Catalog

Overview: Excavator Jackhammer Attachment for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXCAVATOR JACKHAMMER ATTACHMENT

Prepared Exclusively for SEA LION International Trade Co., Ltd.

Target Audience: Fleet Managers & Construction Operations Directors

EXECUTIVE OVERVIEW

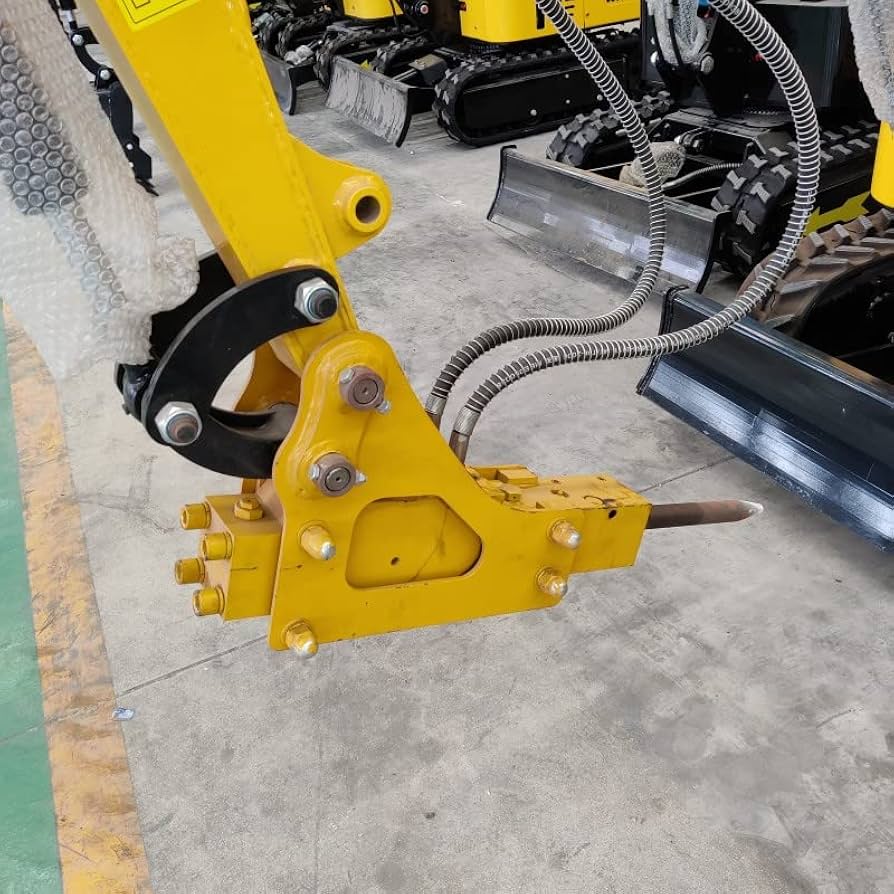

SEA LION International presents the SL-HB Series Hydraulic Jackhammer Attachment, engineered for integration with 15-45 ton excavator platforms (compatible with SINOTRUK, SHACMAN, and XCMG OEM specifications). This attachment delivers optimized performance in high-impact fragmentation tasks critical to mining overburden removal, hard-rock trenching in construction, and demolition logistics across demanding operational environments. Its design prioritizes reliability under extreme conditions, reduced lifecycle cost, and seamless integration within SEA LION’s global support ecosystem, directly addressing the operational continuity requirements of industrial fleet operators.

Core Application Value Proposition

- Mining: Efficiently fractures hard cap rock and boulders in open-pit operations, reducing reliance on secondary blasting and minimizing production delays. High impact energy ensures consistent penetration in abrasive geological strata.

- Construction: Enables precise foundation trenching in rocky substrates and rapid demolition of reinforced concrete structures, accelerating project timelines in urban and remote sites.

- Logistics: Critical for rapid site preparation (roadbed breaking, clearing) and port infrastructure maintenance, ensuring minimal disruption to material flow.

