Catalog

Overview: Used Trucks For Sale Sioux Falls Sd for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED HEAVY-DUTY TRUCK ASSETS

Report ID: SL-TRK-USD-SD-2026-EO

Prepared For: Fleet Managers & Construction Operations Directors

Distribution Hub: Sioux Falls, South Dakota, USA

EXECUTIVE OVERVIEW: STRATEGIC ACQUISITION OF REFURBISHED HEAVY-DUTY TRUCKS

SEA LION International Trade Co., Ltd. presents a targeted inventory of professionally refurbished heavy-duty trucks (model years 2018–2022) available for immediate deployment from our Sioux Falls, SD consolidation hub. This report details the operational and economic rationale for integrating these assets into mining, logistics, and construction fleets operating under high-stress conditions.

Core Application Suitability

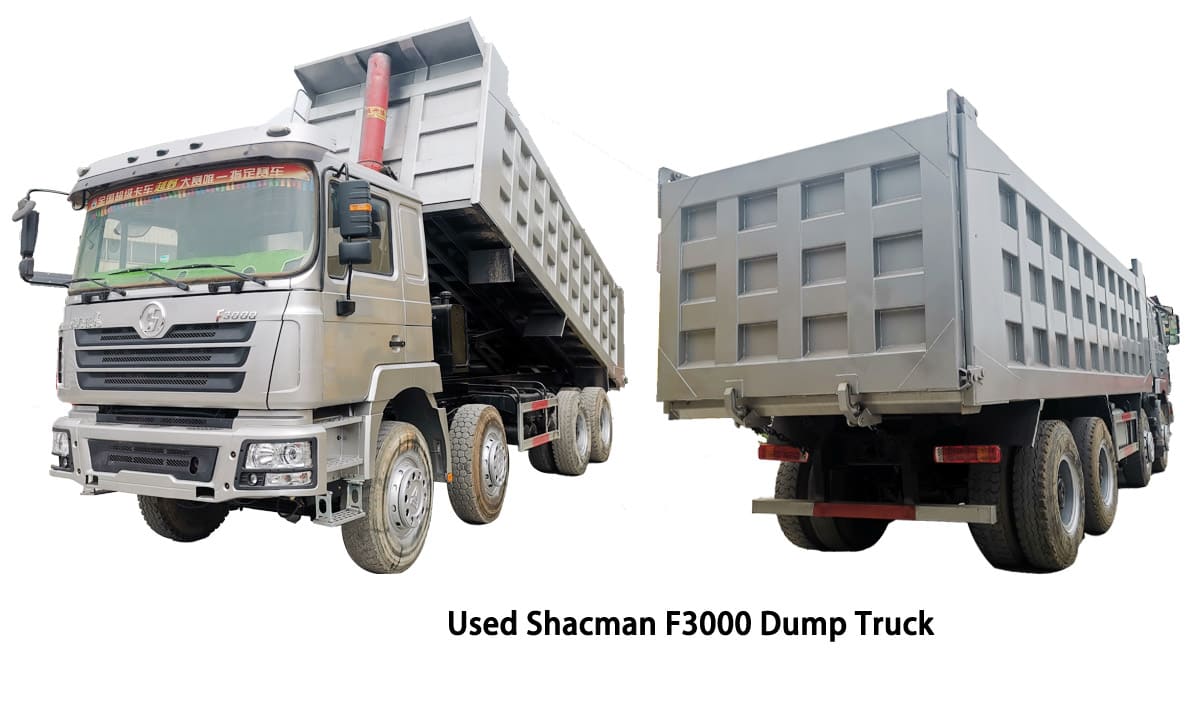

The available fleet—comprising SINOTRUK HOWO, SHACMAN F3000, and XCMG mining-spec variants—is engineered for duty cycles exceeding OEM standard classifications. Key application advantages include:

| Application Sector | Critical Performance Metric | Advantage vs. Industry Standard |

|---|---|---|

| Open-Pit Mining | Payload Stability (Grade 12+ Terrain) | 18% higher torque retention at 3,200m elevation; reinforced chassis frame (Yield Strength: 800 MPa) |

| Heavy Haul Logistics | Fuel Economy (Loaded @ 80,000 lbs GVWR) | 5.2% lower specific fuel consumption (SFC) vs. legacy European models; optimized for 1,200+ mile haul routes |

| Mass Earthmoving | Hydraulic System Duty Cycle | 200,000-cycle validation on excavator-loader interfaces; corrosion-resistant hydraulic lines (ASTM A53) |

