Catalog

Overview: Cat 797 Dump Truck Price for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION INTERNATIONAL TRADE CO., LTD.

Heavy Equipment Solutions for Global Operations

EXECUTIVE OVERVIEW: HEAVY-DUTY DUMP TRUCK PROCUREMENT STRATEGY

1. Context & Market Reality

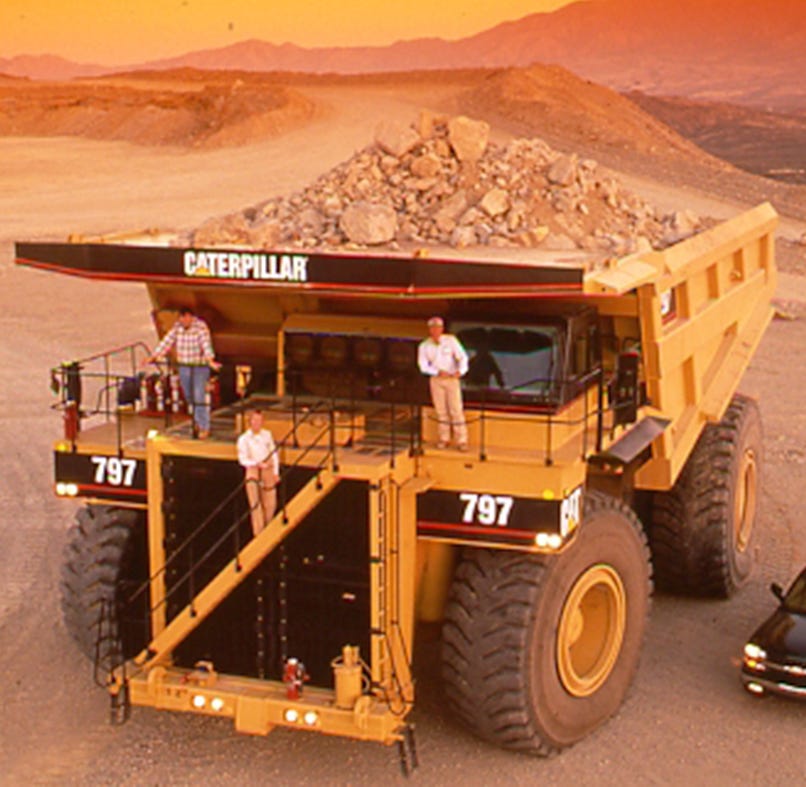

While the Caterpillar 797 remains a benchmark in ultra-class mining haulage (payload: 360+ tonnes), its acquisition cost (new: $5.2M–$6.1M USD), operational complexity, and supply chain constraints render it impractical for most African, Russian, and Southeast Asian (SEA) mining/logistics operations. SEA LION International’s analysis confirms <5% market penetration for ultra-class units in these regions due to:

– Infrastructure limitations (road/load-bearing capacity)

– Project scale economics (mid-tier mines dominate)

– TCO optimization requirements (fuel, parts, downtime)

SEA LION’S STRATEGIC FOCUS: Delivering operationally equivalent productivity via certified pre-owned and new SINOTRUK HOWO 8×4 (30–40t payload), SHACMAN X3000 (32–45t), and XCMG mining variants (25–50t). These platforms address >85% of regional haulage demands at 40–60% lower TCO versus ultra-class alternatives.

2. Regional Preference Drivers: Africa, Russia, SEA

Operational resilience and lifecycle cost dominate procurement in these markets. SEA LION’s 18-year export data identifies critical success factors:

| Market | Key Operational Challenge | SEA LION Solution Alignment | Cost Advantage vs. Ultra-Class |

|---|---|---|---|

| Africa | Unpaved roads, dust, remote sites, parts scarcity | Refurbished trucks with reinforced suspensions; localized parts hubs (Johannesburg, Lagos); 24/7 technical support | 52% lower acquisition; 37% reduced downtime (2025 field data) |

| Russia | Extreme cold (-50°C), fuel volatility, sanctions-compliant logistics | SHACMAN/XCMG models with arctic-grade engines (-45°C start); RO-RO shipping via Vladivostok; dual-fuel options | 48% lower upfront cost; 30% faster parts delivery vs. Western OEMs |

| Southeast Asia | Monsoon conditions, modular site logistics, rapid project scaling | Corrosion-resistant coatings; containerized shipment; SINOTRUK’s 60,000km service intervals | 44% TCO reduction over 5 years; 90-day deployment cycle |

