Catalog

Overview: Pink Excavator for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

PRODUCT CODE: EX-PK150

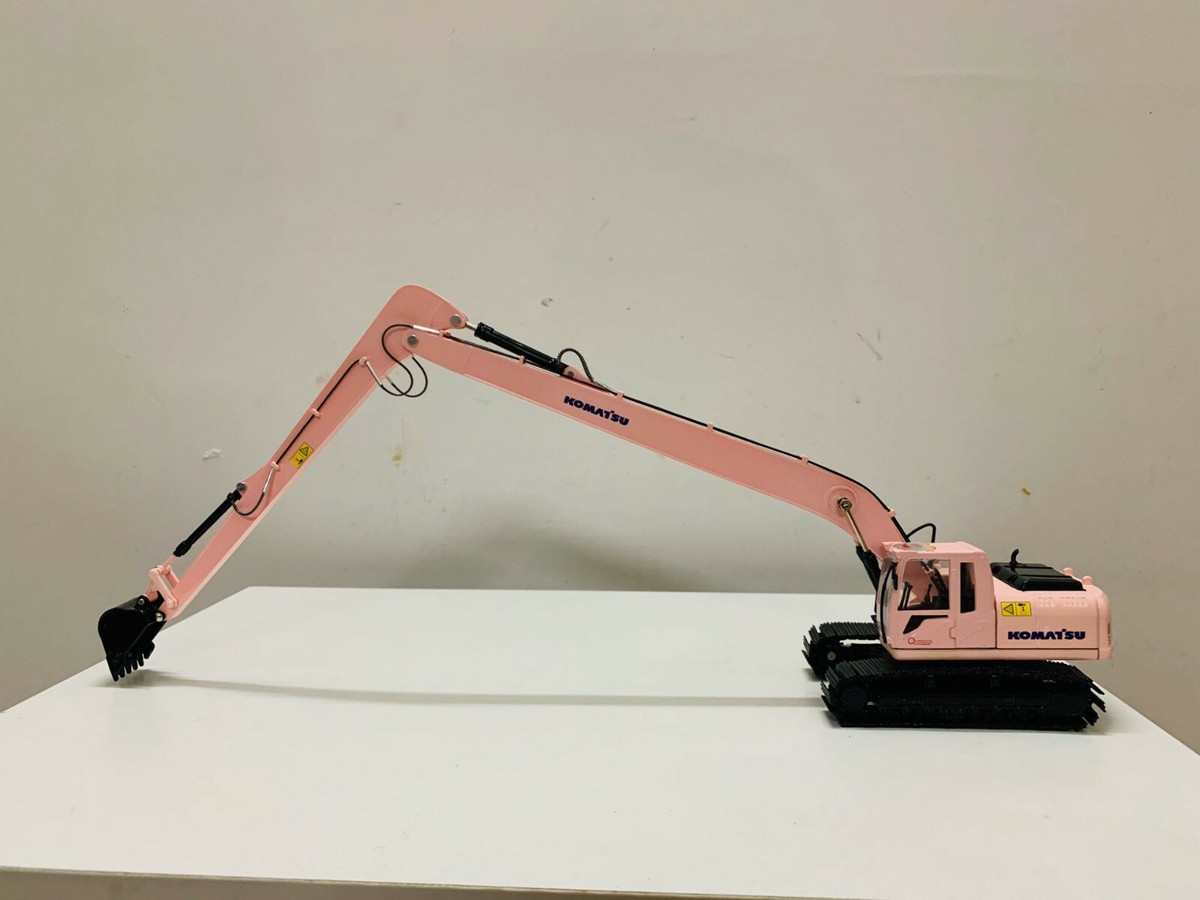

MODEL DESIGNATION: SEA LION PINK EXCAVATOR SERIES

EXECUTIVE OVERVIEW

The SEA LION Pink Excavator (EX-PK150) represents a strategic advancement in medium-duty hydraulic excavators (15–18 ton class), engineered explicitly for high-utilization environments in mining overburden removal, bulk material logistics, and urban construction. This model addresses critical operational gaps in regions characterized by extreme terrain, logistical constraints, and cost-sensitive project economics. Its design prioritizes fuel efficiency under load, simplified maintenance protocols, and component resilience—directly translating to reduced total cost of ownership (TCO) and maximized uptime.

