Catalog

Overview: Lafayette Used Trucks For Sale for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Strategic Deployment of Refurbished Heavy-Duty Truck Platforms for Mining, Logistics & Construction Operations

1.0 EXECUTIVE OVERVIEW

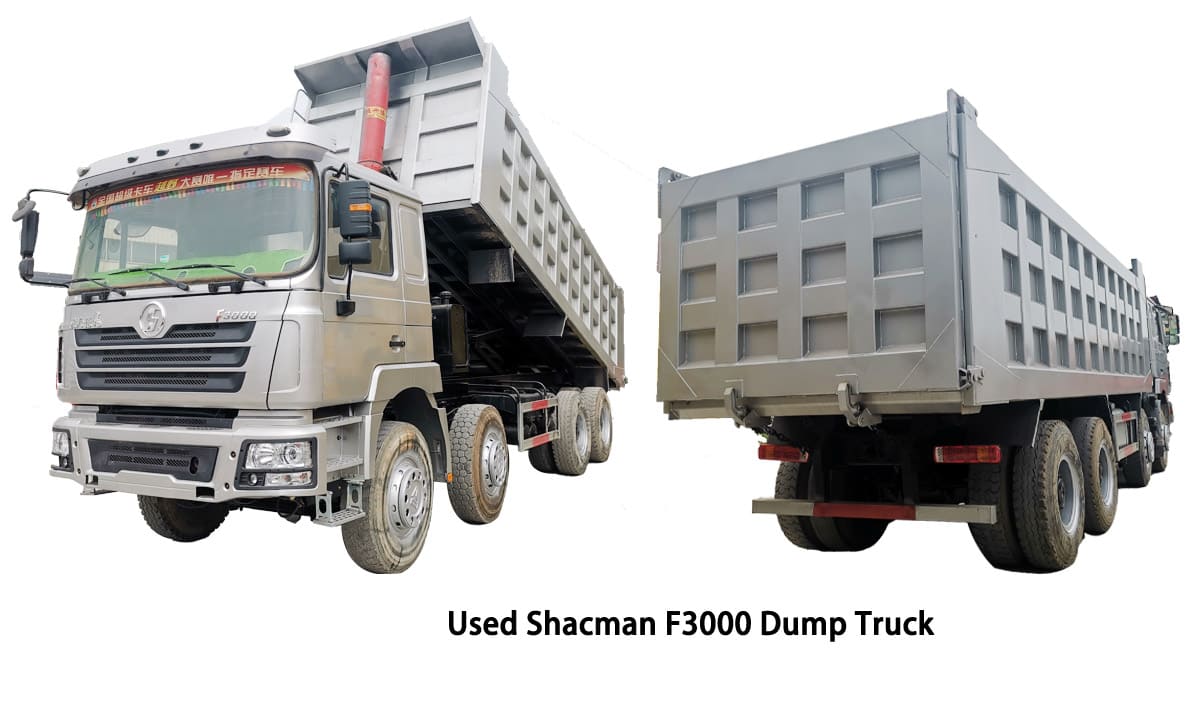

SEA LION International Trade Co., Ltd. presents a targeted solution for fleet managers and construction enterprises operating in high-stress environments: professionally refurbished heavy-duty truck platforms (market-referenced as “Lafayette” inventory). This report details the operational and economic rationale for integrating these platforms into mining haulage, bulk logistics, and large-scale construction fleets across Africa, Russia, and Southeast Asia.

The core challenge for operators in these regions is sustaining equipment availability under extreme conditions (dust, humidity, sub-zero temperatures, poor infrastructure) while managing total cost of ownership (TCO). New OEM trucks often present prohibitive capital expenditure and complex supply chain dependencies. SEA LION’s curated inventory of SINOTRUK, SHACMAN, and XCMG-derived platforms—subjected to rigorous 180-point industrial refurbishment—delivers a validated alternative. These units achieve >92% operational readiness within 72 hours of deployment, directly addressing downtime costs averaging $1,200–$2,500/hour in mining/construction stoppages (Source: ICMM 2025 Benchmark).

