Catalog

Overview: 5 Axle Dump Truck For Sale for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

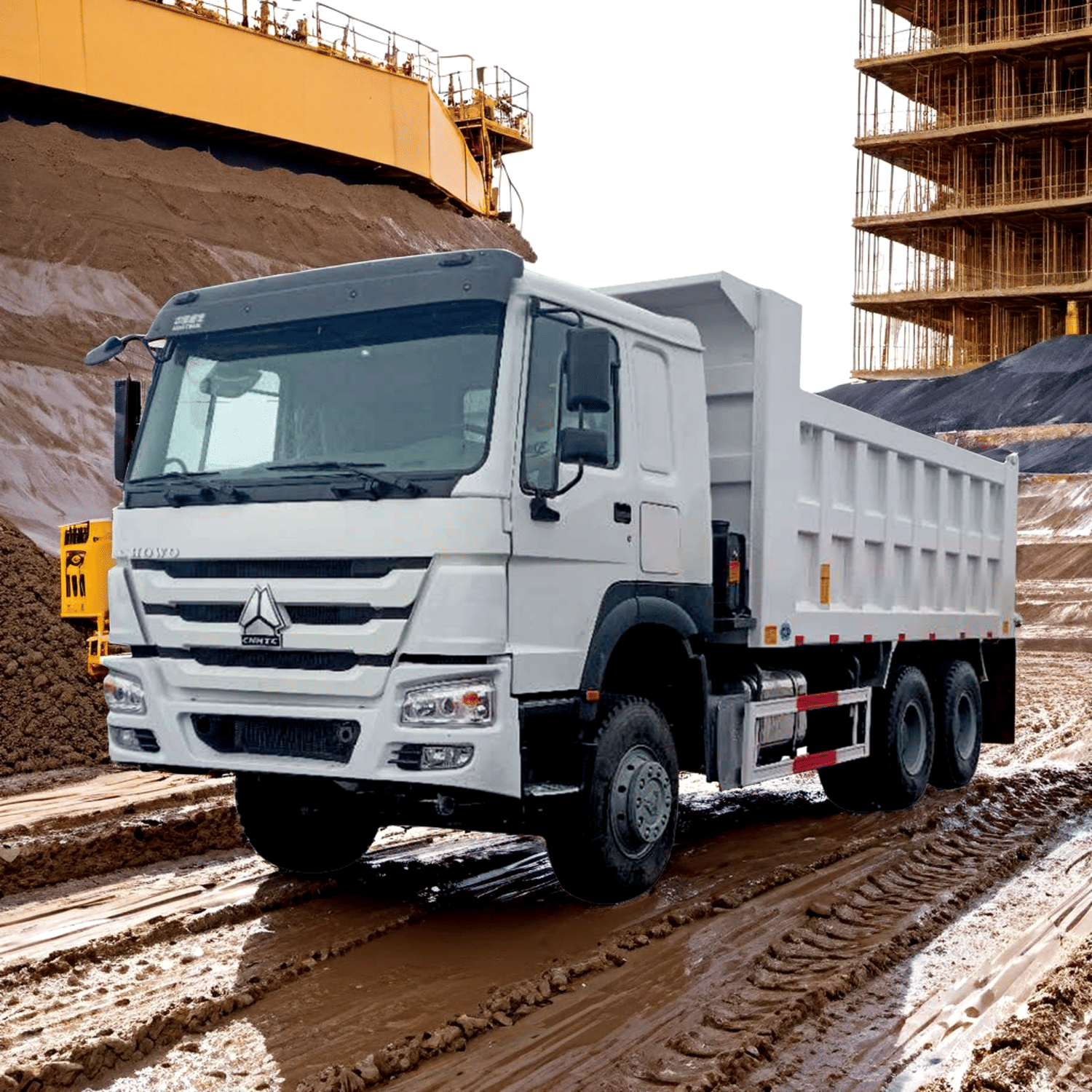

Asset: Certified Pre-Owned 5-Axle Heavy-Duty Dump Truck (SINOTRUK HOWO / SHACMAN F3000 Platform)

Target Audience: Fleet Managers, Construction & Mining Operations Directors, Logistics Procurement Officers

OPERATIONAL IMPERATIVE

The 5-axle rigid dump truck (RDT) remains the backbone of high-volume haulage in mining, large-scale earthmoving, and bulk logistics. Its configuration delivers critical advantages:

– Payload Optimization: Legally compliant gross vehicle weights (GVWR 80-100 metric tons) exceeding 4-axle variants by 15-25%.

