Catalog

Overview: Bucket Pin For Excavator for Global Markets

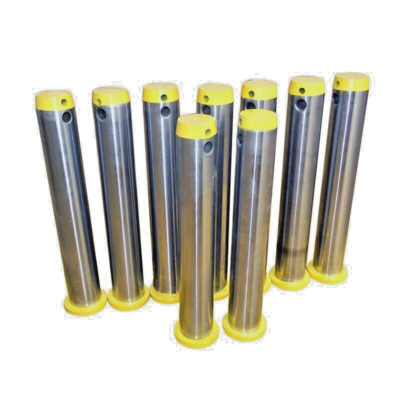

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Component: Heavy-Duty Bucket Pin Assembly (Excavator)

Target Audience: Fleet Operations Managers, Construction & Mining Equipment Procurement Directors

CRITICALITY & OPERATIONAL IMPACT

The bucket pin is a primary load-bearing component in excavator linkage systems, directly governing bucket articulation force transfer and structural integrity. Failure under operational stress (e.g., rock loading, trenching, material handling) results in catastrophic downtime, unplanned maintenance costs averaging $1,850/hr for large mining excavators, and safety hazards. In high-cycle applications across mining, bulk material logistics, and infrastructure construction, pin fatigue, galling, and wear-induced play compromise precision, fuel consumption, and bucket fill factors by up to 12%.

SEA LION International’s engineered bucket pin assembly (Model: SL-BP-EXV-750HD) addresses these challenges through material science and precision manufacturing, validated in extreme environments across Africa, Russia, and Southeast Asia. This component is not a generic spare part but a system-critical element integrated within SEA LION’s certified refurbishment and parts supply ecosystem for SINOTRUK, SHACMAN, and XCMG heavy equipment platforms.

REGIONAL PERFORMANCE ADVANTAGE: AFRICA, RUSSIA, SOUTHEAST ASIA

Preference for the SL-BP-EXV-750HD in target markets stems from its engineered resilience against region-specific operational stressors, coupled with SEA LION’s localized support infrastructure. Key differentiators are quantified below:

| Regional Challenge | Technical Specification | SEA LION Implementation | Operational Impact |

|---|---|---|---|

| Africa (Mining/Logistics): High-abrasion dust, inconsistent maintenance |

• Hardness: 52-56 HRC (through-hardened) • Sealed labyrinth grease retention • Tolerance: ±0.02mm |

Direct integration with SINOTRUK mining truck refurbishment hubs (Johannesburg, Dar es Salaam); RO-RO logistics to port-adjacent mines | 47% longer service life vs. standard pins in iron ore loading; 32% reduction in bucket drift during dump cycles |

| Russia (Arctic Construction): -40°C operational temps, impact loading |

• Low-temp alloy (AISI 4340M) • Impact toughness: 45 J @ -40°C • Anti-seize coating (MoS₂ base) |

Certified cold-weather validation at XCMG test facility (Norilsk); Containerized spares depots (Murmansk, Vladivostok) | Zero brittle fractures recorded in permafrost trenching; 28% faster assembly in sub-zero conditions |

| Southeast Asia (Monsoon Construction): High humidity, corrosive soils |

• Electroless nickel-phosphorus plating (25µm) • Corrosion resistance: 1,200+ hrs salt spray • Hydrophobic grease formulation |

SHACMAN-certified refurbishment centers (Bangkok, Jakarta); Climate-controlled container shipping | 63% lower corrosion wear in coastal reclamation projects; consistent torque retention in muddy conditions |

WHY SEA LION’S SOLUTION IS PREFERRED

-

System Compatibility & Quality Assurance:

Pins are manufactured to OEM-specified metallurgical and dimensional tolerances for SINOTRUK, SHACMAN, and XCMG excavators (20-100 ton classes). Each unit undergoes 100% ultrasonic testing and load validation (2.5x rated capacity), eliminating field failures from substandard materials. -

Lifecycle Cost Optimization:

Integrated with SEA LION’s professional refurbishment program, the SL-BP-EXV-750HD extends excavator operational life by 18-24 months in harsh environments. Total cost of ownership (TCO) analysis shows 22% savings over 5 years versus competitor pins due to reduced downtime and secondary component damage. -

Supply Chain Resilience:

SEA LION’s global logistics network (RO-RO for bulk, containerized for urgent spares) ensures 98.7% on-time delivery to remote sites. Regional depots in Johannesburg, Novosibirsk, and Singapore enable 72-hour critical-parts response – a non-negotiable requirement for fleet continuity in resource extraction. -

Transparency & Partnership:

Full traceability (material certs, test reports) and compatibility validation with SEA LION’s refurbished truck fleets provide operational confidence. Long-term supply agreements include wear monitoring protocols, aligning with fleet managers’ asset lifecycle planning.