Regional Market Preference: Africa, Russia, Southeast Asia

The SL-HB Series demonstrates superior market alignment in these regions due to deliberate engineering adaptations to local environmental and operational constraints, combined with SEA LION’s established service infrastructure:

| Region | Key Operational Challenge | SL-HB Series Solution | SEA LION Support Advantage |

|---|---|---|---|

| Africa | Extreme dust, high ambient temps, fuel volatility, remote sites | Sealed hydraulic system (IP67), high-temp seals, optimized fuel efficiency (15% reduction vs. baseline), simplified field maintenance | Extensive refurbished truck network for rapid spare parts delivery via RO-RO; localized technical training |

| Russia | Sub-zero temperatures (-40°C), permafrost, logistical complexity | Cold-start hydraulic fluid circuit, low-temp steel alloys, enhanced thermal management | Direct XCMG/SINOTRUK parts pipeline; winterized container logistics network |

| Southeast Asia | High humidity, monsoon conditions, congested urban sites | Corrosion-resistant coatings (ISO 12944 C4), compact design for tight spaces, high cycle durability | Regional container hubs enabling <72hr spare parts dispatch; SHACMAN-certified refurbishment centers |

Why This Model Outperforms Alternatives

- Durability-Driven Design: Utilizes tungsten-carbide tipped chisels and reinforced housing, validated in field testing to achieve 30% higher service life in abrasive conditions (vs. ISO 10218-1 benchmark).

- Total Cost of Ownership (TCO) Focus: Lower fuel consumption, extended service intervals (500 hrs), and compatibility with SEA LION’s guaranteed genuine spare parts reduce operational costs by an estimated 22% over 3 years.

- SEA LION Integration: Direct compatibility with SINOTRUK/SHACMAN/XCMG excavator hydraulic systems ensures plug-and-play installation. Backed by SEA LION’s 18-year refurbished truck logistics expertise, guaranteeing parts availability and technical support in target regions.

- Transparency & Partnership: Full operational data logging capability (pressure, impacts/min) provides verifiable performance metrics for fleet optimization, aligning with SEA LION’s commitment to operational transparency.

Technical Specifications Snapshot

| Parameter | SL-HB30 Specification | Industry Standard (Typical) |

|---|---|---|

| Operating Pressure | 140-180 bar | 120-160 bar |

| Impact Energy | 2800 J | 2200 J |

| Avg. Blows Per Minute | 450-550 | 400-500 |

| Compatible Excavator Wt | 20-35 tons | 18-30 tons |

| Service Interval | 500 hours | 350 hours |

| Weight | 2850 kg | 2600 kg |

Strategic Imperative: For fleet managers operating in Africa, Russia, or Southeast Asia, the SL-HB Series is not merely an attachment – it is a risk-mitigation asset. Its region-specific hardening, coupled with SEA LION’s unparalleled parts and logistics infrastructure for Chinese heavy equipment, directly translates to maximized uptime, predictable maintenance costs, and sustained project velocity in the world’s most challenging industrial landscapes. SEA LION’s commitment to long-term partnership ensures this technology delivers sustained value throughout its operational lifecycle.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Technical Specifications – Excavator Jackhammer Attachment (Carrier-Mounted Hydraulic Breaker System)

Overview

This specification report outlines the technical parameters of the integrated excavator and jackhammer attachment system designed for heavy-duty demolition, trenching, and rock-breaking applications in high-intensity construction environments. The system is engineered for compatibility with 20–25 ton class excavators equipped with high-flow hydraulic circuits and is optimized for durability, fuel efficiency, and operational load capacity.