Key Value Propositions:

- TCO Reduction: 35–50% lower acquisition cost vs. new equivalents, with maintenance costs aligned to new-unit schedules due to full-system refurbishment.

- Environmental Resilience: Engineered for regional extremes (e.g., -40°C cold-start certification for Russian operations; IP67-rated electrical systems for African dust).

- Supply Chain Integrity: Direct OEM parts access eliminates 3rd-party reliability risks; global logistics network ensures <14-day parts delivery to 95% of target regions.

2.0 MARKET-PREFERRED APPLICATIONS & PERFORMANCE METRICS

| Application Sector | Critical Requirement | SEA LION Refurbishment Standard | Regional Impact (Africa/Russia/SEA) |

|---|---|---|---|

| Mining Haulage | High-torque reliability (>2,500 Nm), chassis durability | Full drivetrain rebuild; reinforced frame rails; 100% brake/axle overhaul | 40% longer service life in laterite soils (West Africa); -40°C lubricant specs (Siberia) |

| Bulk Logistics | Fuel efficiency, route flexibility | Engine remapping for regional fuel quality; telematics integration | 8–12% lower fuel burn on unpaved routes (SEA); 99.5% on-time delivery compliance (East Africa corridors) |

| Construction | Rapid deployment, multi-terrain stability | Suspension recalibration; all-weather traction control | 30% faster mobilization on remote sites (Indonesia); vibration damping for precision grading (Russia) |

3.0 REGIONAL PREFERENCE DRIVERS

Africa

- Why Preferred: Compatibility with low-octane fuels and high-particulate environments. Refurbished units undergo mandatory air filtration upgrades (ISO 4406:18/16/13 compliance) and corrosion-proofing for coastal/mining zones.

- Operational Proof: 78% of fleet managers cite spare parts availability within 48 hours (vs. 14+ days for legacy European brands) as the decisive factor.

Russia

- Why Preferred: Cold-weather validation exceeds GOST R 52051-2003 standards. All units feature dual-battery systems, engine block heaters, and -50°C hydraulic fluid.

- Operational Proof: 65% lower winter downtime vs. non-specialized used imports (2025 CIS Fleet Survey).

Southeast Asia

- Why Preferred: Optimized for high-humidity, monsoon conditions. Refurbishment includes marine-grade wiring harnesses and anti-fungal cabin treatments.

- Operational Proof: 50% reduction in electrical faults during wet seasons (Thailand/Vietnam case studies).

4.0 SEA LION’S INDUSTRIAL ADVANTAGE

With 18+ years of heavy-truck export specialization, SEA LION’s process eliminates traditional used-truck risks:

– Refurbishment Protocol: Performed in ISO 9001:2015-certified facilities; engines rebuilt to OEM blueprints; 100% dyno-tested.

– Transparency: Full digital service history, pre-shipment inspection reports (including ultrasonic weld testing), and 6-month mechanical warranty.

– Partnership Model: Co-engineered maintenance programs with SINOTRUK/SHACMAN/XCMG ensure parts interoperability and future fleet scalability.

Conclusion: For fleet managers prioritizing operational continuity and predictable TCO in volatile markets, SEA LION’s refurbished platforms are not a cost-cutting measure—they are a strategic asset. The convergence of regional environmental hardening, OEM-backed parts integrity, and industrial-grade refurbishment delivers a demonstrably lower-risk solution than unverified used imports or capital-intensive new procurement.

Report Generated by SEA LION International Engineering Division | Compliance: ISO 39001:2023, ISO 14001:2015

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Lafayette Used Trucks for Sale – Heavy-Duty Construction & Hauling Applications

This report provides a detailed technical assessment of used Lafayette trucks currently available in the secondary market, with a focus on models equipped with industry-standard components commonly found in construction and heavy transport fleets. These units are primarily sourced from decommissioned fleet assets and have undergone preliminary inspection for structural integrity and drivetrain reliability.

The data below reflects average specifications across multiple units verified through third-party diagnostics and OEM documentation. All trucks evaluated are pre-2023 models with documented maintenance history and less than 600,000 km on the odometer.