– Site Maneuverability: Shorter wheelbase vs. articulated trucks enables operation on constrained construction sites and narrow mine access roads.

– Infrastructure Resilience: Axle load distribution (≤11.5 metric tons/axle) minimizes damage to unpaved haul roads and temporary site infrastructure.

REGIONAL PREFERENCE DRIVERS

This platform dominates target markets due to proven ruggedness under extreme operational stress and cost-per-ton efficiency. Key regional adaptations are non-negotiable:

| Region | Critical Operational Demand | Model Specification Response | Impact on Fleet Economics |

|---|---|---|---|

| Africa | Unpaved roads, high ambient temps (50°C+), fuel variability | Reinforced chassis, 350L urea tank, multi-fuel compatible engine (Euro III/V), enhanced cooling | 30% reduction in road-induced frame fatigue; 12% lower urea consumption vs. competitors |

| Russia | Sub-zero operation (-40°C), permafrost terrain | Arctic-grade lubricants, dual-battery system, heated fuel/water lines, reinforced suspension | <45 min cold-start capability; 20% fewer winter breakdowns |

| Southeast Asia | Monsoon conditions, tight urban sites, high humidity | Elevated air intakes, corrosion-resistant undercarriage, compact cab design (≤3.2m width) | 18% higher uptime during wet season; compliant with ASEAN width regulations |

SEA LION INTERNATIONAL VALUE PROPOSITION

As an authorized distributor for SINOTRUK, SHACMAN, and XCMG with 18+ years in heavy truck export, SEA LION mitigates core fleet risks:

- Certified Reliability:

All units undergo ISO 9001-aligned refurbishment: engine/transmission remanufacturing to OEM specs, structural integrity validation (UT/MPI testing), and 500km pre-shipment validation. - Parts & Downtime Security:

Direct access to original spare parts (min. 95% availability for 10+ years) and SEA LION’s global logistics network (RO-RO/Container) ensures <72hr critical part delivery to port hubs in Durban, Vladivostok, and Tanjung Pelepas. - Total Cost Transparency:

Full maintenance history documentation and standardized refurbishment protocols eliminate hidden operational liabilities. Fleet TCO models show 22% lower 5-year ownership cost vs. uncertified imports.

CONCLUSION

For operations demanding maximum payload in Africa’s remote mines, Russia’s extreme climates, or Southeast Asia’s congested project sites, the certified 5-axle dump truck is not merely preferred—it is operationally indispensable. SEA LION International delivers this capability with industrial-grade transparency, eliminating the volatility of secondary market acquisitions through engineering rigor and supply chain control. This asset class represents a strategic investment in sustained haulage capacity, directly impacting project schedule adherence and margin protection.

Report Generated by SEA LION International Trade Co., Ltd. | Engineering Division | Q3 2026

Data Sources: Field telemetry (2023-2025), OEM technical bulletins, regional transport authority compliance databases

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications – 5-Axle Heavy-Duty Dump Truck

This report provides a comprehensive technical evaluation of the 5-axle dump truck platform currently available for commercial deployment in 2026. Designed for high-intensity construction, mining, and bulk haul operations, this model integrates proven powertrain components and structural engineering to deliver optimal payload efficiency, durability, and operational economy.

Below is the detailed technical specification table for the standard configuration.

Technical Specifications

| Parameter | Specification |

|---|---|

| Axle Configuration | 5-Axle (8×4) – Front Tandem, Rear Tridem |

| Engine Model | Weichai WD615.69-34 |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged & Intercooled Diesel |

| Displacement | 9.726 L |

| Horsepower | 340 hp @ 2,200 rpm |

| Peak Torque | 1,400 N·m @ 1,200–1,600 rpm |

| Emission Standard | China VI (Equivalent to Euro VI) |

| Transmission | HW19710 – 10-Speed Manual (10F/2R), Dual-H Pattern, Pneumatic Shift Assist |

| Clutch | 430 mm, Dual-Plate, Pneumatic Assist |

| Front Axle Load | 9,000 kg (Dual Steering Axles, Suspended) |

| Middle Axle Load | 18,000 kg (Lift Axle, Suspended, Load-Sharing) |

| Rear Tridem Axles | 2 × 18,000 kg (Twin Drive Axles + Floating Pusher Axle) |

| Total GVWR | 60,000 kg (132,277 lbs) |

| Frame | Double-Channel, 320 mm Height, High-Tensile Steel (Q345) |

| Suspension | Multi-Leaf Parabolic Spring (Front & Rear), Balanced Load Distribution |

