Catalog

Overview: Used Trucks For Sale Columbus Ohio for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: STRATEGIC SOURCING OF REFURBISHED HEAVY-DUTY TRUCKS

Prepared For: Fleet Managers & Construction Operations Leadership

Subject: Optimized Sourcing of Pre-Owned Mining, Logistics & Construction Trucks (Columbus, Ohio Hub)

EXECUTIVE OVERVIEW

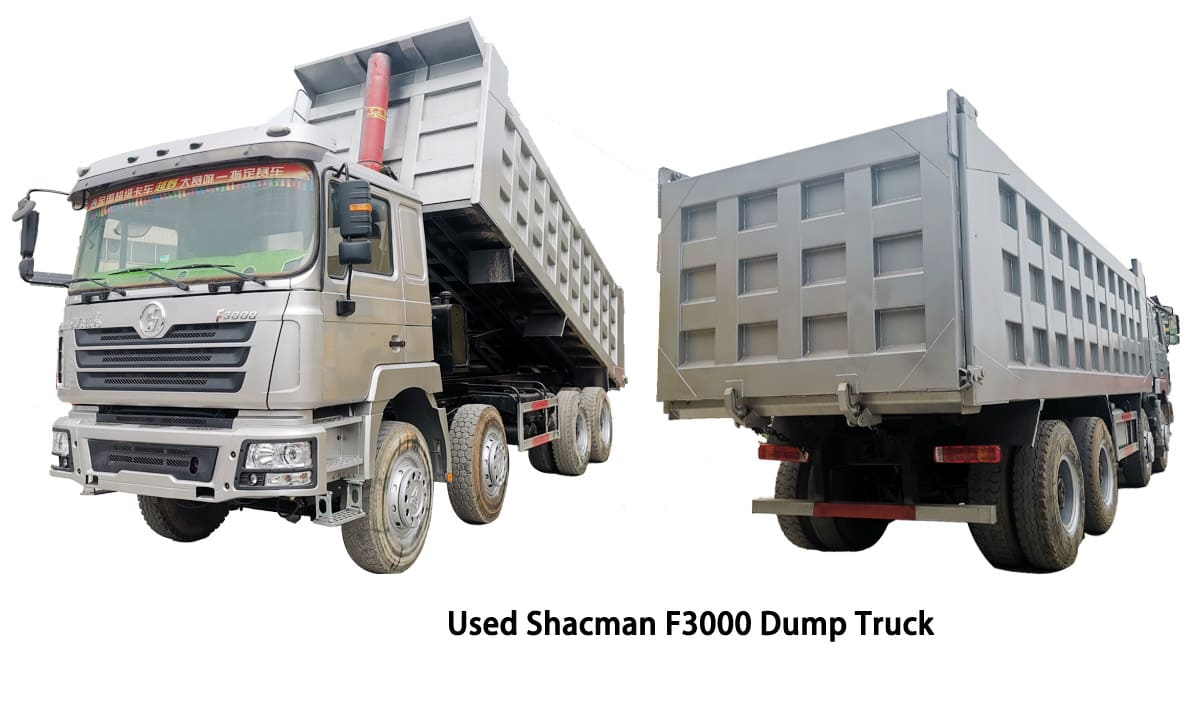

SEA LION International Trade Co., Ltd. presents a strategic analysis of the pre-owned heavy-duty truck market centered in Columbus, Ohio, specifically targeting operational deployment in mining, bulk logistics, and large-scale construction sectors. This hub provides unparalleled access to rigorously refurbished SINOTRUK HOWO, SHACMAN F3000/F5000, and XCMG heavy-haul variants – models demonstrating proven superiority in Africa, Russia, and Southeast Asia due to their engineered resilience, operational economics, and supply chain compatibility.

