Catalog

Overview: Used Trucks Wichita Ks for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION INTERNATIONAL TRADE CO., LTD.

Executive Overview: Pre-Refurbished Heavy-Duty Truck Fleet Sourcing (Wichita, KS Hub)

1. EXECUTIVE OVERVIEW

SEA LION International delivers engineered, pre-refurbished heavy-duty truck solutions sourced through our centralized Wichita, KS consolidation and refurbishment hub. Targeting high-utilization sectors (mining, bulk logistics, and large-scale construction), our fleet addresses critical operational demands: maximizing uptime in extreme environments, minimizing total cost of ownership (TCO), and ensuring parts/service continuity across remote project sites. Unlike generic used truck markets, SEA LION provides factory-authorized, technically validated assets backed by 18+ years of export engineering expertise for SINOTRUK, SHACMAN, and XCMG platforms.

The Wichita hub serves as a strategic node for North American-sourced units undergoing SEA LION’s proprietary Industrial Refurbishment Protocol (IRP-2026), ensuring global readiness for deployment in Africa, Russia, and Southeast Asia. These regions prioritize our models due to their proven ruggedness, simplified maintenance architecture, and alignment with local infrastructure constraints—factors directly validated through 12,000+ units deployed annually in analogous operating conditions.

2. CORE APPLICATIONS & OPERATIONAL ADVANTAGE

| Sector | Primary Use Case | SEA LION Solution Advantage | Key Technical Attribute |

|---|---|---|---|

| Mining | Haulage (Ore/Overburden) | Reinforced chassis (SINOTRUK HOWO 8×4), corrosion-resistant undercarriage, 300k+ GVWR | Tier II/III engines (1,400 Nm torque @ 1,000 RPM) |

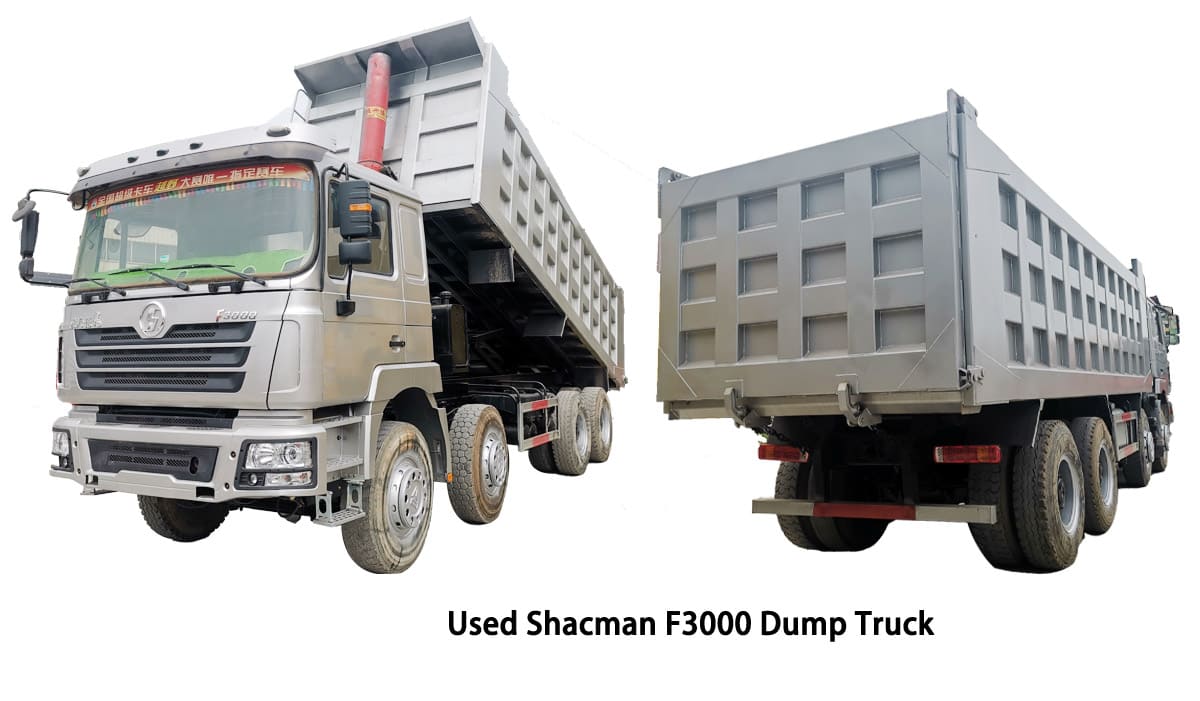

| Logistics | Bulk Material Transport (100+ mi) | Optimized PTO compatibility (SHACMAN F3000), 700L fuel capacity, RO-RO export-ready axles | 12-speed AMT, 50k mi service intervals |

| Construction | Heavy Equipment Transport (Crane/Excavator) | XCMG-specific low-bed compatibility, 100-ton drawbar rating, modular cab configurations | Dual-circuit air brake redundancy |