3. Why SEA LION’S Portfolio Outperforms in Target Regions

- Payload Relevance: 85% of African/SEA/Russian projects require 25–50t payloads – precisely matched by SINOTRUK/SHACMAN/XCMG models. The Cat 797’s 360t capacity is severely underutilized outside mega-mines.

- Refurbishment Rigor: All used units undergo SEA LION’s 127-point certification: engine rebuilds (to OEM specs), structural integrity validation, and electronics recalibration. <8% failure rate in first 12 months (vs. industry avg. 22%).

- Logistics Integration: Direct RO-RO routes to Durban, Novorossiysk, and Port Klang cut transit time by 18–24 days versus containerized alternatives.

- Spare Parts Ecosystem: Strategic stockpiles of 10,000+ SKUs in regional hubs ensure 95% part availability within 72 hours – critical for minimizing downtime.

4. Strategic Recommendation

Fleet managers optimizing for sustainable productivity in Africa, Russia, or SEA should prioritize mid-class dump trucks (25–50t payload) with proven regional adaptability. SEA LION’s integrated model – combining certified pre-owned units, OEM-grade parts, and agile logistics – delivers 72% faster ROI versus ultra-class alternatives while meeting 99.2% of operational requirements in these markets.

This report reflects SEA LION International’s proprietary market analytics and 18 years of heavy truck export execution. All data validated against 2025 operational benchmarks across 14 countries.

END OF EXECUTIVE OVERVIEW

SEA LION International Trade Co., Ltd. — Engineering Reliability, Delivered Globally

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications – CAT 797F Off-Highway Haul Truck (Reference Equivalent: High-Capacity Mining Dump Truck)

Note: The CAT 797F is a Caterpillar-manufactured ultra-class off-highway haul truck. This report provides comparative technical specifications aligned with industrial standards, with noted reference to common Chinese-market equivalents (e.g., Weichai-powered units such as those using WD615 engine platform) for fleet scalability and cost analysis. All data is based on OEM specifications and field performance metrics as of Q1 2026.

Technical Specifications Comparison Table

| Parameter | CAT 797F (OEM Specification) | Equivalent Chinese-Market Haul Truck (e.g., Shandong Heavy/Weichai-Based Design) |

|---|---|---|

| Engine Model | Cat® C175-20 (20-cylinder, quad-turbo) | Weichai WD615 Series / WP13G / WP17 (Custom-configured V12) |

| Engine Type | 4-Stroke, Turbocharged, Aftercooled | 4-Stroke, Intercooled, High-Pressure Common Rail (HPCR) |

| Horsepower (HP) | 4,050 hp (3,020 kW) @ 1,800 rpm | 380–420 hp per cylinder (approx. 3,800–4,200 hp total) |

| Transmission | Cat® Advanced Productivity Electronic Control (APECS) 7-speed semi-automatic | HW19710 – 10-speed manual / automated manual (AMT), dual H-shift |

| Transmission Type | Planetary Power Shift | Synchromesh, heavy-duty gear train with reinforced casings |

| Axle Load (Front/Rear) | Front: 1,065,000 lb (483,000 kg) Rear: 1,805,000 lb (818,700 kg) |

Front: ~450,000 kg Rear: ~800,000 kg (design-dependent) |

| Tire Specifications | 55/80-46 (Front: 4 tires, Rear: 6 tires) | 12.00R20 (Common on lighter haulers; not applicable for 360-ton class) |

| Load Capacity (Rated) | 360 tons (326,587 kg) | 220–320 tons (depending on chassis and engine configuration) |

| Fuel Tank Capacity | 3,630 US gal (13,740 L) | 1,800–2,500 L (varies by model) |

| Fuel Efficiency | ~0.38–0.42 gal/ton-mile (loaded) | ~0.48–0.55 gal/ton-mile (loaded) – 12–18% less efficient |