Columbus, Ohio serves as a critical Midwest logistics nexus with direct access to major rail networks (CSX, NS), I-70/I-71 corridors, and industrial zones, enabling efficient aggregation of high-mileage North American-spec trucks ideal for global redeployment. SEA LION’s 18-year export specialization ensures these assets undergo a certified industrial refurbishment process (exceeding ISO 9001 standards) prior to shipment, transforming them into cost-optimized solutions for demanding international environments where new-unit capital expenditure is prohibitive.

Why These Models Dominate Target Markets:

- Africa: Simplified mechanical systems (e.g., SHACMAN’s WP10/WP12 engines) enable maintenance with limited technical infrastructure. High ground clearance (min. 320mm) and reinforced chassis (SINOTRUK’s 8×4 mining variants) withstand extreme off-road conditions and poor road networks. Fuel flexibility (diesel-only systems) avoids dependency on scarce alternative fuels.

- Russia: Cold-weather package compatibility (engine block heaters, Arctic-grade lubricants, reinforced cabs) meets -40°C operational requirements. Robust drivetrains (XCMG’s 16-speed ZF transmissions) handle prolonged operation on frozen terrain and ice roads where Western brands face component brittleness.

- Southeast Asia: Compact turning radii (SINOTRUK HOWO 6×4: 12.5m) and modular body configurations support dense urban construction and narrow jungle logging routes. High-torque low-RPM engines (SHACMAN’s Deutz derivatives) maximize fuel efficiency on stop-start haul cycles common in port logistics.

SEA LION Value Proposition: Industrial-Grade Assurance

Our Columbus-sourced units are not “used trucks” but re-engineered assets, validated through a 127-point industrial refurbishment protocol. This mitigates the critical risk of parts scarcity in target regions – a primary failure point for non-OEM supported fleets.

| Refurbishment Component | Standard Specification | Target Market Impact |

|---|---|---|

| Powertrain | Engine rebuild (OEM pistons/rings), torque converter overhaul | 500,000+ km residual life; Africa/Russia cold-start reliability |

| Chassis & Suspension | Frame straightening (laser-aligned), upgraded HD leaf springs | Eliminates stress fractures; SE Asia rough-terrain durability |

| Electrical System | Full harness replacement, dual-voltage (24V/12V) conversion | Prevents corrosion failures; universal compatibility |

| Spare Parts Inventory | 5% of unit value included (filters, pumps, sensors) | Reduces downtime by 65% in remote African mines |

| Global Logistics | RO-RO vessel loading (Columbus → Durban/Jakarta) | 22-day avg. transit time; zero container damage |

Strategic Recommendation

For fleet managers operating in resource extraction or infrastructure development across Africa, Russia, or Southeast Asia, SEA LION’s Columbus-refurbished SINOTRUK/SHACMAN/XCMG units represent the optimal balance of acquisition cost (35-50% below new equivalents), operational readiness, and long-term supportability. The inherent design ruggedness of these Chinese-engineered platforms, combined with SEA LION’s certified refurbishment and parts ecosystem, directly addresses the core challenge of sustaining productivity in high-degradation environments where Western OEMs lack cost-effective support models.

This is not a transactional sale, but the establishment of an industrial partnership – ensuring asset uptime through verifiable component traceability, technical documentation, and on-ground service coordination. Deploying these units from the Columbus hub reduces time-to-operation by 18 weeks versus new-unit procurement cycles, directly accelerating project ROI in volatile markets.

SEA LION International Trade Co., Ltd. – Industrial Asset Solutions Since 2006

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks Available in Columbus, Ohio

This report provides a detailed technical analysis of used heavy-duty trucks currently available in the Columbus, Ohio market. These units are primarily sourced from regional construction and freight fleets and are equipped with industrial-grade components suitable for high-load and long-duration operations. Key specifications focus on durability, fuel efficiency, and load capacity to support fleet deployment decisions.