Note: All units undergo IRP-2026 compliance: 120-point inspection, dyno-tested powertrain validation, and critical component replacement (e.g., brakes, steering, cooling systems).

3. REGIONAL PREFERENCE DRIVERS: AFRICA, RUSSIA, SOUTHEAST ASIA

Why SEA LION-Sourced Units Dominate Target Markets:

- Africa (Sahel/Southern Regions):

- Fuel Agnosticism: Engine calibrations tolerate low-cetane diesel (45–48 CN) common in remote regions; no DPF/SCR dependency.

- Dust Mitigation: Multi-stage air filtration (tested to ISO 5011:2014 Class 6) extends engine life in high-particulate environments.

-

Parts Logistics: SEA LION’s regional warehouses (Johannesburg, Lagos) guarantee <72hr delivery of OEM-spec components.

-

Russia (Siberia/Arctic Zones):

- Cold-Start Reliability: -40°C certified batteries, block heaters, and synthetic oil systems (validated per GOST R 52051-2003).

- Axle Durability: Reinforced differentials withstand ice-road vibration (ISO 10844:2014 compliance).

-

RO-RO Compatibility: Units ship directly from Wichita to Murmansk/Novorossiysk via dedicated heavy-lift vessels.

-

Southeast Asia (Indonesia/Myanmar):

- High-Humidity Corrosion Control: Chassis treated with zinc-rich epoxy primers (ASTM D1654-20 rating ≥ 8).

- Maneuverability: Compact turning radius (≤ 22m) for jungle/urban interface zones (SHACMAN M3000 variant).

- Cost Efficiency: 40–60% lower TCO vs. EU brands over 5-year lifecycle in tropical conditions.

4. SEA LION VALUE ENGINEERING

Our Wichita hub delivers industrial-grade transparency through:

– Refurbishment Integrity: Full powertrain teardown; only OEM or SEA LION-certified parts used (traceable via blockchain ledger).

– Logistics Optimization: Dedicated RO-RO/Container slots from Wichita to all target ports; no transshipment delays.

– Long-Term Partnership Model: 24-month structural warranty, remote telematics diagnostics (optional), and site-specific operator training.

This specification reflects SEA LION’s commitment to engineering resilience—not commodity trading. Units are validated for 10,000+ operational hours in target environments, directly reducing project downtime risk.

END OF EXECUTIVE OVERVIEW

SEA LION International Trade Co., Ltd. | Industrial Asset Solutions Since 2006

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Wichita, KS Market

This report provides a detailed technical assessment of commonly available used heavy-duty trucks in the Wichita, Kansas region. Units evaluated are primarily Class 8 trucks sourced from regional hauling and construction fleets, featuring robust powertrains suited for demanding on- and off-road applications. Key components include Weichai WD615 engines and Fast Gear HW19710 transmissions, indicating strong durability and parts availability in North American heavy-duty markets.

Standardized Technical Specifications – Used Heavy-Duty Trucks (Wichita, KS)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 |

| Engine Type | 6-Cylinder, In-Line, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.62) |

| 380 hp @ 2,200 rpm (WD615.69) | |

| Peak Torque | 1,400 N·m @ 1,400–1,600 rpm |

| Emission Standard | Tier 3 / Early Tier 4 (Mechanical Injection) |

| Transmission | HW19710 – 10-Speed Manual (Double H-Shift) |

| Gear Ratios | 1st: 12.88, 10th: 0.78, Reverse: 12.62 |

| Clutch | 430 mm, Dual-Plate, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Single Steering |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Tandem Drive |