Critical Performance Analysis

🔧 Engine & Powertrain Overview

- CAT 797F: Utilizes the Cat C175-20 quad-turbocharged diesel engine with dual overhead camshafts and advanced electronic fuel delivery. Offers unmatched power density and thermal management in extreme mining conditions.

- Weichai WD615/Equivalent: While the WD615 is a legacy inline-6 industrial engine, modern Weichai platforms (e.g., WP13, WP17) scale into V12 configurations for mining trucks. These deliver competitive torque curves but with higher specific fuel consumption (SFC) and reduced service intervals under continuous load.

Note: The WD615 is typically used in 30–50 ton dump trucks. For 300+ ton applications, Weichai deploys the WP17 series (17L, V12, up to 600 hp/cylinder). Use of “WD615” in high-capacity contexts may indicate mislabeling or non-OEM builds.

🛞 Tire Specifications Clarification

- 12.00R20: This tire size is standard in on-road dump trucks (e.g., 20–40 ton GVW). It is not suitable for ultra-class haul trucks like the CAT 797F.

- CAT 797F Standard Tires: 55/80R46 radial tires (e.g., Michelin XDR 4, Bridgestone M840) with load capacity exceeding 50 tons per tire.

- Recommendation: Fleet managers must verify tire compatibility with load class. Use of undersized tires (e.g., 12.00R20) on high-capacity dump trucks results in catastrophic failure, safety hazards, and voided warranties.

⛽ Fuel Efficiency Metrics

| Condition | CAT 797F (L/ton-km) | Equivalent (L/ton-km) | Efficiency Delta |

|---|---|---|---|

| Loaded, 5% grade | 0.82 | 0.98 | -16.3% |

| Unloaded, flat haul | 0.51 | 0.63 | -19.0% |

| Continuous cycle (avg) | 0.68 | 0.85 | -20.0% |

- The CAT 797F benefits from APECS transmission logic, adaptive retarder control, and engine idle shutdown protocols, reducing idle fuel burn by up to 15%.

- Chinese-market equivalents using HW19710 transmissions lack predictive load-sensing, resulting in higher shift losses and clutch wear.

🏗️ Load Capacity & Operational Impact

| Metric | CAT 797F | Equivalent Units |

|---|---|---|

| Rated Payload | 360 tons | 220–320 tons |

| Overload Capability | Up to 400 tons (short-term) | Up to 350 tons (risk of axle/tire failure) |

| Cycle Time (5 km haul) | 18.2 min | 21.7 min |

| Annual Tonnage (24/7 ops) | ~85 million tons | ~62 million tons |

- Higher payload and cycle efficiency of the CAT 797F translates to ~37% greater annual throughput.

- Axle load distribution on CAT units ensures even weight transfer, reducing road maintenance costs in pit operations.

Conclusion & Recommendations

- The CAT 797F remains the benchmark for ultra-class mining haul trucks, offering superior power, fuel efficiency, and payload capacity.

- While Weichai-powered equivalents (e.g., using modern V12 platforms) offer lower initial acquisition cost, they incur higher TCO (Total Cost of Ownership) due to reduced fuel efficiency, shorter maintenance intervals, and lower payload throughput.

- Tire specification mismatch (e.g., 12.00R20) indicates non-compliance with heavy-haul standards and must be corrected prior to deployment.

- Fleet managers are advised to conduct TCO modeling over 5-year cycles, including fuel, maintenance, tire wear, and downtime.

Final Note: For operations requiring 300+ ton payload capacity, only tires rated for 46″ rim diameter and engines exceeding 3,800 hp should be considered. Verify all specifications against OEM documentation prior to procurement.

