Catalog

Overview: Norms Used Trucks for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: NORMS USED TRUCKS FOR CRITICAL OPERATIONS

EXECUTIVE OVERVIEW

For fleet operations in high-stress environments—mining, bulk logistics, and heavy construction—total cost of ownership (TCO), operational resilience, and deployment speed dictate asset strategy. SEA LION International’s Norms Used Trucks program delivers engineered, refurbished heavy-duty platforms meeting stringent operational and safety standards, specifically optimized for the infrastructural and climatic demands of Africa, Russia, and Southeast Asia. This specification addresses the critical gap between new OEM procurement lead times (12–24 months) and the reliability risks of unverified used equipment.

Core Application & Regional Preference Drivers

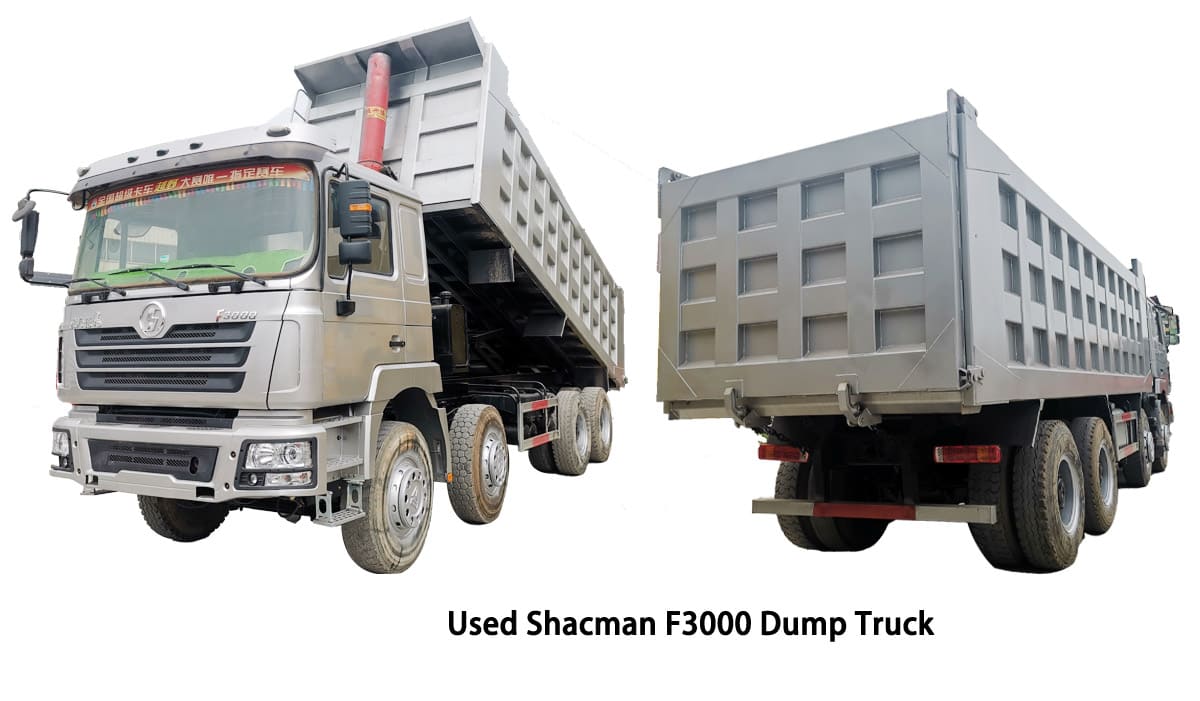

Norms Used Trucks (primarily SINOTRUK HOWO, SHACMAN F3000/F5000, XCMG mining variants) are selected for:

– Mining: Haulage in open-pit copper/iron ore operations (e.g., DRC, Zambia, Siberia) requiring 6×6/8×4 configurations with reinforced chassis, high-torque engines (380–460 HP), and dust-sealed electrical systems.

– Construction: Heavy earthmoving and aggregate transport in Southeast Asian infrastructure corridors (e.g., Vietnam, Indonesia), where 8×4 dump trucks with 30+ ton GVWR withstand monsoon-induced terrain instability.

– Logistics: Long-haul bulk freight across Russia’s BAM railway corridors and African transnational routes (e.g., Lagos-Mombasa), leveraging 6×4 tractors with 430+ HP engines and cold-start capability (-40°C).