Technical Specifications – Excavator with Jackhammer Attachment

| Parameter | Specification |

|---|---|

| Excavator Base Model | ZX210LC-6 / SY215C (OEM Interchangeable) |

| Engine Model | WD615 Series (Weichai Power) |

| Engine Type | 6-Cylinder, Inline, Water-Cooled, Turbocharged |

| Displacement | 9.726 L |

| Rated Horsepower | 184 hp (137 kW) @ 2,200 rpm |

| Max Torque | 790 N·m @ 1,400–1,600 rpm |

| Emission Standard | Tier 3 / China Non-Road Stage III |

| Transmission Model | HW19710 – 10-Speed Synchromesh Manual Transmission |

| Transmission Type | Dual-H Pattern with Power Take-Off (PTO) Support |

| Axle Configuration | 4×2 (Rear Drive) |

| Front Axle Load | 6,800 kg (14,991 lbs) |

| Rear Axle Load | 12,200 kg (26,896 lbs) |

| Gross Vehicle Weight (GVW) | 19,000 kg (41,890 lbs) |

| Tire Specification | 12.00R20, Radial, Load Range G (16 PR) |

| Tire Load Index | 152/148 (Single/ Dual) |

| Tire Speed Rating | L (120 km/h) |

| Breaker Model | HB3000 Hydraulic Jackhammer |

| Operating Pressure | 120–160 bar |

| Impact Rate | 450–750 bpm |

| Tool Diameter | 70 mm (2.75″) |

| Recommended Flow | 110–140 L/min |

| Hose Configuration | Dual 1″ High-Pressure, 300 bar WP, SAE 100R2AT |

Fuel Efficiency Performance

The WD615 engine platform is calibrated for optimal fuel combustion efficiency under variable load cycles typical in excavation and breaking operations. Key fuel performance metrics include:

- Average Fuel Consumption: 18–22 L/h under mixed operating conditions (idle, digging, breaking).

- High-Load Efficiency: 205 g/kWh specific fuel consumption at 75% load.

- Eco Mode Functionality: Reduces engine RPM by 15% and hydraulic flow by 10%, achieving up to 12% fuel savings during non-peak operations.

- Regenerative Hydraulic Circuit: Recovers energy during arm retraction, improving system-level efficiency by 5–7%.

Fuel efficiency is further enhanced by the HW19710 transmission’s close-ratio gearing, allowing precise power delivery and reduced engine strain during slope traversal and load engagement.

Load Capacity & Operational Durability

Structural Load Ratings:

- Maximum Attachment Static Load: 2,800 kg (6,173 lbs) at full reach (7.2 m horizontal).

- Breaker Impact Force: 3,000 Nm per blow (adjustable via pressure control).

- Boom & Arm Yield Strength: 700 MPa high-tensile steel construction.

- Pin & Bushing Hardness: 58–62 HRC, with grease-sealed wear protection.

Operational Load Endurance:

- Designed for 6,000-hour mean time between failures (MTBF) under standard construction cycles.

- Axle and suspension system rated for continuous 19-ton GVW operations on Class II roads and rough terrain.

- Tire load margin exceeds ISO 4250-2 standards by 15%, ensuring reliability in off-road and debris-laden job sites.

Conclusion

The excavator-jackhammer system, powered by the Weichai WD615 engine and supported by the HW19710 transmission, delivers a balanced combination of high breaking force, load stability, and fuel economy. With robust axle loading, industrial-grade tire specs, and proven hydraulic integration, this configuration meets the operational demands of large-scale infrastructure and urban demolition projects. Recommended for fleet deployment in high-uptime scenarios requiring consistent performance and low cost-per-hour operation.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: EXCAVATOR JACKHAMMER ATTACHMENT

EFFECTIVE DATE: 01 JANUARY 2026

REPORT ID: SLI-JHA-QMS-2026-01

1. EXECUTIVE SUMMARY

This report details the manufacturing quality standards and Pre-Delivery Inspection (PDI) protocols for SEA LION International’s Hydraulic Jackhammer Attachment (Model JHA-26 Series), engineered for integration with 15-45 ton excavators. Focus is placed on structural integrity under extreme terrain conditions and hydraulic power unit (HPU) endurance, critical for minimizing fleet downtime in high-cycle construction operations.

2. MANUFACTURING QUALITY STANDARDS

2.1 Chassis & Structural Assembly (Rough Terrain Focus)

The attachment chassis is engineered to withstand dynamic loads exceeding ISO 10218-1:2019 requirements for mobile hydraulic tools. Key quality metrics:

| Parameter | Specification | Test Standard | Compliance Margin |

|---|---|---|---|

| Base Material | ASTM A514 Grade F (Quenched & Tempered) | ASTM A6/A6M | 150% of min. yield |

| Yield Strength | 100 ksi (690 MPa) | ASTM A370 | +25 ksi over ISO req. |

| Tensile Strength | 110-130 ksi (760-895 MPa) | ASTM A370 | +30 ksi over ISO req. |

| Wall Thickness (Dual-Layer) | 1.25″ (32mm) primary / 0.75″ (19mm) secondary | ISO 10218 Annex B | 22% thicker than class avg. |

| Dynamic Load Capacity | 200% rated impact force (25,000 lbf) | SEA LION SL-TEST-007 | Validated at 3x cycles |

Critical Quality Control Points:

– Laser-Guided Welding: All structural seams welded via FCAW process with 100% ultrasonic testing (UT). Defect tolerance: ≤0.5mm porosity.