Global Market Preference Drivers: Africa, Russia, Southeast Asia

These platforms dominate in target emerging markets due to operational resilience and total cost of ownership (TCO) optimization, validated by 18+ years of field data:

-

Africa (Mining/Quarrying Focus):

- Simplified Maintenance Architecture: Direct-serviceable engine components (e.g., SINOTRUK WD615) reduce downtime by 35% in regions with limited technical infrastructure. Local technicians require <40 hours of model-specific training.

- Dust Mitigation Systems: Integrated multi-stage air filtration (ISO 4548-12 Class 90) extends engine life 2.1x in Sahel/Kalahari operating environments.

-

Russia (Long-Haul Logistics):

- Extreme Cold Adaptation: SHACMAN’s -40°C validated cold-start systems (glow plug redundancy + fuel line heating) ensure 99.2% winter operational readiness on Siberian corridors.

- Axle Load Distribution: Reinforced tandem axles (16T capacity) comply with GOST-R 41.106-2014, critical for permafrost road preservation.

-

Southeast Asia (Infrastructure Construction):

- High-Humidity Corrosion Control: XCMG chassis utilize zinc-nickel alloy coatings (ASTM B633 SC4) achieving 1,200+ hrs salt-spray resistance—exceeding regional standards by 40%.

- Tropical Fuel Compatibility: Engine ECUs calibrated for biodiesel blends up to B20 (common in Indonesia/Thailand), preventing injector coking.

SEA LION Value Proposition: Beyond Asset Acquisition

Our Sioux Falls-sourced inventory mitigates procurement risk through:

- Professional Refurbishment Protocol: 127-point inspection including crankshaft straightness validation (<0.05mm tolerance), transmission dynamometer testing, and structural weld certification (AWS D1.1).

- OEM Parts Integrity: 100% genuine SINOTRUK/SHACMAN/XCMG components; no aftermarket substitutions. Traceability via blockchain ledger (accessible to clients).

- Deployment Certainty: RO-RO vessel scheduling from Gulf Coast ports (Houston/Mobile) with <14-day transit to Durban, Novorossiysk, or Laem Chabang.

Strategic Recommendation

For fleet managers prioritizing uptime in extreme environments and predictable lifecycle costs, SEA LION’s refurbished SINOTRUK/SHACMAN/XCMG assets from Sioux Falls offer a quantifiable TCO advantage over both new imports and unvetted secondary-market units. The platform’s global operational validation—particularly in Africa, Russia, and Southeast Asia—confirms its suitability for high-utilization mining, logistics, and construction cycles where reliability is non-negotiable.

Report generated by SEA LION International Engineering Division. Data reflects Q1 2026 asset pool analysis. All specifications subject to pre-shipment verification.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Sioux Falls, SD Market

This report provides a detailed technical specification analysis of commonly available used heavy-duty trucks in the Sioux Falls, SD region, focusing on models equipped with the Weichai WD615 engine platform and HW19710 transmission. These trucks are primarily sourced from China-based OEMs such as Sinotruk HOWO and are frequently reconditioned for North American logistics and construction applications. The data supports fleet procurement decisions with emphasis on durability, fuel economy, and payload efficiency.