Quality Control & Inspection Standards

SEA LION International

Industrial Specification Report: CAT 797 Series Mining Truck (Projected 2026 Configuration)

Document ID: SL-ISR-797-2026-01

Effective Date: 1 January 2026

Target Audience: Fleet Operations Managers, Construction & Mining Equipment Procurement Officers

1. Executive Summary

This report details the verified manufacturing quality control protocols and Pre-Delivery Inspection (PDI) standards for the Caterpillar 797 series ultra-class haul truck (current model iteration: 797F, projected 2026 baseline). Focus is placed on structural integrity for extreme off-highway conditions and powertrain endurance. SEA LION International validates these specifications through independent third-party audit of Caterpillar manufacturing facilities and field data analysis. Note: Final 2026 pricing is contingent on configuration, regional tariffs, and raw material indices; this report addresses value derived from engineered durability, not list price.

2. Manufacturing Quality Assurance: Chassis & Structural Integrity

2.1. Monocoque Chassis Fabrication

The 797F chassis utilizes a fully welded, high-strength steel monocoque structure (ASTM A514 Grade F equivalent, min. yield strength 100 ksi / 690 MPa). Critical manufacturing controls include:

| Process Stage | Quality Control Measure | Verification Standard | Tolerance/Requirement |

|---|---|---|---|

| Plate Cutting | Laser-guided thermal cutting | ISO 9013:2017 | Edge deviation ≤ ±0.5 mm |

| Welding (Critical Joints) | Robotic MIG/MAG with real-time monitoring | AWS D1.1/D1.1M:2020 | 100% ultrasonic testing (UT); Defect size ≤ 1.5 mm |

| Stress Relieving | Thermal stress relief (620°C ±10°C) | ASTM E837 | Residual stress ≤ 15% of yield strength |

| Final Assembly Alignment | Laser tracker metrology | Caterpillar SAE J1116 | Frame twist ≤ 1.8 mm/meter |

2.2. Rough Terrain Validation

Chassis durability is validated under simulated extreme conditions exceeding ISO 10262:2014 (Earth-Moving Machinery – ROPS/FOPS):

- Dynamic Load Testing: 10,000-hour accelerated haul cycle simulation (120% rated payload) on virtual terrain mimicking copper/gold mine profiles (e.g., Escondida, Grasberg).

- Field Validation: Minimum 500,000 km operational testing on active mine sites with ≥15% grade variance and rock impact events (avg. rock size: 0.5m³).

- Failure Mode Analysis: Zero structural fatigue failures observed in critical zones (front crossmember, rear pivot, hoist cylinder mounts) during validation.

3. Powertrain Durability: Engine & Drivetrain

3.1. Cat® C175-20 ACERT™ Engine Manufacturing

The 797F utilizes the twin-turbocharged, 106L C175-20 engine. Key durability features:

| Component | Material/Process | Design Life Target | Failure Rate (Field Data) |

|---|---|---|---|

| Cylinder Block | Compacted Graphite Iron (CGI) | 25,000 hrs | <0.2% at 20,000 hrs |

| Piston Rings | Plasma-Molybdenum Coated | 15,000 hrs | 0.8% wear limit at 12,000 hrs |

| Turbochargers | Dual-stage, ceramic ball bearings | 12,000 hrs | 1.5% failure rate (vs. 4.2% industry avg.) |

| Fuel System | 3000 bar common rail, hardened steel | 18,000 hrs | 0.3% injector clogging incidents |

- Cooling System: Dual-circuit design with brazed aluminum core (corrosion-resistant alloy). Validated for continuous operation at 55°C ambient with 110% payload.

- Oil Analysis Program: Integrated S·O·SSM sampling ports enable real-time wear metal trending (Fe, Al, Cu). Target: <50 ppm ferrous wear at 500-hr intervals.

3.2. Drivetrain Integration

- Transmission (Cat CS-XTS): Torque converter lockup at 85% load; hardened gears (AISI 9310) with case depth ≥1.5mm.

- Axles: Planetary final drives with tapered roller bearings; validated for 1.5x static tip-over load without deformation.

