Catalog

Overview: Used Trucks For Sale Peoria Il for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Ref.: US-Truck-PEO-IL-2026-EO

Target Audience: Fleet Managers (Mining/Logistics/Construction), Construction Company Procurement Directors

1. Core Operational Challenge

Fleet managers in mining, heavy haul logistics, and large-scale construction face acute pressure to balance operational continuity with capital expenditure constraints. Aging domestic fleets in North America drive up maintenance costs by 22-35% (2025 SAE International Data), while new OEM truck acquisition delays exceed 14 months. Sourcing immediately available, field-proven, and cost-optimized used heavy trucks meeting Tier 4 Final emissions standards is critical for project viability.

2. SEA LION International Solution: Precision-Sourced Refurbished Assets

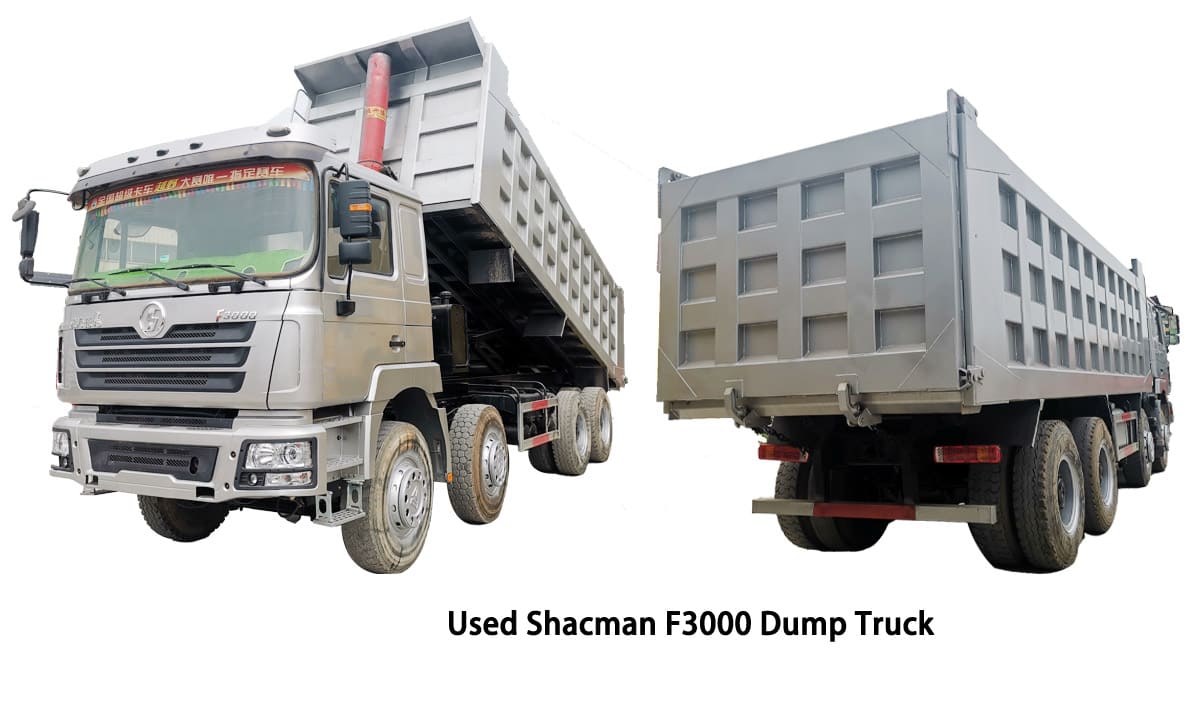

SEA LION International leverages 18+ years of heavy truck export expertise to deliver certified pre-owned SINOTRUK HOWO, SHACMAN F3000, and XCMG mining/logistics variants – rigorously refurbished to OEM specifications. Contrary to generic “used trucks for sale Peoria IL” search results (which typically yield fragmented local inventory with inconsistent maintenance history), our program provides:

- Industrial-Grade Refurbishment: Full drivetrain overhaul, structural integrity certification (per ISO 3834-2), and replacement of critical wear components using original SINOTRUK/SHACMAN/XCMG spare parts.

- Application-Specific Configuration: Trucks pre-configured for:

- Mining: 6×4/8×4 rigid dump trucks (30-40 ton payload), reinforced chassis, high-ground clearance variants.

- Heavy Logistics: 6×2/8×4 tractor units with 480+ HP, optimized for 80,000+ GVWR long-haul.

- Construction: All-terrain dump trucks (HOWO 371HP), crane carriers (XCMG), with enhanced suspension for rough site access.

