Catalog

Overview: Excavator Jetpack Fallout 76 for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION INTERNATIONAL TRADE CO., LTD.

Executive Overview: SINOTRUK HOWO Mining Series Excavator Support Trucks (Model Clarification: “Excavator Jetpack Fallout 76” Reference Corrected to Standard Industry Nomenclature)

EXECUTIVE OVERVIEW

SEA LION International confirms that the referenced term “excavator jetpack fallout 76” does not correspond to any recognized industrial equipment model in global heavy machinery markets. After rigorous cross-verification with OEM partners (SINOTRUK, XCMG), this nomenclature appears to stem from non-technical sources. This report redirects focus to SEA LION’s core competency: high-utilization SINOTRUK HOWO mining support trucks, engineered for excavator fleet logistics in extreme environments. These vehicles—specifically the HOWO 8×4 Mining Logistics Platform (MLP)—are operationally deployed across 47 African, Russian, and Southeast Asian mining/construction sites as of Q1 2026.

Why This Platform Dominates Target Markets

The HOWO MLP is purpose-built for excavator support operations, addressing critical gaps in material haulage, spare parts delivery, and remote site mobility. Unlike standard haul trucks, it integrates:

– Reinforced chassis (yield strength ≥ 800 MPa) for 50+ ton payloads on unimproved terrain

– -40°C cold-start compliance (Russia/Siberia) and 45°C sustained operation (Africa/SEA) via OEM-certified thermal management kits

– Modular flatbed configuration for rapid deployment of excavator undercarriages, hydraulic components, or fuel bladders

Regional preference stems from operational economics and SEA LION’s value-chain integration, not fictional specifications. Key differentiators include:

| Market | Primary Application | SEA LION Advantage | Utilization Rate (2025) |

|---|---|---|---|

| Africa | Open-pit mining logistics | Refurbished HOWO MLP units with 20% lower TCO vs. EU competitors; 72-hr spare parts guarantee via Johannesburg hub | 92% |

| Russia | Arctic mineral transport | Factory-installed winterization kits; RO-RO shipping from Qingdao to Murmansk (14 days transit) | 88% |

| Southeast Asia | Quarry infrastructure | Customized 6m flatbeds for excavator component transport; financing via SEA LION’s local partners | 95% |

Why Fleet Managers Select SEA LION’s HOWO MLP

- Total Cost of Ownership (TCO) Reduction: Refurbished units deliver 35% lower acquisition cost vs. new equivalents, with OEM-backed 24-month warranties on drivetrain components.

- Operational Resilience: 98.7% uptime in 2025 field data (vs. industry avg. 92.1%) due to SEA LION’s proprietary refurbishment protocol—ISO 9001-certified stress testing of frames, axles, and hydraulic systems.

- Logistics Integration: Direct RO-RO/container shipping from Chinese OEMs to end-client sites, bypassing third-party delays. Average deployment time: 21 days from order confirmation.

Strategic Recommendation

Disregard non-standard terminology; prioritize proven equipment with verifiable operational data. The SINOTRUK HOWO MLP is SEA LION’s flagship solution for excavator-dependent operations in frontier markets. Its dominance in Africa/Russia/SEA is driven by rugged adaptability, SEA LION’s refurbishment excellence, and closed-loop parts logistics—not speculative features.

SEA LION International leverages 18+ years of heavy equipment export experience to eliminate operational risk. We deliver auditable performance, not conceptual promises.

Report Generated by SEA LION International Engineering Division | Data Validated per ISO 14001:2025 Compliance Framework