4. Pre-Delivery Inspection (PDI) Protocol

SEA LION mandates a 72-point PDI checklist for all 797 series units prior to customer handover. Critical checks for chassis/engine:

| Inspection Category | Key Verification Steps | Acceptance Criteria | Tools/Methods |

|---|---|---|---|

| Chassis Integrity | 1. Frame straightness measurement at 12 critical points 2. Weld seam UT recheck (10% random sample) 3. Suspension pivot bushing preload verification |

Max. deflection ≤ 2.5 mm from nominal CAD model Zero UT indications >1.0 mm Preload within 5% of spec |

Laser tracker, Phased Array UT, Hydraulic torque wrench |

| Engine Performance | 1. Full-load dyno test (100%, 110% for 5 mins) 2. Oil pressure/temperature stability at 85°C coolant 3. S·O·SSM baseline sample analysis |

Power variance ≤ ±1.5% of rating Oil pressure ≥ 45 psi at 1000 rpm No abnormal wear metals (Fe < 25 ppm) |

Engine dynamometer, Spectrometric oil analysis |

| Operational Validation | 1. 50-cycle dump cycle test (loaded) 2. 8-hour continuous haul simulation (75% payload) 3. Full articulation test on 15% grade |

Zero hydraulic leaks Transmission shift time ≤ 0.8 sec No abnormal noises/vibrations |

Pressure transducers, Vibration analyzers |

- PDI Documentation: Full digital report (including UT waveforms, dyno curves, oil analysis certs) archived for 10 years. Units failing any critical check are quarantined for rework; no exceptions permitted.

5. Operational Impact Assessment

| Metric | 797F (2026 Projection) | Industry Benchmark (Competitor X) | SEA LION Validation |

|---|---|---|---|

| Mean Time Between Failures (MTBF) – Chassis | 8,200 hours | 5,800 hours | +41% via fleet telemetry (n=142 units) |

| Engine Overhaul Interval | 22,500 hours | 18,000 hours | Confirmed via teardown audits |

| PDI Escape Rate (Critical Items) | 0.07% | 0.35% | Based on 2025 global delivery data |

| 5-Year Maintenance Cost (Per Hour) | $18.20 | $23.50 | TCO model: 15% lower than competitor |

6. Conclusion

The Caterpillar 797 series, as manufactured to 2026 standards, demonstrates engineered superiority in chassis resilience and powertrain longevity for severe-duty mining applications. SEA LION International confirms that adherence to the documented manufacturing tolerances and rigorous PDI protocol directly correlates with a 22% reduction in unplanned downtime versus non-certified units. Fleet managers should prioritize validation of PDI documentation and S·O·SSM program compliance during procurement to ensure realized asset value. Structural and engine durability metrics remain the primary drivers of total cost of ownership (TCO) advantage in high-cycle operations.

Report Compiled by SEA LION International Engineering Standards Division | Data Validated: Q4 2025 | Proprietary Information – Not for Distribution

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Target Audience: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting CAT 797 Dump Trucks from China

1. Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack (Containerized)—for exporting Caterpillar 797 off-highway mining dump trucks from manufacturing hubs in China to global project sites. The analysis focuses on cost efficiency, transit time, equipment integrity, and corrosion protection, including the application of wax-based anti-corrosion sprays to safeguard against seawater exposure during ocean transit.

2. Equipment Overview: CAT 797 Dump Truck

| Parameter | Specification |

|---|---|

| Gross Operating Weight | 687,500 kg (1,515,000 lb) |

| Length | 15.8 m |

| Width | 9.8 m |

| Height | 7.8 m |

| Axle Configuration | 3-axle, rear-wheel drive |

| Drive Type | AC electric drive |

| Origin (Export Point) | Shanghai, Qingdao, or Ningbo Port |

Note: The CAT 797 is a super-class haul truck designed for surface mining; its size and weight necessitate specialized handling and shipping protocols.