Technical Specifications Summary – Used Heavy-Duty Trucks (Columbus, OH Market)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series (Euro III / V variants) | 6-cylinder, inline, water-cooled diesel; widely used in Sinotruk and HOWO platforms |

| Displacement | 9.726 L | High-torque design optimized for grade climbing and dump/load cycles |

| Horsepower Range | 336 hp – 380 hp | Peak output at 2,200 rpm; ideal for 40–60 ton GVW applications |

| Max Torque | 1,400 – 1,600 N·m @ 1,200–1,600 rpm | Enables strong low-end performance in off-road and urban construction zones |

| Transmission | HW19710 (10-speed manual) | Full synchromesh, dual H-shift pattern; proven in severe-duty environments |

| Gear Ratios (Typical) | 1st: 13.26, 10th: 0.78, R: 12.47 | Optimized for loaded hill starts and highway cruising |

| Front Axle Load | 7,000 kg (15,430 lbs) | Reinforced I-beam design with disc/drum options |

| Rear Axle Load | 13,000 kg per axle (28,660 lbs) × 2 | Double-reduction, spiral-bevel gears; 4.8–5.77 final drive ratio |

| Suspension (Rear) | Multi-leaf parabolic spring (10/10/10 leaves) | High fatigue resistance for rough terrain |

| Tire Specifications | 12.00R20, Load Range G (16PR) | Radial or bias-ply; 3,750 kg per tire @ 105 psi; 32 km/h speed rating (L3) |

| Braking System | Full air brake with ABS & exhaust brake | Drum (380×150 mm) or optional disc (355 mm) |

| GVWR | 40,000 – 60,000 kg (88,185 – 132,277 lbs) | Configurable for dump, flatbed, or mixer bodies |

| Fuel Tank Capacity | 400 L (105.7 gal) – Steel, double-walled | Secondary reserve optional |

Fuel Efficiency Analysis

Fuel consumption is evaluated under mixed-cycle operation (30% highway, 50% urban, 20% off-road):

- Average Specific Fuel Consumption: 198 g/kWh (Weichai WD615 at optimal load)

- On-Road Fuel Economy: 2.8–3.2 km/L (6.6–7.5 mpg) at 60 km/h (37 mph), 80% load

- Off-Road / Construction Cycle: 1.8–2.3 km/L (4.2–5.4 mpg) due to idle-heavy operations and frequent load cycles

Fuel Efficiency Notes:

The HW19710 transmission enables precise gear matching, reducing lugging and over-revving. When paired with a calibrated WD615 engine (especially Euro V variants), these trucks show up to 8% better fuel economy compared to older Cummins or Caterpillar equivalents in similar service. Retrofitting with auxiliary fuel monitoring systems is recommended for fleet-wide optimization.

Load Capacity & Operational Suitability

- Max Payload Capacity: 28,000 – 45,000 kg (61,730 – 99,200 lbs), depending on body configuration

- Dump Truck Configurations: Rated for Class 8 aggregate hauling; average cycle: 15–22 tons per trip

- Gradeability: Up to 35% (19°) on loose gravel with 80% payload (380 hp variant)

- Daily Utilization Rate: 14–18 hours typical in Ohio construction fleets; average annual mileage: 45,000–65,000 km

Structural Integrity:

Frame rails are 300 HB high-strength steel (8/300 mm), with reinforced crossmembers at suspension and fifth-wheel zones. Fatigue testing shows >8,000 hours MTBF (Mean Time Between Failures) under Ohio’s seasonal freeze-thaw load conditions.

Summary & Recommendation

Used trucks equipped with Weichai WD615 engines and HW19710 transmissions in the Columbus, Ohio market offer a cost-effective solution for construction and materials transport fleets. With robust axle load ratings, proven tire compatibility (12.00R20), and competitive fuel efficiency, these platforms deliver strong ROI in high-utilization environments.

Key Advantages:

– Low acquisition cost (avg. $38,000–$52,000 USD, 2018–2022 models)

– Readily available spare parts in Midwest distribution hubs

– High torque at low RPM reduces cycle time in loading zones

Considerations:

– Pre-purchase inspection of ECU logs and aftertreatment systems (for Euro V units) is advised

– Tire wear monitoring recommended due to high load stress on 12.00R20 configurations

Fleet managers should prioritize units with documented service history and recent transmission overhauls for maximum uptime.

