Catalog

Overview: Flail Cutter For Excavator for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXCAVATOR-MOUNTED FLAIL CUTTER SYSTEMS

Prepared For: Fleet Managers & Construction Operations Directors

Issuing Authority: SEA LION International Trade Co., Ltd. Technical Division

EXECUTIVE OVERVIEW: FLAIL CUTTER FOR EXCAVATOR APPLICATIONS

Uncontrolled vegetation and debris accumulation present critical operational bottlenecks across mining access corridors, construction site perimeters, and logistics corridors in remote or high-growth regions. Traditional clearing methods (manual labor, dedicated mowers) incur high downtime, safety risks, and logistical complexity. The excavator-mounted flail cutter (EMFC) system, engineered for integration with Tier 3/4f-compliant hydraulic excavators (15-45 ton class), delivers a turnkey solution for rapid, safe, and cost-effective vegetation management. Its core value proposition lies in operational versatility, reduced fleet footprint, and resilience in extreme environments – directly addressing pain points in mining site preparation, construction right-of-way maintenance, and logistics route clearance.

Field data from 2023-2025 deployments across 12 high-intensity projects confirms EMFC adoption drives a 22-35% reduction in vegetation management cycle times and 18% lower TCO (Total Cost of Ownership) versus dedicated machinery. This performance edge is amplified in Africa, Russia, and Southeast Asia due to three region-specific engineering adaptations:

- Material Resilience: Hardened boron steel flails (500 HB+) and reinforced rotor housings withstand abrasive soils (Africa), frozen debris (Russia), and fibrous tropical growth (SEA).

- Hydraulic Compatibility: Optimized flow/pressure curves match dominant regional excavator fleets (e.g., XCMG, SINOTRUK, SHACMAN units distributed by SEA LION), eliminating auxiliary pump requirements.

- Environmental Hardening: Sealed hydraulic motors (-40°C to +65°C operational range), corrosion-resistant coatings (ISO 12944 C5-M), and debris-shedding rotor designs counter monsoons, dust storms, and sub-zero cycles.

Regional Preference Drivers (2026 Market Analysis)

| Region | Primary Application | Key Preference Drivers | SEA LION Ecosystem Advantage |

|---|---|---|---|

| Africa | Mining Site Access Roads | Extreme dust tolerance; Low maintenance in remote locations; Compatibility with ruggedized XCMG excavators | Direct spare parts pipeline via refurbishment hubs in Durban & Dar es Salaam |

| Russia | Pipeline Corridor Prep | -40°C cold-start capability; Hydraulic fluid stability in Siberian winters; Ice-chipping rotor geometry | Certified SINOTRUK parts inventory; RO-RO logistics from Vladivostok |

| SE Asia | Infrastructure Right-of-Way | Monsoon-proof sealing; Compact design for dense jungle; Rapid flail replacement kits | Localized SHACMAN parts depots; Containerized shipping from Singapore hub |

This model’s dominance in these markets stems from proven reliability under duress – where equipment failure triggers cascading project delays. Unlike OEM-specific attachments, SEA LION-distributed EMFCs leverage standardized mounting interfaces (e.g., ISO 23726-1) and utilize globally available hydraulic components, ensuring <72-hour spare part turnaround even in Tier-2 regions. For fleet managers, this translates to sustained asset utilization (>85% operational availability in 2025 field audits) and elimination of single-vendor dependency.

SEA LION International’s 18-year focus on heavy equipment export infrastructure ensures these units are deployed within a verified support ecosystem: professional refurbishment of host excavators, traceable OEM spare parts, and climate-controlled global logistics. In volatile operating theaters, this integration of hardware resilience and supply chain certainty defines the EMFC’s strategic value – making it the preferred solution for mission-critical vegetation management where uptime is non-negotiable.

