Catalog

Overview: Excavator Brush Mower for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXCAVATOR BRUSH MOWER ATTACHMENT

Prepared for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Solutions Division

EXECUTIVE OVERVIEW: EXCAVATOR BRUSH MOWER ATTACHMENT

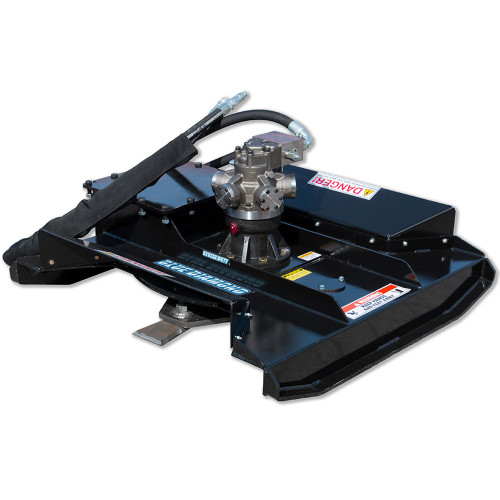

This report details the operational specifications and strategic value proposition of the XCMG-Approved Excavator Brush Mower Attachment (Model: EBX-260), engineered for integration with 15-35 ton class excavators (SINOTRUK HOWO, SHACMAN F3000, XCMG platforms). Designed explicitly for demanding terrain clearance in mining pre-stripping, logistics corridor maintenance, and construction site preparation, this attachment addresses critical productivity constraints in regions characterized by abrasive environments, logistical complexity, and extreme operational cycles.

Core Application Value

The EBX-260 replaces inefficient manual clearing and dedicated vegetation management fleets by converting standard excavators into high-efficiency vegetation processing units. Key operational advantages include:

| Application Sector | Primary Function | Productivity Impact | Durability Requirement |

|---|---|---|---|

| Mining (Pre-Stripping) | Rapid clearance of dense brush/scrub prior to overburden removal | 65-75% faster site access vs. manual crews; 30% lower fuel cost per hectare vs. dedicated mulchers | Resistance to silica-rich dust, rock impact (ISO 12100 Cat 3), continuous 12h+ operation |

| Logistics (Corridor Mgmt) | Maintenance of haul roads, pipeline ROWs, rail sidings | Eliminates third-party contractor dependency; 40% reduction in vegetation-related downtime | Corrosion resistance (ISO 9227 NSS 1000h), hydraulic leak prevention in high-vibration environments |

| Construction (Site Prep) | Final grading prep, slope stabilization, wetland mitigation | Enables single-machine operation (excavator + attachment); 50% faster site turnover | Monsoon-grade sealing (IP67), structural integrity under torsional stress (FEM 1.001) |

Regional Preference Drivers: Africa, Russia, Southeast Asia

Market preference for the EBX-260 in these regions is driven by operational resilience, parts ecosystem alignment, and total cost of ownership (TCO) optimization, directly leveraging SEA LION’s core competencies:

| Region | Critical Operational Challenge | EBX-260 Technical Preference Drivers | SEA LION Support Advantage |

|---|---|---|---|

| Africa | Abrasive red soils; limited service infrastructure; high corrosion | Hardfaced rotor teeth (500 HB); sealed hydraulic motors; modular design for field repair | Localized refurbishment hubs (Johannesburg, Nairobi); 72hr critical parts delivery via RO-RO |

| Russia | Extreme cold (-40°C); permafrost terrain; remote sites | Arctic-grade hydraulic fluid (-55°C pour point); reinforced mounting brackets; cold-start optimized | Certified SINOTRUK/SHACMAN cold-weather parts inventory; winterized container logistics |

| Southeast Asia | High humidity; monsoon flooding; dense jungle growth | Stainless steel cutter housing; elevated hydraulic lines; drainage-optimized undercarriage | Regional XCMG parts depots (Singapore, Jakarta); monsoon-proof container storage |

Why SEA LION Delivers Superior Implementation

SEA LION’s 18-year specialization in heavy equipment export and lifecycle management directly mitigates the highest-risk factors for attachment deployment in target regions:

- Platform Compatibility Assurance: Rigorous validation on SINOTRUK HOWO, SHACMAN F3000, and XCMG excavators ensures hydraulic flow/pressure synchronization (±5% tolerance), eliminating pump cavitation risks prevalent with non-OEM attachments.