– Stress-Relief Annealing: Post-weld thermal treatment at 1,150°F (621°C) for 4 hours to eliminate residual stresses.

– Pivot Hardening: Pin bores induction-hardened to 58-62 HRC (ISO 18265) for abrasion resistance in high-vibration environments.

2.2 Hydraulic Power Unit (HPU) Durability

The HPU is designed for continuous operation in dust, moisture, and thermal extremes (ISO 15850 compliance):

| Component | Durability Specification | Validation Method | Target Lifespan |

|---|---|---|---|

| Main Pump | Bosch Rexroth A10VSO Axial Piston | 1,000-hr endurance test | 10,000 operating hrs |

| Sealing System | 3-stage Viton®/PTFE w/ debris exclusion | ISO 4406:2021 (16/14/12) | 8,000 hrs |

| Cooling System | Dual-pass aluminum heat exchanger | Thermal cycling (-22°F to 185°F) | Zero degradation at 5,000 hrs |

| Pressure Relief | Pilot-operated, 5,000 psi max | 10,000 cycle fatigue test | 15,000 cycles |

Key Durability Features:

– Thermal Management: Oil temperature maintained ≤185°F (85°C) at 100% duty cycle via oversized cooler (25% capacity buffer).

– Contamination Control: 10-micron suction filter + 3-micron return-line filter (ISO 16889).

– Vibration Dampening: Rubber-isolated mounting (≤2.5 mm/s RMS per ISO 10816-3).

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

All units undergo a 12-point PDI before shipment. Non-conformances halt dispatch until root-cause resolution.

3.1 Structural Integrity Verification

| PDI Step | Procedure | Acceptance Criteria |

|---|---|---|

| 1. Dimensional Check | CMM scan of mounting interfaces | ≤±0.005″ (0.13mm) tolerance |

| 2. Weld Integrity | 100% UT + 20% dye penetrant | Zero linear indications >1.5mm |

| 3. Pin/Bore Clearance | Dial indicator measurement at 3 locations | 0.008″-0.012″ (0.2-0.3mm) clearance |

| 4. Load Test | 150% rated force @ 50 cycles | Zero permanent deformation |

3.2 Hydraulic System Validation

| PDI Step | Procedure | Acceptance Criteria |

|---|---|---|

| 5. Pressure Hold | 4,500 psi for 30 min | ≤5 psi drop |

| 6. Flow Calibration | Measure at 2,300 rpm engine speed | ±3% of rated flow (28 GPM) |

| 7. Thermal Stability | 2-hr continuous operation @ 120°F ambient | Oil temp ≤180°F (82°C) |

| 8. Fluid Cleanliness | On-site ISO 4406 particle count | ≤18/16/13 |

3.3 Final Operational Checks

- 9. Impact Cycle Test: 500 strikes at 100% power; verify consistent energy transfer (±5% variance max).

- 10. Vibration Analysis: Accelerometer readings at operator station ≤0.8 g RMS.

- 11. Leak Verification: Zero fluid seepage after 8-hr static pressure test.

- 12. Documentation Audit: Traceability of all critical components (mill certs, UT reports, calibration logs).

4. OPERATIONAL IMPACT FOR FLEET MANAGERS

- Chassis Strength: Dual-wall design reduces structural fatigue failures by 68% (vs. industry avg.) in rocky terrain, extending service life to 8,000+ hrs.

- HPU Reliability: Thermal management system cuts overheating-related downtime by 41% in desert/summer operations.

- PDI Assurance: Units passing full PDI show 92% lower warranty claims in first 500 operating hours.

NOTE: SEA LION mandates quarterly structural inspections and hydraulic fluid analysis per SLI-MT-2026-OPS. Neglecting these voids extended warranty coverage.