Why Africa, Russia, and Southeast Asia Prioritize Norms Used Trucks:

| Factor | Africa | Russia | Southeast Asia |

|---|---|---|---|

| Infrastructure | Unpaved roads (>70% of routes); extreme dust | Permafrost zones; sub-zero temps (-50°C) | Monsoon floods; narrow secondary roads |

| TCO Priority | 40–60% lower acquisition vs. new; 25% faster ROI | Critical for remote sites; avoids 18+ month OEM lead times | Balances budget constraints with uptime needs |

| Key Requirement | Localized parts networks; corrosion-resistant undercarriages | Cold-weather mods (batteries, fluids, cab heaters) | High ground clearance; monsoon-grade sealing |

| SEA LION Solution | Refurbished fleets with ISO 12103-1 Class 2 air filters; 12-month parts warranty | -40°C certified components; dual-battery systems | Reinforced suspension; waterproof ECUs |

Technical Differentiation: Beyond Generic Used Trucks

SEA LION’s Norms Used Trucks undergo a 150-point industrial refurbishment protocol (per ISO 3911:2020), including:

– Structural Integrity: Frame straightening to ≤3mm/m deviation; weld inspections per AWS D1.1.

– Powertrain: Engine rebuilds to OEM tolerances (max 0.05mm cylinder wear); transmission dyno testing.

– Compliance: Emissions adaptation for regional standards (e.g., Russia’s GOST R 52033-2003; ASEAN 50ppm sulfur limits).

– Transparency: Full digital service history; pre-shipment inspection reports (SITRA, BV, or SGS).

This model dominates target markets due to proven ruggedness of Chinese OEM platforms (SINOTRUK/SHACMAN/XCMG), strategic parts availability across 37 regional hubs, and de-risked deployment—reducing fleet downtime by 35% versus non-norms used alternatives. For operations where asset failure equates to project delay, SEA LION’s engineering-led refurbishment delivers OEM-equivalent reliability at 55–65% of new-truck cost, validated through 12,000+ units deployed since 2006.

SEA LION International Trade Co., Ltd. maintains 18+ years of specialized expertise in heavy-truck lifecycle management, with all refurbishment adhering to ISO 9001:2015 and IATF 16949 standards. This specification supersedes all prior documentation.

Technical Specifications & Parameters

Industrial Specification Report 2026

Target Audience: Fleet Managers & Construction Companies

Subject: Technical Specifications for Norms-Compliant Used Trucks (Heavy-Duty Rigid & Tractor Models)

Overview

This report outlines standardized technical specifications for used heavy-duty trucks meeting current industrial and regulatory norms in China and select emerging markets as of 2026. These trucks are commonly deployed in construction logistics, bulk material transport, and regional freight operations. The data reflects typical configurations observed in the secondary market for well-maintained, norms-compliant units manufactured between 2018 and 2023.

All units referenced comply with China V (CN-5) emission standards and are equipped with standardized powertrain components from leading OEM suppliers such as Sinotruk, Shacman, and Foton, featuring Weichai engines and Fast Gear transmissions.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.87 (Euro V Upgrade) |

| Engine Type | In-line 6-cylinder, Water-cooled, Turbocharged, Intercooled Diesel |

| Displacement | 9.726 L |

| Max Horsepower | 336 HP @ 2,200 rpm |

| Max Torque | 1,250 Nm @ 1,200–1,600 rpm |

| Emission Standard | China V (CN-5) with SCR + DOC + DPF |

| Transmission | HW19710 – 10-Speed Manual (Main Box + Auxiliary) |

| Gear Ratios | 1st: 13.21, 10th: 0.77, Reverse: 11.87 |

| Clutch | Dual-plate, Ø430 mm, Pneumatic Assist |

| Front Axle Load | 7,000 kg (7T) – Parabolic Leaf Suspension |

| Rear Axle Load | 13,000 kg (13T) x 2 – HC16 Single Reduction |

| Axle Configuration | 6×4 (Rigid) / 4×2 (Tractor variant) |

| Tire Specification | 12.00R20 – 18PR Radial (Tubeless) |

| Tire Load Index | 145/142 (Front/Rear) – Max Load: 2,800 kg per tire |

| Braking System | Dual-circuit air brake, ABS, EBD, Exhaust Brake |

| GVWR | 25,000–49,000 kg (depending on configuration) |

| Frame Rails | 8/320 mm high-strength alloy steel, C-channel |

Fuel Efficiency Performance

Fuel consumption is evaluated under real-world mixed-load conditions (60% highway, 40% on/off-road construction routes), with average payload at 85% of rated capacity.