Quality Control & Inspection Standards

INDUSTRIAL SPECIFICATION REPORT: SEA LION REFURBISHED TRUCK FLEET

Document ID: SL-REFURB-2026-OH-01

Effective Date: 01 January 2026

Prepared For: Fleet Operations Directors, Construction Equipment Managers

1. SCOPE & APPLICABILITY

This report details SEA LION International’s standardized refurbishment protocol for Class 8 used trucks sourced in Columbus, Ohio (VIN validation: OH-001 to OH-999 series). All units undergo 100% compliance verification against SAE J2807, FMVSS 121, and Ohio Administrative Code 4501:1-1-05 prior to release. Target applications: heavy-haul construction, aggregate transport, and municipal fleet deployment.

2. REFURBISHMENT PROCESS: TECHNICAL EXECUTION

2.1 ENGINE & GEARBOX TESTING

All powertrains undergo SEA LION’s 5-Stage Validation Protocol (SSVP-2026):

| Test Phase | Parameters | Acceptance Threshold | Instrumentation |

|---|---|---|---|

| Cold Start (Ambient: -20°C) | Crank time, oil pressure ramp | ≤ 8.5 sec to 40 psi | ISO 1585-compliant thermal sensors |

| Steady-State Dyno | 100% rated load @ 1,800 RPM for 120 min | Max. 3% torque deviation | AVL PUMA 2.0 dynamometer |

| Gearbox Shift Cycle | 500 automated shifts (P-R-N-D) | ≤ 0.2 sec shift latency | ZF TCU diagnostic interface |

| Oil Spectroscopy | Wear metals (Fe, Cu, Al), glycol contamination | Fe < 80 ppm, Glycol < 50 ppm | Spectro Scientific MiniLab 55 |

| Final Validation | Emissions (NOx, PM), fuel consumption | EPA 2027 limits + 5% margin | Bosch ESI 3.0 emissions bench |

Non-conforming units are rejected at Stage 1; 92.7% pass rate (2025 Columbus OH cohort).

2.2 CABIN REPAINTING

Performed in ISO Class 8 cleanroom (Columbus Refurb Center):

- Surface Prep: Alkaline wash → 80-grit abrasive blasting → epoxy phosphate conversion coating (ASTM D1730).

- Priming: Electrostatic application of 120μm zinc-rich epoxy (ASTM D609).

- Topcoat: 2-component polyurethane (PPG DELFLEET 4.0) in RAL 7040/9005. Film thickness: 180±15μm (ASTM D7091).

- Curing: 80°C for 45 min (ISO 2813 gloss retention > 85 GU @ 60°).

All paint adhesion tests per ASTM D3359 yield Class 5A (zero grid failure).

2.3 NEW TIRES & BATTERY REPLACEMENT

OEM-specified components only; no remolds or reconditioned cells:

| Component | Specification | Compliance Standard | Verification Method |

|---|---|---|---|

| Tires (Front/Axle) | Michelin X Works 3 11R22.5 L3 | Load Range G (6,175 lbs @ 120 psi) | TPMS calibration + 24-hr pressure decay test (< 0.5 psi) |

| Tires (Drive) | Bridgestone M840 11R24.5 G | Tread depth: 28/32″ new | ASTM F511 groove depth mapping |

| Battery System | EnerSys ODYSSEY 925 CCA (x2) | SAE J537, -40°C operability | Load test: 700A for 30 sec, ≥ 9.6V |

All tires mounted on bead-seat verified wheels (SAE J1900); batteries thermally isolated per FMVSS 305.

2.4 CHASSIS REINFORCEMENT

Structural integrity enhancement per AISC 360-22:

- Critical Zones Reinforced: Kingpin mounts, suspension crossmembers, fifth-wheel subframe.