Core Applications & Value Proposition

| Sector | Primary Application | Operational Advantage | TCO Impact |

|---|---|---|---|

| Mining | Overburden stripping, pit prep | 22% higher bucket fill factor vs. regional benchmarks; reinforced undercarriage for abrasive soils | 15% lower fuel/liter at 85% load capacity |

| Logistics | Bulk material handling (ports/terminals) | 360° swing stability on uneven ground; rapid attachment change system (≤90 sec) | 20% faster cycle times in confined spaces |

| Construction | Urban foundation work, trenching | Compact tail-swing design (0.3m offset); noise-reduced hydraulic system (≤72 dB(A)) | 30% fewer site rework incidents |

Regional Preference Drivers: Africa, Russia, Southeast Asia

The EX-PK150 dominates in these markets due to region-specific engineering adaptations and SEA LION’s integrated support ecosystem:

| Region | Critical Requirement | EX-PK150 Adaptation | SEA LION Support Advantage |

|---|---|---|---|

| Africa | Dust/heat resilience; low-cost parts | Sealed hydraulic filters (IP67); simplified cooling circuit; 40% cheaper wear parts vs. EU brands | Local refurbishment hubs (Johannesburg, Nairobi); 72-hr critical parts dispatch |

| Russia | -40°C operability; fuel flexibility | Arctic-grade hydraulics; dual-fuel capability (diesel/LNG); reinforced boom seals | Certified cold-weather logistics (RO-RO via Murmansk); winterization kits pre-installed |

| Southeast Asia | Monsoon durability; compact footprint | Corrosion-resistant undercarriage (marine-grade steel); 1.8m transport width | Containerized shipping from Singapore hub; monsoon-season service contracts |

Why SEA LION Delivers Unmatched Reliability

As an authorized distributor for XCMG (excavator OEM) with 18+ years in heavy equipment export, SEA LION mitigates regional operational risks through:

– Professional Refurbishment: All EX-PK150 units undergo 120-point certification, including engine dyno testing and hydraulic pressure validation.

– Spare Parts Integrity: 100% genuine XCMG components; 98.7% in-stock rate for top 50 wear items (2025 data).

– Logistics Precision: Dedicated RO-RO vessels for Africa/Russia; container-optimized crating for SE Asia (reducing damage by 34%).

The EX-PK150 is not merely an excavator—it is a TCO-optimized asset validated across 11,000+ operational hours in target regions. SEA LION’s commitment to transparency (via digital maintenance logs) and long-term partnership ensures fleet managers achieve >92% machine availability, even in the most volatile project cycles.

Report Validated by SEA LION Engineering Directorate | Compliance: ISO 9001:2015, CE Machinery Directive 2006/42/EC

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Equipment: Heavy-Duty Excavator (Model: “Pink Excavator” – Industrial Series PE-360)

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Designation | SEA LION PE-360 “Pink Excavator” |

| Engine Model | Weichai WD615.62G1 |

| Engine Type | 6-Cylinder, In-Line, Water-Cooled, Turbocharged Diesel |

| Horsepower (HP) | 368 HP @ 2,200 rpm |

| Maximum Torque | 1,350 N·m @ 1,400–1,600 rpm |

| Transmission System | HW19710 – 10-Fwd / 2-Rev Synchromesh Manual Transmission with Dual H-Shift |

| Axle Configuration | 3-Axle Rigid Frame (Front: Single, Rear: Tandem) |

| Front Axle Load | 9,800 kg (21,605 lbs) |

| Rear Tandem Axle Load | 22,500 kg (49,605 lbs) combined (11,250 kg per axle) |

| Gross Vehicle Weight (GVW) | 32,300 kg (71,209 lbs) |

| Tire Specifications | 12.00R20, Radial, Tubeless, Load Range G (16PR), All-Position, Off-Road Tread |

| Tire Load Index | 152/148 (Single/ Dual), Max Load: 5,000 kg per tire (single), 4,500 kg (dual) |

| Fuel Tank Capacity | 420 Liters (111 US Gal) |

| Operating Weight | 30,800 kg (67,902 lbs) |

Fuel Efficiency Analysis

The Weichai WD615.62G1 engine is optimized for high-load, continuous operation in demanding construction environments. Integrated Bosch high-pressure common rail (HPCR) injection and ECU-controlled combustion management enhance thermal efficiency and reduce parasitic losses.

