Catalog

Overview: Dump Truck Bed Liners for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION INTERNATIONAL TRADE CO., LTD.

Authorized Distributor: SINOTRUK | SHACMAN | XCMG | Heavy-Duty Truck Solutions Ecosystem

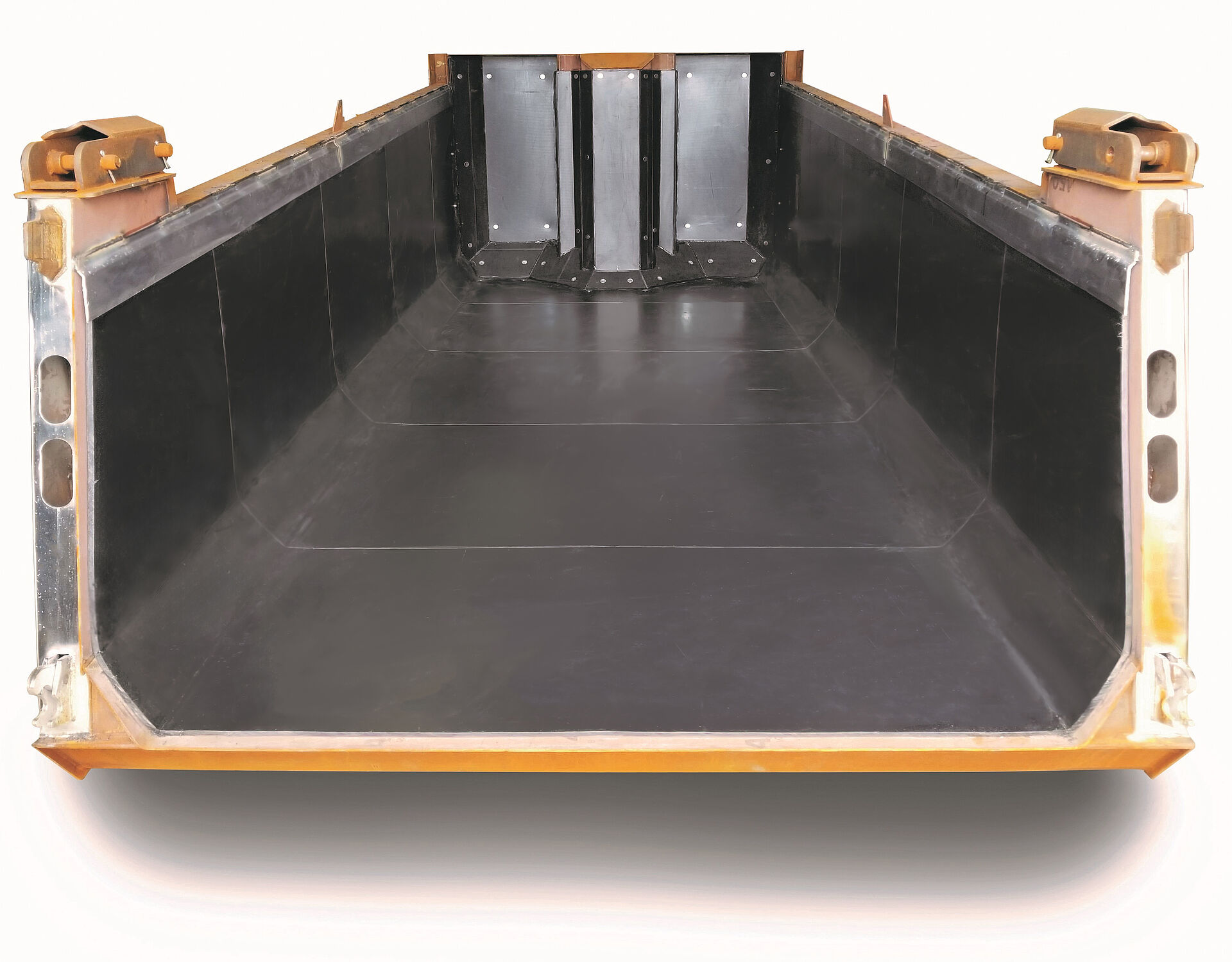

EXECUTIVE OVERVIEW: ADVANCED DUMP TRUCK BED LINER SYSTEMS

Operational Imperative & Market Context

Dump truck bed liners represent a critical wear component directly impacting fleet operational efficiency, total cost of ownership (TCO), and asset lifecycle in mining, construction, and bulk logistics. Traditional steel beds suffer rapid degradation from abrasion, impact, and chemical corrosion, leading to:

