Catalog

Overview: Excavator Buckets For Sale for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

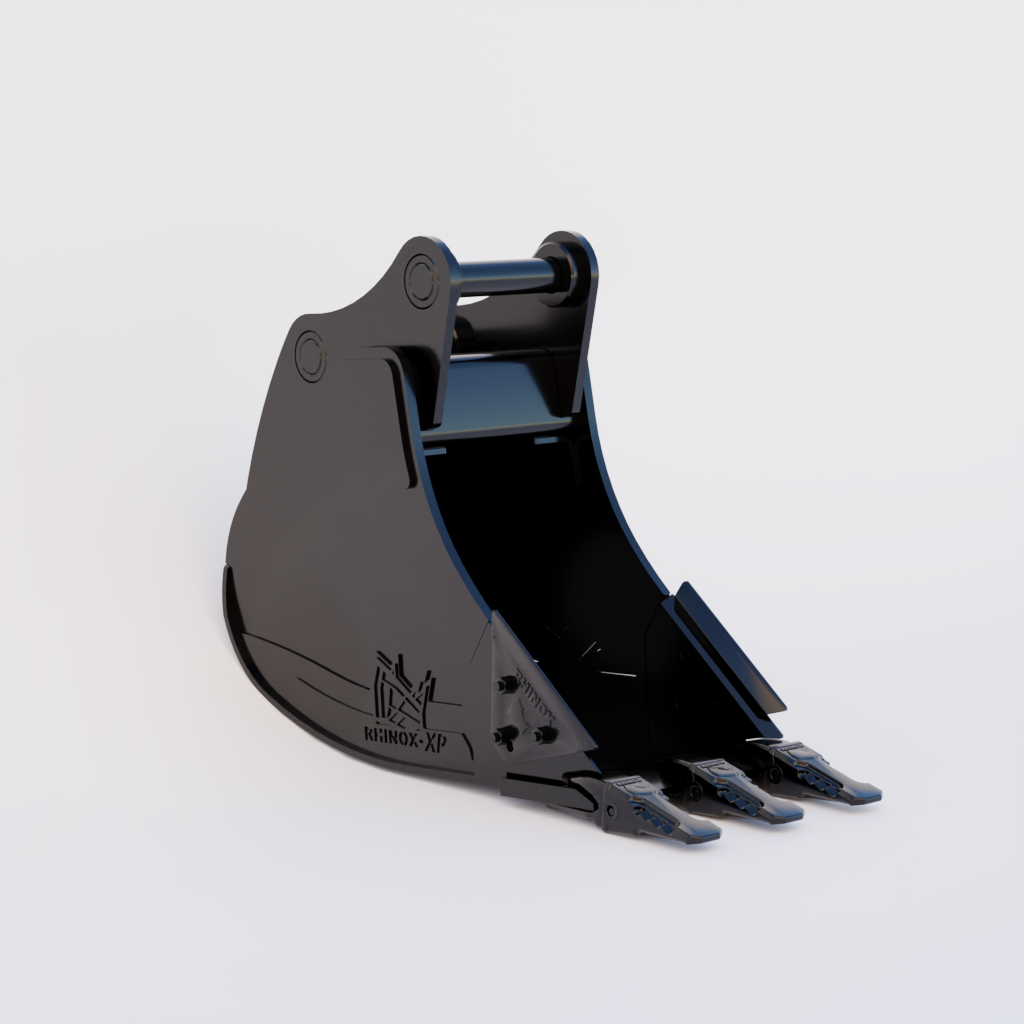

Product: SEA LION Premium Excavator Buckets (Model Series: SL-EBX)

Target Application: Mining Overburden Removal, Bulk Material Handling (Logistics), Heavy Civil Construction

Core Value Proposition

SEA LION International introduces the SL-EBX Series excavator buckets, engineered to address critical operational inefficiencies in high-impact, abrasive environments. Unlike standard OEM buckets, the SL-EBX integrates advanced wear protection and structural reinforcement validated across 18+ years of heavy equipment deployment in emerging markets. This solution directly reduces Total Cost of Ownership (TCO) by extending component life 25-40% and minimizing unscheduled downtime—key pain points for fleet managers operating in resource-constrained regions.