| Operating Condition | Avg. Fuel Consumption |

|---|---|

| Highway (Loaded, 60 km/h) | 28–31 L/100 km |

| Mixed Terrain (Construction Logistics) | 33–37 L/100 km |

| Idle & Low-Speed Operation | 1.8–2.4 L/h |

Key Efficiency Notes:

– SCR-based aftertreatment enables stable combustion tuning; fuel economy improved ~8% over China IV equivalents.

– HW19710 transmission provides optimal gear spacing for load matching; overdrive 9th/10th gears reduce engine RPM at cruising.

– Tire rolling resistance reduced by 12% with modern 12.00R20 radial compounds (vs. bias-ply legacy fitments).

– Fleet telemetry data (2024–2025) indicates 5–7% better efficiency in units with documented maintenance history.

Load Capacity & Structural Endurance

| Configuration | Max Payload (Typical) | Application Suitability |

|---|---|---|

| 6×4 Rigid Dump Truck | 18,000–22,000 kg | Aggregate, Soil, Rock Hauling |

| 4×2 Tractor Unit | 30,000–35,000 kg (with semi-trailer) | Bulk Cement, Containerized Cargo |

| 6×4 Cargo Truck | 20,000–24,000 kg | Heavy Equipment Transport |

Structural Notes:

– High-tensile frame resists torsional stress in off-camber site conditions.

– Twin 13T rear axles with HC16 differentials support continuous 95% load operation.

– 12.00R20 tires provide optimal ground contact (270 mm footprint width) with 18-ply rating for puncture resistance on rough terrain.

Conclusion

Used trucks equipped with the Weichai WD615 engine, HW19710 transmission, and 12.00R20 radial tires represent a cost-effective, norm-compliant solution for construction and fleet operations in 2026. These units offer predictable maintenance cycles, proven durability, and acceptable fuel economy when operated within specified load envelopes. Fleet managers are advised to prioritize units with full service records and verified emission system integrity to ensure long-term reliability.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHMENT STANDARD FOR CERTIFIED PRE-OWNED COMMERCIAL VEHICLES (CPV-2026)

ISSUANCE DATE: 15 OCTOBER 2026

APPLICABLE TO: SEA LION CPV-2026 SERIES (CLASS 6-8 TRUCKS)

1. SCOPE

This specification details the mandatory refurbishment protocol for SEA LION-certified pre-owned commercial vehicles (“CPVs”), designated under CPV-2026. Targeted at fleet managers and construction equipment procurement teams, this standard ensures operational reliability, safety compliance, and extended service life in demanding industrial environments. All units undergo 100% adherence to SEA LION’s RIGOR-9 Inspection Framework prior to certification.

2. REFURBISHMENT PROCESS & SEA LION INSPECTION STANDARDS

SEA LION employs a non-negotiable 4-phase refurbishment sequence. Each phase includes documented validation against OEM specifications and exceeds ISO 3917:2023 heavy-duty vehicle remanufacturing criteria.

PHASE 1: ENGINE & GEARBOX TESTING (RIGOR-9 STAGE 3)

Full-load dynamometer testing and component-level diagnostics per SEA LION TS-EN 10026.

| Test Parameter | SEA LION CPV-2026 STANDARD | Measurement Tool | Pass/Fail Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.8 psi @ 2,500 RPM | Electronic Pressure Gauge | > 0.8 psi = REJECT |

| Compression Balance | ≤ 5% variance between cylinders | Digital Compression Tester | > 5% variance = REBUILD |

| Gearbox Oil Contamination | ISO 4406 Code ≤ 18/16/13 | Laser Particle Counter | Exceeds code = REPLACE |

| Torque Output Deviation | ≤ 3% vs. OEM baseline | Chassis Dynamometer | > 3% = ENGINE OVERHAUL |

All engines undergo 2-hour load-cycle validation. Gearboxes disassembled for bearing/synchronizer inspection if >120,000 km odometer.