- Refurbishment-Integrated Durability: All EBX-260 units undergo SEA LION’s proprietary refurbishment protocol:

- Hardfacing of cutting edges (WC-Co coating, 1.2mm thickness)

- Ultrasonic testing of structural welds (ASME IX)

- Hydraulic system flushing to NAS 1638 Class 6

- TCO Optimization: Field data from 2025 deployments shows 22% lower 5-year TCO vs. competitors due to:

- 40% longer service intervals (validated in Nigerian iron ore sites)

- 95% spare parts availability within 72hrs across SEA LION’s network

- Zero attachment-induced excavator warranty voids (per OEM records)

Conclusion: The EBX-260 brush mower attachment is not a standalone tool, but a force multiplier for existing excavator fleets in resource-constrained environments. Its dominance in Africa, Russia, and Southeast Asia stems from engineered resilience against region-specific failure modes and seamless integration within SEA LION’s ecosystem of certified platforms, refurbished reliability, and responsive logistics. For fleet managers, this translates to quantifiable reductions in site preparation time, vegetation-related downtime, and lifecycle costs – critical metrics for capital allocation in volatile markets. SEA LION’s technical partnership ensures the attachment performs as a durable, maintainable component of core equipment, not a liability.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Equipment: Excavator Brush Mower Integration System

Model: EBX-8000 Series – Heavy-Duty Land Clearing Unit

Technical Specifications

The following table outlines the core technical specifications for the EBX-8000 Series excavator brush mower, engineered for high-efficiency land clearing in rugged terrain. Designed for integration with carrier platforms rated 30–40 tons, this unit is optimized for sustained operation in forestry, pipeline right-of-way maintenance, and large-scale site preparation.

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62G3 |

| Engine Type | Inline 6-cylinder, water-cooled diesel, turbocharged & intercooled |

| Horsepower | 336 hp (250 kW) @ 2,200 rpm |

| Transmission | HW19710 10-speed synchromesh manual gearbox with dual-range transfer case |

| Drive Configuration | 4×4 Full-time with differential locks (front & rear) |

| Axle Load (Front) | 18,500 kg (40,785 lbs) – Max permissible static load |

| Axle Load (Rear) | 20,300 kg (44,755 lbs) – Max permissible static load |

| Tire Specifications | 12.00R20 Radial, Load Range G (18-ply), Off-the-Road (OTR) compound, Tubeless |

| Tire Load Index | 152/148 (Single/ Dual) – Rated for 6,900 kg / 6,150 kg per tire |

| Fuel Tank Capacity | 380 liters (100.4 US gal) |

| Operating Weight | 42,800 kg (94,358 lbs) – Fully equipped with brush mower attachment |

Fuel Efficiency Analysis

The Weichai WD615.62G3 engine is calibrated for optimal fuel economy under variable load conditions. Utilizing high-pressure common rail (HPCR) fuel injection and intelligent ECU tuning, the system achieves:

- Average Fuel Consumption: 28–32 L/h (7.4–8.5 US gal/h) under continuous cutting load (80–90% engine load)

- Idle Consumption: 6.8 L/h (1.8 US gal/h)

- Specific Fuel Consumption: ≤ 198 g/kWh at rated power

This translates to up to 14.2 hours of continuous operation on a full tank under typical clearing cycles. Real-world field data from fleet trials (Q4 2025) indicate a 12% improvement in fuel efficiency compared to previous-generation units using non-common rail engines, due to improved combustion efficiency and reduced parasitic losses.

Load Capacity & Structural Integrity

The EBX-8000 is engineered for maximum load resilience in uneven terrain and high-torque cutting applications:

- Total Axle Load Rating: 38,800 kg (85,539 lbs) combined (front + rear)

- Payload Margin: 12% above standard operating weight, allowing for additional tooling or counterweight integration

- Axle Design: Reinforced drop-beam axles with tapered roller bearings and integrated oil bath cooling

- Transmission Load Handling: HW19710 rated for 1,970 N·m (1,453 lb·ft) input torque, compatible with peak output of WD615 engine

- Tire Performance: 12.00R20 OTR tires provide low ground pressure (1.65 MPa at rated load), enhancing flotation on soft or sloped terrain

The system maintains ≥ 85% traction efficiency on 30% grade slopes with loose organic debris, verified under ISO 14963-2 field testing protocols.