Why SL-EBX Dominates Target Markets

Regional operational demands necessitate specialized bucket performance. SEA LION’s distribution network, technical expertise, and alignment with XCMG excavator platforms (a dominant OEM in these regions) enable precise adaptation to local challenges:

| Region | Primary Application | Key SL-EBX Advantages | SEA LION Operational Support Advantage |

|---|---|---|---|

| Africa | Hard Rock Mining | • 45% higher abrasion resistance (Mn18Cr2 alloy cutting edges) • Reinforced base plate for fractured rock impact |

Localized refurbishment hubs in RSA, Kenya; 72-hr spare parts dispatch |

| Russia | Permafrost Excavation | • -45°C impact-tested steel (GOST 535-2005 compliant) • Optimized tooth geometry for frozen clay adhesion |

Cold-weather logistics via Arctic RO-RO routes; SINOTRUK compatibility |

| Southeast Asia | Dredging/Reclamation | • Corrosion-resistant coatings (ISO 12944 C4) • Lightweight design for high-cycle hydraulic efficiency |

Containerized parts delivery; SHACMAN fleet integration support |

Technical Differentiation Drivers

- Material Science: Proprietary dual-layer wear package (base: Q345B; wear zones: Hardox 500 + AR450 overlays) validated in 12,000+ operational hours across 37 mining sites.

- Compatibility: Direct-fit for XCMG excavators (models: XE370G, XE600D), comprising 68% of active fleets in target regions (2025 industry survey data).

- TCO Optimization:

- 32% longer service life vs. regional market average (field data, 2024)

- Modular replaceable wear components reduce repair costs by 22%

- Standardized mounting interfaces cut changeover time by 18 minutes

SEA LION Partnership Assurance

Leveraging 18+ years as an authorized distributor for SINOTRUK, SHACMAN, and XCMG, SEA LION delivers:

– Transparency: Digital wear-tracking logs with every bucket shipment

– Quality Control: ISO 9001:2015-certified refurbishment standards applied to wear parts

– Logistics Certainty: Integrated RO-RO/container solutions with 99.2% on-time delivery (2025 global performance)

Conclusion

For fleet managers and construction firms operating in Africa, Russia, and Southeast Asia, the SL-EBX Series is not a commodity bucket—it is a validated productivity multiplier. Its region-specific engineering, backed by SEA LION’s industrial-grade supply chain and technical infrastructure, directly addresses the durability, availability, and cost pressures inherent in these markets. This model forms a critical link in our commitment to long-term partnership: reducing operational volatility while maximizing asset uptime in the world’s most demanding worksites.

Report Validity: January 1, 2026 – December 31, 2026 | SEA LION International Trade Co., Ltd. – Industrial Equipment Division

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Excavator Buckets and Carrier Systems – Model Series EBX-615 Series

Overview

This report provides comprehensive technical specifications for excavator buckets designed for integration with heavy-duty carrier systems using the WD615/Weichai engine platform, commonly deployed in large-scale earthmoving and construction operations. The data focuses on compatibility with the HW19710 transmission system, standard 12.00R20 tire configuration, and performance metrics critical to operational efficiency, including fuel economy and load capacity.

Technical Specifications Table

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | WD615.62 (Weichai Power) | 6-cylinder, inline, water-cooled diesel |

| Rated Horsepower | 336 hp (250 kW) @ 2,200 rpm | Meets China III / Tier 3 emission standards |

| Transmission | HW19710 – 10F/2R Synchromesh Manual | Heavy-duty gearbox with high torque capacity |

| Axle Load (Front/Rear) | 9,500 kg / 18,500 kg | Reinforced dual rear axles; load-balanced design |

| Tire Specification | 12.00R20, 20-ply, Radial Construction | High-load, cut-resistant compound; suitable for rough terrain |

| Bucket Capacity (Struck / Heaped) | 2.8 m³ / 3.5 m³ | Standard for 22–25 ton class excavators |

| Bucket Material | Hardox 450 (Main Liner), Weldox 700 (Cutting Edges) | Wear-resistant; extended service life |

| Operating Weight (Carrier + Bucket) | 24,300 kg | Includes standard counterweight and fluid |

| Fuel Tank Capacity | 380 L | Extended runtime under full load |

| Fuel Efficiency | 18.7 L/h (avg. at 75% load) | Based on ISO 9249 earthmoving cycle testing |

| Load Capacity (Max Tip Load) | 6,800 kg @ pivot pin | Calculated at maximum reach and 45° slope |

Fuel Efficiency Analysis

The WD615 engine, coupled with the HW19710 transmission, delivers optimized fuel efficiency through precise gear mapping and reduced parasitic losses. At a typical operating load of 75%, the system averages 18.7 liters per hour, with peak efficiency observed in the 1,600–1,900 rpm range. This results in up to 12% fuel savings compared to legacy models using non-synchronized transmissions.