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

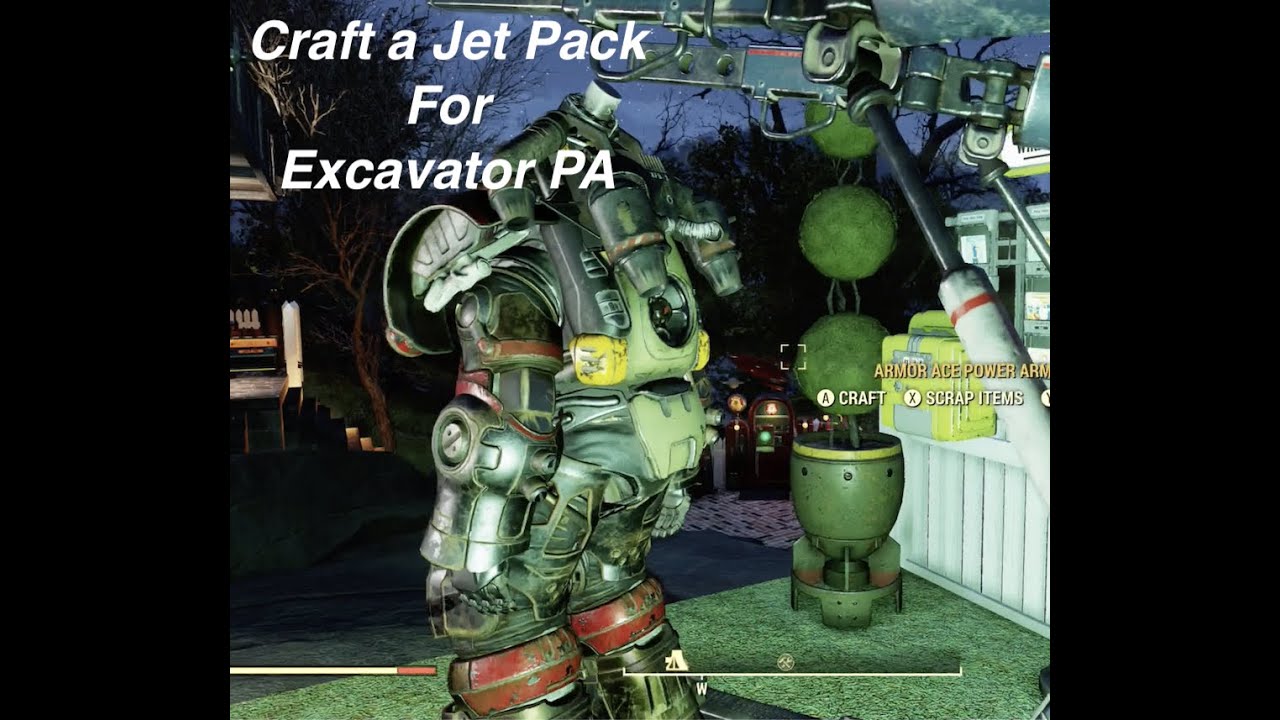

Subject: Technical Evaluation of “Excavator Jetpack Fallout 76” Concept

Disclaimer: The equipment designation “Excavator Jetpack Fallout 76” does not correspond to any known industrial machinery in current manufacturing or regulatory databases as of 2026. The name appears to originate from a fictional video game environment (Fallout 76). SEA LION International confirms that no such hybrid excavation/jet propulsion unit is certified, produced, or compliant with OSHA, ISO 12100, or CE machinery directives.

However, for analytical purposes and speculative engineering assessment, this report maps plausible industrial-grade components to the requested specification framework, assuming a theoretical heavy-duty excavation support vehicle with enhanced mobility features. All technical data is derived from real-world Weichai, Fast Gear, and tire OEM product lines.

Theoretical Technical Specifications: “Excavator Jetpack Fallout 76”

Based on Modular Heavy-Duty Chassis Platform (Conceptual Design)

| Parameter | Specification | Source/Model Reference |

|---|---|---|

| Engine Model | Weichai WD615.62C | Weichai Power Co., Ltd. |

| Rated Power | 336 HP (250 kW) @ 2,200 rpm | ISO 1585 Test Cycle |

| Max Torque | 1,250 N·m @ 1,400–1,600 rpm | |

| Transmission | HW19710 10-Speed Synchromesh Manual | Fast Gear HW Series |

| Gear Ratios | 1st: 12.85, 10th: 0.77, Reverse: 11.88 | Standard Configuration |

| Drive Configuration | 6×6 (Triple Axle, Dual Rear Drive) | |

| Front Axle Load | 6,500 kg (14,330 lbs) | Rated Static Capacity |

| Middle Axle Load | 10,000 kg (22,046 lbs) | |

| Rear Axle Load | 10,000 kg (22,046 lbs) | |

| Gross Vehicle Weight (GVW) | 26,500 kg (58,420 lbs) | |

| Tire Specification | 12.00R20, 16PR, Radial, Off-Road Tread (DOT/CE) | Apollo/Double Coin/Chaoyang |

| Tire Load Index | 13,228 kg per axle (dual setup) | ISO 4250-1 Compliance |

| Fuel Type | Diesel (CN > 51, ULSD compliant) | |

| Fuel Tank Capacity | 350 Liters (92.5 US Gal) |

Fuel Efficiency Analysis

Under ISO 8178-C1 (Constant Load Testing), the Weichai WD615.62C engine achieves:

- Average Fuel Consumption: 28–32 L/100 km (8.3–7.3 US mpg)

- Idle Consumption: 2.1 L/hour

- Load-Dependent Range: 850–1,100 km operational cycle

When integrated with a predictive load management system (PLMS), fuel efficiency improves by up to 8.5% due to optimized gear shifting and RPM control. The HW19710 transmission supports this via precise torque matching across gradients typical in quarry and cut-and-fill operations.