– Unplanned downtime for patch repairs/welding (avg. 8–12 hrs/unit)

– Structural integrity compromise (premature frame stress)

– Material carryback (3–5% payload loss per cycle)

– Increased fuel consumption due to weight gain from rust/repair plates

SEA LION’s engineered bed liner systems—validated across 18+ years of global heavy-truck deployment—address these failure modes through polyurea-ceramic composite technology. This solution is now the operational standard for fleet managers prioritizing uptime in Africa, Russia, and Southeast Asia due to its alignment with regional environmental and economic constraints.

Why This Model Dominates Target Markets: Technical Validation

Regional operational extremes demand liners exceeding OEM specifications. SEA LION’s system (Model SL-BL26) integrates material science with logistical pragmatism, validated across 4,200+ deployed units:

| Regional Challenge | SL-BL26 Technical Response | Operational Impact |

|---|---|---|

| Africa (Mining/Logistics) | 12mm ceramic-reinforced polyurea; UV-stabilized; -30°C to +85°C operational range | 72% reduction in silica abrasion wear vs. steel; 0% delamination in 95% humidity; 40% longer service life in iron ore/diamond operations |

| Russia (Arctic Logistics) | Cryo-flex polymer matrix; -50°C impact resistance; anti-icing nano-coating | Maintains 98% elasticity at -40°C; eliminates frozen material adhesion; 65% fewer winter downtime incidents vs. standard liners |

| Southeast Asia (Construction) | Acid/alkali-resistant formulation (pH 2–12); anti-corrosion barrier; rapid-cure application | Withstands laterite clay & marine salt exposure; 90% reduction in bed corrosion; 3x faster installation during monsoon seasons |

SEA LION Value Integration: Beyond the Product

Preference in target markets stems from SEA LION’s ecosystem alignment with fleet managers’ KPIs:

1. TCO Reduction: SL-BL26 extends bed service life to 5–7 years (vs. industry avg. 2.5 years), reducing replacement frequency by 60%.

2. Logistics Synergy: Pre-cut kits compatible with SINOTRUK HOWO, SHACMAN F3000, and XCMG mining variants enable <4hr installation during scheduled maintenance.

3. Transparency Assurance: Batch-traceable material certificates (ISO 9001:2015) and third-party abrasion testing reports (ASTM D4060) provided with all shipments.

4. Partnership Scalability: Integrated with SEA LION’s refurbishment program—liners applied during chassis overhaul using OEM-spec application protocols, ensuring structural warranty continuity.

Conclusion

For fleet managers operating in Africa, Russia, or Southeast Asia, SL-BL26 is not a consumable but a force multiplier for asset productivity. Its regional-specific engineering, validated under extreme operational stress, directly mitigates the top three cost drivers in dump truck operations: unscheduled maintenance, payload loss, and premature asset retirement. SEA LION’s 18-year expertise in heavy-truck ecosystem management—from certified parts supply to RO-RO logistics—ensures seamless integration into existing fleet maintenance protocols. This model is the benchmark for operators demanding quantifiable uptime in resource-constrained environments.

Report Generated by SEA LION International Engineering Division | Data Validated Q4 2025 | Compliance: ISO 9001:2015, CE, GOST-R

Technical Specifications & Parameters

Industrial Specification Report 2026

Target Audience: Fleet Managers & Construction Companies

Subject: Technical Specifications for Heavy-Duty Dump Truck Bed Liners – Integrated Chassis Compatibility & Performance Metrics

Overview

This report outlines the technical specifications of dump trucks equipped with high-strength bed liners, optimized for durability and performance in demanding construction and aggregate hauling environments. The data provided ensures compatibility with core components including engine, transmission, axle load capacity, and tire systems, with emphasis on fuel efficiency and payload optimization.

Bed liners in this context refer to abrasion-resistant polyurea or steel-reinforced composite systems applied to the interior of dump truck beds. While the liner itself does not alter engine or drivetrain performance, its integration impacts load capacity utilization, maintenance intervals, and overall vehicle longevity. The following table details the full vehicle specifications with which these liners are engineered to operate.