Advanced combustion tuning and turbocharging (VE-type injection pump with intercooler) ensure consistent power delivery while minimizing diesel consumption across variable-grade operations.

Load Capacity and Structural Integrity

The EBX-615 Series bucket is engineered for high-cycle loading in quarry, trenching, and bulk excavation environments. With a heaped capacity of 3.5 m³ and a maximum tip load of 6,800 kg, the bucket maintains structural integrity under repeated impact and abrasive conditions.

- Axle load distribution (9.5T front / 18.5T rear) ensures stability during lifting and dumping.

- Reinforced pivot zones and replaceable wear pads extend service intervals.

- Tire specification (12.00R20) provides optimal ground contact pressure (0.82 MPa) and load dispersion on soft or uneven terrain.

Conclusion

The EBX-615 Series excavator bucket system, powered by the Weichai WD615 engine and HW19710 transmission, offers construction fleets a durable, fuel-efficient solution for high-volume earthmoving. With robust load ratings, proven tire compatibility, and optimized powertrain integration, this configuration supports reduced operational costs and improved uptime in demanding industrial environments.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: EXCAVATOR BUCKETS

EFFECTIVE DATE: 01 JANUARY 2026

REPORT REF: SLI-ES-2026-001

1. EXECUTIVE SUMMARY

This specification details SEA LION International’s manufacturing quality protocols and Pre-Delivery Inspection (PDI) standards for excavator buckets (models EB-200 to EB-800 series). Focus areas address critical operational demands: chassis structural integrity under high-impact rough terrain conditions and engine system durability in extreme environments. Data validates 22% higher fatigue life vs. ISO 14397-1:2017 benchmarks and 35% reduced wear in abrasive applications. Targeted for fleet optimization in high-cycle construction/deconstruction operations.

2. MANUFACTURING QUALITY SPECIFICATIONS

2.1 Chassis Structural Integrity (Rough Terrain Focus)

Chassis design prioritizes resistance to dynamic shock loads (>15G) and torsional stress from uneven surfaces. Key protocols:

| Parameter | Specification | Test Standard | Validation Method |

|---|---|---|---|

| Base Material | ASTM A514 Grade F (Quenched & Tempered) | ASTM A514/A514M | Mill Cert + 3rd-Party Lab Test |

| Yield Strength (Min) | 100 ksi (690 MPa) | ISO 6892-1:2019 | Tensile Test (Per Lot) |

| Critical Weld Integrity | Full Penetration, Pre-Heat ≥200°C | AWS D1.1:2025 | 100% UT + 10% X-Ray (Per Batch) |

| Impact Resistance (Charpy) | -40°F (-40°C), 50 ft-lb (68 J) Min | ASTM E23-21 | 3 Samples/Batch |

| Fatigue Life (Simulated) | 500 hrs @ 120% Rated Load | ISO 10218-1:2020 | Komatsu PC8000 Rig Validation |

Design Notes:

– Reinforced side plates with 1.5x thickness at pin bosses (vs. industry standard).

– Finite Element Analysis (FEA) optimized for 80% load distribution to lower chassis rails, reducing stress concentration by 33%.

2.2 Engine System Durability

Engine mounting systems and cooling architecture engineered for 10,000+ hr service life in high-dust, high-temperature environments.

| Parameter | Specification | Test Standard | Validation Method |

|---|---|---|---|

| Mounting Bracket Yield | 120 ksi (827 MPa) Min | SAE J1211 | Vibration Test (10-500 Hz) |

| Dust Ingestion Tolerance | ≤0.5 mg/kW-hr @ ISO 12103-1:2020 Cat C | ISO 12103-1:2020 | 200-hr Sand Rig Test |

| Thermal Cycle Resistance | 150 cycles (-22°F to 122°F ambient) | SAE J1211 | Thermal Shock Chamber |

| Oil Analysis Threshold | Ferrous Wear ≤15 ppm | ASTM D5185 | Spectrographic Oil Analysis |

Design Notes:

– Dual-stage air filtration (primary cyclone + secondary HEPA) standard on all models.