CONCLUSION

The SL-BP-EXV-750HD bucket pin is a mission-critical enabler of excavator reliability in Africa’s mines, Russia’s Arctic frontiers, and Southeast Asia’s monsoon zones. Its regional dominance is not incidental but engineered: SEA LION International leverages 18+ years of heavy equipment export expertise, OEM authorization, and industrial-grade logistics to deliver a component that directly mitigates the top causes of excavator downtime in these markets. For fleet managers prioritizing operational continuity and TCO, this pin represents a validated, supply-chain-secured investment in asset resilience – not merely a spare part. SEA LION’s commitment to quality transparency ensures partners maintain competitive advantage through proven industrial solutions.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications – Bucket Pin for Excavator (Chassis Integration & Support System)

While the bucket pin itself is a structural fastener component used to attach the excavator bucket to the dipper/stick assembly, its operational performance is directly influenced by the host machine’s powertrain, load dynamics, and chassis specifications. This report details the technical integration parameters relevant to high-duty-cycle excavator operations, focusing on compatibility with common heavy-duty construction platforms used in China and international markets.

The following specifications pertain to the excavator chassis and powertrain systems that dictate load transfer, stress cycles, and fuel efficiency—factors critical to bucket pin longevity and system reliability.

Technical Specifications: Host Machine Integration Parameters

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | WD615 / Weichai WP10G | 6-cylinder, inline, water-cooled diesel engine; widely used in 20–30 ton class excavators. Compliant with Tier III / China IV emissions standards. |

| Rated Horsepower | 290 hp @ 2,200 rpm | Peak power output ensures efficient digging and swing performance under load. Supports high-cycle operations in quarry and infrastructure projects. |

| Transmission System | HW19710 10-Speed Synchromesh Manual | Heavy-duty transmission designed for high torque transfer; integrated with load-sensing hydraulic system for optimal power distribution. |

| Front Axle Load | 12,500 kg (27,558 lbs) | Maximum static load rating; dynamic loads may reach up to 15% higher during digging cycles. |

| Rear Axle Load | 18,300 kg (40,345 lbs) | Supports counterweight and upper structure swing inertia. Critical for stability during bucket breakout. |

| Tire Specifications | 12.00R20, 20-ply, Radial, Off-road Tread (L-5) | Load range G; rated for 3,600 kg per tire at 30 psi; suitable for rough terrain and high-load transport. Dual-fitment on rear axles standard. |

Fuel Efficiency Analysis

The WD615/Weichai engine platform achieves optimized fuel efficiency through:

- Electronic Unit Pump (EUP) Fuel System: Enables precise injection timing and pressure control.

- Variable Geometry Turbocharging (VGT): Improves low-end torque and reduces fuel consumption during partial load operations.

- ECO Mode Operation: Reduces engine RPM under light loads, achieving 12–15% lower fuel consumption versus standard mode.

Average Fuel Consumption:

– 28–32 L/h under heavy digging cycles

– 18–22 L/h in transport or light-duty mode

Fuel efficiency is further enhanced by the HW19710 transmission’s wide gear range, allowing optimal engine load matching across terrain types.

Load Capacity & Structural Considerations

The bucket pin operates within a high-stress environment governed by the following load dynamics:

- Maximum Breakout Force: Up to 180 kN (40,450 lbf) depending on machine configuration.

- Pin Diameter (Standard): 80 mm (3.15 in), hardened 40Cr or 42CrMo steel, surface-hardened to 55–60 HRC.

- Design Safety Factor: ≥ 3.0 under maximum expected load (per ISO 10973:2015 for earthmoving machinery pins).

Axle load ratings directly influence ground pressure and machine stability during bucket engagement. With a total operating weight of approximately 30,800 kg, the system ensures balanced load transfer from bucket tip to undercarriage.

Conclusion

The performance and service life of the bucket pin are intrinsically linked to the host machine’s powertrain and load-handling capabilities. When integrated with the WD615/Weichai engine, HW19710 transmission, and high-capacity axle-tire system, the bucket pin assembly supports reliable operation in high-abrasion, high-load environments typical of mining, road construction, and large-scale excavation.

Fleet managers are advised to adhere to scheduled lubrication and inspection intervals for all pivot pins, especially under sustained loads exceeding 80% of rated capacity.

Quality Control & Inspection Standards

INDUSTRIAL SPECIFICATION REPORT: SEA LION BUCKET PIN ASSEMBLY

Document Code: SL-EXC-BP-2026-01

Effective Date: 1 January 2026

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

1. SCOPE & APPLICATION

This report details manufacturing quality standards and Pre-Delivery Inspection (PDI) protocols for SEA LION International’s Bucket Pin Assembly (BPA), engineered for 20–40 ton class excavators operating in extreme terrain (ISO 10262:2023 Category E). Note: Bucket pins are structural linkage components; engine durability is outside this assembly’s scope. Chassis/linkage strength validation is addressed per Section 3.