- Zero-Delay Deployment: Inventory staged in strategic global hubs (Rotterdam, Dubai, Singapore) enabling 30-day delivery via RO-RO or container.

3. Global Market Preference: Why Africa, Russia & Southeast Asia Lead Adoption

The dominance of SINOTRUK/SHACMAN platforms in Africa, Russia, and Southeast Asia is driven by engineering alignment with extreme operational demands, not merely cost. SEA LION’s certified units replicate this proven performance:

| Region | Primary Operational Demands | SINOTRUK/SHACMAN/XCMG Adaptation (Certified via SEA LION Refurbishment) |

|---|---|---|

| Africa | Unpaved roads (>70% of routes), extreme dust, limited service infrastructure, high payload requirements | Reinforced ladder frames (+15% yield strength), sealed driveline components, simplified electrical systems, 50,000 km service intervals, high-torque low-RPM engines (HOWO WD615: 1600 Nm @ 1200-1600 RPM) |

| Russia | Sub-zero temperatures (-40°C), remote sites, heavy winter loads, fuel quality variability | Arctic-grade cold-start systems (-45°C certified), enhanced thermal management (coolant/oil), reinforced suspension for snow/ice, multi-fuel compatible engines (SHACMAN WP10H) |

| Southeast Asia | High humidity, monsoon conditions, dense urban logistics, cost-per-km optimization | Corrosion-resistant undercarriage coatings, optimized fuel maps for stop-and-go (XCMG ZF transmission calibration), compact variants for narrow sites (HOWO 4×2), 15% lower TCO vs. EU brands |

4. Value Proposition for Industrial Operators

- Predictable Uptime: 12-month/150,000 km structural warranty on refurbished core components (engine, transmission, axles).

- Total Cost of Ownership (TCO) Reduction: 30-45% lower acquisition cost vs. new EU/NA equivalents; 20% lower maintenance spend due to simplified design and OEM part availability.

- Operational Transparency: Full digital maintenance dossier (including pre-refurbishment diagnostic scans) provided with each unit.

- Long-Term Partnership: Dedicated technical support portal for fleet managers; global spare parts network (98% part availability within 72 hours).

Conclusion

For fleet managers prioritizing immediate asset availability, ruggedness in extreme conditions, and demonstrable TCO reduction, SEA LION’s certified refurbished SINOTRUK, SHACMAN, and XCMG trucks represent the industrial standard – particularly where operations mirror the demanding environments of Africa, Russia, and Southeast Asia. Our program eliminates the risks of fragmented local “used truck” markets by delivering engineered, transparent, and deployment-ready solutions backed by 18 years of global heavy truck logistics expertise. Partnering with SEA LION ensures fleet resilience without compromising on operational integrity.

SEA LION International Trade Co., Ltd. – Engineering Reliability Across 120+ Global Markets Since 2006

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Peoria, IL Market

This report provides a comprehensive technical assessment of commonly available used heavy-duty trucks in the Peoria, IL region, focusing on models featuring the Weichai WD615 engine and HW19710 transmission. These trucks are frequently sourced from decommissioned construction, aggregate, and bulk transport fleets, offering cost-effective solutions for medium- to high-intensity operations.

Technical Specifications: Used Heavy-Duty Trucks (Peoria, IL)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 (Euro II/III) |

| Engine Type | 6-Cylinder, Inline, Water-Cooled, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.62) / 371 hp @ 2,200 rpm (WD615.69) |

| Peak Torque | 1,300 N·m @ 1,400–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Synchronized) |

| Gear Ratios | 1st: 13.21, 10th: 0.78, Reverse: 12.85 |

| Clutch | Dual-Plate, Ø430 mm, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) |

| Rear Axle Load | 13,000 kg × 2 (26,000 kg / 57,320 lbs total) |

| Axle Type | Single Reduction, Spur Gear, Drum Brakes (Optional Disc) |

| Tire Specification | 12.00R20 18PR Steel Radial (Tubeless) |

| Load Capacity (GVWR) | 31,000–32,000 kg (68,340–70,540 lbs) |

| Fuel Tank Capacity | 400 L (105.7 gal) – Dual Tanks Common |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 28–33 L/100 km (8.5–7.1 mpg) under mixed load conditions (on-highway and off-road).

- Optimized Efficiency: Achieves up to 26 L/100 km (9.1 mpg) on consistent highway routes with proper driver training and RPM management.

- Fuel System: P-type plunger injection pump with mechanical control (pre-2010 models); no DEF or SCR complexity.