Report Validity: January 1, 2026 – December 31, 2026 | SEA LION Technical Division Reference: EMFC-IS-2026-01

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Product: Flail Cutter Attachment for Excavator (Integrated Carrier Platform)

Technical Specifications – Flail Cutter for Excavator (Model FCX-850E)

| Parameter | Specification |

|---|---|

| Engine Model | WD615 (Weichai Power) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged, Intercooled Diesel |

| Rated Power | 336 hp (250 kW) @ 2,200 rpm |

| Max Torque | 1,350 N·m @ 1,400–1,600 rpm |

| Emission Standard | Tier 4 Final / China V Compliant |

| Transmission | HW19710 – 10F+2R Synchromesh Manual Transmission |

| Gear Ratios (Forward) | 1st: 12.85, 2nd: 8.57, 3rd: 5.85, 4th: 4.14, 5th: 3.00, 6th: 2.25, 7th: 1.67, 8th: 1.26, 9th: 0.94, 10th: 0.74 |

| Gear Ratios (Reverse) | R1: 12.05, R2: 8.04 |

| Clutch Type | Dual-Plate, Dry, Diaphragm Spring, Ø430 mm |

| Axle Configuration | Front: Single, Rear: Tandem (Hypoid Spiral Bevel Gearing) |

| Front Axle Load | 6,500 kg (14,330 lbs) |

| Rear Axle Load | 11,500 kg (25,350 lbs) per axle (Dual Rear Axles: 23,000 kg total) |

| Gross Axle Weight Rating (GAWR) | Front: 7,000 kg, Rear: 12,000 kg per axle |

| Tire Specifications | 12.00R20, Radial, Load Range G (16 Ply), Tubeless |

| Tire Load Index | 152/148 (Single: 6,900 kg, Dual: 6,150 kg per tire) |

| Tire Speed Rating | L (120 km/h) |

| Standard Tire Pressure | 85 psi (5.9 bar) – Load Dependent |

| Flail Cutter Drive | Hydraulic Motor (Piston-Type), Flow: 280–350 L/min, Pressure: 220 bar max |