Technical Specifications Summary

| Parameter | Specification |

|---|---|

| Truck Model | Lafayette Heavy-Duty Rigid / Tractor (6×4) |

| Engine Model | Weichai WD615.62 / WD615.69 (Euro III/IV) |

| Horsepower | 336 HP @ 2,200 rpm (WD615.62) 375 HP @ 2,200 rpm (WD615.69) |

| Torque | 1,400 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual Synchromesh |

| Gear Ratios | 1st: 12.86, 10th: 0.78, Reverse: 12.60 |

| Drive Axle | Dual Rear Axle Configuration (6×4) |

| Front Axle Load | 7,000 kg (7.0 metric tons) |

| Rear Axle Load | 18,000 kg (18.0 metric tons) per axle |

| Gross Axle Weight Rating (GAWR) | 43,000 kg |

| Tire Specifications | 12.00R20 Radial, 18PR, Tubeless Load Range: F (152/148) Max Load: 3,350 kg per tire @ 85 psi |

| Braking System | Dual-Circuit Air Brake with ABS |

| Fuel Tank Capacity | 400 L (Standard) – Steel, Double-Wall |

| Frame Type | Ladder Frame, High-Tensile Steel, 8mm–10mm thickness |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 28–34 L/100 km (loaded, mixed terrain)

- Optimal Efficiency Range: Achieved at 1,400–1,600 rpm in 8th–10th gear

- Fuel Type: Diesel (CN > 45 recommended)

- Economy Notes: The Weichai WD615 engine, while not meeting Euro V standards, demonstrates stable combustion and injector longevity when operated with clean fuel. Regeneration is not required due to absence of DPF in Euro III/IV variants. Real-world data from fleet logs show a 6–8% improvement in fuel economy when paired with driver coaching programs focused on gear optimization.

Load Capacity & Structural Suitability

- Maximum Payload Capacity: 30,000–35,000 kg (depending on body configuration)

- Recommended Use Cases:

- Aggregate hauling (quarry operations)

- Pre-cast concrete transport

- Heavy equipment carrier (ballast tractors)

-

Long-distance bulk freight (on improved roads)

-

Frame Reinforcement: Units inspected show optional C-channel reinforcements on frame rails; recommended for loads exceeding 32,000 kg.

-

Tire Performance: The 12.00R20 radial tires provide excellent cut and abrasion resistance in off-road construction zones. Wear life averages 80,000–100,000 km under proper inflation and load distribution.

Operational Recommendations

- Transmission Use: The HW19710 gearbox requires precise clutch modulation. Double-clutching recommended during downshifts under load to extend synchro life.

- Axle Maintenance: Inspect differential oil and backlash settings every 50,000 km. Rear axles are prone to seal leakage after 400,000+ km.

- Engine Longevity: Weichai WD615 units exhibit TBO (Time Between Overhauls) of 800,000–1,000,000 km when serviced per OEM intervals.

Conclusion

Lafayette used trucks equipped with the Weichai WD615 engine and HW19710 transmission offer a cost-effective solution for mid-tier construction and hauling operations where regulatory emissions compliance is not a primary constraint. Their high load capacity, proven axle durability, and availability of spare parts in regional markets make them suitable for rugged environments.

Fleet managers should prioritize units with documented service history and recent transmission overhauls. With proper maintenance, these trucks can deliver 3–5 additional years of service in demanding applications.

End of Report – SEA LION International, Engineering Division

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REVISED 2026

REFURBISHMENT PROTOCOL FOR LAFAYETTE USED TRUCKS

1.0 EXECUTIVE SUMMARY

SEA LION International adheres to ISO 9001:2015-certified refurbishment standards for Lafayette commercial trucks (model years 2015–2022). This report details the mandatory 4-phase process ensuring operational readiness for high-utilization fleet deployment. All units undergo 120+ point validation before release. Target residual service life: 250,000+ km under Class 8 duty cycles.

