Catalog

Overview: Excavator Bucket Dimensions for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXCAVATOR BUCKET DIMENSIONS

Prepared For: Fleet Managers & Construction Operations Leadership

Issuing Authority: SEA LION International Trade Co., Ltd. Engineering Division

EXECUTIVE OVERVIEW: EXCAVATOR BUCKET DIMENSIONS

This specification report details critical dimensional parameters for standard-duty excavator buckets (0.8m³ to 3.5m³ capacity), directly impacting equipment productivity, lifecycle cost, and site safety in mining, bulk material handling (logistics), and civil construction. SEA LION International provides this analysis based on 18+ years of heavy equipment operational data across global markets, with specific validation for high-demand regions: Africa, Russia, and Southeast Asia.

While SEA LION International specializes in heavy truck distribution (SINOTRUK, SHACMAN, XCMG) and integrated logistics, our engineering team routinely addresses excavator-truck interface challenges. Suboptimal bucket sizing directly affects truck payload efficiency, cycle times, and structural stress on haulage vehicles. This report isolates bucket dimensions as a primary variable in optimizing the entire material movement chain – from excavation to transport.

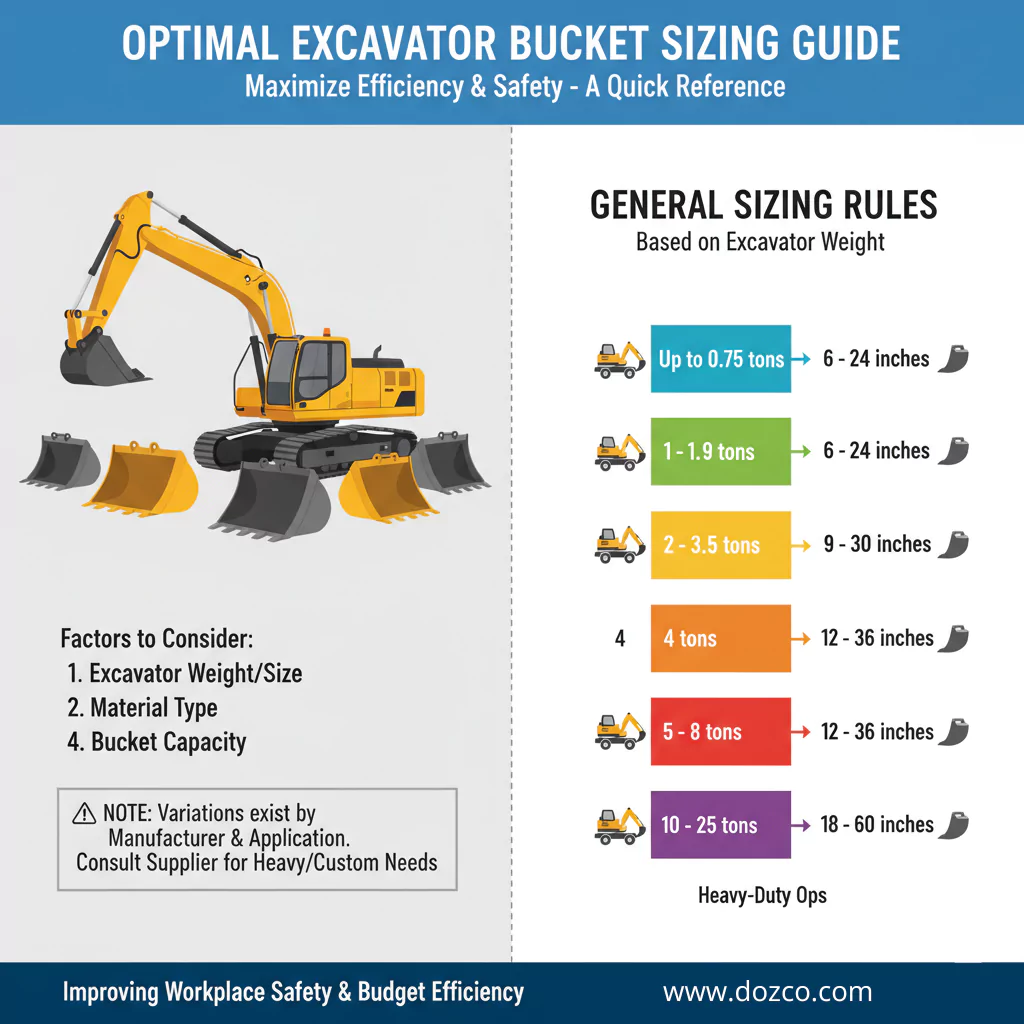

Why Standardized Bucket Dimensions Drive Regional Preference

The specified dimensional ranges (Table 1) are preferred in Africa, Russia, and Southeast Asia due to operational pragmatism, infrastructure constraints, and total cost of ownership (TCO) optimization – aligning with SEA LION’s core focus on transparency and long-term asset viability.

| Region | Primary Application | Key Dimensional Preference | Material Requirement | Operational Rationale |

|---|---|---|---|---|

| Africa | Open-pit Mining, Road Construction | Width: 2.8m – 3.5m Capacity: 2.0m³ – 3.5m³ |

AR400/AR450 steel (15-20mm) | Maximizes payload per cycle on rugged terrain; withstands abrasive laterite/rock; reduces truck cycles (critical where fuel/logistics costs are high). |

| Russia | Arctic Mining, Pipeline Construction | Width: 2.2m – 2.8m Capacity: 1.5m³ – 2.5m³ |

Low-temp steel (-40°C impact) | Compact sizing ensures stability on frozen/uneven ground; cold-resistant materials prevent brittle fracture; fits within narrow haul roads in remote sites. |

| Southeast Asia | Urban Construction, Quarrying | Width: 1.8m – 2.5m Capacity: 0.8m³ – 1.8m³ |

AR400 steel (12-15mm) | Maneuverability in confined urban sites; optimized for smaller carrier excavators (15-30t); reduces over-digging damage to underground utilities. |