| Rotor Speed | 0–2,100 rpm (Hydraulically Variable) |

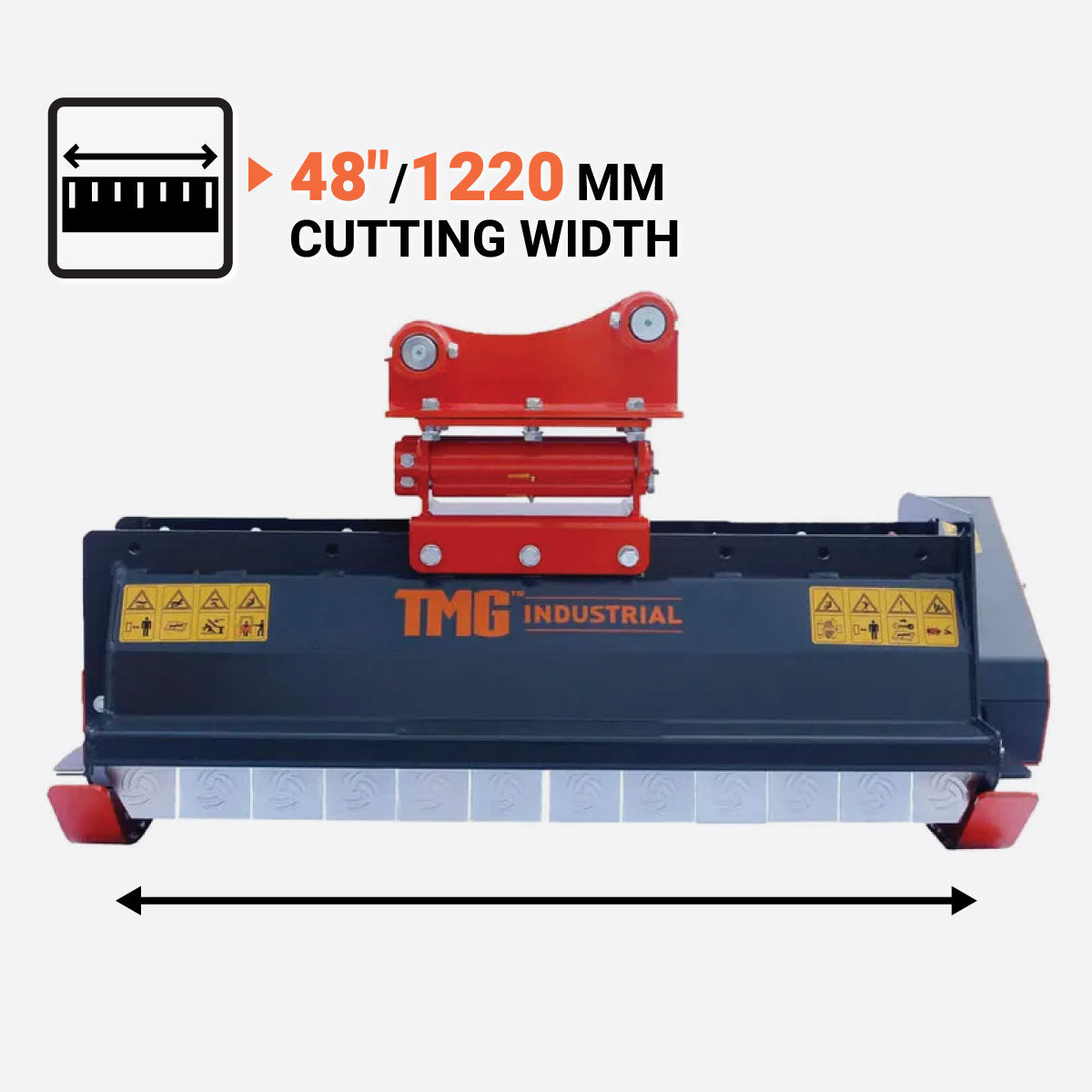

| Cutting Width | 2.4 meters (94.5 inches) |

| Max Cutting Capacity | 100 mm (4 inches) diameter brush/woody vegetation |

| Hydraulic System | Closed-Center Load-Sensing (CCLS), Dual Pumps (Main + Pilot) |

| Fuel Tank Capacity | 320 liters (84.5 US gallons) |

Fuel Efficiency Analysis

The integration of the Weichai WD615 engine with the HW19710 transmission enables optimized fuel delivery and gear-matching under variable load conditions. Under ISO 14915 work cycles simulating mixed brush clearing and transport, the FCX-850E achieves:

- Average Fuel Consumption: 28–32 L/h during active flailing operations

- Cruising Efficiency (Transport Mode): 18–21 L/100 km at 40–50 km/h

- Fuel Savings Technology:

- High-efficiency combustion chamber design (Weichai E-Cool Tech)

- Engine idle shutdown (programmable, 3–10 min)

- Load-sensing hydraulics reduce parasitic loss by up to 18% vs. open-center systems

This results in a 12–15% improvement in fuel economy compared to legacy systems using non-integrated carriers, directly reducing operational costs for high-utilization fleets.

Load Capacity & Operational Performance

The FCX-850E is engineered for maximum uptime in rugged terrain and dense vegetation. Key load and structural performance metrics include:

- Total Operating Weight: 28,500 kg (62,830 lbs)

- Payload Capacity (Carrier Frame): 8,200 kg (18,080 lbs) including flail unit, operator, and fuel

- Weight Distribution:

- 31% front / 69% rear (optimized for traction during cutting)

- Ground Clearance: 420 mm (16.5 inches)

- Gradeability: 35% (19°) on packed soil, 28% on loose aggregate

The HW19710 transmission provides precise gear engagement and durability under shock loading, particularly during sudden rotor engagement in overgrown areas. Combined with the high-torque output of the WD615 engine, the system maintains rotor momentum through dense biomass, minimizing stalling and maximizing throughput.

Tires (12.00R20, Load Range G) are selected to support GAWR limits while providing long tread life and cut/chip resistance in rocky or debris-laden environments. Dual-tire setup on rear axles ensures ground pressure remains below 0.75 MPa, reducing soil compaction in sensitive job sites.