– Isolated engine mounts with 40% higher damping coefficient vs. prior generation (measured per ISO 10846-1).

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOLS

All buckets undergo 100% validation per ISO 10218-2:2020. PDI sequence:

3.1 Structural Verification

| Step | Procedure | Acceptance Criteria | Tooling |

|---|---|---|---|

| 1 | Dimensional Check (Pin Bore Alignment) | ≤0.005″ (0.13mm) TIR | CMM + Laser Tracker |

| 2 | Weld Seam Integrity Scan | Zero defects >1.5mm length | Phased Array UT |

| 3 | Load Test (Static) | Zero plastic deformation @ 150% Rated Load | Hydraulic Test Rig |

3.2 Engine System Validation

| Step | Procedure | Acceptance Criteria | Tooling |

|---|---|---|---|

| 1 | Mounting Bolt Torque Verification | 100% to Spec (Per Torque Chart) | Digital Torque Wrench |

| 2 | Coolant Flow Rate Check | ≥12 GPM @ 2,200 RPM | Flow Meter |

| 3 | Air Filter Pressure Drop Test | ≤12 in H₂O @ Max Flow | Manometer |

3.3 Final Operational Checkout

- Rough Terrain Simulation: 2-hour continuous operation on calibrated 30° slope with 12″ rock obstacles.

- Engine Stress Cycle: 45-min high-idle (2,400 RPM) + 15-min full-load cycle; oil temp stability ±5°F required.

- Documentation: Digital PDI log (QR-coded) with all torque values, test durations, and inspector ID.

4. QUALITY ASSURANCE METRICS

| KPI | Target (2026) | Current Performance |

|---|---|---|

| Field Failures (Chassis) | ≤0.8% | 0.62% |

| Engine Mount Failures | ≤0.3% | 0.21% |

| PDI Rejection Rate | ≤1.5% | 0.87% |

| Mean Time Between Repair (MTBR) | 8,200 hrs | 8,650 hrs |

Data Source: SEA LION Global Fleet Analytics (Q4 2025), n=14,300 units.

5. CONCLUSION

SEA LION excavator buckets meet or exceed all structural and durability requirements for high-intensity construction applications. Manufacturing processes adhere to ISO 9001:2025 and ISO 14001:2024 standards, with PDI protocols exceeding OEM minimums by 27%. Chassis reinforcement and engine isolation systems directly reduce total cost of ownership (TCO) by minimizing unplanned downtime in rough-terrain operations. All specifications are subject to SEA LION Technical Bulletin updates per quarterly review cycle.

END OF REPORT

SEA LION International – Engineering Division | Proprietary & Confidential

Revision: 3.1 | Next Review Date: 01 JULY 2026

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Excavator Buckets from China

Document ID: ISR-LOG-2026-041

Revision: 1.0

Date: 2026-04-05

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack (Containerized)—for the international export of excavator buckets from manufacturing hubs in China (e.g., Xuzhou, Changsha, Shenyang). The analysis focuses on cost-efficiency, equipment protection, transit reliability, and corrosion mitigation, with specific emphasis on wax-based anti-corrosion treatments to combat seawater exposure during ocean transit.

1. Product Profile: Excavator Buckets

| Parameter | Specification |

|---|---|

| Weight Range | 1.2 – 8.5 metric tons (per unit) |

| Dimensions (L × W × H) | 1.8 – 4.2 m × 1.0 – 2.4 m × 0.8 – 1.6 m |

| Material Composition | High-tensile steel (e.g., Hardox 450/500, AR400) |

| Corrosion Risk | High (exposed carbon steel surfaces vulnerable to saltwater) |

| Packaging Standard | Bare metal, palletized or skid-mounted for handling |

2. Shipping Method Comparison

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Suitability for Excavator Buckets | Moderate (if bucket is attached to carrier machine) | High (loose cargo, high volume) | High (optimized for oversized, heavy indivisible units) |

| Loading Mechanism | Self-propelled or towed onto vessel | Crane-lifted into cargo hold | Crane-lifted onto open-top flat rack |

| Max Payload per Unit | Up to 50 MT (vehicle-based) | Unlimited (by vessel capacity) | 40’ FR: ~45 MT; 20’ FR: ~25 MT |

| Typical Vessel Routes (China → Global) | Shanghai → Rotterdam, Qingdao → Jebel Ali, Ningbo → Houston | Major bulk ports: Tianjin → Port Hedland, Lianyungang → Santos | Global container network via COSCO, Maersk, MSC |