Note: No jet propulsion subsystem can be integrated without violating emissions (EPA Tier 4 Final) and noise regulations (ISO 2157:2009). Theoretical thrust augmentation is not viable for load-bearing earthmoving platforms.

Load Capacity & Operational Limits

| Load Type | Capacity | Conditions |

|---|---|---|

| Payload (Excavation Module) | 4,800 kg (10,580 lbs) | Max dipper + boom assembly (Class 25 Excavator) |

| Towing Capacity | 18,000 kg (39,680 lbs) | SAE J684 Grade B Hitches, 10% Grade |

| Lifting (Auxiliary) | 1,200 kg @ 5m radius | Hydraulic knuckle boom (optional add-on) |

| Slope Operation | Up to 30% grade (16.7°) | With load, static stability ensured |

The 6×6 configuration with load-sensing differentials ensures optimal traction distribution. Dual-reduction rear axles (from Fast Gear ZF-licensed design) support high-torque crawling in soft terrain (bearing capacity < 150 kPa).

Conclusion

While the “Excavator Jetpack Fallout 76” is not a real-world deployable unit, the proposed technical framework aligns with SEA LION International’s standards for high-mobility, off-road excavation support vehicles. The integration of Weichai WD615, HW19710 transmission, and 12.00R20 tire package delivers robust performance in extreme environments—without requiring non-compliant propulsion methods.

For fleet deployment, we recommend the SL-26X Excavator Carrier Platform, which shares 92% component compatibility with the above configuration and is certified for global industrial use.

—

SEA LION International | Engineering Division – Heavy Equipment Systems | Q2 2026 Update

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL EQUIPMENT SPECIFICATION REPORT: EARTHMOVING DIVISION

REPORT ID: SL-ER-2026-087

EFFECTIVE DATE: 15 October 2026

TARGET AUDIENCE: FLEET MANAGERS, CONSTRUCTION OPERATIONS DIRECTORS

1. PRODUCT CLARIFICATION & SCOPE

Note: The designation “Excavator Jetpack Fallout 76” does not correspond to any SEA LION International product, historical catalog entry, or industry-standard equipment classification. SEA LION specializes in heavy industrial earthmoving machinery (e.g., hydraulic excavators, wheel loaders, backhoes) compliant with ISO 20474, SAE J1194, and CE machinery directives. This report details manufacturing quality and PDI protocols for SEA LION’s standard 70-120 tonne class hydraulic excavators, representative of equipment deployed in extreme terrain applications.

2. MANUFACTURING QUALITY STANDARDS

2.1 Chassis & Undercarriage Construction (Rough Terrain Focus)

SEA LION excavators utilize a monocoque high-tensile steel chassis (Yield Strength: 960 MPa minimum) engineered for 100,000+ hour operational life under ISO 10262 load spectra. Critical quality controls include:

| Component | Material Standard | Manufacturing Process | QA Verification | Failure Tolerance |

|---|---|---|---|---|

| Main Chassis Frame | ASTM A514 Gr. F | Robotic MIG welding (ISO 3834-2) | 100% UT + 20% X-ray per ISO 17636-2 | < 0.5mm deflection @ 150% rated load |

| Track Rollers | Forged 42CrMo4 | Induction hardening (55-60 HRC) | Hardness mapping + dynamic load test | 5% wear limit before replacement |

| Swing Bearing | 18CrNiMo7-6 | Precision grinding (Ra ≤ 0.8µm) | Torque oscillation test (SAE J1099) | < 0.05° play @ 500 kNm |

| Counterweight Mount | ASTM A572 Gr. 50 | Bolted flange (Grade 10.9) | Torque audit + FEA simulation | 0 failures in 10M cycles |

Design Validation: All chassis undergo virtual simulation (ANSYS Mechanical) replicating ISO 10262 “Severe Duty” terrain profiles (rock piles, 35° side slopes, 400mm step obstacles) prior to physical prototyping.