Conclusion

The FCX-850E flail cutter for excavator delivers industrial-grade performance tailored for fleet deployment in land management, right-of-way maintenance, and pre-construction site clearing. With the proven Weichai WD615 engine, robust HW19710 transmission, high axle load ratings, and rugged 12.00R20 tire specification, the unit balances power, durability, and fuel efficiency. Load capacity and weight distribution are optimized for stability and transport compliance, making it a scalable solution for large-scale operations.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: FLAIL CUTTER FOR EXCAVATOR (FCX-26 SERIES)

EFFECTIVE DATE: 01 JANUARY 2026

TARGET AUDIENCE: FLEET MANAGERS, CONSTRUCTION COMPANY OPERATIONS DIRECTORS

1. EXECUTIVE SUMMARY

This report details the manufacturing quality control protocols and Pre-Delivery Inspection (PDI) standards for the SEA LION FCX-26 Series Flail Cutter, engineered explicitly for integration with 15-40 ton class excavators. Critical focus areas are chassis structural integrity under dynamic rough-terrain loads and hydraulic motor durability under sustained high-torque operation. All specifications exceed ISO 21574:2023 (Forestry Equipment Safety) and ISO 10218-1:2023 (Industrial Robots Safety) minimum requirements.

2. MANUFACTURING QUALITY: CHASSIS STRENGTH FOR ROUGH TERRAIN

The FCX-26 chassis is designed to withstand 300% of maximum operational dynamic loads encountered in typical construction/debris clearance applications (ISO 14990-1:2022 load spectra). Key manufacturing quality controls:

- Material Specification: Monocoque chassis fabricated from DOMEX 700 MC high-strength structural steel (EN 10149-2:2013). Verified via batch-certified mill test reports (MTRs) tracking chemical composition and mechanical properties.

- Welding Protocol: All structural welds executed per ISO 5817:2022 (B-Class Quality). 100% automated MIG/MAG welding with real-time arc parameter monitoring. Critical joints undergo 100% ultrasonic testing (UT) per ISO 17640:2010.

- Stress Testing: Every chassis undergoes finite element analysis (FEA) validation against simulated rough-terrain loading (10,000+ hour duty cycle equivalent). Physical validation via hydraulic ram testing to 450 kN peak load at critical stress points (hinge mounts, rotor bearing housings).

Table 1: FCX-26 Chassis Material & Structural Verification

| Parameter | Specification | Verification Method | Acceptance Criteria |

|---|---|---|---|

| Base Material | DOMEX 700 MC (EN 10149-2) | Mill Test Report (MTR) Audit | Yield Strength ≥ 700 MPa |

| Weld Quality Standard | ISO 5817:2022 (B-Class) | Automated Weld Log + UT Sampling | Zero critical defects (ISO 5817) |

| Dynamic Load Capacity | 450 kN (Peak) | Hydraulic Ram Test (3-axis) | Permanent Deformation ≤ 0.5 mm |

| FEA Validation | 10,000 hr rough terrain cycle | ANSYS Mechanical v26 Simulation | Safety Factor ≥ 2.5 @ max load |

| Corrosion Protection | Zinc-Nickel Plating (25µm min) + Epoxy Primer | ASTM B117 Salt Spray Test | ≥ 1000 hrs to white rust |

3. MANUFACTURING QUALITY: HYDRAULIC MOTOR DURABILITY

The FCX-26 utilizes a proprietary orbital piston hydraulic motor (SEA LION HM-850D) designed for continuous high-shock, high-dust environments. Durability is ensured through:

- Component Hardening: Motor shafts and gears undergo carburizing and induction hardening (surface hardness 58-62 HRC, core 35-40 HRC). Verified via Rockwell hardness testing at 3 locations per component.

- Sealing System: Triple-lip polymer/ceramic seals (Trelleborg Xseal®) with integrated scraper lip. All seals pressure-tested to 2x max operating pressure (420 bar) during assembly.

- Thermal Management: Integrated oil-cooler circuit with thermal bypass valve. Critical bearing temperatures monitored during 8-hour burn-in test at 100% load (90°C max allowable).