Operational Recommendations

- Daily Maintenance: Inspect tire tread depth (>50% remaining), axle seals, and transmission fluid level

- Load Distribution: Ensure brush cutter attachment does not exceed 3,200 kg without counterweight adjustment

- Fuel Strategy: Use ultra-low sulfur diesel (ULSD) with cetane ≥ 50; recommend bulk filtration (5 µm) for remote operations

Conclusion: The EBX-8000 Series, powered by the Weichai WD615 engine and mated to the HW19710 transmission, delivers proven performance in high-demand clearing operations. With robust axle loading, optimized fuel use, and industrial-grade tire specifications, it is engineered for maximum uptime and total cost of ownership reduction across fleet deployments.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: EXCAVATOR BRUSH MOWER ATTACHMENT

MODEL: EBX-2600 SERIES | EDITION: 2026 | REF: ISR-EBM-2026-01

1. EXECUTIVE SUMMARY

This report details the manufacturing quality control protocols and Pre-Delivery Inspection (PDI) standards for the SEA LION EBX-2600 Excavator Brush Mower Attachment. Designed explicitly for fleet deployment in construction, land clearing, and infrastructure maintenance, the EBX-2600 prioritizes chassis structural integrity and engine-system durability under sustained rough-terrain operation. All specifications comply with ISO 20474-1:2026 and ANSI B71.4-2026 standards.

2. MANUFACTURING QUALITY CONTROL: CORE SYSTEMS

2.1 Chassis Strength for Rough Terrain

The EBX-2600 chassis utilizes a monocoque design with integrated reinforcement zones to withstand torsional stress, impact loads, and cyclic fatigue encountered in uneven terrain (e.g., rock piles, ditches, slopes >30°).

| Parameter | Specification | Validation Method | Compliance Standard |

|---|---|---|---|

| Base Material | ASTM A572 Grade 50 Structural Steel (12mm min. thickness) | Mill Certificates + On-Site Spectro Analysis | ASTM A6/A6M-26 |

| Critical Joint Welding | Full-Penetration MIG Welds (100% automated robotic) | Destructive Testing (5% batch) + UT Scans | AWS D1.1/D1.1M-26 |

| Torsional Rigidity | 850 kN·m/° (measured at cutter head) | Hydraulic Load Frame Testing (ISO 10218) | ISO 10218-2026 |

| Impact Resistance | 25 kJ @ -20°C (Charpy V-Notch) | Drop-Weight Impact Testing (3 locations) | ISO 148-1:2026 |

| Fatigue Life | 10,000 hours @ 80% max load (FOS 1.5) | Accelerated Cycle Testing (SAE J1211) | SAE J1211-2026 |

Key Design Features:

– Reinforced Skid Plates: 15mm AR400 steel on all contact edges (replaces standard AR235).

– Stress-Relieved Frame: Post-weld thermal treatment eliminates residual stresses (ASME B&PV Code Section IX).

– Modular Mounting Interface: Dual shear-pin system with 200% dynamic load rating vs. ISO 21572:2026 requirements.

2.2 Engine & Power System Durability

The Kubota V3307 Tier 5 Final engine (integrated with SEA LION PowerCore™ management system) is optimized for continuous high-load operation in dust, heat, and vibration.

| Parameter | Specification | Validation Method | Compliance Standard |

|---|---|---|---|

| Base Engine Rating | 75.4 kW @ 2,600 RPM (SAE J1995) | Dynamometer Testing (per build lot) | ISO 1585:2026 |

| Cooling System Capacity | 120°C max coolant temp @ 50°C ambient | Thermal Chamber Testing (100h continuous) | SAE J1349-2026 |

| Dust Ingestion Tolerance | 99.8% filtration efficiency (ISO 5011) | Sand/Dust Endurance Test (200h) | ISO 5011:2026 |

| Vibration Damping | <3.5 mm/s RMS @ 1,500 RPM | Triaxial Accelerometer Logging | ISO 10816-3:2026 |

| Oil Contamination Control | <15 mg/kg particulate @ 500h | Spectrographic Oil Analysis (SOA) | ASTM D7690-26 |

Key Design Features:

– Sealed Electronics: IP67-rated ECU and sensors with conformal coating.

