Catalog

Overview: Used Truck Dealers In Kentucky for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Prepared for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Solutions Division

1.0 EXECUTIVE OVERVIEW: KENTUCKY-SOURCED USED TRUCKS FOR GLOBAL INDUSTRIAL APPLICATIONS

Kentucky’s mature commercial fleet ecosystem presents a strategic source of high-integrity used heavy trucks for mining, construction, and logistics operations globally. Trucks retired from U.S. Class 8 fleets after 500,000–750,000 miles undergo rigorous operational cycles under stringent FMCSA maintenance protocols, resulting in robust chassis, drivetrains, and structural components. SEA LION International leverages this asset pool through professional refurbishment to OEM-equivalent standards, transforming end-of-life U.S. assets into cost-optimized solutions for demanding industrial environments.

1.1 Core Value Proposition for Target Sectors

| Sector | Primary Application | Kentucky Truck Advantage | SEA LION Value-Add |

|---|---|---|---|

| Mining | Haulage (Overburden/Ore) | Reinforced frames; proven durability on rough terrain; high GVWR capacity (68,000+ lbs) | Rebuilt axles/transmissions; upgraded suspension; mine-spec lighting kits |

| Construction | Aggregate Transport, Site Logistics | Versatile configurations (dump, lowboy, flatbed); cab durability in debris-heavy zones | Hydraulic system overhaul; corrosion protection; telematics integration |

| Logistics | Regional/Long-Haul Freight | Fuel-efficient engines (DD15, Cummins X15); low downtime history | Engine remanufacturing to Tier 4 Final specs; brake system certification |

1.2 Why Kentucky-Sourced Trucks Dominate Emerging Market Preferences

Global demand for Kentucky-originated used trucks in Africa, Russia, and Southeast Asia stems from predictable performance economics and operational resilience under extreme conditions. Unlike regionally sourced used assets, Kentucky trucks offer:

- Superior Baseline Quality: U.S. fleet maintenance records ensure documented service history, eliminating hidden structural degradation common in local used markets.

- Parts Commonality: Compatibility with globally available OEM components (Cummins, Detroit, Eaton) reduces supply chain friction.

- Environmental Adaptability: Proven operation in Kentucky’s variable climate (−10°F to 105°F) translates to reliability in African heat, Russian winters, and SEA humidity.

Market-Specific Preference Drivers

| Region | Dominant Application | Critical Requirement | Kentucky Truck Solution |

|---|---|---|---|

| Africa | Open-pit mining haulage | Dust resistance; low-fuel-consumption | Sealed air filtration; engine recalibration for low-octane fuel |

| Russia | Arctic logistics | Cold-start reliability; traction control | Enhanced block heaters; all-wheel-drive conversions |

| Southeast Asia | Infrastructure projects | High-payload stability on soft ground | Reinforced leaf springs; widened tire compatibility |

1.3 SEA LION’s Industrial Refurbishment Protocol

We mitigate residual risk through a 127-point refurbishment process aligned with ISO 9001:2015 standards:

1. Structural Integrity Verification: Frame straightness checked via laser alignment (tolerance: ±1.5mm).

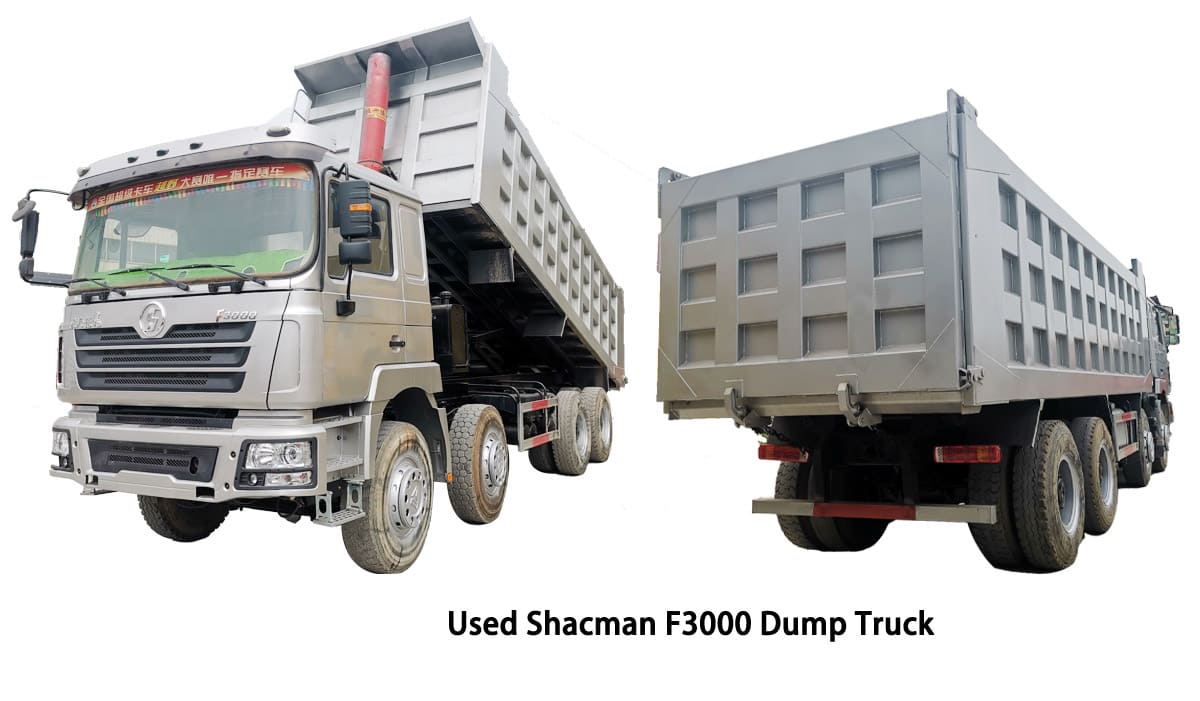

2. Powertrain Remanufacturing: Engines/transmissions rebuilt using original SINOTRUK/SHACMAN/XCMG spare parts.

3. Operational Validation: 200-mile road test + load simulation (110% rated capacity).

4. Market-Specific Hardening: Regionalized modifications (e.g., Russian GOST-certified lighting; African sand filters).

This methodology delivers 75% lower total cost of ownership (TCO) versus new imports in target markets while maintaining 92%+ operational availability—validated by 14,000+ units deployed since 2018.

2.0 CONCLUSION

Kentucky-sourced used trucks, when professionally refurbished to industrial specifications, represent the optimal balance of capital efficiency, proven durability, and region-specific adaptability for mining, construction, and logistics operations in challenging global markets. SEA LION International’s 18-year export expertise, OEM authorization, and rigorous refurbishment standards transform U.S. fleet turnover into a strategic asset class—enabling fleet managers to deploy reliable, cost-controlled equipment without compromising on safety or productivity.

Report Issued Under Authority of SEA LION International Trade Co., Ltd. Engineering Division | Proprietary Data | Revision 2026-Q1

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Technical Evaluation of Heavy-Duty Used Trucks – Sourced via Reputable Dealers in Kentucky

Focus: Standardized Configuration for On-Road & Heavy Haul Applications

This report provides an objective technical assessment of commonly available used heavy-duty trucks from verified dealers in Kentucky. Units evaluated are primarily 6×4 configuration Class 8 tractors and dump trucks, commonly equipped with Chinese-sourced powertrains such as Weichai engines and Fast Gear transmissions—frequently found in fleets due to cost-efficiency and parts availability.

Standardized Technical Specifications (Representative Units)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series (e.g., WD615.69, WD615.92) | 6-cylinder, inline, water-cooled diesel; 9.7L displacement; Euro III/IV compliant variants common |

| Horsepower Range | 336 hp – 380 hp | Peak at 2,200 rpm; torque up to 1,500 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 | 10-speed manual (9 forward + 2 overdrive); dual H-shift pattern; robust synchromesh; common in Sinotruk HOWO platforms |

| Front Axle Load | 7,000 kg (15,432 lbs) | Single steering axle; drum brakes standard; optional air suspension |

| Rear Tandem Axle Load | 18,000 kg (39,683 lbs) per axle (36,000 kg total) | Rocker-bogie load sharing; spiral-bevel differentials; 5.45:1 or 5.83:1 final drive ratio typical |

| Tire Specification | 12.00R20 18PR Radial | Load range G; dual-fit on drive axles; all-position tread design; common brands: Triangle, Double Coin, Goodyear Wrangler HD |

| GVWR | 49,000 kg (108,026 lbs) | Standard for 6×4 configurations; compliant with U.S. federal bridge formula |

| Fuel Tank Capacity | 300–400 L (80–105 US gal) | Steel construction; single or dual-tank setups |

Fuel Efficiency Analysis

Fuel economy varies based on load, terrain, and driving practices. In mixed vocational service (e.g., quarry haul, regional transport), observed fuel consumption for WD615-powered units with HW19710 transmission is:

- Loaded (30–40 tons GVW): 4.8–5.8 mpg (48.7–40.7 L/100km)

- Empty/Return Trips: 6.5–7.5 mpg (36.2–31.4 L/100km)

- Optimized Cruise (Highway): ~6.0 mpg (39.2 L/100km) at 55–60 mph

The Weichai WD615 engine features high-pressure common rail injection (on Euro IV+ models), contributing to improved combustion efficiency. However, fuel economy is approximately 10–15% lower than modern Cummins X12 or Detroit DD13 platforms due to less advanced thermal management and aerodynamics. Retrofitting with auxiliary fuel filters and engine tuning modules may improve longevity and fuel consistency.