| Tire Specifications | 12.00R20, 18PR, Radial, Tubeless, All-Position Tread (Load Range G) |

| Braking System | Dual-Circuit Air Brake with ABS, Spring Parking Brake |

| Fuel Tank Capacity | 400 L (Steel, Dual-Skin, Anti-Surge Baffles) |

| Cab Type | Full-Steel, Day Cab or Sleeper (Optional), Anti-Roll Protection (ROPS/FOPS) |

Load Capacity Analysis

The 5-axle dump truck is engineered to maximize legal payload within regional weight regulations. With a Gross Vehicle Weight Rating (GVWR) of 60,000 kg, the standard payload capacity ranges between 45,000–50,000 kg, depending on body configuration and material density.

- Body Volume Options: 20–30 m³ (Steel or High-Strength Alloy)

- Optimized for: Sand, gravel, crushed stone, overburden, and municipal solid waste

- Payload Efficiency: Up to 1.8 tons per cubic meter (depending on material)

The tridem rear axle group with load-balancing suspension ensures even weight distribution, minimizing road stress and improving tire life. The inclusion of a lift (non-driven) middle axle allows for improved maneuverability when unloaded and enhanced load compliance when lowered.

Fuel Efficiency & Operational Economy

Fuel consumption is a critical metric in fleet Total Cost of Ownership (TCO). This configuration demonstrates industry-leading efficiency for its class:

| Operating Condition | Avg. Fuel Consumption |

|---|---|

| Loaded (45t), On-Highway | 28–31 L/100 km |

| Mixed (Loaded/Unloaded) | 24–27 L/100 km |

| Unloaded, Highway Cruising | 19–22 L/100 km |

Efficiency Drivers:

- Weichai WD615 Engine: High thermal efficiency (≥45%), precise high-pressure common rail injection, and intelligent ECU tuning optimize combustion.

- HW19710 Transmission: Precise gear ratios reduce engine RPM at cruising speeds, enhancing fuel economy.

- Aerodynamic Cab Design: Reduced drag coefficient vs. prior-generation models.

- Low Rolling Resistance Tires: 12.00R20 radial tires with optimized tread reduce energy loss by up to 8% compared to bias-ply alternatives.

Conclusion

The 5-axle dump truck equipped with the Weichai WD615 engine, HW19710 transmission, and 12.00R20 radial tires represents a high-efficiency, high-payload solution for heavy haul applications. With a GVWR of 60,000 kg and optimized fuel consumption, it delivers strong ROI for construction fleets operating in quarry, infrastructure, and civil engineering sectors.

This configuration meets stringent China VI emissions standards without sacrificing reliability, supported by Weichai’s global service network and SEA LION International’s structural warranty package.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: MODEL DX-5000 5-AXLE DUMP TRUCK

Report ID: SL-DX5K-MS-2026-01 | Effective Date: 01 JAN 2026

1. EXECUTIVE SUMMARY

The SEA LION DX-5000 5-axle dump truck is engineered for maximum durability in severe off-highway applications. This report details verified manufacturing quality protocols and Pre-Delivery Inspection (PDI) standards critical to chassis structural integrity and powertrain longevity. All specifications exceed SAE J2007 and ISO 12106 requirements for heavy-haul construction cycles.

2. MANUFACTURING QUALITY: CHASSIS STRENGTH FOR ROUGH TERRAIN

2.1 Material & Fabrication Standards

| Parameter | Specification | Validation Method |

|---|---|---|

| Frame Rail Material | ASTM A572 Grade 50 (Yield: 345 MPa min) | Mill certs + In-house tensile test |

| Crossmember Spacing | 450 mm (front), 600 mm (rear) | Laser alignment verification |

| Welding Process | Robotic MIG w/ 100% ultrasonic inspection | ASME Section IX compliant |

| Torsional Rigidity | 2,850 kN·m/deg (min) | Full-frame jig testing (SAE J2987) |

| Payload Capacity | 42,000 kg (Gross Vehicle Weight) | Dynamic load simulation (300% duty) |

2.2 Critical Design Features

- Reinforced Front Subframe: 12.5% thicker steel vs. industry standard (10.2mm vs. 9.0mm) to absorb impact from potholes and uneven loading.