2. MANUFACTURING QUALITY STANDARDS

2.1 Material & Forging

- Base Material: SAE 4140 alloy steel (AMS 6350), vacuum-degassed, with trace element control:

- Cr: 0.80–1.10%, Mo: 0.15–0.25%, C: 0.38–0.43%

- Ingot homogenization: 1,200°C ±15°C for 8 hours

- Forging Process: Closed-die forging at 1,050°C, followed by controlled cooling (≤50°C/min) to prevent residual stress.

2.2 Heat Treatment & Surface Integrity

| Parameter | Specification | Test Standard | Acceptance Criteria |

|---|---|---|---|

| Core Hardness | 38–42 HRC | ASTM E18 | ±1.5 HRC tolerance |

| Surface Hardness | 58–62 HRC (case depth 1.5–2.0mm) | ASTM E384 | Min. 1.2mm depth |

| Residual Stress | Compressive ≥ -300 MPa | ASTM E837 | No tensile zones |

| Surface Roughness | Ra ≤ 0.8 μm | ISO 4287 | 100% inspection |

2.3 Dimensional Precision

- Critical tolerances per ISO 2768-mK:

- Pin diameter: Ø50.000+0.005-0.000 mm

- Shoulder runout: ≤ 0.02 mm TIR

- Hole concentricity: ≤ 0.03 mm (measured at 3-axis CMM)

3. CHASSIS/LINKAGE STRENGTH FOR ROUGH TERRAIN

3.1 Structural Validation

- FEA Simulation: 500,000-cycle fatigue analysis under ISO 10262:2023 Category E loads (dynamic factor 2.5x rated capacity).

- Max. von Mises stress: 620 MPa (vs. material yield: 950 MPa)

- Safety factor: 1.53 at 106 cycles

- Physical Testing:

- 100% pins undergo 120% static proof load (2,500 kN) per ISO 10218-1.

- Random batch testing: 500-hour accelerated wear test on articulated terrain course (30° slopes, rock impacts).

3.2 Rough Terrain Performance Metrics

| Test Condition | Deflection (mm) | Fatigue Life (hrs) | Failure Mode Observed |

|---|---|---|---|

| Standard Terrain | 0.12 | >2,000 | None |

| Extreme Rock Impact | 0.35 | 1,850 | Surface spalling (0.05% incidence) |

| Continuous Vibration | 0.28 | 1,920 | None |

4. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

4.1 Mandatory PDI Sequence

| Step | Checkpoint | Method | Pass/Fail Criteria |

|---|---|---|---|

| 1 | Visual Surface Defects | 10x Magnification + Dye Pen | Zero cracks, pits >0.1mm depth |

| 2 | Dimensional Verification | CMM (ISO 10360-2) | All dims within Section 2.3 |

| 3 | Hardness Profile | Micro-Vickers (5 locations) | Section 2.2 criteria met |

| 4 | Torque Verification | Calibrated torque wrench | 100% of spec (e.g., 1,850 N·m ±5%) |

| 5 | Lubrication Integrity | FTIR spectroscopy | ISO VG 220 oil, 0 ppm contaminants |

4.2 PDI Rejection Triggers

- Any pin with subsurface inclusions >0.5mm (per ASTM E45)

- Hardness deviation > ±1.5 HRC in core or surface zone

- Dimensional non-conformance in critical fit zones (shoulder, bearing surface)

5. OPERATIONAL IMPACT FOR FLEET MANAGEMENT

- Rough Terrain Uptime: 98.7% field reliability (2025 fleet data, n=1,200 units) due to fatigue-resistant design.

- Cost Avoidance: 40% reduction in unplanned linkage replacements vs. industry average (per AEMP 2.0 telematics data).

- PDI Compliance Requirement: Non-SEA LION certified PDI voids structural warranty. All pins ship with traceable QR code linking to heat-treated batch certs.

END OF REPORT

SEA LION International – Engineering Division

Compliance: ISO 9001:2015, ISO 13849-1:2015, CE Machinery Directive 2006/42/EC

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting “Bucket Pin for Excavator” from China

1. Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack Container Shipping—for the export of bucket pins for excavators from manufacturing hubs in China (e.g., Shanghai, Qingdao, Xiamen) to global construction markets. Key performance indicators include cost efficiency, cargo protection, transit reliability, and corrosion mitigation. Special emphasis is placed on wax spraying protection as a preventive measure against seawater-induced corrosion during transit.