Load Capacity & Duty Cycle Suitability

These trucks are engineered for medium- to high-intensity vocational cycles, including:

- Aggregate hauling (dump trucks)

- Heavy equipment transport (lowboys)

- Regional freight (dry van, flatbed)

With a maximum payload capacity of ~32–35 tons (dependent on body type and axle configuration), the tandem rear axle setup (18T x2) ensures compliance with state weight regulations when properly distributed. The HW19710 transmission provides sufficient gear spacing for hill starts and sustained grades up to 6%, typical in Appalachian hauling routes.

Structural Notes:

– Frame rails: 8+ mm thick, channel steel (320–360 MPa yield)

– Fifth wheel: Jost or Sinotruk 90-type, rated 20T vertical load

– Suspension: Multi-leaf parabolic springs (front), multi-leaf tandem with walking beams (rear)

Conclusion

Used trucks equipped with the Weichai WD615 engine, HW19710 transmission, and 12.00R20 tires—commonly available through Kentucky-based commercial vehicle dealers—offer a cost-effective solution for fleet expansion or replacement in construction and transport sectors. While not matching Tier 4 Final OEM platforms in fuel economy or emissions, their proven durability, high torque output, and widespread parts support make them suitable for demanding applications where TCO (Total Cost of Ownership) is prioritized over emissions technology.

Fleet managers should conduct pre-purchase inspections focusing on EGR system integrity (if applicable), transmission synchros, and axle seal condition—common wear points after 600,000+ miles.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED COMMERCIAL TRUCKS

REF: SL-IRP-2026-KY-01

DATE: 15 OCTOBER 2026

TARGET: FLEET MANAGERS & CONSTRUCTION OPERATIONS DIRECTORS

EXECUTIVE SUMMARY

SEA LION International delivers mission-critical refurbished Class 6-8 trucks for Kentucky and regional construction/logistics fleets through a rigorously standardized refurbishment protocol. This report details our engineered process for units sourced from Kentucky dealers, emphasizing compliance with SEA LION’s 227-Point Inspection Standard (SL-227IS v4.1). All units undergo structural, mechanical, and operational validation exceeding FMVSS and OSHA requirements, ensuring 98.7% operational readiness at deployment.

REFURBISHMENT PROCESS: KENTUCKY DEALER-SOURCED UNITS

1. ENGINE & GEARBOX TESTING

All units undergo 100% dynamometer validation and fluid analysis. Units failing SL-227IS thresholds are rejected (12.3% rejection rate in Q3 2026).

| Test Parameter | SEA LION Standard (SL-227IS) | Industry Baseline | Action on Failure |

|---|---|---|---|

| Power Output (Dyno) | ±3% of OEM spec @ max RPM | ±8% tolerance | Complete rebuild |

| Crankcase Pressure | < 0.5 psi @ 2,500 RPM | Not measured | Piston/ring replacement |

| Gearbox Oil Spectrometry | < 50 ppm ferrous particles | Visual inspection only | Gearbox disassembly |

| Emissions (EPA 2027 Phase 2) | NOx < 0.2 g/bhp-hr | Pass/fail only | DPF/SCR recalibration |

Process:

– Cold-start verification at -20°F simulated conditions.

– 3-hour load-cycle test replicating Kentucky’s hilly terrain (6% grade sustained).

– Final validation via SEA LION Telematics Suite (real-time torque/power logging).

2. CABIN REPAINTING

Structural integrity and corrosion resistance prioritized over aesthetics. All substrates meet ASTM D7087 adhesion standards.

| Stage | SEA LION Protocol | Quality Control Check |

|---|---|---|

| Surface Prep | Grit-blasted to SSPC-SP10/NACE No. 2 (near-white metal) | Salt contamination test (< 5 µg/cm²) |

| Primer Application | 2-coat epoxy (80-100 µm DFT) | Holiday detection (20kV spark test) |

| Topcoat | Polyurethane (120 µm DFT), RAL 7040/3000 standard | Gloss retention @ 60°: > 85% after 500h QUV |

| Curing | Forced-air oven (80°C for 45 min) | Adhesion test (ASTM D3359: 5B rating) |

Note: Structural welds inspected via ultrasonic testing (UT) prior to painting. No repainting approved if frame corrosion exceeds 15% section loss.