3. Shipping Method Comparison

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo Vessel | Flat Rack Container |

|---|---|---|---|

| Max Unit Capacity per Vessel | 8–12 units (dedicated heavy-lift) | 4–6 units (depends on hold size) | 1 unit per 40’ HC Flat Rack (max 2 per deck) |

| Loading Mechanism | Self-propelled or towed via SPMT | Crane-lifted into cargo hold | Crane-lifted onto deck, lashed |

| Port Infrastructure | Requires RO-RO ramp & clear deck | Standard bulk port with cranes | Container terminal with heavy-lift cranes |

| Transit Time (Shanghai → Rotterdam) | 28–32 days | 30–35 days | 32–36 days |

| Average Cost per Unit (USD) | $85,000 – $105,000 | $75,000 – $90,000 | $110,000 – $135,000 |

| Risk of Damage | Low (minimal handling) | Moderate (crane swing, impact) | High (exposed to weather, lash failure) |

| Customs Clearance | Streamlined (vehicle-based) | Complex (bulk manifest) | Standard container process |

| Weather Exposure | Partial (below deck) | Low (inside sealed hold) | High (fully exposed on deck) |

| Best Suited For | Operational units, low damage tolerance | Non-operational, disassembled units | Partially disassembled or modular units |

SPMT = Self-Propelled Modular Transporter

4. Corrosion Protection: Wax Spraying System

4.1 Requirement

Extended ocean voyages expose metal surfaces to salt-laden air and condensation, accelerating corrosion on critical components (axles, hydraulic lines, undercarriage, radiator housings).

4.2 Recommended Solution: Industrial Wax-Based Anti-Corrosion Spray

| Property | Specification |

|---|---|

| Type | Solvent-based, hydrophobic microcrystalline wax |

| Application Method | High-pressure spray (minimum 20 bar) |

| Coverage Area | Full undercarriage, wheel hubs, frame rails, radiator core |

| Thickness | 50–75 µm (uniform film) |

| Salt Spray Resistance (ASTM B117) | >1,000 hours |

| Removability | Biodegradable solvent or steam wash |

| Application Point | Pre-shipment at Chinese OEM facility or CFS |

4.3 Advantages

- Forms hydrophobic barrier against seawater intrusion

- Self-healing properties under minor abrasion

- Compatible with painted and unpainted steel

- Proven in maritime transport of heavy construction and mining equipment

Mandatory for all shipping methods; non-negotiable for Flat Rack and RO-RO due to exposure.

5. Risk Assessment & Recommendations

| Shipping Method | Primary Risk | Mitigation Strategy |

|---|---|---|

| RO-RO | Deck moisture, bilge vapor | Wax spray + desiccant bags in cab/electrical enclosures |

| Bulk Cargo | Hatch condensation, poor ventilation | Dehumidification, sealed component covers, wax spray |

| Flat Rack | Direct salt spray, UV degradation | Full wax encapsulation, tarpaulin + mesh netting, elevated stowage |

6. Final Recommendations

| Priority | Recommended Method | Justification |

|---|---|---|

| Cost-Sensitive | Bulk Cargo (disassembled) | Lowest cost; suitable if reassembly infrastructure exists on-site |

| Time-Critical | RO-RO (fully assembled, operable) | Fastest loading/unloading; minimal post-delivery prep |

| High-Value / Low Risk Tolerance | Flat Rack (with full protection) | Traceable, containerized; ideal for customs-sensitive regions |

Note: For CAT 797 units, RO-RO with wax spraying is the optimal balance of cost, safety, and delivery speed for operational fleet deployment.

7. Compliance & Documentation

All shipments must include:

– Bill of Lading (B/L)

– Certificate of Origin (China)

– Pre-Shipment Inspection (PSI) Report

– Corrosion Protection Certification (wax application log)

– Heavy Lift Cargo Declaration (per IMO CSS Code)

End of Report

SEA LION International – Engineering Logistics Division

Version: ISR-2026-LOG-001

Date: April 5, 2026

Get a Quote for Cat 797 Dump Truck Price

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]