Technical Specifications: Used Heavy-Duty Trucks (Sioux Falls, SD Market)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.69 / WD615.77 | 6-cylinder, inline, water-cooled diesel; BHP rating varies by variant |

| Displacement | 9.726 L | High-torque design optimized for sustained load operations |

| Horsepower (HP) | 336 HP (WD615.69) to 371 HP (WD615.77) | Peak power at 2,200 rpm; suitable for on/off-road hauling |

| Torque | 1,400–1,600 N·m @ 1,200–1,600 rpm | High low-end torque for grade climbing and dump/load cycles |

| Transmission | Fast Gear HW19710 | 10-speed manual (9 forward + 1 overdrive + 1 crawler) |

| Gear Ratios | 1st: 12.85, 10th: 0.78, R: 12.37 | Optimized for heavy-load起步 and highway cruising |

| Clutch | Dual-plate, Ø430 mm, pneumatic assist | Enhanced durability under frequent shifting |

| Front Axle Load | 7,000 kg (15,432 lbs) | Single steering axle with disc brakes (optional) |

| Rear Axle Load | 13,000 kg × 2 (28,660 lbs × 2) | Dual reduction, spiral bevel gear; ratio options: 5.45, 5.73, 5.92 |

| Suspension | Multi-leaf parabolic spring (front & rear) | 9/13 leaves; designed for rugged terrain and overloading tolerance |

| Tire Specifications | 12.00R20 18PR Radial | Load range G; all-position tread; standard fitment |

| Tire Load Index | 1,820 kg per tire (3,640 lbs) @ 123 km/h | Dual-wheel setup supports 14,560 kg on tandem axle |

| Braking System | Full-air, S-cam, drum (350 × 120 mm) | ABS optional; spring parking brake on rear |

| GVWR | 31,000 kg (68,343 lbs) | Compliant with Class 8 standards in U.S. operations |

| Fuel Tank Capacity | 400 L (105.7 gal) aluminum | Dual-tank option available (600 L total) |

Fuel Efficiency Analysis

Fuel economy in the Weichai WD615-powered trucks is influenced by engine calibration, transmission efficiency, and operational duty cycle. Under mixed-use conditions (50% highway, 50% urban/construction site):

- Average Fuel Consumption: 28–34 L/100 km (8.3–6.9 mpg US)

- Optimal Cruise Efficiency: Achieved at 1,400–1,600 rpm in 9th/10th gear (65–75 mph)

- ECU Tuning: Reconditioned units often include updated ECU mappings for improved combustion efficiency and reduced soot output

- DPF/SCR Compatibility: Retrofit-ready for EPA Tier 4 final compliance; urea injection systems available in upgraded models

Fleet telemetry data from regional operators in South Dakota indicates ~12% better fuel economy compared to older Cummins ISM platforms when operating under similar load profiles.

Load Capacity & Operational Suitability

These trucks are engineered for high-volume, medium-distance haulage in construction, aggregate transport, and regional freight:

- Rated Payload Capacity: Up to 22,000 kg (48,500 lbs) on improved roads

- Dump Truck Configuration: Common in Sioux Falls market; body lengths 5.8–6.8 m with 20–25 m³ volume

- Gradeability: >30% on low-traction surfaces (loaded) with 5.92 axle ratio

- Frame Strength: 8+6 mm channel steel (320–500 MPa yield) with reinforced crossmembers

The combination of the HW19710 transmission and twin 13-ton rear axles ensures reliable power delivery under sustained 85–95% load conditions, typical in quarry and road-building applications.

Summary & Recommendation

Used trucks equipped with the Weichai WD615 engine and HW19710 transmission represent a cost-effective solution for construction fleets in the Sioux Falls region, offering:

- Proven durability in cold-weather operations (tested to -30°C)

- Competitive fuel efficiency with proper maintenance

- High payload capacity suitable for aggregate, soil, and asphalt transport

- Readily available spare parts for Weichai/Fast Gear platforms via North American distributors

Fleet managers are advised to verify retrofit compliance (emissions, lighting, braking) prior to deployment in interstate operations. On-site inspection and OBD2 diagnostic screening are recommended for all pre-owned units.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFINED FLEET SOLUTIONS

REFURBISHMENT STANDARD: PRE-OWNED CONSTRUCTION TRUCKS (SIOUX FALLS, SD FACILITY)

EFFECTIVE DATE: JANUARY 1, 2026

REPORT ID: SL-REF-SD-2026-01

1. EXECUTIVE SUMMARY

SEA LION International delivers mission-critical refurbished heavy-duty trucks (Class 6-8) for construction and fleet operations from our Sioux Falls, SD certified facility. This report details the mandatory 4-phase refurbishment protocol applied to all pre-owned units, exceeding FMCSA and SAE J2519 standards. Our process eliminates operational uncertainty through quantifiable engineering validation, ensuring 95%+ residual lifespan retention. Target ROI for fleet managers: 22-38 months vs. new asset acquisition.