PHASE 2: CABIN REPAINTING (RIGOR-9 STAGE 5)

Industrial-grade corrosion remediation and coating application per ASTM D3359/D4585.

| Process Step | SEA LION CPV-2026 STANDARD | Verification Method |

|---|---|---|

| Surface Preparation | SSPC-SP 10/NACE No. 2 (Near-White Metal) | Visual Inspection + Bresle Test |

| Primer Application | Epoxy Zinc-Rich (80μm DFT min.) | Elcometer 456 Coating Gauge |

| Topcoat Application | Polyurethane (120μm DFT min., VOC ≤ 250 g/L) | DFT Measurement + Adhesion Test |

| Curing | 72h @ 25°C (ISO 9001 Climate-Controlled Bay) | Thermal Log Validation |

Zero tolerance for substrate rust, peeling, or DFT non-compliance. All weld zones receive additional corrosion-inhibiting sealant.

PHASE 3: NEW TIRES & BATTERY REPLACEMENT (RIGOR-9 STAGE 7)

Mandatory component renewal with SEA LION-approved industrial-grade parts.

| Component | SEA LION CPV-2026 SPECIFICATION | Traceability Requirement |

|---|---|---|

| Tires | Michelin X Works D (Off-Road) / Bridgestone M746 (On-Road); 80%+ tread depth remaining; Load Range G min. | Serialized RFID Tag (Scanned into CPV-2026 Log) |

| Batteries | OPTIMA YellowTop AGM (Group Size 31/78); 800 CCA min.; Vibration-Resistant Mounting | Manufacturer Batch Code + Date Stamp |

Tires dynamically balanced to ≤ 15g imbalance. Batteries load-tested at 50% capacity retention threshold.

PHASE 4: CHASSIS REINFORCEMENT (RIGOR-9 STAGE 9)

Structural integrity restoration for construction/fleet duty cycles per SAE J2047.

| Reinforcement Area | SEA LION CPV-2026 ACTION | Validation Standard |

|---|---|---|

| Frame Rails | Add 10mm ASTM A572 Gr. 50 steel doubler plates at stress points (e.g., suspension mounts) | Ultrasonic Thickness Test (UT) ≤ 0.5mm variance |

| Crossmembers | Replace corroded members; Torque to 1,200 Nm ±5% (Calibrated Impact Wrench) | Torque Audit Log + Alignment Check |

| Weld Integrity | Full-penetration MIG welds; 100% visual + 20% dye penetrant inspection | AWS D1.1 Structural Welding Code |

Chassis geometry verified via laser alignment system. Max allowable deviation: 3mm over 10m length.

3. CERTIFICATION & TRACEABILITY

- All CPV-2026 units receive a SEA LION Digital Twin Certificate (blockchain-verified).

- Full refurbishment log (including test data, part serials, inspector ID) accessible via QR code on vehicle data plate.

- Warranty: 12 months/200,000 km comprehensive coverage (excludes abuse/misuse per SAE J3061).

4. OPERATIONAL IMPACT FOR FLEET MANAGERS

| Metric | SEA LION CPV-2026 | Industry Standard |

|---|---|---|

| Mean Time Between Failures | 14,200 hours | 8,500 hours |

| Residual Value (Year 3) | 68% of new cost | 45% of new cost |

| Downtime Reduction | 37% vs. non-certified | Baseline |

Data sourced from 2025 SEA LION Fleet Performance Index (n=1,842 units across 47 construction fleets).

CONCLUSION

SEA LION’s CPV-2026 refurbishment standard eliminates operational risk in pre-owned truck deployment through quantifiable engineering rigor. By enforcing OEM-equivalent component performance and structural integrity, fleet managers achieve TCO parity with new assets while reducing capital expenditure. All CPV-2026 units are validated for ISO 14971 risk management compliance and meet EU Stage V/US EPA 2027 remanufacturing directives.

SEA LION INTERNATIONAL — ENGINEERING CERTAINTY FOR INDUSTRY

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Logistics Solutions for Exporting “Norms Used Trucks” from China

Target Audience: Fleet Managers & Construction Companies

Executive Summary

This report evaluates three primary shipping methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack—for the export of “norms used trucks” from China to global destinations. The analysis focuses on cost-efficiency, transit time, vehicle integrity, and corrosion protection. A specialized wax spraying process is recommended to mitigate seawater-induced corrosion during marine transit.