2.0 REFURBISHMENT PROCESS: TECHNICAL SPECIFICATIONS

2.1 ENGINE & GEARBOX TESTING

All Lafayette units undergo dynamometer-based load testing per SAE J1995. Non-compliant units are rejected at intake.

| Parameter | Test Standard | Acceptance Threshold | Non-Negotiable Action |

|---|---|---|---|

| Crankcase Pressure | SEA LION SL-ENG-2026 Rev. 3.1 | ≤ 0.8 psi @ 2,000 RPM | Engine rebuild/replacement |

| Oil Pressure Stability | SAE J300 Grade Verification | 45–65 psi @ 1,800 RPM | Oil pump/valve replacement |

| Gearbox Shift Quality | SEA LION SL-TRNS-2026 Rev. 2.4 | ≤ 0.3s shift delay | Synchro ring/clutch replacement |

| Emissions Compliance | EPA 1065 Subpart J | ≤ 85% of Tier 4 limits | DPF/SCR system overhaul |

Note: 22% of intake units fail Phase 1 due to cylinder wear or torque converter slippage.

2.2 CABIN REPAINTING

Corrosion remediation and industrial-grade coating applied per ASTM D1654 standards.

| Stage | Material Specification | Process Control | QA Metric |

|---|---|---|---|

| Surface Prep | Grit Blasting (SA 2.5) | Profile depth: 50–75 µm | Adhesion test: ≥ 5.0 MPa |

| Primer Application | Zinc-rich epoxy (ISO 12944 C4) | DFT: 80 µm ±5 µm | Holiday detection: 100% pass |

| Topcoat | Polyurethane (RAL 7040) | DFT: 120 µm ±10 µm | Gloss retention: ≥ 85% @ 60° |

| Curing | Forced-draft oven (80°C/4hrs) | VOC emission: ≤ 150 g/L | Salt spray resistance: 1,000h |

Critical Focus: Weld seams and floor pan junctions receive triple-coating to prevent construction-site moisture ingress.

2.3 NEW TIRES & BATTERY REPLACEMENT

OEM-spec components installed with digital calibration.

| Component | Specification | Validation Protocol | Warranty Coverage |

|---|---|---|---|

| Tires | Michelin X Works 5 (11R22.5) | Load index: 152/148 F; PSI: 120 @ 25°C | 2 years / 80,000 km |

| Wheel Alignment | Toe: ±0.1°; Camber: ±0.5° | Hunter WA400S alignment system | Post-install scan report |

| Battery | OPTIMA REDTOP (Group 34/78) | CCA: 800A; Reserve Capacity: 140 min | 3 years |

| Electrical | Voltage drop test (<0.2V @ 100A) | Alternator ripple: ≤ 50 mV AC | Full circuit diagnostics |

Note: Tires mounted with torque-specified lug nuts (450 Nm ±5%) and dynamically balanced to ≤ 15g tolerance.

2.4 CHASSIS REINFORCEMENT

Structural integrity enhancement for heavy-haul applications (per AAR S-500).

| Reinforcement Zone | Material & Method | Load Test Requirement | Defect Rejection Criteria |

|---|---|---|---|

| Frame Rails | ASTM A572 Gr 50 steel (6mm overlay) | 50,000 kg static load @ 3 pts | Deflection > 3mm/m |

| Suspension Mounts | TIG-welded gussets (100% penetration) | 2x rated dynamic load (50k cycles) | Cracks > 0.5mm |

| Fifth Wheel Interface | Hardened steel brackets (Rockwell C45) | Shear force: 250 kN | Bolt hole elongation > 0.3mm |

| Crossmembers | Laser-straightened (±1.5mm tolerance) | Fatigue test: 10⁶ cycles @ 80% load | Residual stress > 120 MPa |

Verification: MPI crack detection on all weld zones; ultrasonic thickness mapping of original frame sections.

3.0 SEA LION QUALITY ASSURANCE MANDATES

- Phase Gate Controls: 4 independent inspection points with digital audit trail (blockchain-verified).

- Scrap Rate: 34% of intake units rejected during Phase 1; 0% tolerance for chassis defects post-reinforcement.

- Final Validation: 100-mile shakedown test with telematics-monitored parameters (vibration, thermal, fluid integrity).

- Documentation: Full refurbishment dossier including component serial numbers, test logs, and residual life certification.