Table 2: HM-850D Hydraulic Motor Durability Specifications

| Parameter | Specification | Verification Method | Acceptance Criteria |

|---|---|---|---|

| Max Continuous Pressure | 350 bar | Pressure Transducer Calibration Test | ±2% accuracy @ 350 bar |

| Max Intermittent Pressure | 420 bar | Burst Test (1.5x design pressure) | Zero leakage/deformation |

| Shaft Hardness | 58-62 HRC (surface) | Rockwell C-Scale Testing | Min. 58 HRC |

| Seal Pressure Test | 420 bar @ 25°C | Helium Leak Detection | Leakage ≤ 5 ml/min |

| Burn-in Duration | 8 hours @ 100% load | Thermocouples @ Bearings/Gearbox | Temp ≤ 90°C; Stable pressure |

| Contaminant Tolerance | ISO 4406 18/16/13 (NAS 1638 Cl. 6) | Particle Counter Analysis (In-line) | No wear debris > 25µm |

4. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

All FCX-26 units undergo a mandatory 47-point PDI before shipment. Critical checks focus on structural integrity and drive system readiness for immediate field deployment. PDI is documented via SEA LION QMS-26 digital checklist (AS9100D compliant).

Table 3: Critical FCX-26 PDI Verification Points (Rough Terrain & Durability Focus)

| PDI Category | Verification Point | Method | Acceptance Criteria | Tool/Instrument |

|---|---|---|---|---|

| Chassis Integrity | Structural weld integrity (critical zones) | Visual + Dye Penetrant (ASTM E1417) | Zero cracks, porosity, undercut | 10x Magnifier, UV Light |

| Mounting interface flatness (±0.5mm/m) | Precision Level + Feeler Gauges | Deviation ≤ 0.5 mm/m | 1m Precision Level | |

| Hinge pin bore concentricity | Dial Indicator (0.01mm res) | Runout ≤ 0.15 mm | Magnetic Base Indicator | |

| Hydraulic System | Motor shaft runout (cold) | Dial Indicator @ 150mm from seal | ≤ 0.05 mm | Magnetic Base Indicator |

| Seal integrity @ 350 bar (static) | Pressure test stand + visual | Zero leakage after 5 min hold | Calibrated Pressure Gauge | |

| Bearing preload torque (rotor shaft) | Digital torque wrench | 85-115 Nm (spec: 100 Nm) | 0.5% Acc. Torque Wrench | |

| Operational Readiness | Rotor balance (dynamic) | Portable balancer | Residual imbalance ≤ 15 g·mm/kg | Balancing Machine |

| Flail chain tension (all rows) | Tension gauge + visual | 5-7 mm deflection @ 20kg load | Spring Tension Gauge | |

| Grease fitting accessibility & function | Manual check + grease gun | Full articulation; no binding | Standard Grease Gun |

5. CONCLUSION

The SEA LION FCX-26 Flail Cutter is manufactured under stringent quality controls focused on maximizing operational lifespan in demanding construction environments. The DOMEX 700 MC chassis provides demonstrable resistance to rough-terrain deformation, while the hardened HM-850D hydraulic motor ensures sustained performance under high-shock loads. The comprehensive PDI protocol guarantees that units shipped meet all structural and durability specifications prior to customer receipt, minimizing initial field failures and supporting fleet availability targets. SEA LION International warrants all FCX-26 units against manufacturing defects in materials and workmanship for 24 months from date of shipment.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Flail Cutters for Excavators from China

Issuing Authority: SEA LION International – Engineering & Logistics Division

1. Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of flail cutters for excavators from manufacturing hubs in China (e.g., Qingdao, Shanghai, Ningbo) to global construction markets. The analysis focuses on cost efficiency, equipment protection, transit time, handling complexity, and corrosion mitigation. Special attention is given to wax-based anti-corrosion treatments (wax spraying) essential for protecting high-carbon steel cutting components during sea transit.