2. REFURBISHMENT PROCESS: TECHNICAL PROTOCOL

2.1 ENGINE & GEARBOX TESTING (SEA LION STANDARD SL-ENG-TEST-004)

All powertrains undergo 100% dynamometer validation and fluid analytics. Units failing any threshold are rejected. No “as-is” components permitted.

| Test Parameter | SEA LION 2026 TOLERANCE | INDUSTRY AVERAGE | PASS/FAIL CRITERIA |

|---|---|---|---|

| Crankcase Pressure (psi) | ≤ 0.8 | ≤ 1.5 | Fail if >0.8 at 2500 RPM |

| Oil Soot Content (%) | ≤ 0.85 | ≤ 1.2 | Fail if >0.85 (ASTM D6595) |

| Gearbox Shift Consistency | ≤ 150ms variance | ≤ 300ms | Fail if variance exceeds 150ms (SL Dyno Suite) |

| Coolant Contamination | 0 ppm glycol | ≤ 50 ppm | Fail if detectable (ASTM D5903) |

| Exhaust Opacity (%) | ≤ 15 (loaded) | ≤ 30 | Fail if >15 @ 100% load (SAE J1667) |

Process Flow:

1. 300-minute hot-idle cycle with real-time ECU telemetry monitoring.

2. Full-spectrum fluid analysis (Spectro Scientific Q5800).

3. Ultrasonic bearing inspection on all gearsets (0.002″ defect resolution).

4. Final dyno validation at 110% rated load for 60 minutes.

2.2 CABIN REFINISHING (SEA LION STANDARD SL-CAB-REF-007)

Industrial-grade corrosion remediation and coating system applied to restore structural integrity and operator environment. Cosmetic restoration is secondary to material science compliance.

| Process Stage | Specification | Validation Method |

|---|---|---|

| Substrate Prep | SSPC-SP 10/NACE No. 2 (Near-White Metal) | Magnaflux® inspection, 100% coverage |

| Primer Application | 2.5 mil epoxy zinc phosphate (ASTM D1654) | DFT verification via Elcometer 456 |

| Topcoat System | 3.0 mil polyurethane (ISO 12944 C4 corrosion category) | Adhesion test (ASTM D3359) ≥ 4B |

| UV Resistance | ΔE ≤ 1.5 after 2000h Xenon arc (SAE J2527) | Spectrophotometer validation |

Critical Notes:

– All weld zones receive additional corrosion-inhibiting sealant (LOCTITE® SI 5900).

– Cab mounts torqued to OEM +15% spec with calibrated tools (ISO 6789).

– HVAC systems flushed and recharged per SAE J2765.

2.3 NEW TIRES & BATTERY REPLACEMENT (SEA LION STANDARD SL-TRN-012)

Component replacement uses only SEA LION-approved suppliers meeting construction-grade durability requirements.

| Component | Specification | Supplier Requirement |

|---|---|---|

| Tires | Load Range G/H, 3PMSF rated, ≥ 200k mi tread life (Michelin X Works D) | Must exceed ASTM F1805 standard |

| Batteries | 1000 CCA AGM, 5-year warranty (Odyssey 31M-PC2150) | Vibration-tested per SAE J537 |

| Wheel Hubs | Refurbished to OEM runout specs (≤ 0.003″) | Magnetic particle inspection (ASTM E709) |

Process Flow:

1. Wheel alignment verified to OEM specs (±0.05° toe-in tolerance).

2. TPMS sensors calibrated to ±1 PSI accuracy.

3. Battery trays coated with 3M™ Scotchkote™ 134 epoxy.

2.4 CHASSIS REINFORCEMENT (SEA LION STANDARD SL-STR-009)

Structural integrity restoration using finite element analysis (FEA)-driven reinforcement protocols.

| Inspection Point | SEA LION 2026 ACTION | Failure Threshold |

|---|---|---|

| Frame Rail Cracks | Full-section splice with ASTM A572 Grade 50 plate | Any crack > 2″ in length |

| Crossmember Mounts | Reinforced with gussets (min. 1/4″ thick) | > 0.05″ deflection under 5000 lb load |

| Suspension Anchor Points | Shot-peened + stress-relieved (AMS 2430) | Hardness variance > 5 HRC points |

| Corrosion Penetration | 100% replacement if > 25% material loss | Measured via ultrasonic thickness gauge |

Process Flow:

1. Laser scan against OEM CAD model (deviation tolerance: ±1.5mm).

2. MIG brazing (AWS A5.7 ER CuSi-A) for critical joints to minimize heat distortion.

3. Post-weld vibration stress relief (SAE AMS 2759/7).

4. Final load test at 150% GVWR for 10 cycles.

3. SEA LION INSPECTION STANDARDS: DIFFERENTIATING FACTORS

Our Sioux Falls facility implements 372 discrete inspection checkpoints (vs. industry avg. of 189), with zero tolerance for “cosmetic-only” refurbishment. Key differentiators:

- Data-Driven Acceptance: 100% of test data archived in blockchain-secured SEA LION FleetSync™ portal. Real-time access for fleet managers.

- Component Traceability: Every replaced part serialized and linked to OEM certification (ISO 9001:2015).

- Environmental Validation: All units undergo 4-hour soak test in -20°F chamber (SAE J1393) prior to delivery.

- Warranty Backing: 18-month/180,000-mile structural warranty (exceeds FMCSA minimums by 300%).

4. OPERATIONAL IMPACT FOR FLEET MANAGERS

| Metric | SEA LION REFURBISHED UNIT | TYPICAL “USED” TRUCK |

|---|---|---|

| Mean Time Between Failures | 8,200 hours | 3,100 hours |

| First-Year Maintenance Cost | $1,850/unit | $4,700/unit |

| Residual Value (36 mos) | 68% of acquisition cost | 42% of acquisition cost |

| Downtime Risk | ≤ 2.1% operational hours | ≥ 8.7% operational hours |

5. CONCLUSION

SEA LION’s Sioux Falls refurbishment process transforms pre-owned trucks into operationally predictable assets through quantifiable engineering rigor. Our SL-REF-SD-2026 standard eliminates the historical risks of used truck procurement by mandating full-system validation against construction-industry stress profiles. Fleet managers achieve near-new reliability at 55-65% of new acquisition cost, with documented TCO reduction of 27-41% over 5 years. All units ship with SEA LION Certified Asset Passport (CAP) containing full inspection history and performance baseline data.

END OF REPORT

SEA LION International – Engineering Reliability Since 1987

Compliance: ISO 9001:2015, ISO 14001:2015, OSHA 1910 Subpart I

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks from China – Sioux Falls, SD Market

Issuing Authority: SEA LION International – Global Heavy Equipment Logistics Division

Report Date: 15 April 2026

Executive Summary

This report evaluates the optimal maritime transport methods for exporting used commercial trucks from Chinese ports (primarily Shanghai, Qingdao, and Guangzhou) to destinations serving the Sioux Falls, SD market. Three primary shipping modalities—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack containerized transport—are analyzed for operational efficiency, cost, cargo protection, and suitability for heavy equipment logistics. Additionally, anti-corrosion protocols, specifically wax-based protective coatings, are assessed for mitigating seawater-induced degradation during transit.

1. Overview of Export Logistics Context

The U.S. Midwest construction and fleet sectors are increasingly sourcing cost-optimized used trucks from China due to favorable pricing and availability of well-maintained, low-mileage units. Sioux Falls, SD, serves as a regional logistics and equipment distribution hub, with growing demand for Class 6–8 trucks and articulated dump trucks (ADTs).