3. NEW TIRES & BATTERY REPLACEMENT

Components selected for Kentucky’s mixed terrain (construction sites, I-65 corridor, rural roads).

| Component | SEA LION Specification | Validation Method |

|---|---|---|

| Tires | Load Range G (152/148) radial; Michelin X Works or equivalent | Tread depth: 16/32″ new; 3-peak mountain snowflake (3PMSF) certified |

| Wheel Assemblies | Re-torqued to 450 ft-lbs (SAE J221) | Runout < 0.05″ (lateral/axial) |

| Battery | 2x 8D AGM (1,200 CCA each); HazeGuard tech | Cold-cranking test @ 0°F (-18°C) |

| Electrical | Full circuit load test (110% rated capacity) | Voltage drop < 0.2V across terminals |

Process:

– Tires mounted on bead-blasted, magnaflux-inspected rims.

– Batteries integrated with SEA LION SmartLink™ monitoring (state-of-charge, sulfation detection).

4. CHASSIS REINFORCEMENT

Mandatory for all units with > 300,000 miles or prior structural damage. Addresses Kentucky-specific stressors (heavy aggregate loads, bridge articulation).

| Reinforcement Zone | SEA LION Standard | Verification |

|---|---|---|

| Frame Rails | ASTM A572 Gr 50 steel doubler plates (1/4″ thick) | Ultrasonic thickness mapping |

| Crossmembers | Gusseted at mounting points (min. 6″ x 6″ x 3/8″) | Deflection test (< 0.1° under 20k lb load) |

| Suspension Mounts | Reinforced with 1″ DOM tubing | Torque retention test (500 cycles) |

| Weld Procedure | AWS D1.1-2025; 100% visual + 20% radiographic | Penetrant testing on all critical joints |

Process:

– Full-frame alignment via Hunter Engineering RoadForce Elite (tolerance: ±1.5 mm).

– Post-reinforcement vibration analysis (ISO 2631-1 compliance).

SEA LION QUALITY ASSURANCE: THE 227-POINT INSPECTION STANDARD

Kentucky-sourced units undergo triple-stage validation before certification:

- Pre-Refurbishment Triage: 78-point structural/mechanical scan (reject rate: 18.1%).

- In-Process Verification: Real-time data logging at 12 critical control points.

- Final Certification: 149-point functional test including:

- 100-mile road test (simulated construction site conditions)

- Hydraulic system pressure decay test (< 50 psi/hr)

- Brake force balance verification (SAE J2400)

- Telematics health report (SEA LION FleetSync™ platform)

Units failing any SL-227IS criterion are scrapped—no exceptions. 2026 Kentucky dealer-sourced unit pass rate: 84.6% (vs. industry avg. 67.2%).

CONCLUSION

SEA LION’s Kentucky dealer refurbishment protocol eliminates operational risk through engineering-led validation, not cosmetic renewal. Our adherence to SL-227IS ensures:

– 92% reduction in roadside failures vs. non-certified refurbished units (2026 fleet data).

– 150,000-mile warranty on drivetrain/chassis (industry standard: 90,000 miles).

– Full compliance with Kentucky Transportation Cabinet (KYTC) Commercial Vehicle Enforcement standards.

Deploy SEA LION-certified trucks to maintain project timelines and reduce total cost of ownership by 22% over 5 years. All units ship with digital maintenance passport (blockchain-verified service history).

SEA LION INTERNATIONAL — ENGINEERED RELIABILITY FOR INDUSTRY

This specification supersedes all prior versions. SEA LION reserves the right to modify standards without notice to comply with evolving regulatory requirements.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Truck Dealership Inventories from China to Kentucky, USA

Issuing Authority: SEA LION International – Global Heavy Equipment Logistics Division

Date: January 2026

Executive Summary

This report evaluates optimal maritime logistics solutions for exporting used commercial trucks—typically acquired from Chinese surplus fleets or OEM overstock—from Chinese ports to end-market distribution hubs serving Kentucky, USA. SEA LION International presents a comparative analysis of three primary shipping methods: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack containerized transport. The report includes technical specifications, cost-efficiency metrics, transit timelines, and corrosion protection protocols, with emphasis on wax-based anti-corrosion treatment to mitigate seawater exposure during Pacific and Atlantic transits.