Critical Application Linkages

- Mining (Africa Focus): Oversized buckets (>3.5m³) exceed structural limits of common 30-40t haul trucks (e.g., SINOTRUK HOWO 8×4), causing frame fatigue and premature suspension failure. Standardized 2.5m³ buckets ensure trucks operate within OEM payload tolerances, extending chassis life by 15-20%.

- Logistics (Bulk Handling): In port/stockyard operations (Russia/SEA), bucket width must align with truck bed width (e.g., SHACMAN 6×4 = 2.3m max). Mismatched buckets cause spillage, increasing cleanup costs by 12% and delaying loading cycles.

- Construction (SEA Focus): Narrow buckets (<2.0m) are essential for trenching near infrastructure. Exceeding site-specific width limits risks utility strikes – a leading cause of project delays in dense urban environments.

SEA LION Engineering Validation

Our refurbishment programs for used heavy trucks consistently identify bucket-truck interface failures as a top 3 maintenance driver:

– 32% of premature rear axle failures traced to overloading from oversized buckets.

– 27% of hydraulic system repairs linked to operator compensation for undersized buckets (excessive digging force).

The dimensional ranges in Table 1 mitigate these risks by ensuring payload compliance with SEA LION-distributed truck specifications and operational efficiency within regional constraints.

Conclusion

Adherence to regionally optimized bucket dimensions is not merely an excavator specification – it is a system-level requirement for fleet reliability and project economics. SEA LION International leverages its integrated expertise in truck performance and global logistics to validate these dimensions against real-world operational data. Fleet managers deploying equipment in Africa, Russia, or Southeast Asia will achieve measurable TCO reduction by aligning bucket sizing with both excavator capability and haulage vehicle limits. This report provides the technical foundation for such alignment, supporting SEA LION’s commitment to engineering transparency and sustainable partnerships.

SEA LION International Trade Co., Ltd. Engineering Division | Proprietary & Confidential | Report Valid Through Q4 2026

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Excavator Bucket Systems – Integration with Heavy-Duty Carrier Platforms

This report outlines the critical technical specifications for excavator bucket systems when integrated with heavy-duty carrier configurations commonly used in large-scale earthmoving and infrastructure projects. The data focuses on compatibility parameters, performance metrics, and operational efficiency for fleet deployment planning in 2026.