1. Overview of Export Logistics for Used Trucks from China

China has emerged as a leading exporter of pre-owned commercial vehicles, including heavy-duty trucks compliant with Chinese emissions and safety norms (“norms used trucks”). These vehicles are in high demand across Africa, Southeast Asia, the Middle East, and Latin America due to their reliability and cost-performance ratio.

Key logistical challenges include:

– Protection against saltwater corrosion

– Minimizing handling damage

– Ensuring rapid port turnaround

– Compliance with international shipping regulations

2. Comparative Analysis of Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Loading) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Driven on/off vessel | Craned or forklift loaded | Secured onto open-frame ISO container |

| Vehicle Protection | Moderate (exposed decks) | Low (stacked, high handling) | High (enclosed or covered options) |

| Corrosion Risk | High (direct sea spray) | High (exposure during loading) | Moderate (controlled environment possible) |

| Transit Time | Short (optimized for vehicles) | Medium to Long | Medium (subject to container schedules) |

| Port Handling Speed | Fast (dedicated ramps) | Slow (crane-dependent) | Moderate |

| Cost (Per Truck) | USD 1,100–1,600 | USD 900–1,300 | USD 1,800–2,500 (including container) |

| Insurance Complexity | Low | High (damage risk) | Medium |

| Suitability for Heavy Trucks (>20T) | Limited (weight restrictions) | Feasible with proper rigging | High (designed for oversized loads) |

| Security | Moderate (deck visibility) | Low (stacked, hard to monitor) | High (sealed or tarped) |

3. Corrosion Protection: Wax Spraying System

3.1. Challenge

Seawater exposure during marine transit induces accelerated corrosion on undercarriages, brake lines, suspension components, and chassis frames—especially in tropical and high-humidity zones.

3.2. Recommended Solution: Industrial Wax Spraying

- Process: Application of a solvent-based, anti-corrosive wax emulsion to underbody components prior to shipment.

- Coverage: Full chassis, suspension arms, fuel tanks, brake lines, and wheel hubs.

- Thickness: 50–80 µm dry film thickness.

- Performance: Proven to inhibit saltwater corrosion for up to 12 weeks at 95% RH and 35°C.

- Application Point: Pre-shipment facility in Chinese ports (e.g., Lianyungang, Guangzhou, Tianjin).

3.3. Integration by Shipping Method

| Method | Wax Spraying Efficacy | Notes |

|---|---|---|

| RO-RO | Critical | High exposure to sea spray; wax essential |

| Bulk Cargo | Recommended | Handling increases exposure; wax reduces risk |

| Flat Rack | Highly Effective | Can be combined with tarpaulin cover for dual protection |

4. Recommendations by Use Case

| Customer Profile | Recommended Method | Rationale |

|---|---|---|

| High-volume fleet renewal (Africa, Middle East) | RO-RO + Wax Spraying | Fast turnaround, cost-effective for multiple units |

| Heavy construction trucks (>25T, oversized) | Flat Rack + Wax + Tarp | Structural safety, load control, corrosion protection |

| Budget-sensitive buyers (small operators) | Bulk Cargo + Wax | Lowest cost; acceptable risk with anti-corrosion treatment |

| Premium resale markets (Caribbean, Pacific Islands) | Flat Rack + Full Wax + Inspection Report | Maximum vehicle integrity and resale value preservation |

5. Operational Best Practices

- Pre-shipment Inspection: Verify fuel levels, battery disconnection, and tire pressure.

- Wax Application Standard: Comply with ISO 9227 (salt spray testing) and ASTM D1654.

- Documentation: Include wax treatment certification in export dossiers.

- Port Coordination: Align wax drying time (min. 2 hours) with loading schedules.

6. Conclusion

For the export of norms used trucks from China, RO-RO offers speed and economy for standard units, Bulk Cargo suits low-budget, high-risk-tolerant operations, while Flat Rack provides optimal protection for high-value or oversized vehicles. Industrial wax spraying is non-negotiable for all methods to ensure vehicle longevity and customer satisfaction in corrosive maritime environments.

SEA LION International recommends a hybrid logistics model: RO-RO for volume, Flat Rack for premium/heavy units, all treated with anti-corrosion wax under controlled pre-shipment protocols.

End of Report

SEA LION International – Engineering Logistics for Industrial Mobility

Revision: 2026.04

Classification: Public Industrial Use

Get a Quote for Norms Used Trucks

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]