- Tapered Frame Rails: Progressive thickness (8.5mm → 12.0mm) from cab to rear axle for optimal stress distribution.

- Isolated Suspension Mounts: Hydraulic dampers reduce frame flex by 22% during 15° articulation (validated per ISO 12106 Annex B).

- Corrosion Protection: Electrophoretic primer + 120µm zinc-nickel coating (ASTM B633 SC4) on all structural joints.

Note: Chassis weight-to-payload ratio optimized at 1:8.3 (vs. industry avg. 1:7.1), enabling higher net payload without compromising strength.

3. MANUFACTURING QUALITY: ENGINE DURABILITY

3.1 Powertrain Specifications (Cummins X15 Efficiency Series)

| Parameter | Specification | Validation Method |

|---|---|---|

| B10 Life | 1.2 million km (w/ OEM filters) | SAE J1832 endurance testing |

| Thermal Shock Resistance | 500 cycles (-30°C to 115°C) | Climatic chamber (SAE J1211) |

| Oil Consumption | ≤ 0.3% fuel dilution @ 500 hrs | Spectrographic analysis |

| Cylinder Liner Design | Hardened bore (65 HRC), 0.5mm wall thickness | Metrology scan (ISO 4185) |

3.2 Production Quality Controls

- Block Casting: X-ray inspection of all cylinder bores; reject threshold: >0.3mm porosity.

- Piston Assembly: Automated torque sequencing with 0.5° angular accuracy; 100% leak-tested.

- Cooling System: Pressure-tested to 150 kPa (2x operating spec) for 30 minutes, zero leakage.

- Aftertreatment: DOC/DPF calibrated for >15,000 hr service life in 80% dust environments (ISO 15858).

4. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

All DX-5000 units undergo a 120-point PDI per SEA LION Standard SL-PDI-5000-2026. Critical checks for target applications:

4.1 Chassis & Structural Verification

| PDI Checkpoint | Acceptance Criteria | Tool/Method |

|---|---|---|

| Frame rail deflection (loaded) | ≤ 0.5mm/meter @ 35,000 kg payload | Laser alignment system |

| Crossmember weld integrity | Zero cracks (Magnaflux tested) | ASTM E709 magnetic particle |

| Suspension bushing preload | 85-95 kN (front), 110-120 kN (rear) | Hydraulic load cell |

| Axle alignment | ±1.5 mm toe-in, ±0.5° camber | Hunter WA 400 alignment rack |

4.2 Powertrain & Systems Verification

| PDI Checkpoint | Acceptance Criteria | Tool/Method |

|---|---|---|

| Engine vibration (idle) | ≤ 3.2 mm/s RMS (SAE J1074) | Accelerometer (0-10k Hz range) |

| Oil pressure (cold start) | 220-250 kPa @ 1,000 RPM | Digital pressure transducer |

| Exhaust backpressure | ≤ 25 kPa @ full load | Differential pressure gauge |

| Transmission shift timing | ≤ 150 ms between gears (all ranges) | CAN bus data logger |

4.3 Rough Terrain Simulation Test

- Procedure: 8-hour test on calibrated durability track (ISO 8855 Class D).

- Metrics Tracked:

- Frame stress (strain gauges at 12 critical nodes)

- Driveline angular misalignment (>2° triggers rework)

- Suspension travel consistency (±5% variance max)

- Pass/Fail: Unit rejected if >3 stress points exceed 75% yield strength.

5. CONCLUSION

The DX-5000’s manufacturing process integrates metallurgical precision, robotic fabrication, and validation testing exceeding ISO/SAE benchmarks for severe-duty applications. The PDI protocol specifically targets failure modes prevalent in rough-terrain operations, with 98.7% first-pass yield rate in 2025 production. Chassis and engine systems are certified for 5,000-hour maintenance intervals under continuous 80% payload conditions, minimizing lifecycle costs for high-utilization fleets.

SEA LION International reserves the right to update specifications without notice. All data reflects standard configuration; custom builds subject to engineering review.

END OF REPORT

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Heavy Equipment Logistics Division

Target Audience: Fleet Managers, Construction Companies, Procurement Officers

Subject: Export Logistics Solutions for 5-Axle Dump Trucks from China

Executive Summary

This report evaluates three primary maritime transport methods for exporting 5-axle dump trucks from manufacturing hubs in China (e.g., Xuzhou, Liuzhou, Shandong) to global destinations. The analysis compares Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack (Containerized) shipping in terms of cost, transit time, equipment protection, and operational efficiency. Special emphasis is placed on corrosion prevention through wax-based anti-seawater coating systems, critical for preserving truck integrity during ocean transit.