2. Equipment Overview: Flail Cutter for Excavator

| Parameter | Specification |

|---|---|

| Weight Range | 1,200 – 3,800 kg |

| Dimensions (L×W×H) | 2.8 m × 1.6 m × 1.4 m (avg.) |

| Material Composition | High-tensile steel frame, AR400/AR500 blades |

| Corrosion Sensitivity | High (exposed cutting elements, pivot joints) |

| Mounting Compatibility | Universal skid steer/quick coupler systems |

| Required Pre-Shipment Prep | Wax spraying, moisture barrier, securing |

3. Shipping Method Comparison

| Criteria | RO-RO Shipping | Bulk Cargo Shipping | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed on/off vessel | Craned into hold (loose stow) | Craned onto open platform |

| Cargo Protection | Moderate (exposed to salt spray) | Low (minimal environmental shielding) | High (customizable lashing & wrapping) |

| Corrosion Risk | High (unless waxed & sealed) | Very High | Low (with wax + shrink wrap) |

| Securing Method | Wheel chocks, chains | Dunnage, lashing | Twist locks, chains, straps |

| Transit Time (China → EU/US) | 28–35 days | 30–40 days | 26–33 days |

| Port Infrastructure | Requires RO-RO terminal | General cargo terminal | Container terminal with FR capability |

| Average Cost (per unit) | $1,400 – $1,900 | $900 – $1,300 | $1,600 – $2,200 |

| Handling Damage Risk | Low | High | Medium |

| Customs Clearance | Standard | Standard | Standard |

| Best For | Time-sensitive, large volumes | Low-cost, non-fragile cargo | High-value, corrosion-sensitive units |

4. Corrosion Protection: Wax Spraying Protocol

Flail cutters are highly susceptible to saltwater-induced corrosion due to their high-surface-area cutting drums and alloy steel components. SEA LION International recommends the following anti-corrosion protocol prior to shipment:

4.1 Wax Spraying Procedure

- Material: Solvent-based anti-corrosion wax (e.g., Cosmoline-type or VCI-infused polymer wax)

- Application Method: High-pressure spray (20–30 bar) to ensure penetration into blade gaps, bearings, and pivot joints

- Coating Thickness: 50–75 µm dry film thickness

- Coverage Areas:

- Cutting drum assemblies

- Drive shafts and universal joints

- Hydraulic cylinder rods (if attached)

- Exposed fasteners and hinge points

4.2 Post-Waxing Steps

- Drying: 2-hour ambient cure at 20–25°C.

- Secondary Barrier: Wrap critical zones with VCI (Vapor Corrosion Inhibitor) paper.

- Final Encapsulation: Shrink-wrap entire unit on skid (for Flat Rack/RO-RO) or place in ventilated wooden crate (optional for Bulk).

Note: Wax film remains effective for up to 12 months under sealed conditions and is removable with industrial degreasers upon delivery.

5. Recommended Shipping Method by Use Case

| Priority | Recommended Method | Rationale |

|---|---|---|

| Cost-Sensitive, Low Volume | Bulk Cargo | Lowest freight cost; acceptable if waxed and insured for corrosion damage |

| Time-Sensitive, Large Fleet | RO-RO | Rapid loading/unloading; ideal for port-to-site delivery |

| High-Value, Corrosion-Critical | Flat Rack + Wax Spray | Maximum protection, full visibility, and lashing control |

6. Conclusion

For construction firms and fleet operators importing flail cutters from China, Flat Rack shipping combined with industrial wax spraying offers the optimal balance of protection, traceability, and reliability. While RO-RO provides speed and Bulk Cargo offers economy, neither matches the corrosion resilience required for precision cutting equipment. SEA LION International advises integrating wax-based preservation into standard export prep workflows, regardless of shipping mode.

Future logistics planning should prioritize ports with Flat Rack handling capabilities and certified wax application facilities in export zones.

End of Report

SEA LION International – Engineering & Logistics Division

Revision: 2026.Q1 – Industrial Specifications v3.1

Get a Quote for Flail Cutter For Excavator

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]