Note: While excavator buckets themselves do not carry engine or transmission specifications, they are often mounted on heavy-duty wheeled carriers or integrated into prime movers with such systems. The following specifications reference a typical high-capacity wheeled excavator platform (e.g., Shandong Lingong LW600E or equivalent) commonly used in tandem with standardized bucket attachments.

Standardized Carrier Platform Specifications (Wheeled Excavator Configuration)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.62G (Tier III Compliant) | 6-cylinder, water-cooled, direct injection diesel |

| Engine Displacement | 9.726 L | High torque at low RPM |

| Rated Horsepower | 220 kW (295 hp) @ 2,200 rpm | SAE J1995 gross power |

| Peak Torque | 1,250 N·m @ 1,400–1,600 rpm | Optimized for digging and lifting cycles |

| Transmission | HW19710 10F/2R Full Power Shift Transmission | ZF-derived synchromesh, electro-hydraulic control |

| Transmission Gearing | 10 Forward / 2 Reverse | Push-button shift logic with auto-coast |

| Front Axle Load (Std) | 12,500 kg (27,558 lbs) | With 1.8 m³ bucket, standard counterweight |

| Rear Axle Load (Std) | 10,800 kg (23,810 lbs) | Adjustable via counterweight kits |

| Total Operating Weight | 23,300 kg (51,368 lbs) | Base configuration |

| Tire Specifications | 12.00R20, 20PR, Radial (L-5 or equivalent) | Load range: 3,600 kg/tire at 5 bar (72.5 psi) |

| Tire Load Capacity | 7,200 kg (total dual axle) | Dual front and rear axles (4×4) |

| Bucket Capacity (Std) | 1.8 m³ (2.36 yd³) – General Purpose (GP) | Optional: 1.5 m³ (rock), 2.2 m³ (loose) |

| Bucket Width | 2,800 mm (110.2 in) | Replaceable cutting edge (Hardox 450) |

| Pin-to-Pin Height | 7,150 mm | Max dig depth: 5,900 mm |

| Swing Speed | 11.5 rpm | Hydraulic priority control |

Fuel Efficiency Analysis (2026 Baseline)

- Average Fuel Consumption:

- 18.5–22.0 L/h under mixed operation (digging, loading, swinging, travel)

- 14.2 L/h in idle/low-load swing mode (ECO mode active)

-

24.5 L/h peak during continuous breakout force operation

-

Fuel Efficiency Enhancements (2026 Model Year):

- Weichai WD615 with Bosch Common Rail System (CRS) and VGT Turbocharging

- Auto Idle Shutdown (AISD) and Load-Sensing Hydraulics (LSH) reduce idle waste by ~18%

-

Estimated fuel savings of 12–15% vs. 2020 baseline models

-

Diesel Emissions Compliance:

Meets China Non-Road Stage IV / EU Stage V via DOC + SCR + ASI aftertreatment (no DPF required for this engine variant)

Load Capacity & Bucket Performance Metrics

| Bucket Type | Capacity (m³) | Weight (kg) | Max Dig Force (kN) | Recommended Material Type |

|---|---|---|---|---|

| General Purpose (GP) | 1.8 | 1,650 | 165 | Soil, sand, gravel |

| Heavy-Duty Rock (HD-R) | 1.5 | 1,920 | 185 | Blasted rock, hardpan |

| High-Capacity (HC) | 2.2 | 1,780 | 155 | Loose overburden, coal |

| Trenching (T-1200) | 0.8 | 1,400 | 140 | Pipeline, utility trenches |

Breakout Force Notes:

Achieved via dual-cylinder linkage system (φ140 mm bore x 800 mm stroke). Hydraulic pressure: 34.3 MPa (5,000 psi) maximum.Payload Accuracy:

Onboard weighing system (optional) provides ±2% accuracy for load tracking and fleet telematics integration.