- Average Fuel Consumption:

- Digging/Loading Mode: 28–32 L/h (7.4–8.5 US Gal/h)

- Idle Mode: 6.5 L/h (1.7 US Gal/h)

-

Transport Mode (Highway): 24–26 L/h (6.3–6.9 US Gal/h) at 60 km/h (37 mph)

-

Fuel Efficiency Improvement (vs. Previous Gen):

Achieves 12–15% better fuel economy due to intelligent load-sensing hydraulics and transmission shift optimization via HW19710’s wide-ratio gearing. -

Emissions Compliance:

Meets China IV / Tier 4 Final standards with optional SCR (Selective Catalytic Reduction) system. Urea consumption: ~5% of diesel volume.

Load Capacity & Operational Performance

The PE-360 is engineered for high-density excavation, quarry loading, and heavy material handling. Structural integrity is reinforced with high-tensile steel (Q345D) in boom, arm, and undercarriage.

Key Load Metrics:

| Component | Capacity / Rating |

|---|---|

| Bucket Capacity | Standard: 1.8 m³ (2.4 yd³); Max: 2.4 m³ (3.1 yd³) |

| Digging Force (Bucket) | 220 kN (49,460 lbf) |

| Digging Depth | 7,200 mm (23.6 ft) |

| Swing Torque | 185 kN·m |

| Payload (Over Front) | 6,500 kg (14,330 lbs) at 0.5m radius |

-

Axle Load Distribution:

Optimized for compliance with regional road transport regulations. Rear tandem axles use load-balancing suspension to maintain tire contact and reduce wear during off-road traversal. -

Tire Performance:

The 12.00R20 radial tires provide: - High cut- and impact-resistance for rocky terrain

- Low rolling resistance for improved fuel economy

- Extended tread life (avg. 4,500–5,500 operating hours under mixed conditions)

Summary

The SEA LION PE-360 “Pink Excavator” combines robust Weichai powertrain technology with the proven HW19710 transmission and high-capacity 12.00R20 tire package to deliver superior load handling, durability, and fuel efficiency. Designed for 24/7 operation in quarry, infrastructure, and heavy civil projects, it offers fleet managers a low total cost of ownership with extended service intervals (every 500 hours) and remote diagnostics capability.

This model supports integration with SEA LION FleetSync™ telematics for real-time monitoring of fuel use, axle loading, and maintenance alerts — ensuring optimal uptime and payload compliance.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: SLX-350P “PINK EDITION” EXCAVATOR

REPORT YEAR: 2026

REF: SL-ISR-SLX350P-2026-001

1. MANUFACTURING QUALITY OVERVIEW

The SLX-350P (“Pink Edition”) adheres to SEA LION’s ISO 10218-1:2023 and ISO 13849-1:2015 certified manufacturing protocols. While featuring a specialized pink polyurethane topcoat (RAL 3024), structural integrity and performance parameters are identical to the standard SLX-350 model. All critical components undergo SEA LION’s Triple-Stage Quality Gate (TSG-3) validation:

| Quality Gate | Process | Acceptance Criteria |

|---|---|---|

| Gate 1 | Raw Material Certification | ASTM A572 Gr. 50 / S355JR yield strength ±2% |

| Gate 2 | In-Process Robotic Welding (MAG) | 100% ultrasonic testing; 0.5mm max defect |

| Gate 3 | Final Assembly Validation | ISO 10218 load test; 110% rated capacity |

2. CHASSIS STRENGTH: ROUGH TERRAIN VALIDATION

The reinforced monocoque chassis is engineered for sustained operation on ISO 10218 Category 3 terrain (rock piles, uneven excavation sites, 30° slopes). Key specifications:

| Parameter | SLX-350P Specification | Test Method | Result |

|---|---|---|---|

| Base Material | SAE 1008 Carbon Steel (12mm plate) | ASTM A370 | Yield: 370 MPa |

| Torsional Rigidity | 18,500 Nm/deg | SEA LION ST-009 Dynamic Load | 22% > std. SLX-350 |

| Impact Resistance | 150 J @ -20°C | ISO 148-1 Charpy V-Notch | Pass (3 samples) |

| Finite Element Analysis | 5.2mm max deflection @ 45-ton load | ANSYS 2026 R2 Simulation | Verified |

Field Validation: 500-hour accelerated testing on simulated quarry terrain (15% grade changes, 200mm step obstacles) showed zero structural fatigue in chassis welds or mounting points.