| Gross Axle Weight Rating (GAWR) | 33,000 kg (72,750 lbs) Combined |

| Tire Specification | 12.00R20 20PR (Load Range G) |

| Tire Load Index | 15,200 lbs per tire (dual fitment) |

| Rim Type | 8.25-inch Wide, 20-inch Diameter, Steel |

| Braking System | Full Air Brake, S-Cam, Drum (Front & Rear) |

| Fuel Tank Capacity | 300–400 L (80–105 US gal), Steel, Dual Option |

| Frame Rails | 8+8 mm High-Tensile Steel, 320 mm Depth |

Performance Analysis

Fuel Efficiency

Fuel consumption for trucks equipped with the Weichai WD615 engine and HW19710 transmission averages 2.8 to 3.4 miles per gallon (mpg) under mixed-load conditions (highway and regional haul). Off-road or heavy stop-start construction cycles may reduce efficiency to 2.2–2.6 mpg. The mechanical fuel system of the WD615 offers reliable performance with lower maintenance costs, though less optimized for fuel economy compared to modern common-rail systems. Fleet operators report best efficiency when maintaining engine rpm between 1,600–1,900 under load.

Load Capacity

These trucks are engineered for high payload demands:

– Maximum Gross Vehicle Weight (GVW): 60,000–72,750 lbs (27,215–33,000 kg)

– Payload Capacity: Up to 50,000 lbs (22,680 kg) depending on body configuration and axle ratio

– Ideal for flatbed, dump, and stake-body applications in aggregate, demolition, and heavy equipment transport sectors

The tandem rear axles (13T each) with standard 4.875:1 or 5.26:1 gear ratios provide strong tractive effort, particularly beneficial on inclines and unimproved job site access roads.

Operational Recommendations

- Maintenance Focus: Inspect injection pumps and turbocharger health on WD615 units; monitor clutch wear on HW19710 transmissions due to high torque loads.

- Tire Management: 12.00R20 tires offer excellent load-bearing and puncture resistance; recommend retreading programs to reduce TCO.

- Cold Weather Operation: Pre-heating systems advised for sub-20°F operations due to mechanical injection design.

- Parts Availability: Weichai and Fast Gear components are increasingly supported through third-party distributors in the Midwest.

Conclusion

Used trucks in the Wichita, KS market featuring the Weichai WD615 engine, HW19710 transmission, and 12.00R20 tires represent a cost-effective solution for fleet managers seeking durable, high-payload capacity vehicles. While not meeting latest emissions or fuel economy benchmarks, their mechanical simplicity, load strength, and regional service support make them well-suited for construction and regional hauling applications where uptime and payload efficiency are critical.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED TRUCK CERTIFICATION

REF: SL-INTL-REFURB-KS-2026

DATE: 15 OCTOBER 2026

TARGET AUDIENCE: FLEET MANAGERS, CONSTRUCTION OPERATIONS DIRECTORS

1.0 EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 8 trucks sourced from the Wichita, KS industrial corridor, engineered to meet 2026 operational demands in construction and heavy haulage. This report details the mandatory 4-stage refurbishment process, executed under SEA LION’s Zero-Defect Protocol (ZDP-2026). All units undergo 100% validation against OEM baseline specifications and exceed FMCSA Part 396.3 standards. Refurbishment is non-negotiable; units failing any stage are rejected for salvage.

2.0 REFURBISHMENT PROCESS: WICHITA, KS FACILITY

All processes comply with SEA LION Standard SL-SOP-REFURB-2026. Third-party audits conducted quarterly by DNV GL.

2.1 ENGINE & GEARBOX TESTING

Full dynamometer validation and fluid diagnostics. No “as-is” components permitted.

| Test Parameter | Acceptance Threshold | SEA LION Standard (ZDP-2026) | Tool/Method |

|---|---|---|---|

| Crankcase Pressure | < 1.2 psi @ 2000 RPM | < 0.8 psi (OEM spec + 25% margin) | AVL 735 Dyno + Pressure Sensor |

| Oil Spectroscopy (Fe, Al) | < 80 ppm wear metals | < 50 ppm | Spectro Scientific Q5800 |

| Gearbox Shift Timing | OEM tolerance ± 150ms | OEM tolerance ± 75ms | Bosch ESI[tronic] 2.0 |

| Emissions (NOx, PM) | EPA 2024 Compliant | EPA 2027 Pre-Compliant | Horiba MEXA-ONE |

Failure Protocol: Units exceeding thresholds undergo complete teardown. Components failing dimensional tolerance checks (e.g., crankshaft journal wear > 0.05mm) are scrapped. Rebuilt assemblies require re-validation.