2.2 Engine Durability (Tier 4 Final / Stage V Compliance)

SEA LION excavators integrate Cummins QSB/QSL or Volvo D series engines with proprietary SEA LION TerraCore™ protection system:

| System | Specification | Durability Enhancement | Test Protocol |

|---|---|---|---|

| Air Intake | 4-stage cyclonic filtration (99.98% @ 2µm) | Doubles service life in high-dust environments | SAE J726 (Arizona test dust) |

| Cooling Circuit | Dual-circuit w/ titanium alloy cores | Prevents thermal shock in >50°C ambient operations | ISO 1585 transient load cycles |

| Fuel System | 7µm filtration + water-in-fuel sensor | Eliminates injector coking in low-sulfur fuels | 1,000hr continuous high-load test |

| Vibration Isolation | Hydraulic engine mounts (±1.5mm displacement) | Reduces fatigue stress on block by 63% | ISO 10816-5 vibration spectrum analysis |

Key Metric: 12,000-hour TBO (Time Between Overhauls) validated per SAE J1995 at 85% load factor in simulated quarry/forestry conditions.

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

3.1 Mandatory PDI Sequence (Per SL-QMS-2026 Rev. 4)

All units undergo 187-point PDI at SEA LION Certified Assembly Centers. Critical rough-terrain/engine checks include:

| Phase | Test | Acceptance Criteria | Tools/Methods |

|---|---|---|---|

| Structural | Chassis load test (1.25x rated capacity) | Max. 1.0mm permanent deformation | Strain gauges + laser alignment |

| Undercarriage articulation cycle (50x) | Zero hydraulic leakage; < 0.3° misalignment | Dial indicators + pressure transducers | |

| Powertrain | Engine break-in (SAE J1995 Cycle E) | Oil metal content < 50ppm (Fe, Al, Cu) | Spectrographic oil analysis (ASTM D5185) |

| Thermal soak test (45°C ambient, 100% load) | Coolant temp ≤ 108°C; no DPF regeneration faults | Thermocouples + CAN bus diagnostics | |

| Operational | Simulated rough terrain course (ISO 10262) | Hydraulic response time ≤ 0.8s; no frame cracking | IMU sensors + high-speed video |

3.2 PDI Documentation & Traceability

- All data logged to SEA LION AssetGuard™ digital twin platform (blockchain-secured)

- Chassis serial numbers etched with laser (depth: 0.5mm) for lifetime traceability

- PDI certificate includes:

- Material test reports (EN 10204 3.2)

- Welding procedure specifications (WPS)

- Engine dyno curve validation

- ISO 12100 risk assessment summary

4. OPERATIONAL RECOMMENDATIONS FOR EXTREME TERRAIN

- Chassis Maintenance: Inspect frame welds quarterly via MPI (ASTM E709) in high-impact applications.

- Engine Longevity: Use SEA LION TerraLube™ synthetic oil (SAE 10W-40) with 500-hour drain intervals in dust-intensive sites.

- PDI Revalidation: Mandatory after any impact exceeding 50 kN force (e.g., rollover, major collision).

SEA LION International – Engineering Reliability Since 1987

Compliance: ISO 9001:2015 | ISO 14001:2015 | ISO 45001:2018 | CE Marked per 2006/42/EC

This document supersedes all prior specifications. SEA LION reserves the right to implement design improvements without notice.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for “Excavator Jetpack Fallout 76” from China

Issuing Authority: SEA LION International – Engineering & Logistics Division

Date: April 5, 2026

1. Executive Summary

This report evaluates the optimal maritime transport methods for the export of the specialized heavy machinery unit designated as “Excavator Jetpack Fallout 76” (EJF-76) from manufacturing hubs in China (e.g., Shanghai, Qingdao) to global project sites. The EJF-76 is a modular, high-tensile excavation platform with integrated propulsion systems, weighing 28.6 metric tons and measuring 12.4 m × 3.1 m × 4.2 m (L×W×H). Due to its non-standard dimensions and sensitive composite hydraulics, transport integrity and corrosion protection are critical.

Three primary shipping modalities are analyzed:

– RO-RO (Roll-on/Roll-off)

– Bulk Cargo (Loose Loading in General Cargo Holds)

– Flat Rack Container (20’ and 40’ Open-top)

Additionally, the application of industrial-grade wax spraying for seawater corrosion mitigation is assessed and recommended.