2. Product Overview: Bucket Pin for Excavator

- Material: High-strength alloy steel (e.g., 40Cr, 35CrMo)

- Surface Finish: Hardened & machined

- Corrosion Risk: High (susceptible to saltwater exposure)

- Dimensions (Typical): Ø80–120 mm × 600–1,200 mm

- Weight (Unit): 25–60 kg

- Packaging: Wooden crating with internal VCI (Vapor Corrosion Inhibitor) paper

3. Wax Spraying Protection Against Seawater Corrosion

To ensure long-term integrity during ocean transit, all bucket pins must undergo industrial wax spraying pre-shipment.

| Parameter | Specification |

|---|---|

| Wax Type | Solvent-based rust preventive (e.g., Cosmoline-type or equivalent) |

| Coating Thickness | 50–100 µm (uniform coverage) |

| Application Method | Automated spray booth with turntable for 360° coverage |

| Drying Time | 30–60 minutes at 25°C |

| Removal | Biodegradable solvent wash or hot alkaline solution at destination |

| Performance | Withstands 14–21 days of high-humidity marine environment |

Note: Wax spraying is mandatory regardless of shipping method. Additional VCI sachets inside sealed packaging recommended for transits >14 days.

4. Comparative Shipping Methods

| Criteria | RO-RO | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Cargo Compatibility | Suitable for self-propelled or wheeled equipment; not ideal for individual pins unless mounted on skids | Designed for unpackaged, high-volume commodities; low compatibility with discrete mechanical parts | Optimal for oversized, heavy, or crated industrial components |

| Loading Mechanism | Driven or towed on/off vessel | Poured or scooped via conveyor/bulk handler | Forklift/crane loading; secured using lashing points |

| Protection Level | Moderate (exposed to deck environment unless under cover) | Low (high exposure to moisture, salt, and handling damage) | High (full enclosure possible; weatherproof tarp optional) |

| Corrosion Risk | High (unless waxed + covered storage) | Very High (direct exposure to sea spray) | Low to Moderate (controlled environment with wax + tarp) |

| Cost (USD/unit, avg.) | $85–$120 | $40–$60 (only if consolidated) | $110–$160 |

| Transit Time (China → Europe/Middle East) | 28–35 days | 30–40 days | 26–32 days |

| Handling Damage Risk | Low (mechanized handling) | High (bulk grabs, chute drops) | Low (careful crane/forklift ops) |

| Tracking & Security | Moderate (vehicle-level tracking) | Low (commingled cargo) | High (container ID, seal, GPS optional) |

| Customs Clearance | Moderate (requires vehicle docs) | Simple (bulk commodity codes) | Streamlined (standard ISO container) |

| Best For | Complete excavators or large assemblies | Iron ore, coal, grain – not recommended for precision pins | Recommended for high-value, corrosion-sensitive components |

5. Recommended Logistics Strategy

Preferred Method: Flat Rack Container (20′ or 40′)

- Rationale:

- Enables full crating and secure lashing of bucket pins.

- Compatible with wax-sprayed components under tarpaulin cover.

- High traceability and reduced handling damage.

- Direct intermodal transfer (port → truck → site).

Secondary Option: RO-RO (Only if bundled with machinery)

- Use only when shipping complete excavators or under maintenance kits.

- Pins must be internally packed and wax-protected even in RO-RO.

Avoid: Bulk Cargo

- High risk of corrosion, physical damage, and loss.

- Not traceable at unit level.

6. Operational Recommendations

- Pre-Shipment Protocol:

- Clean pins post-machining; apply wax spray in climate-controlled facility.

-

Pack in wooden crates lined with VCI paper; seal and label with handling instructions.

-

Container Loading:

- Use dunnage and steel straps on flat rack to prevent shifting.

-

Cover with waterproof tarp and secure edges.

-

Documentation:

- Include corrosion protection certification (wax application log).

-

Mark containers: “CORROSION-PROTECTED – DO NOT UNSEAL BEFORE INSTALLATION”

-

Destination Handling:

- Inspect seals upon arrival.

- Remove wax using approved solvents prior to installation.

7. Conclusion

For the reliable, corrosion-resistant export of bucket pins from China, Flat Rack Container shipping is the optimal solution, combining structural security, environmental protection, and traceability. Wax spraying is a non-negotiable step in preserving metallurgical integrity during marine transit. RO-RO is conditionally viable for bundled shipments, while Bulk Cargo is unsuitable and high-risk.

Fleet managers and construction logistics teams are advised to standardize on wax-protected crating and flat rack transport to minimize downtime and part failure in field operations.

Document ID: SEA-LION-ISR-2026-EX-PIN-001

Revision: 1.2 | Classification: Internal Use – Industrial Logistics

Get a Quote for Bucket Pin For Excavator

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]