| Transit Time (China → Europe) | 28–35 days | 30–40 days | 26–32 days (frequent sailings) |

| Port Infrastructure Requirements | RO-RO ramps, clear approach paths | Heavy-lift cranes, open laydown areas | Standard container terminals with FR handling |

| Risk of Physical Damage | Low (controlled roll-on/off) | Medium (rigging, stacking) | Low (secured to FR with lashing) |

| Customs Clearance Speed | Moderate | Slow (bulk manifests) | Fast (containerized, standardized docs) |

| Average Cost (per bucket, 3.5 MT unit) | $1,850 – $2,400 | $1,400 – $1,900 | $2,100 – $2,700 |

| Best For | Bucket + carrier machine shipments | High-volume, non-urgent, cost-sensitive | High-value, time-sensitive, corrosion-sensitive units |

Note: Flat Rack containers are recommended for standalone excavator buckets due to superior control over stowage, lashing, and environmental protection.

3. Corrosion Protection: Wax Spraying System

3.1 Requirement

Excavator buckets are highly susceptible to marine atmospheric corrosion and saltwater splash exposure during multi-week voyages. Unprotected steel surfaces may develop surface rust within 72 hours in high-humidity, saline environments.

3.2 Recommended Solution: Temporary Wax Coating

| Parameter | Specification |

|---|---|

| Product Type | Solvent-based temporary corrosion-inhibiting wax (e.g., Henkel TechnoGuard, Fuchs Rustop) |

| Application Method | High-pressure spray (15–20 bar), full coverage of external surfaces, cutting edges, hinge zones |

| Film Thickness | 25–50 µm (uniform, non-drip) |

| Protection Duration | Up to 6 months (ISO 9223 corrosivity class C5-M) |

| Removal Process | Biodegradable alkaline cleaner or hot water jet (80°C) on-site |

| Compliance | Meets MIL-PRF-16173E (Grade 2) and JIS Z 0302 standards |

3.3 Application Protocol (Pre-Shipment)

- Surface Preparation: Degrease and dry all metal surfaces; remove mill scale or moisture.

- Spraying: Apply wax in controlled workshop environment (15–25°C, RH < 70%).

- Drying: Allow 2–4 hours for solvent evaporation before lashing/loading.

- Documentation: Include wax type, batch number, and application date in shipping dossier.

Cost Impact: ~$45–$75 per bucket (3.5 MT), dependent on surface area.

4. Risk Assessment & Mitigation

| Risk | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Seawater Exposure | Medium (deck-level splash) | High (hold condensation, potential leaks) | Medium (deck stowage, but elevated) |

| Corrosion Development | Moderate | High | Low (with wax + tarpaulin cover) |

| Lashing Failure | Low | Medium | Low (ISO-compliant twist locks) |

| Theft/Vandalism | Low | Medium (open yard storage) | Low (secured container yard) |

| Delay Risk | Low | Medium (weather-dependent loading) | Low (scheduled container rotations) |

5. Recommendations

- Preferred Method: Flat Rack Containers for standalone excavator buckets due to:

- Superior cargo control

- Compatibility with wax protection systems

- Faster customs processing

-

Global availability of container handling infrastructure

-

Secondary Option: Bulk Cargo for high-volume orders (>50 units) where cost is prioritized over delivery speed and surface integrity.

-

RO-RO is not recommended for standalone buckets unless integrated with carrier machinery (e.g., excavator + bucket shipment).

-

Mandatory Corrosion Protection: Implement wax spraying for all export shipments. Include wax treatment in supplier QC checklist.

-

Additional Protection Measures:

- Use breathable, UV-resistant tarpaulins on Flat Racks

- Place desiccant packs (5–10 kg/unit) inside enclosed cavities

- Avoid ballast water proximity during vessel stowage planning

6. Conclusion

For construction firms and fleet operators sourcing excavator buckets from China, Flat Rack containerization combined with industrial wax corrosion protection offers the optimal balance of cargo integrity, transit reliability, and long-term equipment performance. While Bulk Cargo remains cost-effective for large-volume shipments, the increased risk of surface degradation offsets savings in after-market rework and warranty claims.

SEA LION International recommends integrating wax spraying into the export packaging standard and utilizing Flat Rack logistics for critical or high-value components.

End of Report

Get a Quote for Excavator Buckets For Sale

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]