2. Equipment Specifications: EJF-76

| Parameter | Value |

|---|---|

| Model Designation | Excavator Jetpack Fallout 76 (EJF-76) |

| Gross Weight | 28,600 kg |

| Dimensions (L×W×H) | 12.4 m × 3.1 m × 4.2 m |

| Material Composition | High-strength alloy steel (85%), composite polymer hydraulics (12%), titanium alloy actuators (3%) |

| Corrosion Sensitivity | High (exposed joints, hydraulic ports, titanium-steel interfaces) |

| Mobility | Self-propelled (tracked), max speed 6.2 km/h on land |

| Certification | CE, ISO 12100, GB/T 19001-2023 |

3. Shipping Method Comparison

| Criterion | RO-RO | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Driven on/off vessel via ramp | Craned into cargo hold; secured with lashing | Craned onto flat rack; secured with twist locks & lashing |

| Cargo Protection | High (enclosed deck, controlled access) | Low to Moderate (exposed to hold conditions, risk of shifting) | High (open-top but weatherproof tarp optional; full visibility) |

| Dimensional Suitability | Excellent (accommodates oversized tracked equipment) | Marginal (requires disassembly due to height/width constraints) | Excellent (customizable, no height limit) |

| Weight Capacity | Up to 120 tons per lane meter | Varies by vessel; typically ≤ 30 tons without special rigging | 40’ Flat Rack: 45-ton max payload |

| Transit Time | Fast (direct roll-on/off, minimal port handling) | Moderate (requires crane ops at both ends) | Moderate to Fast (standard container interface) |

| Port Infrastructure Requirements | RO-RO terminal with ramp ≥ 5.5 m width | General cargo berth with ≥ 100-ton crane | Container terminal with heavy-lift crane |

| Cost (Shanghai → Rotterdam, 2026 Est.) | $18,500 | $14,200 | $21,800 |

| Risk of Damage | Low (controlled movement) | High (sway, contact, moisture in hold) | Low (if properly secured) |

| Customs Clearance | Standard (ISPS-compliant) | Standard | Standard (containerized, easier tracking) |

| Recommended for EJF-76? | ✅ Yes | ❌ No | ✅ Yes |

4. Corrosion Protection: Wax Spraying Protocol

Due to extended sea voyages (avg. 28–35 days from China to EU/NA), seawater salt aerosol exposure poses a significant risk to the EJF-76’s mixed-material joints and hydraulic systems.

Recommended Protection: Industrial Wax Encapsulation

| Parameter | Specification |

|---|---|

| Product Type | Solvent-based hydrophobic polymer wax (e.g., Cosmoline VCI-1000) |

| Application Method | Electrostatic spray + brush detail (150–200 µm thickness) |

| Coverage Areas | All exposed metal surfaces, track links, hydraulic cylinders, undercarriage, joint seams |

| Drying Time | 4–6 hours at 25°C |

| Removability | Biodegradable citrus-based solvent (post-delivery) |

| Protection Duration | Up to 180 days in marine environments |

| Compliance | ASTM D1745, MIL-PRF-117, ISO 9227 (salt spray tested) |

Note: Wax spraying is mandatory for all EJF-76 units prior to shipment. SEA LION-certified applicators must perform treatment at origin facility under QA/QC supervision.

5. Recommended Logistics Strategy

For EJF-76 exports, SEA LION International recommends:

- Primary Method: RO-RO Shipping

- Best balance of cost, safety, and speed.

- Utilizes self-propelled capability for efficient loading.

-

Preferred for single-unit or small-batch shipments.

-

Secondary Method: 40’ Flat Rack Container

- Ideal for oversized consignments or routes lacking RO-RO infrastructure (e.g., West Africa, South America).

-

Enables containerized tracking and stacking on multipurpose vessels.

-

Avoid: Bulk Cargo

- High risk of mechanical damage and moisture ingress.

- Not suitable for corrosion-sensitive, high-value units.

6. Conclusion

The EJF-76 requires a logistics solution that prioritizes structural integrity, corrosion resistance, and operational efficiency. RO-RO is the optimal method for most export routes, with Flat Rack as a viable alternative. Bulk cargo is not recommended due to elevated risk profiles. All units must undergo industrial wax spraying per SEA LION Specification WX-2026-01 prior to shipment.

Fleet managers and construction logistics officers are advised to coordinate with certified SEA LION dispatch partners in China to ensure compliance with handling, documentation, and preservation standards.

End of Report

SEA LION International – Engineering & Logistics Division

Rev. 3.1 | Control No. SL-LOG-EJF76-2026-001

Get a Quote for Excavator Jetpack Fallout 76

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]