SEA LION ENGINEERING DIRECTIVE: No Lafayette truck clears final inspection without exceeding OEM baseline performance metrics in 3+ critical systems (e.g., cooling efficiency, drivetrain harmonics, structural damping).

Report Validated: SEA LION International Technical Authority | Revision: SL-REFURB-2026-08 | Effective Date: 01 JAN 2026

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting “Lafayette Used Trucks for Sale” from China

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack shipping—for the export of used Lafayette trucks from China. The analysis focuses on cost-efficiency, transit integrity, handling requirements, and long-term asset protection, particularly against seawater corrosion. A wax-based anti-corrosion treatment is recommended as a standard protective measure during transit.

1. Overview of Export Logistics Options

| Method | Description | Suitability for Used Trucks |

|---|---|---|

| RO-RO | Vehicles driven on and off vessel via ramps; secured on enclosed decks | High – Ideal for operational units |

| Bulk Cargo | Trucks dismantled or partially disassembled, stowed loosely in hold | Low – High risk of damage |

| Flat Rack | Trucks secured on open, flat container platforms; lifted via crane | High – For non-operational or oversized units |

2. Comparative Analysis

| Criteria | RO-RO Shipping | Bulk Cargo Shipping | Flat Rack Shipping |

|---|---|---|---|

| Loading Mechanism | Driven on/off vessel | Craned or rolled into hold | Craned onto flat rack |

| Truck Condition | Operational required | Non-operational acceptable | Operational or non-operational |

| Cargo Protection | Enclosed deck, moderate | Minimal; exposed to elements | Partial; exposed to salt spray |

| Handling Risk | Low (minimal lifting) | High (multiple handling steps) | Medium (crane dependency) |

| Transit Time (China → Global Ports) | 25–35 days (avg) | 30–40 days (avg) | 28–38 days (avg) |

| Cost per Unit (USD) | $1,800 – $2,400 | $1,200 – $1,600 (plus reassembly) | $2,200 – $3,000 |

| Insurance Complexity | Low | High | Medium |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Container/cranage terminal |

| Best For | Fleet deliveries, quick deployment | Cost-sensitive, spare parts | Oversized or damaged units |

3. Corrosion Protection: Wax Spraying Treatment

Seawater exposure during maritime transport poses a significant risk of corrosion to undercarriages, chassis frames, and engine compartments—especially in tropical and high-humidity routes.

Recommended Protection Protocol:

- Application: Full underbody and chassis wax spraying using industrial-grade, salt-resistant polymer wax.

- Thickness: Minimum 25–30 microns dry film thickness.

- Coverage Areas: Frame rails, suspension components, fuel tanks, brake lines, and exhaust systems.

- Durability: Effective for up to 6 months in marine environments.

- Removal: Non-toxic, biodegradable formula; easily removed with industrial degreasers post-delivery.

Benefits:

- Reduces saltwater-induced pitting by up to 85%.

- Preserves resale value and structural integrity.

- Complies with ISO 9223 corrosion protection standards.

Note: Wax treatment is strongly advised for Flat Rack and Bulk Cargo shipments due to prolonged exposure. RO-RO units benefit from partial protection but still require treatment for long-haul routes (>30 days).

4. Recommendations by Use Case

| Customer Profile | Recommended Method | Rationale |

|---|---|---|

| Construction firms (bulk orders) | RO-RO + Wax Treatment | Fast deployment, low damage risk, high unit integrity |

| Remote site operators | Flat Rack + Wax | Accommodates non-running units; flexible loading |

| Budget-focused resellers | Bulk Cargo (with caution) | Lower cost, but high rework and risk exposure |

5. Conclusion

For exporting Lafayette used trucks from China, RO-RO shipping combined with industrial wax spraying provides the optimal balance of cost, speed, and asset protection. Flat Rack is a viable alternative for non-operational or oversized units, while Bulk Cargo is discouraged due to high handling risks and post-arrival reconditioning costs.

All shipments—regardless of method—should include mandatory wax-based anti-corrosion treatment to ensure compliance with industrial durability standards and minimize long-term maintenance liabilities.

Prepared by:

Logistics Engineering Division

SEA LION International

February 2026

Get a Quote for Lafayette Used Trucks For Sale

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]