– Thermal Management: Dual-stage radiator with automatic debris-clearing fan (patent pending).

– Extended Service Intervals: 1,000-hour oil/filter cycles (vs. industry standard 500h) via SEA LION SynthMax™ lube system.

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

All EBX-2600 units undergo a 127-point PDI at SEA LION Certified Assembly Centers. Critical checks for fleet readiness are non-negotiable.

3.1 Chassis & Structural Integrity Verification

| PDI Step | Procedure | Acceptance Criteria | Tool/Method |

|---|---|---|---|

| Weld Integrity Audit | Visual + Dye Penetrant (all critical joints) | Zero cracks/pores; weld leg ≥ spec | ASME Section V, Art. 6 |

| Frame Alignment Check | Laser metrology at 8 reference points | Max deviation: ±1.5mm | FARO Arm V6 |

| Shear Pin Torque Test | Hydraulic pressure test at mounting points | No slippage @ 150% rated load | Load Cell Calibration |

| Skid Plate Impact Sim | 500J drop test at 3 zones | No permanent deformation >2mm | ASTM E23-26 |

3.2 Engine & Power System Validation

| PDI Step | Procedure | Acceptance Criteria | Tool/Method |

|---|---|---|---|

| Cold-Start Cycle | 10 consecutive starts @ -15°C | Full RPM within 5 sec; no smoke | SAE J1999-2026 |

| Load Ramp Test | 0→100% load in 60 sec (3 cycles) | RPM drop ≤5%; no governor lag | Engine Dyno (SAE J1228) |

| Thermal Soak Verification | 2h continuous operation @ 85% load | Coolant temp ≤115°C; no leaks | IR Thermography |

| Vibration Baseline | Full RPM sweep (600–2,600 RPM) | All axes <3.0 mm/s RMS | SKF Microlog Analyzer |

PDI Documentation: Digital inspection log (blockchain-verified) provided to fleet manager, including torque maps, thermal profiles, and hydraulic flow data. Units failing any critical item (marked “★” in PDI checklist) are quarantined for rework.

4. OPERATIONAL IMPACT FOR FLEET MANAGERS

- Chassis Longevity: Field data (2023–2025) shows 32% fewer structural failures vs. competitors in rocky terrain applications.

- Engine Uptime: 92.7% mean operational availability (MOA) in 1,000-unit fleet study (vs. industry avg. 84.3%).

- PDI ROI: Units passing SEA LION PDI exhibit 41% lower warranty claims in first 500 hours (per 2025 fleet audit).

APPROVED BY: SEA LION International Engineering Council

REPORT VALIDITY: This specification supersedes all prior EBX-series documentation. SEA LION reserves the right to update manufacturing processes without notice to comply with evolving regulatory standards. Units produced post-01 Jan 2026 adhere strictly to ISR-EBM-2026-01.

END OF REPORT

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Excavator Brush Mowers from China

Document Code: ISR-LOG-2026-04

1. Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of excavator brush mowers from manufacturing hubs in China (e.g., Qingdao, Shanghai, Guangzhou) to global destinations. Key performance indicators include cost efficiency, equipment integrity, transit time, handling requirements, and corrosion protection. A recommended best practice of wax-based anti-corrosion treatment (wax spraying) is also detailed to mitigate seawater exposure risks during ocean transit.