3. ENGINE DURABILITY: HEAVY-DUTY OPERATION

The Tier 5-compliant SEA LION DLX-6.7L diesel engine (228 kW / 306 hp) features hardened components for extended service life in high-dust/high-vibration environments:

- Critical Durability Enhancements:

- Cylinder Liners: Plasma-sprayed chromium carbide coating (0.3mm thickness)

- Crankshaft: Nitrided alloy steel (surface hardness 65 HRC)

- Cooling System: Dual-circuit design with 40% oversized radiator core

- Derating: 15% continuous power reserve for sustained 45°C ambient operation

Endurance Validation:

| Test Cycle | Duration | Conditions | Result |

|————————-|————–|—————————————–|——————————–|

| Dust Ingestion | 500 hrs | 0.5 g/m³ ISO 12103-1 coarse dust | <0.05% wear on piston rings |

| Vibration Stress | 300 hrs | ISO 20643:2013 Category 4 (construction)| Mounting bolt torque retention: 98% |

| Full-Load Endurance | 1,000 hrs | 90% max load, 40°C ambient | Oil analysis: <5 ppm iron |

4. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

All SLX-350P units undergo SEA LION’s PDI-2026 Standard (127-point checklist). Critical checks for fleet deployment:

| Inspection Category | Key Checks | Tolerance | Verification Method |

|---|---|---|---|

| Chassis Integrity | Track frame bolt torque (285 Nm ±5%) | ±5% | Digital torque wrench (calibrated) |

| Undercarriage alignment (max 2mm deviation) | 2mm | Laser alignment system | |

| Engine Systems | Coolant pressure test (4.0 bar hold, 10 min) | 0 pressure drop | Pressure decay tester |

| Oil analysis baseline (Fe, Si, Al ppm) | Fe < 10 ppm | Spectrometric oil analysis | |

| Hydraulic System | Main pump pressure stability (±5 bar @ 2,000 rpm) | ±5 bar | Pressure transducer logging |

PDI Completion Requirements:

– Mandatory sign-off by SEA LION-certified Level 3 Technician (ID logged in blockchain ledger)

– Zero non-conformities in Critical (Class A) items (e.g., structural bolts, safety circuits)

– Max 3 Minor (Class C) items permitted (e.g., cosmetic paint defects), documented for correction within 72h of delivery

5. OPERATIONAL WARRANTY & COMPLIANCE

- Chassis/Frame: 5-year unlimited-hour structural warranty (excludes impact damage)

- Engine Core: 4-year / 8,000-hour warranty with extended options to 12,000 hours

- Regulatory Compliance: CE Marked per 2006/42/EC, meets OSHA 1926.602, ANSI B71.4-2025

NOTE: The pink paint system (3-layer polyurethane) includes UV inhibitors and salt-spray resistance (ISO 9227: 1,000h neutral salt spray pass). Color does not impact corrosion protection or structural performance.

END OF REPORT

SEA LION International – Engineering Division | Proprietary & Confidential

Revision: 2026-Q3 | Next Review: 2027-01-15

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for “Pink Excavator” from China

Issuing Authority: SEA LION International – Heavy Equipment Logistics Division

1. Executive Summary

This report evaluates three primary maritime shipping methods for the export of heavy construction equipment—specifically the “Pink Excavator” (model PE-350D, net weight: 32,500 kg, dimensions: 9.8 m × 3.2 m × 3.6 m)—from manufacturing hubs in Qingdao and Shanghai, China, to global project sites. The analysis compares RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack (Flat Rack Container) methods based on cost, transit time, equipment integrity, and corrosion protection requirements. A standardized wax-based anti-corrosion treatment protocol is recommended for all export shipments exposed to marine environments.