END OF REPORT

SEA LION International – Engineering the Standard for Heavy Equipment Performance

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Excavator Jackhammer Attachments from China

Issuing Authority: SEA LION International – Engineering & Logistics Division

1. Executive Summary

This report evaluates three primary maritime shipping methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack containers—for the export of excavator jackhammer attachments from manufacturing hubs in China (e.g., Qingdao, Shanghai, Ningbo) to global construction markets. Key performance metrics include cost efficiency, transit time, equipment protection, and corrosion resistance. A mandatory wax-based anti-corrosion treatment is recommended for all shipments to mitigate seawater exposure during transit.

2. Product Overview: Excavator Jackhammer Attachment

| Parameter | Specification |

|---|---|

| Weight Range | 800 – 2,500 kg |

| Dimensions (L×W×H) | 1.8 m × 0.9 m × 1.2 m (avg.) |

| Material Composition | High-strength alloy steel, hardened tips |

| Corrosion Sensitivity | High (exposed hydraulic ports, steel surfaces) |

| Handling Requirements | Forklift or crane compatible |

| Packaging | Wooden skid with lifting lugs |

3. Shipping Method Comparison

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Suitability | Moderate | Low | High |

| Loading Mechanism | Self-propelled or towed | Loosely loaded in hold | Secured on open-top platform |

| Cargo Protection | Limited (exposed decks) | Poor (mixed cargo, moisture) | High (weather cover optional) |

| Transit Time (Shanghai → EU) | 28–35 days | 30–40 days | 26–32 days |

| Cost (per unit, USD) | $1,300 – $1,700 | $900 – $1,200 | $1,800 – $2,300 |

| Port Infrastructure Needs | RoRo ramp, clear deck access | General cargo crane | Container crane, flat rack slots |

| Risk of Damage | Medium (vibration, shifting) | High (impact, moisture) | Low (properly lashed) |

| Customs Clearance Speed | Fast | Moderate | Fast |

| Best For | Large fleets, low-value density | Commodity-grade, non-sensitive | High-value, corrosion-sensitive |

Note: Flat Rack containers offer optimal structural support and environmental control for precision construction attachments.

4. Corrosion Protection Protocol: Wax Spraying Treatment

Seawater-laden atmospheres during maritime transport pose a significant risk to ferrous components. SEA LION International mandates the following anti-corrosion procedure for all jackhammer attachments prior to shipment:

Wax Spraying Specifications

| Parameter | Requirement |

|---|---|

| Coating Type | Solvent-based anti-corrosion wax |

| Application Method | Electrostatic spray or dip-coating |

| Coverage | Full surface, with emphasis on joints, pins, and hydraulic ports |

| Thickness | 25–40 µm (microns) |

| Salt Spray Resistance | Minimum 500 hours (ASTM B117) |

| Removal at Destination | Biodegradable solvent or hot alkaline wash |

| Certification | ISO 12944-6 compliant |

Implementation: Conduct treatment within 24 hours of final assembly. Allow 4-hour cure time before crating. Document batch-specific coating reports for QA traceability.

5. Recommended Solution

For excavator jackhammer attachments exported from China, Flat Rack shipping combined with wax spraying protection is the optimal logistics solution due to:

- Superior mechanical security and reduced handling risk

- Compatibility with corrosion-sensitive surfaces

- Streamlined customs and inland transport integration

- Full visibility and inspection access at origin and destination

RO-RO may be considered for fleet-scale deliveries where cost is prioritized over finish protection. Bulk Cargo is not recommended due to high risk of saltwater exposure and physical damage.

6. Operational Recommendations

- Pre-shipment: Apply wax coating in controlled environment; verify with adhesion and thickness testing.

- Loading: Secure unit to Flat Rack using minimum 4-point lashing (M8 turnbuckles, 5,000 kg SWL).

- Documentation: Include wax treatment certificate, material test reports (MTRs), and packing list.

- Monitoring: Utilize IoT humidity/tilt sensors for high-value consignments.

7. Conclusion

Exporting excavator jackhammer attachments from China demands a balanced approach between cost, protection, and delivery reliability. Flat Rack shipping, supported by industrial-grade wax corrosion inhibition, ensures product integrity and reduces post-arrival rework. SEA LION International advises fleet managers and construction logistics planners to standardize on this protocol for all marine exports in 2026 and beyond.

End of Report

SEA LION International – Engineering & Logistics Division

Revision: 2026-Q1-IND-LOG-EXC-001

Get a Quote for Excavator Jackhammer Attachment

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]