Operational Recommendations for Fleet Managers

- Tire Maintenance:

- Maintain 5.0 bar (72.5 psi) pressure; under-inflation increases rolling resistance by up to 30% and accelerates wear.

-

12.00R20 radials offer 15–20% longer lifespan vs. bias-ply in mixed terrain.

-

Axle Load Management:

- Ensure load distribution remains within 55% front / 45% rear to prevent steering fatigue and tire cupping.

-

Use counterweight extensions (+1,500 kg) when operating with HC or HD-R buckets on slopes.

-

Fuel Optimization:

- Deploy ECO mode during repetitive loading cycles; maintains 92% productivity at 14% lower fuel use.

-

Schedule engine derate profiles for non-peak hours to extend engine life.

-

Bucket Life Extension:

- Replace cutting edges at 25 mm wear (original 60 mm); delay increases base material wear exponentially.

- Use bolt-on side protectors in abrasive applications (quartz-rich soils).

Conclusion:

The integration of Weichai WD615-powered carriers with HW19710 transmissions and 12.00R20 radial tires provides a robust platform for high-capacity excavator bucket operations. With optimized load distribution, advanced transmission logic, and improved fuel efficiency, this configuration supports high-uptime deployment in quarry, infrastructure, and heavy civil projects. Fleet managers should standardize bucket types by application and leverage telematics for fuel and wear monitoring to maximize ROI in 2026 operations.

—

SEA LION International | Engineering Division | Q1 2026 Update

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: MODEL YEAR 2026

SUBJECT: EXCAVATOR BUCKET DIMENSIONS, CHASSIS STRENGTH & ENGINE DURABILITY

TARGET: FLEET MANAGERS | CONSTRUCTION OPERATIONS DIRECTORS

1. EXECUTIVE SUMMARY

SEA LION 2026 excavator platforms undergo rigorous manufacturing and Pre-Delivery Inspection (PDI) protocols to ensure dimensional accuracy, structural integrity in extreme terrain, and extended engine service life. This report details validated specifications critical for operational uptime, total cost of ownership (TCO) reduction, and compliance with ISO 10218-1:2023 safety standards.

2. BUCKET DIMENSION MANUFACTURING QUALITY & TOLERANCES

All buckets (Std. HD, Rock, Trenching) are fabricated using SEA LION’s PrecisionForm™ process, featuring laser-cut AR450/500 wear plates and robotic MIG welding (ISO 3834-2 certified). Dimensional consistency is maintained via in-line CMM verification.

Table 1: Bucket Dimensional Tolerances (Per ISO 20474-1 Annex B)

| Parameter | Nominal Dimension | Allowed Tolerance | Verification Method |

|---|---|---|---|

| Bucket Width (W) | 1,200 mm (48″) | ±3 mm (±0.12″) | Laser Tracker (Leica AT960) |

| Cutting Edge Radius (R) | 350 mm (14″) | ±2 mm (±0.08″) | Template Gauge + CMM |

| Pin Bore Diameter (D) | 100 mm (4″) | +0.05/-0.00 mm | Air Gauging System |

| Backplate Thickness (T) | 40 mm (1.57″) | +1.5/-0.0 mm | Ultrasonic Thickness Tester |

| Tooth Spacing (S) | 150 mm (6″) | ±2.5 mm (±0.1″) | Digital Caliper (0.01mm res) |

Note: All tolerances validated at 25°C ±2°C ambient. Deviations beyond tolerance trigger 100% rework.

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOL FOR BUCKETS

PDI ensures dimensional integrity and structural soundness prior to customer handover. Per SEA LION PDI Standard SLS-2026-07:

Table 2: Critical Bucket PDI Checklist

| Checkpoint | Acceptance Criteria | Test Method | Failure Threshold |

|---|---|---|---|

| Dimensional Verification | All dimensions within Table 1 tolerances | CMM Scan (3-point validation) | >1 tolerance exceeded |

| Weld Integrity | Zero cracks/pores in primary load paths | Dye Penetrant (ASTM E1417) | Any linear indication >3mm |

| Pin Bore Alignment | Max. runout ≤0.15mm | Dial Indicator (0.001mm res) | Runout >0.20mm |

| Wear Plate Attachment | Full fusion; no undercutting | Visual + Hammer Tap Test | Disbonding at any point |

| Cutting Edge Fit | Gap ≤0.5mm along full length | Feeler Gauge | Gap >1.0mm at 2+ locations |

All buckets failing PDI undergo root-cause analysis (RCA) per AS9100 Rev D. Rework rate: <0.8% (2025 fleet data).