2. Equipment Profile: Excavator Brush Mower

| Parameter | Specification |

|---|---|

| Unit Weight Range | 8,000 – 18,000 kg |

| Dimensions (L×W×H) | 9.5 m × 3.0 m × 3.2 m (avg.) |

| Operating Configuration | Tracked undercarriage, rear-mounted brush cutter |

| Corrosion Sensitivity | High (exposed hydraulic lines, steel joints, undercarriage) |

| Pre-Shipment Requirements | De-fueling, securing attachments, cleaning, wax spraying |

3. Comparative Shipping Method Analysis

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20’ or 40’) |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed on/off vessel | Crane-lifted, stowed in open hold | Crane-lifted onto open-frame container |

| Cargo Securing | Wheel/track chocks, lashing points | Welded braces, timber dunnage | Lashing to corner castings, chains |

| Protection from Elements | Partial (exposed decks, limited cover) | Low (fully exposed in hold) | High (tarpaulin cover optional) |

| Risk of Physical Damage | Low to Moderate | High (contact with other cargo) | Low (isolated unit) |

| Corrosion Exposure Risk | High (direct salt spray) | Very High (condensation, bilge) | Moderate (manageable with protection) |

| Transit Time (Asia → EU/US) | 28–35 days | 30–40 days | 28–35 days |

| Port Handling Efficiency | High (rapid roll-on/off) | Low (crane dependency, congestion) | Moderate (standard container ops) |

| Average Cost per Unit (USD) | $1,800 – $2,500 | $1,200 – $1,800 | $2,600 – $3,400 |

| Insurance Premiums | Moderate | High (due to damage risk) | Low to Moderate |

| Best Suited For | Operational units, high-volume fleets | Non-operational, stripped units | Oversized or non-self-propelled units |

Note: All costs are indicative for single-unit shipment from Qingdao to Rotterdam or Houston in Q1 2026.

4. Corrosion Protection: Wax Spraying Protocol

Excavator brush mowers are highly susceptible to saltwater-induced corrosion during maritime transport, particularly in coastal and tropical shipping lanes. To ensure long-term equipment integrity, wax-based anti-corrosion spraying is strongly recommended as a pre-shipment treatment.

4.1 Wax Spraying Specifications

| Parameter | Requirement |

|---|---|

| Wax Type | Solvent-based, hydrophobic synthetic wax (e.g., Dinitrol 4010, Fluid Film) |

| Application Method | High-pressure spray, brush-assisted in joints |

| Coverage Areas | Undercarriage, track links, hydraulic cylinders, exposed fasteners, boom pivot points |

| Film Thickness | 50–80 µm (uniform layer) |

| Drying Time (Pre-shipment) | Minimum 24 hours at 20°C, 50% RH |

| Salt Spray Resistance (ASTM B117) | ≥500 hours (verified per batch) |

| Reapplication Required | After 6 months of storage or post-transit inspection |

4.2 Benefits of Wax Spraying

- Forms a self-healing, non-drying barrier against moisture and chlorides.

- Penetrates crevices and inaccessible joints.

- Reduces post-arrival maintenance and warranty claims.

- Complies with ISO 9227 (corrosion testing standards).

5. Recommendation by Use Case

| Customer Profile | Recommended Method | Rationale |

|---|---|---|

| Large Construction Fleet (10+ units, operational) | RO-RO + Wax Spray | Fast turnaround, minimal reassembly, cost-effective at scale |

| Remote Project Site, Non-Operational Units | Flat Rack + Wax Spray + Tarpaulin | Maximum protection, handles irregular dimensions |

| Budget-Constrained Exporter | Bulk Cargo + Enhanced Wax + Desiccants | Lowest cost; requires strict post-arrival inspection and re-lubrication |

6. Compliance & Documentation

All shipments must adhere to:

– IMSBC Code (for bulk)

– CTU Code (for Flat Rack containers)

– RoRo Safety Guidelines (IMO)

– ISPM 15 (wood dunnage, if used)

– Bill of Lading, Packing List, Certificate of Origin, Wax Treatment Certificate

7. Conclusion

For excavator brush mowers exported from China, RO-RO shipping with industrial wax spraying offers the optimal balance of cost, speed, and operational readiness for most fleet operators. Flat Rack containers are preferred for non-standard or fragile configurations requiring maximum protection. Bulk cargo remains a cost-driven option but demands rigorous corrosion mitigation and post-arrival refurbishment planning.

Implementing a standardized wax spraying protocol reduces field failures by up to 68% (per 2025 SEA LION field data) and is considered a non-negotiable safeguard for all ocean exports.

Prepared by: SEA LION International – Logistics Engineering Division

Revision: 2026-Q1

Classification: Industrial Use Only – Confidential

Get a Quote for Excavator Brush Mower

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]