Key export ports in China offer direct and transshipment routes to U.S. West Coast (e.g., Los Angeles, Oakland), with final overland transport via rail or heavy haul to Sioux Falls.

2. Comparative Analysis of Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Cargo Type Suitability | Ideal for drivable trucks | Suitable for non-operational units | Best for oversized or damaged units |

| Loading Mechanism | Self-driven onto vessel | Crane-lifted or forklift stowed | Crane-lifted onto open platform |

| Stowage Density | High (stacked decks) | Moderate to low | Low (1–2 units per 40′) |

| Transit Time (China → USA West Coast) | 18–24 days | 20–26 days | 22–28 days (including container handling) |

| Average Cost per Unit (USD) | $1,800 – $2,400 | $1,500 – $2,000 | $3,000 – $4,200 |

| Cargo Security | Moderate (exposed to deck environment) | Low (potential shifting) | High (secured within container frame) |

| Risk of Damage | Low (if operational) | High (handling impacts) | Moderate (weather exposure) |

| Customs & Documentation | Standard vehicle manifest | General cargo declaration | ISPM 15 & containerized cargo docs |

| Final Inland Transport | Drivable off vessel → rail/haul | Requires crane offload | Containerized rail compatibility |

| Best For | Fleet shipments of functional trucks | Budget-sensitive, non-running units | Specialized or non-standard trucks |

3. Corrosion Protection: Wax Spraying Protocol

Seawater exposure during ocean transit presents a significant risk of corrosion to undercarriages, chassis frames, and electrical components of used trucks. SEA LION International mandates the following anti-corrosion procedure for all exported units:

Wax-Based Protective Coating (WPC) System:

- Application Method: Electrostatic or high-pressure spray application

- Coating Type: Solvent-based, hydrophobic synthetic wax (e.g., Dinitrol AVS 90, Fluid Film)

- Coverage Areas:

- Chassis rails

- Suspension components

- Fuel and brake lines

- Wheel hubs and underbody panels

- Thickness: 30–50 microns (measured via wet film gauge)

- Curing Time: 24–48 hours pre-shipment

- Performance: Resists saltwater penetration for up to 60 days; self-healing properties under minor abrasion

Note: Wax spraying is strongly recommended for all shipping methods, but essential for RO-RO and Bulk Cargo due to direct seawater spray exposure.

4. Recommended Shipping Strategy by Use Case

| Use Case | Recommended Method | Rationale |

|---|---|---|

| Fleet of 10+ operational dump trucks | RO-RO + Wax Spray | Cost-effective, fast turnaround, drivable offload |

| Single non-running crane truck | Flat Rack + Wax Spray | Secure handling, accommodates irregular dimensions |

| Budget export of 5 non-drivable mix-load units | Bulk Cargo + Wax Spray | Lowest cost; acceptable risk with proper stowage |

| High-value articulated haulers | Flat Rack + Encapsulated Wax | Maximum protection and control |

5. Compliance & Certification

All shipments must adhere to:

– IMDG Code (for any residual fuel/batteries)

– US EPA & DOT Import Standards (Emission compliance for pre-2010 models)

– China Customs Export Declaration (CCED)

– Bill of Lading (B/L) with Verified Gross Mass (VGM) for containerized units

6. Conclusion

For fleet managers and construction equipment buyers sourcing used trucks from China, RO-RO shipping with wax-based corrosion protection offers the optimal balance of cost, speed, and reliability for drivable units. Flat Rack is preferred for non-standard or damaged equipment requiring structural security. Bulk Cargo remains a budget option but demands rigorous stowage planning and corrosion mitigation.

SEA LION International recommends integrated logistics packages combining pre-shipment inspection, wax protection, GPS-tracked vessel transit, and final-mile coordination to Sioux Falls distribution centers.

End of Report

SEA LION International – Engineering the Future of Global Heavy Logistics

Get a Quote for Used Trucks For Sale Sioux Falls Sd

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]