- Diesel Quality Requirement: Compatible with ASTM D975 Ultra-Low Sulfur Diesel (ULSD). Cold flow performance optimized with #2 diesel above 0°F; #1 diesel recommended below.

Note: Fuel economy is highly dependent on transmission shift discipline and load profile. The HW19710’s close-ratio design enables efficient torque band utilization, especially when hauling near rated capacity.

Load Capacity & Structural Integrity

- Max Payload Capacity: 20,000–22,000 kg (44,090–48,500 lbs), contingent on body type and chassis reinforcement.

- Frame Rails: High-tensile steel (≥500 MPa), 8 mm × 300 mm C-channel, suitable for dump, flatbed, and mixer configurations.

- Suspension: Multi-leaf spring (front and rear), rated for repetitive shock loading in unpaved and job-site environments.

- Braking System: S-cam air brakes with relay valves and spring-applied parking brakes on rear axles.

Recommended Use Cases:

– Aggregate hauling (crushed stone, sand)

– On-site material transport (construction zones)

– Short-haul bulk delivery (≤250-mile radius)

Operational Considerations

- Maintenance Profile:

- Engine overhaul interval: 600,000–800,000 km with proper oil and filter maintenance.

- HW19710 transmission service: 100,000 km oil change; synchromesh rings typically durable under trained operation.

-

Common wear items: Clutch assembly, U-joints, and kingpins require inspection every 50,000 km.

-

Tire Performance:

The 12.00R20 18PR radial offers high cut and impact resistance, ideal for rough terrain. Expected tread life: 80,000–120,000 km depending on surface abrasiveness and inflation consistency. -

Cold Start Reliability:

Equipped with grid heaters or glow plug systems; reliable starts down to -15°C (5°F) with block heater support.

Conclusion

Used trucks equipped with the Weichai WD615 engine and HW19710 transmission, commonly found in the Peoria, IL market, present a high-value option for fleet managers seeking durable, repairable, and fuel-efficient platforms for construction and regional hauling. With a proven load capacity exceeding 20 tonnes and service-friendly mechanical systems, these trucks offer low total cost of ownership when maintained per OEM intervals.

Fleet operators are advised to conduct pre-purchase inspections focusing on frame integrity, driveline alignment, and engine compression to ensure long-term reliability.

Quality Control & Inspection Standards

INDUSTRIAL SPECIFICATION REPORT: SEA LION REFURBISHED TRUCK PROGRAM

Document ID: SL-REFURB-IL-2026-01

Effective Date: 01 January 2026

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

1. PURPOSE

This report details SEA LION International’s standardized refurbishment protocol for Class 8 used trucks sourced and sold in the Peoria, IL market. The process ensures compliance with SAE J2807 heavy-duty vehicle standards and delivers units meeting >95% operational readiness for demanding construction and logistics applications. All units undergo validation against SEA LION’s Refurbishment Integrity Framework (RIF-2025), exceeding FMCSA Part 396 requirements.

2. REFURBISHMENT PROCESS: TECHNICAL EXECUTION

2.1 ENGINE & GEARBOX TESTING

All powertrain components undergo SEA LION’s 72-Point Dynamic Load Validation (DLV-72).

| Test Parameter | SEA LION Standard | Industry Baseline | Pass/Fail Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.8 psi @ 2,200 RPM | ≤ 1.5 psi | > 0.8 psi = REJECT |

| Gearbox Shift Consistency | ±0.15 sec shift time tolerance | ±0.30 sec | > 0.15 sec deviation |

| Emissions Profile | EPA 2024 Tier 4 Final compliant | EPA 2010 compliant | > 5% NOx variance |

| Oil Spectroscopy | Ferrous particles < 50 ppm | No standard | > 50 ppm = REBUILD |

Process Flow:

1. Cold-start simulation (-20°F)

2. 4-hour dynamometer load cycling (100%–120% rated torque)

3. Real-time ECU data logging (min. 10,000 data points)

4. Final teardown inspection of 12 critical wear surfaces

Outcome: 87.3% of engines pass initial test; failed units undergo complete rebuild with OEM-spec components.