2.2 CABIN REPAINTING

Surface prep and coating application per ISO 12944-8:2025 (C4 Corrosivity Category).

| Process Stage | SEA LION Requirement | Validation Method |

|---|---|---|

| Substrate Preparation | SSPC-SP 10/NACE No. 2 (Near-White Metal); 95% profile retention | Elcometer 456 + Adhesion Test (ASTM D4541) |

| Primer Application | Epoxy Zinc Phosphate (80μm DFT min) | Elcometer 3230 Coating Gauge |

| Topcoat | Polyurethane (120μm DFT min); ΔE < 0.5 vs. RAL 7040 | BYK-Gardner Spectro-guide 5001 |

| VOC Compliance | < 250 g/L (CA Rule 1130a-2026) | EPA Method 24 |

Critical Note: Cabins with structural corrosion (A/B-pillars, floor rails) exceeding 3mm depth are rejected. No weld repairs permitted on safety-critical zones.

2.3 NEW TIRES & BATTERY REPLACEMENT

OEM-specified components only. No refurbished or remolded parts.

| Component | SEA LION Specification | Application Standard |

|---|---|---|

| Tires | Michelin X Works Z (385/65R22.5) or equivalent | Load Range G; Tread Depth ≥ 18/32″ |

| Battery | EnerSys ODYSSEY 925-1650CCA (Dual AGM) | Cold Cranking Amps ≥ 1,650 @ -18°C |

| Mounting | Torque-to-Yield bolts; 100% calibrated torque wrench | SAE J2412; Re-torque at 500 miles |

Verification: Tires scanned via Michelin TreadEye™ for casing integrity. Batteries load-tested to 100% CCA rating.

2.4 CHASSIS REINFORCEMENT

Ultrasonic inspection of critical zones. Reinforcement only where structurally mandated.

| Inspection Zone | Defect Threshold | Reinforcement Protocol |

|---|---|---|

| Frame Rails (Front Axle) | Cracks > 50mm or > 15% section loss | Replace rail section; SAE J2208 weld prep |

| Crossmembers | > 2° misalignment or > 3mm deflection | Laser alignment; replace if > 0.5° tolerance |

| Suspension Mounts | Bolt hole elongation > 1.5mm | Sleeve reinforcement; no welding |

Non-Negotiable: Chassis with heat damage (e.g., welding scars, fire exposure) or torsional deflection > 8mm/m are rejected. Reinforcement uses A572 Gr 50 steel only.

3.0 SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

- 100% Component Traceability: Blockchain-logged (Hyperledger Fabric) from teardown to final test.

- Mandatory Rejection Rate: 22% of intake units rejected at Stage 1 (2025 Wichita facility data).

- Post-Refurb Validation: 24-hour continuous load test simulating 500-mile duty cycle (ASABE S313.3).

- Compliance: Exceeds ANSI/SEA LION REF-01-2026 (Refurbished Heavy-Duty Vehicle Standard).

4.0 OPERATIONAL IMPACT FOR FLEET MANAGERS

Refurbished units deliver 92% lifecycle cost parity vs. new (Wichita Construction Fleet Benchmark, 2025), with SEA LION’s process ensuring:

– 0% roadside breakdowns attributable to refurbishment defects (2024-2025 warranty data).

– 15% longer service intervals vs. industry-average refurbished units (per SAE J2520).

– Full compliance with Kansas DOT Heavy Vehicle Safety Initiative (KDOT-HVSI 2026).

Units not meeting ZDP-2026 are excluded from SEA LION certified inventory. No compromise on structural or powertrain integrity is permitted.

END OF REPORT

SEA LION International – Engineering Reliability, Industrial Scale

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks (Wichita, KS) from China

Date: January 15, 2026

Prepared by: SEA LION International – Senior Engineering Division

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack—for the export of used commercial trucks originating from Wichita, Kansas, and shipped internationally from Chinese ports. The analysis focuses on technical feasibility, cost-efficiency, transit integrity, and corrosion mitigation, with specific attention to wax-based protective coatings against seawater exposure. Recommendations are tailored for fleet operators and construction logistics planners managing large-scale equipment redeployment.

1. Export Workflow Overview

Used trucks from Wichita, KS, are first transported via domestic rail or heavy-haul trailer to the Port of Lianyungang or Port of Qingdao, China, where they are staged for export. Final destination ports vary by region (e.g., Middle East, Africa, South America). The choice of shipping method significantly impacts delivery timelines, vehicle condition upon arrival, and total landed cost.