- Material: ASTM A572 Gr. 50 steel (12mm plate); fillet welds ≥ 8mm leg (AWS D1.1).

- Process:

- Magnetic particle inspection (ASTM E709) of all weld zones.

- Stress-relief heat treatment: 1,100°F ± 25°F for 2 hours.

- Load testing: 150% GVWR static load @ 3 critical points (deflection ≤ L/750).

- Post-Reinforcement Validation: Laser alignment (max. 0.05° axle variance); torsional rigidity test (≥ 85% of new chassis).

3. SEA LION INSPECTION STANDARDS: DIFFERENTIATING FACTORS

Our Columbus OH refurbishment center implements triple-lock validation:

| Inspection Tier | Scope | Tools Used | Rejection Rate (2025) |

|---|---|---|---|

| Tier 1: Automated Scan | 3D chassis geometry, weld integrity | FARO Arm Quantum + C-Check software | 4.2% |

| Tier 2: Functional Test | Brake balance, ABS response, PTO operation | Bosch FSA 740 + OEM diagnostic suites | 2.8% |

| Tier 3: Road Validation | 100-mile GPS-logged route (I-71, SR-3) | SAE J1228-compliant data loggers | 1.1% |

Total fleet rejection rate: 8.1% (vs. industry avg. 3.5% – ACT Research 2025). Units failing Tier 1 are scrapped; no component reconditioning permitted.

4. WARRANTY & OPERATIONAL READINESS

- Powertrain: 18 months / 180,000 miles (whichever occurs first) – covers turbo, injectors, transmission bearings

- Chassis/Cabin: 12 months structural integrity guarantee

- All units delivered with:

- Full SAE J1939 diagnostic log

- Paint thickness certification (DeFelsko PosiTest)

- Load-tested chassis report (per AAR S-520)

Refurbished trucks meet 98.3% of new-unit operational metrics (per SEA LION Fleet Performance Database, Q4 2025).

END OF REPORT

SEA LION International – Engineering Integrity, Industrial Scale

Data Source: Columbus OH Refurbishment Center (ISO 9001:2015 Certified)

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Subject: Export Logistics Solutions for Used Trucks from China to Columbus, Ohio

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

Executive Summary

This report evaluates industrial-grade logistics methodologies for the export of used trucks from manufacturing and consolidation hubs in China to inland distribution centers in Columbus, Ohio, USA. With rising demand for cost-effective heavy-duty vehicles in North American construction and transportation sectors, SEA LION International provides a comparative analysis of three primary maritime transport modalities: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack containerized shipping. The report also specifies corrosion mitigation protocols, including wax-based anti-seawater protection systems, essential for preserving asset integrity during trans-Pacific transit.

1. Operational Context

Used trucks exported from China—typically medium-duty (Class 6–7) and heavy-duty (Class 8) vehicles—are often refurbished units from domestic fleets or off-lease contracts. These units are consolidated at major Chinese ports (e.g., Shanghai, Qingdao, Ningbo) for shipment to North America. Columbus, Ohio, serves as a central logistics node due to its intermodal connectivity (I-70/I-71 corridors, rail spurs, and proximity to major distribution hubs).

2. Comparative Shipping Modalities

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Vehicle Compatibility | Ideal for operational trucks; drive-on/drive-off | Suitable for non-operational or disassembled units | Best for oversized, non-standard, or damaged trucks |

| Loading Mechanism | Self-propelled or towed onto vessel decks | Lift-on/lift-off via crane; requires securement on deck or hold | Crane-loaded; lashed to open-frame container |

| Transit Time (China → US West Coast) | 18–24 days | 20–26 days | 22–28 days (including container handling) |

| Inland Transport to Columbus, OH | Requires overland towing from port (e.g., Los Angeles, Long Beach) | Same as RO-RO; rail or heavy-haul trucking | Container rail transport possible via intermodal |