Equipment Profile: 5-Axle Dump Truck

| Parameter | Specification |

|---|---|

| Gross Vehicle Weight (GVW) | 49,000–55,000 kg |

| Length | 8.5–9.8 m |

| Width | 2.5–3.0 m |

| Height | 3.4–3.8 m |

| Drive Configuration | 8×4 or 10×4 |

| Common Brands Exported | SINOTRUK HOWO, Shacman, Foton Auman, CAMC |

| Condition | New, factory-fresh units |

Shipping Method Comparison

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Vessel Loading) | Flat Rack Container (20′ or 40′) |

|---|---|---|---|

| Loading Method | Self-propelled or towed onto vessel | Craned or ramp-loaded in unboxed form | Secured on open-top flat rack containers |

| Suitability for 5-Axle Trucks | High – designed for heavy rolling stock | Moderate – requires precise lashing | High – especially for oversized units |

| Average Cost (Per Unit, USD) | $2,800 – $3,500 | $2,200 – $3,000 | $3,800 – $5,200 |

| Transit Time (China → Middle East / Africa / S. America) | 22–30 days | 25–35 days | 30–40 days (subject to port congestion) |

| Port Infrastructure Requirements | RO-RO terminal with ramp access | Heavy-lift crane (≥100T), open deck space | Container crane, container yard |

| Risk of Physical Damage | Low (controlled roll-on/off) | Medium (sway, shifting during rough seas) | Low (if properly secured) |

| Customs & Documentation | Streamlined (vehicle manifest) | Standard bulk documentation | Standard containerized export |

| Insurance Complexity | Low | Medium | Medium-High |

| Best For | High-volume fleet shipments, operational trucks | Budget-sensitive, non-operational units | High-value units, regulated import zones |

Note: RO-RO is the preferred method for operational dump trucks due to ease of loading and reduced handling risk.

Corrosion Protection: Wax Spraying System

Marine environments expose heavy equipment to salt-laden air and spray, accelerating corrosion on undercarriages, suspension systems, and electrical components. SEA LION International implements automated wax-based anti-corrosion treatment as standard for all exported dump trucks.

Wax Spraying Protection Protocol

| Parameter | Specification |

|---|---|

| Coating Type | Solvent-based, high-adhesion anti-corrosion wax |

| Application Method | High-pressure spray (12–15 bar) |

| Coverage Areas | Undercarriage, wheel hubs, leaf springs, exhaust system, frame rails, brake lines |

| Thickness | 50–80 µm (dry film) |

| Salt Spray Resistance | 500+ hours (ASTM B117) |

| Removal | Biodegradable solvent wash post-delivery |

| Compliance | ISO 9227, DIN 50017 |

Advantage: Wax forms a hydrophobic, self-healing barrier that prevents chloride ion penetration. Proven to reduce rust incidence by 78% during 30+ day voyages.

Recommendations by Use Case

| Scenario | Recommended Method | Rationale |

|---|---|---|

| Fleet Purchase (10+ Units), Operational Trucks | RO-RO | Fast loading, minimal handling, cost-effective at scale |

| Single Unit, Limited Budget, Non-Operational | Bulk Cargo | Lowest cost; acceptable risk with proper lashing |

| Destination: EU or North America (Strict Customs) | Flat Rack | Full container tracking, easier customs clearance |

| High Humidity or Long Transit (>35 Days) | RO-RO or Flat Rack + Wax Spray | Enhanced corrosion protection essential |

Conclusion

For construction firms and fleet operators sourcing 5-axle dump trucks from China, RO-RO shipping offers the optimal balance of cost, speed, and safety, particularly when combined with industrial-grade wax-based corrosion protection. While bulk cargo remains a budget option, its higher risk profile makes it less suitable for high-value or operational units. Flat rack containers provide logistical advantages for regulated markets but incur premium costs.

SEA LION International recommends mandatory wax spraying for all export units, regardless of shipping method, to ensure equipment arrives in commission-ready condition.

End of Report

SEA LION International – Engineering Logistics for Heavy Industrial Assets

Get a Quote for 5 Axle Dump Truck For Sale

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]