. Refurb | SEA LION Refurb | Impact |

|---|---|---|---|

| Mean Time Between Failures | 4,200 miles | 9,800 miles | 32% reduction in downtime |

| 3-Year Residual Value | 41% of OEM cost | 58% of OEM cost | $28,500+ asset value retention |

| Warranty Claim Rate | 18.7% | 4.2% | Lower TCO per operating hour |

APPROVED BY: SEA LION International Engineering Council

REPORT VALIDITY: This specification supersedes all prior versions effective 01 JAN 2026. SEA LION reserves the right to modify processes without notice to maintain compliance with evolving FMVSS/SAE standards. All refurbished units ship with ASTM E2917-13-compliant certification dossiers.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Target Audience: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from Abilene, TX via China Ports

1. Executive Summary

This report evaluates three primary maritime logistics methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks originating from Abilene, Texas, transshipped through Chinese ports. The analysis focuses on cost-efficiency, transit integrity, corrosion protection, and operational compatibility with heavy-duty vehicle fleets. A standardized wax-based anti-corrosion treatment is recommended for all methods to mitigate seawater exposure during transit.

2. Operational Overview

Used trucks from Abilene, TX are typically consolidated and transported via rail or heavy-haul truck to U.S. Gulf Coast ports, then shipped to China for re-export to Southeast Asia, Africa, or the Middle East. Final export leg from Chinese ports (e.g., Shanghai, Ningbo, Shenzhen) requires selection of optimal maritime transport mode based on vehicle condition, volume, and destination port infrastructure.

3. Comparative Analysis: RO-RO vs. Bulk Cargo vs. Flat Rack

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Loading Method | Self-driven onto vessel | Craned/lifted into hold | Craned onto open-frame container |

| Vehicle Compatibility | Operational units only | Operational or non-operational | All conditions (incl. inoperable) |

| Cargo Securing | Wheel chocks, lashing straps | Wooden blocking, steel strapping | Twist locks, lashing points |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Container terminal with crane |

| Transit Time (China → SEA) | 10–14 days | 12–16 days | 14–18 days |

| Average Cost per Unit (USD) | $1,800 – $2,200 | $1,500 – $1,900 | $2,400 – $3,000 |

| Risk of Damage | Low (driven handling) | Medium (rigging impact risk) | Low to Medium (secure if properly lashed) |

| Stackability | No (deck-only placement) | No | Yes (single layer only) |

| Weather Exposure | Partial (open decks) | High (if not covered) | High (open design) |

| Best For | High-volume, drivable fleets | Mixed-condition, cost-sensitive loads | Oversized, heavy, or damaged units |

4. Corrosion Protection: Wax Spraying Treatment

Marine environments expose metal surfaces to salt-laden air and condensation, accelerating corrosion—especially on undercarriages, brake systems, and electrical housings.

Recommended Protocol:

- Treatment: Application of hydrophobic, solvent-based wax spray (e.g., lanolin-derived or synthetic polymer) to chassis, suspension, and engine undercarriage.

- Coverage: Minimum 95% of exposed ferrous components.

- Application Point: Prior to loading at Chinese transshipment yard.

- Durability: Effective for up to 45 days of marine exposure.

- Compliance: Meets ISO 9227 (salt spray resistance) and ASTM D1748 (humidity testing).

Note: Wax treatment reduces post-transit reconditioning costs by up to 30% and extends resale lifespan in tropical and coastal markets.

5. Risk Mitigation Recommendations

| Risk Factor | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Corrosion | Apply wax + desiccant bags | Full wax + tarpaulin cover | Full wax + plastic sheeting |

| Mechanical Damage | Pre-shipment drivability test | Rigging certification required | Load distribution analysis |

| Theft/Vandalism | GPS tracking, sealed decks | Guarded storage, CCTV | Sealed container with tamper tags |

| Port Delays | High vessel frequency | Variable scheduling | Container yard congestion risk |

6. Conclusion & Strategic Recommendation

For fleet managers exporting drivable used trucks from Abilene, TX via China:

– RO-RO is optimal for cost and speed when vehicles are operational.

– Flat Rack is superior for damaged, oversized, or non-running units despite higher cost.

– Bulk Cargo offers lowest cost but highest risk; recommended only for budget-sensitive, high-tolerance operations.

Mandatory Requirement: All units must undergo industrial-grade wax spraying prior to shipment to ensure corrosion resistance across all methods.

Future logistics planning should integrate centralized wax treatment zones at Chinese transshipment hubs to standardize protection and reduce field failures.

Prepared by: SEA LION International – Logistics Engineering Division

Date: April 5, 2026

Document Code: SL-LOG-2026-041

Classification: Industrial Use – Distribution A

Get a Quote for Used Trucks Abilene Tx

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]