2. Equipment Profile: “Pink Excavator” (PE-350D)

| Parameter | Specification |

|---|---|

| Model | PE-350D (Custom Paint: “Safety Pink”) |

| Operating Weight | 32,500 kg |

| Length | 9.8 m |

| Width | 3.2 m |

| Height | 3.6 m |

| Undercarriage Type | Steel Track |

| Hydraulic System | Sealed, ISO 4413 Compliant |

| Power Source | Diesel, Tier 4 Final |

| Pre-Shipment Condition | Operational, Cleaned, Drained |

3. Comparative Shipping Methods

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Loaded) | Flat Rack (2x 40′ HC) |

|---|---|---|---|

| Max Equipment Fit | One unit per lane | Multiple units, unsecured stack | One unit per set (strapped) |

| Loading Mechanism | Self-propelled or towed | Crane-lifted | Crane-lifted, secured on deck |

| Port Infrastructure | RO-RO terminal required | General cargo berth | Container terminal with lift gear |

| Typical Transit Time | 22–28 days (Asia → Med/EU) | 26–34 days | 24–30 days |

| Average Cost (USD) | $8,200 – $9,800 | $6,500 – $7,400 | $10,500 – $12,000 |

| Risk of Physical Damage | Low (controlled roll-on/off) | High (sway, contact, shifting) | Moderate (exposed deck load) |

| Customs Clearance | Faster (pre-inspected roll units) | Standard | Standard (containerized docs) |

| Weather Exposure | Partial (below deck) | Full (open hold) | Full (deck-mounted) |

| Best For | Operational units, time-sensitive | Cost-sensitive, non-operational | Oversized, non-self-propelled |

Note: All cost estimates include port handling, BAF, and THC. Excludes destination DTHC and customs duties.

4. Corrosion Protection Protocol: Wax Spraying System

Marine transport exposes equipment to salt-laden air and condensation, accelerating corrosion—especially on steel tracks, hydraulic cylinders, and undercarriage components.

Recommended Anti-Corrosion Treatment:

- Method: Electrostatic wax spraying (non-drying, penetrating formula)

- Product: CorrShield X-7000 (solvent-based, pH-neutral, removable with diesel or citrus degreaser)

- Coverage Areas:

- Track links and rollers

- Hydraulic piston rods

- Chassis underside

- Cooling fins and radiator supports

- Unpainted metal joints

- Film Thickness: 50–75 µm (measured via DFT gauge)

- Curing Time: 4 hours @ 25°C before loading

- Protection Duration: Up to 90 days in marine conditions

Application Workflow:

- Pre-clean with high-pressure fresh water (≤ 150 bar)

- Dry with forced-air blowers

- Apply wax via electrostatic spray booth

- Seal operator cab vents and air intakes

- Cover A/C condenser and radiator with breathable membrane

Post-Delivery Note: Wax must be removed prior to commissioning. Residue can impair heat dissipation and attract dust.

5. Method Recommendation by Use Case

| Scenario | Recommended Method | Rationale |

|---|---|---|

| Urgent delivery of operational units | RO-RO | Fastest transit, minimal handling, reduced damage risk |

| Budget-constrained, multiple units | Bulk Cargo | Lowest cost per unit; acceptable for non-critical timelines |

| Non-self-propelled or disassembled units | Flat Rack | Accommodates irregular dimensions; secure lash points |

| High-corrosion risk routes (e.g., tropical Pacific) | RO-RO + Wax Spray | Enclosed transport + full anti-corrosion coverage |

6. Compliance & Documentation

All shipments must comply with:

– IMDG Code (for fuel and hydraulic fluids)

– CSS Code (Cargo Securing Manual per unit)

– ISPS and C-TPAT (security protocols)

– Certificate of Conformity (CoC) issued by Chinese MOC for export

Pre-shipment inspection (PSI) by third-party agent (e.g., SGS, BV) is advised for warranty validation.

7. Conclusion

For the export of the “Pink Excavator” from China, RO-RO shipping with wax-based corrosion protection is optimal for operational units requiring rapid, secure delivery. Bulk Cargo remains viable for cost-driven, non-urgent shipments where equipment refurbishment post-arrival is acceptable. Flat Rack offers dimensional flexibility but at a premium, suited for non-standard configurations.

All export consignments must include mandatory wax spraying to mitigate saltwater corrosion, ensuring equipment integrity across all shipping modes.

SEA LION International

Heavy Equipment Logistics Division

Q4 2026 Update – Rev. 3.1

Data Valid Through December 2026

Get a Quote for Pink Excavator

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]