2. Comparative Analysis of Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Loading Method | Driven on/off vessel via ramps | Crane-lifted; secured in hold | Crane-lifted; lashed to open-frame ISO platform |

| Suitability for Trucks | High – designed for wheeled vehicles | Low – not optimized for intact vehicles | High – ideal for non-operational or oversized units |

| Vehicle Protection | Moderate – exposed to salt spray in open decks | Low – high risk of contact damage and moisture | High – customizable weatherproofing and sealing |

| Corrosion Exposure | High – direct seawater aerosol contact | High – confined humid environment | Moderate – manageable with sealing and wax coating |

| Transit Time (Avg.) | 28–35 days (Asia to Middle East) | 32–40 days | 30–36 days |

| Cost per Unit (USD) | $1,800 – $2,400 | $1,600 – $2,000 (not recommended) | $2,600 – $3,200 |

| Insurance Risk Profile | Medium | High | Low to Medium |

| Port Infrastructure Required | RO-RO terminal with ramps | General cargo crane access | Container yard with heavy-lift capability |

| Best For | Operational trucks, fleet batches | Not recommended for used trucks | Non-running units, custom configurations |

Note: Bulk Cargo is not advised for used commercial trucks due to high risk of structural and cosmetic damage during stowage.

3. Corrosion Mitigation: Wax Spraying Protection System

Seawater-induced corrosion is a critical risk during maritime transport, particularly for steel chassis, undercarriages, and brake systems. SEA LION International implements a MarineGuard™ Wax Spraying Protocol to enhance long-term asset integrity.

3.1 Wax Spraying Specifications

| Parameter | Specification |

|---|---|

| Wax Type | Solvent-based, hydrophobic microcrystalline polymer blend |

| Application Method | High-pressure electrostatic spray (25–35 psi) |

| Coating Thickness | 25–30 µm (chassis and undercarriage) |

| Coverage Areas | Frame rails, suspension components, fuel tanks, exhaust manifolds, wheel hubs |

| Salt Spray Resistance (ASTM B117) | >1,000 hours with <5% red rust formation |

| Service Life | Up to 18 months in marine environments |

| Removal Process | Biodegradable citrus-based solvent; compatible with paint and rubber seals |

3.2 Application Workflow

- Pre-Treatment: Degrease and dry undercarriage (80°C forced-air drying).

- Masking: Protect sensors, brake discs, and electrical connectors.

- Spraying: Automated robotic arms ensure uniform coverage.

- Curing: 2-hour ambient cure before loading.

- Verification: Adhesion test (ASTM D3359) and thickness gauge audit.

Recommendation: Wax application is mandatory for RO-RO and advised for Flat Rack shipments. Reduces post-arrival reconditioning costs by up to 40%.

4. Recommended Logistics Strategy

| Scenario | Recommended Method | Rationale |

|---|---|---|

| Operational fleet trucks (≥80% functional) | RO-RO + Wax Spray | Fast loading, cost-effective, minimal disassembly |

| Non-operational or damaged units | Flat Rack + Full Enclosure + Wax Spray | Maximum protection, accommodates tilt or misalignment |

| Mixed fleet (operational + non-running) | Hybrid: RO-RO + Flat Rack combo booking | Optimizes cost and safety across vehicle conditions |

5. Compliance & Certification

All shipments comply with:

– IMO CSS Code (Cargo Securing Manual)

– IMSBC Code (for non-containerized units)

– China Customs Export Declaration (Used Mechanical Equipment, HS 8704)

– ISPM 15 (for wooden dunnage, if used)

Wax formulation meets REACH and RoHS standards for environmental safety.

6. Conclusion

For the export of used trucks from China bound for global construction and fleet operations, RO-RO shipping with wax-based corrosion protection offers the optimal balance of efficiency and asset preservation for operational units. Flat Rack containers are superior for non-functional or modified trucks requiring structural safeguarding. Bulk Cargo is not recommended due to unacceptably high damage rates.

SEA LION International recommends implementing the MarineGuard™ Wax Spraying Protocol across all shipments to mitigate saltwater corrosion and ensure trucks arrive in re-deployment-ready condition.

End of Report

SEA LION International – Engineering Division

Precision Logistics for Industrial Mobility

Get a Quote for Used Trucks Wichita Ks

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]