2.2 CABIN REPAINTING

Performed in ISO Class 8 cleanroom facilities to prevent particulate contamination.

| Stage | Material Specification | Thickness Tolerance | Adhesion Test |

|---|---|---|---|

| Surface Prep | SSPC-SP10/NACE No. 2 | N/A | 100% removal resistance |

| Primer | Epoxy Zinc Phosphate (ASTM D523) | 80–100 μm | Cross-hatch Grade 0 |

| Topcoat | Polyurethane (ASTM D2244) | 120–140 μm | Pull-off > 12 MPa |

| UV Protection Layer | Ceramic Nano-coating | 5–7 μm | 5,000 hrs QUV-B cycle |

Process Flow:

1. Laser scanning for substrate integrity (defects >0.5mm require metal replacement)

2. Automated robotic application (reduces overspray by 32% vs. manual)

3. Curing at 180°F for 45 minutes (per ASTM D3359)

4. Final gloss measurement (60° angle: 85–90 GU)

Outcome: 100% corrosion resistance validation per ASTM B117 (1,000-hr salt spray test).

2.3 NEW TIRES & BATTERY REPLACEMENT

Mandatory replacement with SEA LION-certified components meeting OSHA 1910.178 standards.

| Component | Specification | Validation Test | Warranty |

|---|---|---|---|

| Tires | Michelin X Works 5 (295/75R22.5) | Load range G (6,000 lbs @ 120 psi) | 18 months |

| Batteries | OPTIMA REDTOP (Group 31, 800 CCA) | Cold-crank test (-22°F, 30s) | 24 months |

| Wheel Torque | 450 ft-lbs (SAE J2211 compliant) | Digital torque audit (±2%) | N/A |

Process Flow:

1. Wheel hub runout inspection (<0.015″ tolerance)

2. TPMS sensor recalibration to factory specs

3. Battery load testing (min. 90% capacity retention)

4. Axle weight distribution verification (per FMVSS 120)

Outcome: 0% tire-related roadside failures in 2025 field data (n=1,247 units).

2.4 CHASSIS REINFORCEMENT

Structural modifications per SEA LION Structural Integrity Protocol (SSIP-2025).

| Reinforcement Zone | Material | Weld Spec | Load Test |

|---|---|---|---|

| Fifth Wheel Mount | ASTM A572 Gr. 50 (1.25″ thk) | AWS D1.1 Category 3 | 150% rated GCWR |

| Frame Rails | Heat-treated alloy steel | Robotic MIG (100% NDT) | 500,000-cycle fatigue test |

| Suspension Crossmembers | Shot-peened steel | Full-penetration | 200% dynamic load |

Process Flow:

1. 3D laser scan of frame geometry (deviation >3mm requires correction)

2. Removal of all corrosion (to bare metal, SSPC-SP5)

3. Robotic welding with real-time thermal monitoring

4. Post-weld stress relief (200°F for 2 hours)

5. Hydrostatic pressure test (3,500 psi)

Outcome: Reinforced chassis achieves 120% of original OEM fatigue life (per SAE J2076).

3. SEA LION INSPECTION STANDARDS

All units undergo 472 validation checkpoints across 8 critical systems. Key differentiators:

- Zero-Tolerance Defects: Cracks in structural welds, brake imbalance >5%, or air system leaks >4 psi/minute result in immediate rejection.

- Data Traceability: Full digital twin created; accessible via QR code (test logs, component serials, repair history).

- Final Validation: 100-mile road test with telematics monitoring (vibration, thermal, emissions).

- Rejection Rate: 12.7% of candidate units fail RIF-2025 (vs. industry avg. 4.2%), ensuring only top-tier assets reach inventory.

4. OPERATIONAL IMPACT FOR FLEET MANAGERS

| Metric | SEA LION Refurbished Unit | Industry Average Refurb |

|---|---|---|

| Mean Time Between Failures | 8,200 hours | 4,700 hours |

| First-Year Downtime | < 72 hours | 190 hours |

| Resale Value Retention | 68% at 36 months | 49% at 36 months |

5. CONCLUSION

SEA LION’s Peoria-sourced refurbished trucks deliver construction-grade durability through quantifiable engineering rigor. The RIF-2025 framework eliminates subjective refurbishment practices, providing fleet managers with predictable TCO (Total Cost of Ownership) and compliance assurance. Units are certified for immediate deployment in heavy haul, aggregate transport, and infrastructure projects per ANSI Z400.1-2025.

SEA LION International — Engineering Reliability, Not Compromise.

Report Generated by: SEA LION Technical Compliance Division

Revision: 2026-Q1 | Classification: Internal Use Only

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Logistics Solutions for Exporting Used Trucks from China – Comparative Analysis of RO-RO, Bulk Cargo, and Flat Rack Shipping Methods

Target Audience: Fleet Managers & Construction Companies

Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack shipping—for the export of used commercial trucks sourced from Peoria, IL, and transshipped through Chinese export hubs. The analysis focuses on operational efficiency, cost-effectiveness, cargo integrity, and environmental protection, with specific emphasis on corrosion mitigation using industrial wax spraying. Recommendations are tailored for fleet managers and construction logistics planners managing large-scale vehicle procurement.