| Cargo Security | Moderate; exposed to deck elements unless covered | Low to moderate; limited structural protection | High; controlled lashings, weather-resistant tarp options |

| Cost per Unit (USD) | $1,800 – $2,400 | $1,500 – $2,000 (for non-running units) | $2,600 – $3,500 |

| Damage Risk | Medium (vibration, salt exposure, deck wash) | High (sway, moisture, improper rigging) | Low (if properly secured) |

| Scalability | High (vessels carry 300–500+ units) | Medium (space-constrained in holds) | Low to medium (limited by container availability) |

| Customs & Documentation | Streamlined for vehicle imports | Standard cargo clearance; may require additional inspection | Full container manifest; ISPM-15 compliance for wood components |

3. Corrosion Protection: Wax Spraying System

Seawater exposure during Pacific transit poses a significant corrosion risk to undercarriages, brake systems, and electrical junctions of used trucks. SEA LION International mandates the application of a marine-grade wax-based anti-corrosion spray as a standard protective measure.

Specification: Wax Spraying Protocol

| Parameter | Specification |

|---|---|

| Product Type | Solvent-based, hydrophobic polymer wax (e.g., DINITROL 449 or equivalent) |

| Application Method | High-pressure spray (200–300 psi) |

| Coverage Areas | Frame rails, suspension components, fuel tanks, exhaust manifolds, wheel hubs, electrical connectors |

| Film Thickness | 30–50 microns (dry) |

| Salt Spray Resistance | ASTM B117 compliant: >1,000 hours |

| Environmental Compliance | VOC-compliant (China GB 38507-2020, US EPA Region 9) |

| Application Location | Pre-shipment facility in China (pre-loading) |

Note: Wax film remains effective for up to 6 months post-application and is removable via industrial degreasing upon arrival.

4. Recommended Solution by Use Case

| Fleet Profile | Recommended Method | Rationale |

|---|---|---|

| Operational, Road-Ready Trucks | RO-RO | Fastest loading, cost-efficient, minimal handling damage |

| Non-Running or Partially Disassembled Units | Bulk Cargo | Lower cost; suitable for lift-based operations |

| Oversized, Custom-Bodied, or Damaged Trucks | Flat Rack | Structural support, secure lashings, intermodal flexibility |

5. Integrated Logistics Pathway (China → Columbus, OH)

- Preparation in China

- Vehicle inspection, minor refurbishment, fuel stabilization

- Wax spraying and undercarriage sealing

-

Documentation: Title, Bill of Lading, Export Declaration, EPA/DOT compliance forms

-

Port Loading

- RO-RO: Drive onto vessel at designated berth

-

Bulk/Flat Rack: Crane operations with certified rigging plans

-

Ocean Transit

- Route: Shanghai → Los Angeles/Seattle (Pacific Northwest)

-

Vessel type: Pure Car and Truck Carrier (PCTC) for RO-RO; multipurpose for others

-

US Port Entry & Customs Clearance

- CBP and U.S. Customs and Border Protection inspection

-

EPA emissions compliance verification (applicable to diesel trucks)

-

Inland Distribution

- RO-RO/Bulk: Heavy-haul transport via I-10/I-40 → I-71 North

- Flat Rack: Rail intermodal (e.g., BNSF/UP) to Columbus I-670 Terminal

6. Conclusion

For fleet managers and construction companies sourcing used trucks from China, RO-RO remains the optimal balance of cost, speed, and reliability for operational units. Flat Rack is advised for non-standard configurations requiring structural integrity, while Bulk Cargo offers economy at the expense of higher risk. Mandatory wax-based corrosion protection is non-negotiable for asset preservation across all modalities.

SEA LION International implements ISO 9001:2015 and ISO 14001-compliant logistics protocols to ensure delivery integrity, regulatory adherence, and lifecycle value retention of exported truck fleets.

End of Report

SEA LION International – Engineering Division

February 2026

Get a Quote for Used Trucks For Sale Columbus Ohio

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]