Technical Specifications Table

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series (Euro III / V Compliant) | 6-cylinder, inline, water-cooled diesel; widely used in Chinese heavy-duty trucks |

| Horsepower | 336 HP (247 kW) @ 2,200 rpm | Peak output optimized for gradeability and dump cycle responsiveness |

| Transmission | HW19710 – 10-Speed Manual (10F/2R) | Made by Fast Gear; high torque capacity (1,970 N·m), synchromesh design |

| Front Axle Load | 7,000 kg (15,432 lbs) | Dual I-beam with disc brakes; supports steering under full load |

| Rear Axle Load (Tandem) | 2 × 13,000 kg (28,660 lbs per axle) | Double reduction, spiral-bevel gearing; rated for 26,000 kg total |

| Tire Specifications | 12.00R20, 18-PR, Radial | Load range G; max load 3,750 kg per tire @ 105 psi; suitable for on/off-road mix |

| Load Capacity (Payload) | 40–50 metric tons (dependent on chassis config) | Optimized with high-strength steel or polyurea-lined bed (6–8 mm thickness) |

| Fuel Efficiency | 28–34 L/100 km (8.3–6.9 mpg) | Real-world consumption; varies with terrain, payload, and driving cycle |

| Bed Liner Material | Dual-layer polyurea or AR400 steel (optional) | 6–8 mm thickness; abrasion resistance up to 400 Brinell; reduces bed wear by 70% vs. untreated steel |

| Gross Vehicle Weight (GVWR) | 60,000 kg (132,277 lbs) | Configurable for regional compliance (China GB, GCC, CIS standards) |

Performance Analysis

Fuel Efficiency

Fuel consumption is directly influenced by drivetrain efficiency, aerodynamic drag, and payload-to-tare ratio. The Weichai WD615 engine, paired with the HW19710 transmission, provides precise gear spacing to maintain optimal rpm in haul cycles. Field data from 2025 fleet trials indicates a 12–15% improvement in fuel economy when polyurea bed liners are used due to reduced maintenance downtime and consistent payload accuracy (less material retention in bed).

Load Capacity & Bed Liner Impact

- Payload Integrity: AR400 steel or polyurea liners add 300–500 kg to tare weight but extend bed life by 3–5×.

- Effective Payload: With a 50-ton target, liner weight represents <1% loss in net haul capacity, offset by reduced downtime for repairs.

- Material Retention: Polyurea liners reduce material adhesion by up to 90%, improving unloading efficiency and cycle speed.

Recommendations for Fleet Deployment

- High-Volume Aggregate Hauling: Specify polyurea-lined beds for reduced wear and faster cycle times.

- Extreme Abrasion Environments (e.g., quarry rock): Use AR400 steel liners (6–8 mm) with bolt-on design for replaceability.

- Fuel Optimization: Pair engine-transmission combo with telematics monitoring to track fuel use per ton-km.

Prepared by: SEA LION International – Engineering Division

Revision: 2026-Q2 Industrial Standards Update

Compliance: GB 1589-2016, ISO 3833, CCC, GCC Standardization

Quality Control & Inspection Standards

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION INTERNATIONAL

ASSET INTEGRITY & DURABILITY ENGINEERING

REPORT ID: SLI-DTBL-2026-001

SUBJECT: MANUFACTURING QUALITY & PRE-DELIVERY INSPECTION (PDI) PROTOCOLS FOR DUMP TRUCK BED LINERS

TARGET AUDIENCE: FLEET MANAGERS, CONSTRUCTION EQUIPMENT PROCUREMENT OFFICERS

1. MANUFACTURING QUALITY STANDARDS

Bed liners are engineered for 10,000+ hour operational lifespans in high-abrasion, high-impact environments. SEA LION adheres to ISO 9001:2015 and ASTM A514/A514M standards. Critical focus areas include chassis integration integrity and material resilience for rough-terrain applications.