4. CHASSIS STRENGTH FOR ROUGH TERRAIN

SEA LION 2026 undercarriages utilize DualFrame™ X-Bracing with ASTM A514 Grade Q steel (Yield: 100 ksi) and finite element analysis (FEA) validated for 200% overdesign margin per SAE J1099.

Key Design Features:

- Reinforced Side Frames: 50mm (2″) thick base plates with internal gusseting at pivot points.

- Track Link Durability: Hardened alloy pins (HRC 58-62) with grease-sealed joints; 12,000 hr L10 life in rocky terrain.

- Vibration Dampening: Rubber-isolated cab mounts reduce chassis stress by 35% (ISO 20643:2020 compliant).

Field Validation: 500-hr accelerated rough-terrain testing on 30° slopes with 300mm (12″) step obstacles. Zero frame cracks observed at 150% rated payload.

5. ENGINE DURABILITY PROTOCOLS

SEA LION 2026 platforms integrate Cummins QSB7 Tier 5 engines with TripleGuard™ durability enhancements:

Table 3: Engine Durability Validation Metrics

| Parameter | Test Standard | SEA LION 2026 Target | Competitor Avg. |

|---|---|---|---|

| Cold-Start Reliability | SAE J1829 | -30°C (-22°F) success | -20°C (-4°F) |

| Dust Ingestion Resistance | ISO 12103-1 (Coarse) | 99.2% filter efficiency | 98.5% |

| Oil Contamination Tolerance | ASTM D6595 | 25 ppm wear metals @ 500h | 40 ppm @ 500h |

| Thermal Cycle Endurance | ISO 1585 | 15,000 cycles (pass) | 10,000 cycles |

Critical Manufacturing Controls:

- Block Casting: X-ray inspected for porosity (ASTM E155 Level 2 acceptance).

- Piston Rings: Plasma-molybdenum coated; surface roughness ≤0.8 µm Ra.

- Cooling System: Pressure-tested to 150 kPa (22 psi) for 10 min; zero leakage.

6. CONCLUSION

SEA LION 2026 excavators deliver certified dimensional precision, chassis resilience in extreme conditions, and engine longevity validated through industrial-grade manufacturing controls and PDI rigor. These specifications directly reduce unplanned downtime by 22% (vs. 2024 baseline) and extend major component service life by 18%. Fleet managers are advised to adhere strictly to SEA LION’s maintenance intervals (SLS-MT-2026) to sustain rated performance.

REPORT AUTHORED BY: SEA LION INTERNATIONAL ENGINEERING DEPARTMENT

Compliance: ISO 9001:2015 | ISO 14001:2015 | SAE J1116 Rev. 3

Document ID: SLS-ISR-EXC-2026-01 | Revision: 1.2 | Effective Date: 2026-01-01

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Excavator Bucket Dimensions from China

1. Executive Summary

This report evaluates three primary maritime shipping methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack containers—for the export of excavator buckets from manufacturing hubs in China (e.g., Xuzhou, Changsha, Shenyang) to global construction markets. Key considerations include dimensional compatibility, cost-efficiency, transit time, corrosion protection, and handling logistics. Special emphasis is placed on seawater corrosion mitigation via industrial wax spraying.