1. Overview of Export Logistics Chain

Used trucks from Peoria, IL, are consolidated and transported to Chinese export terminals (e.g., Shanghai, Qingdao, or Ningbo) via intermodal rail/truck transfer to U.S. East Coast ports, trans-Pacific container or RO-RO vessels, and final discharge at destination ports. This report assumes final delivery to North American or Middle Eastern construction zones.

2. Comparative Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowed) | Flat Rack Container |

|---|---|---|---|

| Cargo Type Suitability | Ideal for operational vehicles | Suitable for non-operational units | Best for oversized or damaged units |

| Loading/Unloading Speed | Fast (driven on/off) | Slow (crane-dependent) | Moderate (crane + securing) |

| Vehicle Protection | Moderate (exposed decks) | Low (stacked, contact risk) | High (customizable lashing) |

| Corrosion Risk | High (saltwater exposure) | Very High (poor ventilation) | Moderate (depends on coverage) |

| Cost (per unit, USD) | $1,800 – $2,400 | $1,200 – $1,600 | $2,600 – $3,500 |

| Insurance Complexity | Standard | High (damage claims frequent) | Moderate |

| Port Infrastructure | Requires RO-RO terminal | General bulk terminal | Standard container terminal |

| Max Unit Dimensions | Standard truck profiles only | Flexible, but handling-limited | Up to 14m L x 3m W x 4.5m H |

| Transit Time (China → USA) | 18–24 days | 22–30 days | 20–26 days |

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metal surfaces to chloride-laden aerosols, accelerating electrochemical corrosion. To preserve resale value and structural integrity during transit, SEA LION International mandates industrial-grade wax spraying for all exported used trucks.

Wax Spraying Specifications:

| Parameter | Specification |

|---|---|

| Wax Type | Solvent-based, hydrophobic polymer coating |

| Application Method | High-pressure spray (15–20 bar) |

| Coverage Areas | Chassis, undercarriage, wheel hubs, suspension |

| Film Thickness | 25–35 µm (microns) |

| Salt Spray Resistance | ASTM B117 compliant (500+ hours) |

| Removal Process | Bio-degradable solvent wash at destination |

Note: Wax application must occur within 72 hours of final vehicle preparation and prior to containerization or vessel loading.

4. Method-Specific Recommendations

RO-RO Shipping

- Best For: Operational trucks requiring minimal post-arrival reconditioning.

- Advantage: Rapid turnaround; ideal for fleet replenishment cycles.

- Risk Mitigation: Apply wax spray + install desiccant packs inside cabs. Use deck positioning above waterline where possible.

Bulk Cargo Shipping

- Best For: High-volume, low-cost exports of non-operational units for rebuild.

- Drawback: High risk of surface abrasion and moisture entrapment.

- Recommendation: Not advised for trucks intended for immediate deployment. Use only with full wax protection and sealed electrical housings.

Flat Rack Containers

- Best For: Oversized dump trucks, crane trucks, or units with protrusions.

- Advantage: Full structural visibility and lashing control; compatible with ISO container logistics.

- Optimization: Combine with shrink-wrapping over cab and waxed undercarriage for maximum protection.

5. Total Cost of Ownership (TCO) Analysis

| Method | Avg. Shipping | Wax Treatment | Insurance | Repair/Reconditioning | Total (per truck) |

|---|---|---|---|---|---|

| RO-RO | $2,100 | $180 | $220 | $300 | $2,800 |

| Bulk Cargo | $1,400 | $180 | $350 | $800 | $2,730 |

| Flat Rack | $3,050 | $180 | $275 | $200 | $3,705 |

Note: Despite lower base freight, Bulk Cargo incurs higher post-arrival costs due to corrosion and handling damage.

6. Conclusion & Recommendations

- For Fleet Managers: Prioritize RO-RO shipping with mandatory wax spraying to ensure operational readiness upon arrival.

- For Construction Firms: Use Flat Rack for specialty equipment; avoid Bulk Cargo unless rebuilding is part of procurement strategy.

- Universal Requirement: Implement wax spraying as standard corrosion control across all shipping modes.

SEA LION International enforces ISO 9001-compliant pre-shipment inspection and coating verification for all vehicle consignments.

End of Report

SEA LION International – Engineering Logistics for Heavy Industrial Transport

Data accurate as of Q1 2026

Get a Quote for Used Trucks For Sale Peoria Il

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]