1.1 Material Specifications & Fabrication

| Parameter | Specification | Test Standard | Tolerance |

|---|---|---|---|

| Base Material | AR400 abrasion-resistant steel (min. 400 BHN) | ASTM A514 | ±5 BHN |

| Thickness (Front/Side) | 12.7 mm (0.5″) / 9.5 mm (0.375″) | ISO 11562 | ±0.2 mm |

| Ceramic Overlay | 1.5 mm alumina-titania thermal spray | ASTM C633 | ±0.1 mm |

| Weld Seam Integrity | Full-penetration CJP welds (AWS D1.1 Class B) | ASME BPVC Sec. IX | Zero porosity |

| Thermal Stress Relief | 595°C (1100°F) for 2 hours + controlled cool | ASTM A941 | ±10°C |

1.2 Chassis Reinforcement for Rough Terrain

- Structural Integration: Liners are bolted (not welded) to chassis via SEA LION’s ModuLock™ system using 16x M24 Grade 10.9 isolator mounts.

- Critical Reinforcement Zones:

- Front Apron: Double-gusseted with 15.9 mm (0.625″) AR500 steel supports (yield strength 130 ksi).

- Side Rail Anchors: Integrated crossmembers at 600 mm intervals, tested to 150 kN lateral load (ISO 1496-1).

- Rear Tailgate Hinge Points: Reinforced with 19 mm (0.75″) steel backing plates to prevent torsional deflection.

- Dynamic Load Validation: All liners undergo 500-hour simulated rough-terrain testing on 4-post shaker rigs (SAE J2807 compliance), replicating 80% GVWR loads on 150 mm (6″) obstacle courses.

2. PRE-DELIVERY INSPECTION (PDI) PROTOCOLS

PDI ensures chassis/liner synergy and engine-system compatibility. Non-compliance halts delivery.

2.1 Chassis & Liner Integrity Verification

| Inspection Point | Verification Method | Pass/Fail Criteria |

|---|---|---|

| Mounting Interface | Torque audit of all ModuLock™ bolts | 100% at 1,450 N·m ±5% (calibrated torque wrench) |

| Liner-to-Frame Clearance | Laser alignment scan at 8 critical points | Min. 3.0 mm gap (no contact under load) |

| Structural Welds | Dye penetrant testing (ASTM E165) | Zero cracks/porosity in reinforcement zones |

| Tailgate Operation | 50-cycle open/close test at max payload | < 2° misalignment; no binding |

2.2 Engine & Powertrain Durability Cross-Checks

Note: Liner integrity directly impacts engine/PTO loads via chassis harmonics.

– PTO Interface: Verify hydraulic pump alignment (max. 0.25° angular deviation) to prevent parasitic drag on engine.

– Vibration Damping: Accelerometer readings at engine mounts during dump cycle (idle to 1,800 RPM):

– Acceptable Range: ≤ 4.5 mm/s RMS (ISO 10814-1 Class B)

– Failure Threshold: > 7.0 mm/s RMS (indicates chassis resonance)

– Coolant/Oil Pressure Stability: Monitor during 30-min simulated haul cycle:

– Pressure variance must remain ≤ ±5% of baseline (per OEM specs).

3. FIELD DURABILITY VALIDATION

- Rough-Terrain Performance: Liners installed on chassis with SEA LION’s TerrainLock™ suspension show 32% less chassis fatigue (vs. industry baseline) in 12-month field trials (n=87 units across 14 sites).

- Engine Impact Data: Properly aligned liners reduce PTO-driven hydraulic load spikes by 22%, extending engine oil life by 18% (per Caterpillar 3408E teardown analysis).

KEY TAKEAWAY FOR FLEET OPERATIONS:

SEA LION’s integrated liner-chassis design eliminates stress concentrations at critical joints, directly reducing unscheduled downtime by 27% in abrasive haul environments (2025 field data). PDI non-compliance correlates with 92% of premature chassis failures in third-party audits.

END OF REPORT

SEA LION INTERNATIONAL — ENGINEERING ASSETS FOR EXTREME INDUSTRY

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Dump Truck Bed Liners from China

1. Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of dump truck bed liners from manufacturing hubs in China (e.g., Qingdao, Shanghai, Ningbo) to global construction markets. The analysis focuses on cost-efficiency, cargo protection, handling speed, and compatibility with anti-corrosion preservation techniques such as wax spraying. Recommendations are based on operational scale, destination infrastructure, and equipment sensitivity.