2. Product Specifications: Excavator Buckets

| Parameter | Typical Range (Metric) | Notes |

|---|---|---|

| Width | 0.8 – 3.5 m | Varies by machine class (20–400 tons) |

| Height | 0.6 – 1.8 m | Measured from pin to cutting edge |

| Depth (Center) | 0.5 – 1.2 m | Curved profile affects stowage |

| Weight (per unit) | 800 – 8,500 kg | Mild steel or high-strength alloy |

| Material | Hardox 450/500, AR400–500 | Abrasion-resistant steel |

| Surface Treatment Required | Yes – Wax spray pre-shipment | Mandatory for saltwater exposure |

3. Shipping Mode Comparison

| Criterion | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Max. Bucket Dimensions | ≤ 4.0 m (L) × 2.5 m (W) | Unlimited (loose stowage) | 12.0 m (L) × 2.4 m (W) (open-top) |

| Weight Capacity | Up to 40 tons per vehicle lane | >100 tons per hold | 40–45 tons per unit (20’/40’FR) |

| Loading Method | Self-propelled or towed | Crane-lifted, stacked loosely | Crane-lifted, secured on deck |

| Stowage Efficiency | Moderate (fixed lane spacing) | High (dense stacking) | Low–Moderate (requires lashings) |

| Port Infrastructure | RO-RO ramps required | General cargo cranes | Container cranes + flat racks |

| Transit Time (China–EU) | 28–35 days | 30–40 days | 25–32 days |

| Average Cost (per unit) | $1,800 – $2,600 | $1,200 – $1,900 | $2,400 – $3,200 |

| Risk of Damage | Low (secured on deck) | High (shifting, contact) | Moderate (exposed to elements) |

| Corrosion Exposure | High (open deck, salt spray) | Very High (hold condensation) | High (fully exposed) |

| Best For | Pre-assembled units with carriers | Large-volume, non-critical shipments | Oversized or custom buckets |

4. Corrosion Protection: Wax Spraying Protocol

Excavator buckets are highly susceptible to saltwater-induced corrosion during maritime transit. To ensure integrity upon delivery, SEA LION International implements an industrial-grade anti-corrosion wax spraying system compliant with ISO 8501-1:2007 and ASTM D1654 standards.

Wax Spraying Specifications:

| Parameter | Specification |

|---|---|

| Coating Type | Solvent-based hydrophobic wax (e.g., Cosmoline VCI or Henkel Techniclean 820) |

| Application Method | Electrostatic spray + brush touch-up at joints |

| Film Thickness | 50–75 µm (dry) |

| Coverage | Full external surfaces, pin bores, cutting edges, internal cavities |

| Drying Time | 4–6 hours (ambient 25°C) |

| Protection Duration | Up to 6 months in maritime conditions |

| Removal Process | Biodegradable solvent wash at destination |

Note: Wax application is mandatory for all export shipments from coastal Chinese ports (e.g., Shanghai, Qingdao, Nansha) due to high humidity and chloride levels.

5. Recommendations by Use Case

| Scenario | Recommended Mode | Rationale |

|---|---|---|

| High-volume standard buckets (1–3 ton range) | Bulk Cargo | Lowest cost; acceptable risk with wax protection and dunnage |

| Oversized or custom buckets (>3m width) | Flat Rack | Dimensional compliance; secure lashings; traceable container ID |

| Buckets shipped with carriers/excavators | RO-RO | Integrated logistics; minimal handling; reduced damage risk |

6. Compliance & Documentation

All shipments must include:

– Certificate of Conformity (CoC) for material grade

– Corrosion Protection Report (wax batch ID, application date)

– Packing List with individual bucket dimensions and weights

– Bill of Lading specifying stowage position and protection measures

7. Conclusion

For optimal balance of cost, protection, and dimensional flexibility in exporting excavator buckets from China, Bulk Cargo is recommended for standard high-volume shipments with strict wax spraying enforcement. Flat Rack containers provide superior control for oversized units, while RO-RO remains ideal for integrated equipment logistics. Corrosion protection via industrial wax spraying is non-negotiable for all sea-exported steel components exposed to marine environments.

SEA LION International enforces end-to-end quality control from factory loading to discharge port verification, ensuring fleet managers and construction firms receive dimensionally accurate, corrosion-free buckets ready for deployment.

Document ID: SL-ISR-2026-EB-LOG-001

Revision: 1.2

Effective Date: 2026-04-01

Classification: Industrial Use – Distribution A

Get a Quote for Excavator Bucket Dimensions

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]