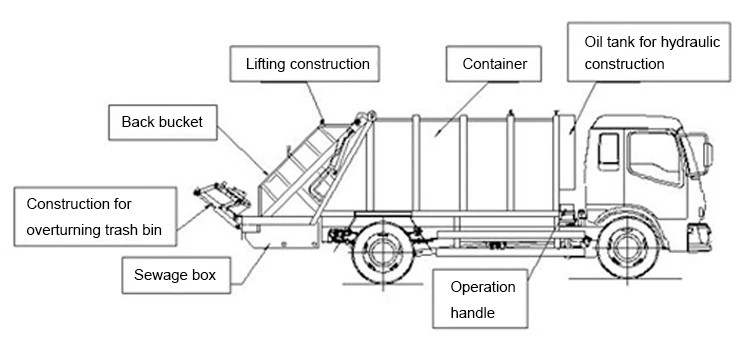

Description

China 6×4 18CBM Compactor Garbage Truck For Sale

Product Description

| Compactor garbage truck | ||

| # | Descriptions | Specifications and types |

| General | Truck Brand | Howo |

| Chassis Brand | Sino truck (HOWO) | |

| Approx. Dimension | 9850*2500*3300 mm | |

| GVW./Kerb Wt. | 25000/ 15440kg | |

| Cab | Cab Capacity | 2 persons’ seat |

| Air Conditioner | Air Conditioner is optional | |

| Chassis | Drive Type | 6X4,LHD or RHD |

| Fuel Type | Diesel | |

| Engine Make & Model | Sinotruk engine | |

| Power | 300 Ps / 213 KW | |

| Emission Standard | Euro II or EURO III or EURO IV | |

| Brake | Air Brake | |

| Wheelbase/No.of axle | 3625+1350 mm / 2 | |

| Tyre Specfication | 11.00-20,12.00-20 18PR | |

| Tyre Number | 10 tyres and 1 spare tyre | |

| Max Speed | 75 km/h | |

| Paint | Automative metallic paint | |

| Capacity | 16-18 CBM | |

| Structure& Function |

Equipped with hermetic dustbin, hydraulic system and operating system Automatic compress and uninstall, sewage can be collected by the dump tank. Lock system is operated by machinery hydraulic system can reduce second pollution mostly. |

|

| Refuse compactor structure parameters | |

|

Equipment |

|

| Structure | Body, sub frame, lifting rear part, the loading device, the pushing-out plate, hydraulic and electric systems |

| Loading capacity | 18m3 |

| System of loading | Mechanized, rear loading |

| Modes of the pressing | Manual,semi-automatic,automatic,lifting rear part operation manual,loading,pushing,pressing, pushing out automatic |

|

Body |

|

| Version | All-metal |

| Shape | arc-shaped |

| Sidewalls | Sheet carbon steel (thickness: 4 mm) |

| Bottom | Sheet carbon steel (thickness: 4 mm) |

| Roof | Sheet carbon steel (thickness: 4 mm) |

| Front frame | Sheet carbonaceous steel (thickness: 5 mm) |

| Rear frame | n-shaped profile from sheet carbon steel (thickness:5 mm) |

| Basis | 120x120mm (thickness: 5 mm) |

|

Loading bunker |

|

| Loading bunker | All-metal with sidewalls and a loading ladle |

| Volume | 1.8 m3 |

| Sidewalls | Sheet carbon steel (thickness: 4 mm) |

| Ladle floor material | Sheet carbon steel (thickness: 4 mm) |

| Liquid drain | Drainage channel,sewage tank |

| Working zone Lighting | 2 lamps |

| Mechanism of raising | Two hydraulic cylinders |

| Ensuring tightness | Between the body and lifting back part in the lower part profile acid-proof rubber is used. |

|

Pressing system |

|

| Features | Control mode diversification,bidirectional compression |

| Pressure | 16Mpa |

| Compaction ratio | 3.0:1 |

| Loading cycle | 25-30 second |

| Unloading cycle | 15-20 second |

| pressing mechanism | The giving plate and hinge related pressing plate moving on two directing bars |

| Pressing mode | Automatic pressing

(1 full cycle and continuous pressing) and controlling of each cycle of pressing separately |

| Control of pressing | Control from the external panel on the bunker |

|

Lifting rear part |

|

| Mechanism of lifting | Two hydraulic cylinders |

| Function description | Suitable for various rubbish bins |

|

Others |

|

| Color and Logo | Optional |

| Standard configuration | Chassis,arc-shaped body,sub frame,rear lifting part,loading bunker,pushing-out plate,hydraulic system,pressing system,sewage tank,climbing ladder,pneumatic control. |

| Selective configuration | PLC electric automatic control,multifunctional rear lifting part,rear handrail and footplate,other shapes of body,rear swing arm,and etc. |

Product Images

Rear flipping

Application Scene

Reviews

There are no reviews yet.