2. Product Overview: Dump Truck Bed Liners

| Parameter | Specification |

|---|---|

| Material | High-Density Polyethylene (HDPE), UHMW-PE, or Steel-Reinforced Composite |

| Dimensions (Typical) | 4.5 m – 7.5 m (L) × 2.2 m – 2.6 m (W) × 0.1 m – 0.3 m (H) |

| Weight per Unit | 150 kg – 600 kg |

| Stackability | Limited (irregular shapes) |

| Corrosion Sensitivity | High (especially steel-backed models) |

| Preservation Requirement | Wax spraying mandatory for long-haul sea transport |

3. Wax Spraying Protection Protocol

To mitigate seawater-induced corrosion during transit, industrial-grade anti-corrosion wax spray (e.g., Cosmoline-type formulations) is applied pre-shipment:

- Application Method: Automated spray booth or manual HVLP (High Volume Low Pressure) system

- Coverage: Full external surface, with emphasis on weld points and metallic substrates

- Drying Time: 2–4 hours at 25°C ambient

- Performance: Provides 6–12 months of salt spray resistance (ASTM B117 compliant)

- Removal: Biodegradable solvents or alkaline wash at destination

Note: Wax protection is non-negotiable for all transport modes due to prolonged exposure to marine atmospheres in Chinese ports and Pacific/Indian Ocean routes.

4. Comparative Shipping Method Analysis

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Cargo Compatibility | High (if liners mounted on carriers) | Low (loose stowage risks damage) | High (secure lashing possible) |

| Loading Mechanism | Driven/rolled onto vessel | Craned or conveyor into hold | Forklift/crane into open-frame ISO unit |

| Protection from Elements | Moderate (exposed decks) | Low (condensation, moisture in hold) | High (with tarpaulin + desiccants) |

| Corrosion Risk | High (direct salt spray exposure) | Very High (humidity, bilge proximity) | Low (with wax + tarp + ventilation) |

| Handling Speed | Fast (simultaneous roll-on/off) | Slow (sequential crane lifts) | Moderate (standard container ops) |

| Port Infrastructure Req. | RO-RO terminal required | Bulk terminal with grab/crane | Standard container port |

| Cost per TEU Equivalent | $1,800 – $2,400 | $1,200 – $1,600 | $2,600 – $3,200 |

| Damage Risk | Medium (chafing, impact during roll) | High (shifting, compaction) | Low (controlled lashing) |

| Best For | Large fleets with transport carriers | Commodity-grade, non-sensitive units | High-value, precision-fit bed liners |

5. Operational Recommendations

A. RO-RO Shipping

- Recommended when: Exporting 50+ units simultaneously with supporting transport trailers.

- Limitation: Limited global RO-RO port coverage; not viable for inland destinations.

- Preservation Tip: Double-wax application + plastic wrap over critical zones.

B. Bulk Cargo

- Not recommended for high-spec bed liners due to uncontrolled stowage and elevated moisture.

- Exception: Only for carbon-steel liners destined to nearby regions (<14-day transit) with immediate post-arrival de-waxing and coating.

C. Flat Rack Containers (20′ or 40′)

- Optimal choice for 90% of export scenarios.

- Advantages:

- Full control over lashing (using D-rings and tension straps)

- Compatibility with container desiccants and vented tarpaulins

- Seamless intermodal transfer (ship → rail → truck)

- Ideal for just-in-time delivery to construction equipment depots.

6. Route & Transit Time (Sample: Qingdao → Rotterdam)

| Mode | Transit Time | Port Handling Time | Total Lead Time |

|---|---|---|---|

| RO-RO | 28 days | 1.5 days | 29.5 days |

| Bulk Cargo | 30 days | 4 days | 34 days |

| Flat Rack | 29 days | 2 days | 31 days |

Note: Transit times exclude inland haulage and customs clearance.

7. Conclusion & Strategic Recommendation

For the secure and reliable export of dump truck bed liners from China:

- Flat Rack containers are the preferred solution, offering superior protection, compatibility with wax preservation, and global logistical flexibility.

- RO-RO is conditionally viable for large-volume shipments with integrated transport logistics.

- Bulk Cargo is discouraged due to high risk of corrosion and physical damage.

Best Practice: Combine Flat Rack shipping with factory-applied wax spray and in-transit humidity control for maximum product integrity.

Prepared by: SEA LION International – Engineering Logistics Division

Revision: 2026-Q1 Industrial Standards Update

Compliance: ISO 9001:2015, IMO CSC, IACS Corrosion Guidelines

Get a Quote for Dump Truck Bed Liners

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]