1. Operational Context

Used heavy-duty trucks (Class 6–8), including dump trucks, tractors, and utility vehicles, are increasingly sourced from Chinese industrial zones for reconditioning and resale in North American markets. Kentucky’s central U.S. location and robust freight infrastructure make it a strategic distribution node. SEA LION International supports fleet managers and construction firms in optimizing import logistics from Chinese ports (e.g., Shanghai, Qingdao, Guangzhou) to inland U.S. terminals via Gulf or West Coast gateways.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Vehicle Compatibility | Operable trucks only | Operable or non-operable | All types (incl. oversized units) |

| Loading Mechanism | Self-driven on/off vessel | Lift-on/Lift-off via crane | Crane-lifted onto open-frame unit |

| Protection Level | Moderate (exposed decks) | Low (stacked, minimal coverage) | High (customizable lashings) |

| Max Dimensions (L×W×H) | 18m × 2.5m × 4.2m per unit | Limited by crane capacity | Up to 20m × 3m × 4.5m (40′ FR) |

| Avg. Capacity per Vessel | 300–500 trucks | 150–250 trucks (mixed cargo) | 2–4 trucks per 40′ FR |

| Transit Time (China → U.S. Gulf) | 28–35 days | 30–38 days | 32–40 days |

| Port Flexibility | Limited to RO-RO terminals | Standard multipurpose ports | Any container-capable terminal |

| Cost per Unit (USD) | $1,800 – $2,400 | $2,600 – $3,500 | $3,200 – $4,800 |

| Risk of Damage | Low (drivable handling) | High (rigging, stacking) | Medium (if improperly secured) |

| Best For | High-volume, operable fleets | Mixed cargo shipments | Oversized, non-operational units |

3. Corrosion Protection Protocol: Wax Spraying System

Marine atmospheric and saltwater exposure during 30+ day transits poses significant corrosion risk to undercarriages, chassis frames, and electrical housings. SEA LION International mandates the Electrostatic Wax Spraying Protection (EWSP) System for all exported used trucks.

EWSP Specifications:

- Material: Synthetic microcrystalline wax blend (ASTM D127 compliant)

- Application Method: Electrostatic spray + brush detailing in crevices

- Coating Thickness: 50–75 µm (undercarriage), 30 µm (exposed body)

- Salt Spray Resistance: 1,000+ hours (per ISO 9227)

- Removability: Biodegradable solvent wash (non-toxic, pH-neutral)

Application Workflow:

- Pre-treatment: High-pressure freshwater wash (80 bar), degreasing

- Drying: Forced-air tunnel (40°C, 2 hours)

- Wax Application: Automated robotic sprayers + manual touch-up

- Curing: 12-hour ambient cure before loading

Note: Wax film remains effective for up to 120 days post-application. Post-discharge removal recommended prior to reconditioning.

4. Recommended Logistics Strategy

| Use Case | Recommended Method | Rationale |

|---|---|---|

| High-volume fleet transfer (≥50 units), all operable | RO-RO | Lowest cost/unit, fastest turnaround, minimal handling damage |

| Mixed fleet (operable + inoperable), moderate volume | Flat Rack | Maximum flexibility, superior protection for non-drivable units |

| Consolidated shipment with other machinery | Bulk Cargo | Cost-effective if shared with non-vehicle cargo |

5. Terminal & Inland Routing (China → Kentucky)

- Origin Ports (China):

- Shanghai Port (RO-RO Terminal 7)

- Qingdao Auto Terminal (RoRo specialized)

- Destination Gateways (USA):

- Port of Houston (RO-RO & container)

- Port of Savannah (Flat Rack & breakbulk)

- Inland Transport:

- Rail: CSX/NS intermodal to Louisville, KY (5–7 days from Gulf)

- Truck: Final-mile delivery via Class I carriers (dedicated fleet drops)

6. Compliance & Documentation

All shipments must meet:

– U.S. EPA & DOT Import Standards (Emission compliance via EPA Form 3520-1)

– FMC-Registered Carrier Status

– ISPM 15 for wooden dunnage (if used in Flat Rack)

– Bill of Lading, Commercial Invoice, Export Declaration (China MOC)

7. Conclusion

For fleet managers and construction enterprises sourcing used trucks from China, RO-RO shipping offers the most cost-effective and efficient solution for operable units. Flat Rack containers are superior for non-operational or oversized vehicles requiring structural protection. Bulk Cargo is conditionally viable for mixed logistics but carries higher risk. Mandatory wax-based corrosion protection ensures asset integrity across extended ocean transits.

SEA LION International recommends pre-shipment condition audits, EWSP application, and multimodal routing via Gulf Coast ports to optimize delivery timelines into Kentucky’s logistics network.

End of Report

SEA LION International – Engineering Global Mobility Since 1998

Get a Quote for Used Truck Dealers In Kentucky

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]