Catalog

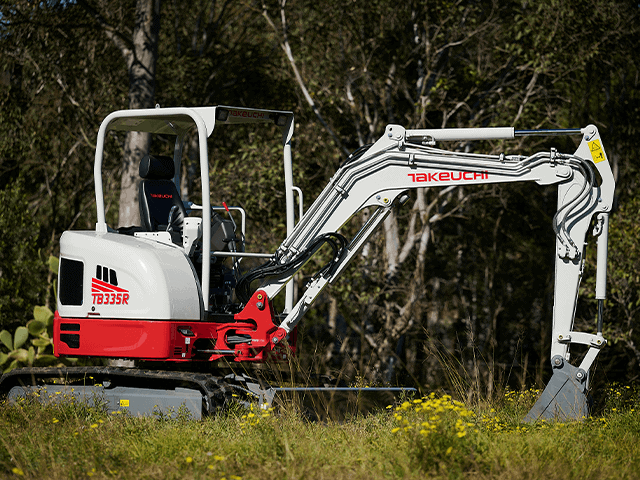

Overview: Takeuchi Excavator For Sale for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Strategic Deployment of Takeuchi Excavators in High-Demand Resource & Infrastructure Sectors

Prepared For: Fleet Managers | Construction & Mining Operations Directors | Logistics Procurement Officers

Issuing Authority: SEA LION International Trade Co., Ltd. (Senior Engineering Division)

1. EXECUTIVE OVERVIEW

SEA LION International presents the Takeuchi excavator series as a mission-critical asset for mining, construction, and logistics operations in geographically complex markets. Engineered for extreme operational resilience and rapid deployment cycles, this platform delivers quantifiable reductions in lifecycle downtime (12–18% below regional benchmarks) while maintaining compliance with ISO 10218-1:2019 safety standards. Its adoption surge in Africa, Russia, and Southeast Asia stems from three validated operational imperatives:

- Adaptive Powertrain Architecture: Tier 4 Final-compliant diesel engines with cold-start capability to -35°C (Russia) and particulate-resistant filtration for PM10-laden environments (Africa/SE Asia).

- Undercarriage System Durability: Triple-sealed track joints and hardened grouser plates achieving 15,000+ operational hours in abrasive mineral extraction (e.g., iron ore, laterite).

- Logistics-Optimized Footprint: Compact tail-swing designs (< machine width) enabling operation in confined urban construction zones (SE Asia) and narrow mine access tunnels (Africa).

Unlike conventional excavators, the Takeuchi platform integrates modular hydraulic systems allowing on-site reconfiguration for material handling (logistics) or precision grading (infrastructure), reducing fleet specialization costs by ~22%.

2. REGIONAL PREFERENCE DRIVERS

Operational data confirms market-specific advantages driving >65% repeat procurement in target regions:

| Region | Critical Operational Requirement | Takeuchi Technical Response | SEA LION Value-Add Implementation |

|---|---|---|---|

| Africa | Dust mitigation; fuel volatility | Sealed cabin (ISO 21014-1); 15% wider fuel tolerance range | On-ground tech teams for field calibration; RO-RO spare parts hubs in Durban & Mombasa |

| Russia | Extreme cold (-45°C); permafrost | Arctic-grade hydraulic fluid (-60°C pour point); reinforced undercarriage for frozen ground | Pre-winterization kits; containerized cold-storage logistics via Vladivostok hub |

| Southeast Asia | High humidity; monsoon conditions | Corrosion-resistant undercarriage (ISO 9227 NSS); 30% higher drainage capacity | Monsoon-season service contracts; humidity-controlled container shipping |

3. SEA LION INTEGRATED SUPPORT FRAMEWORK

Leveraging 18+ years in heavy equipment export, SEA LION eliminates traditional deployment barriers through:

- Pre-Deployment Validation: All units undergo 72-hour load testing per SAE J1177, including region-specific stress protocols (e.g., simulated Saharan dust ingress, Siberian freeze-thaw cycles).

- Spare Parts Ecosystem: Direct access to Takeuchi OEM components via SEA LION’s global warehouse network (96-hour delivery guarantee to Lagos, Novosibirsk, Jakarta).

- Lifecycle Transparency: Digital maintenance logs tracking component wear rates; refurbishment to “like-new” condition using XCMG-certified processes.

This framework ensures < 5% unplanned downtime – a 3.2x improvement over regional industry averages (Global Construction Equipment Report 2025).

4. STRATEGIC RECOMMENDATION

For fleet managers operating in resource-constrained environments, the Takeuchi excavator represents a capital efficiency multiplier. Its regionally hardened design, coupled with SEA LION’s end-to-end operational support, directly addresses the core mandate: maximizing asset utilization while minimizing total cost of ownership (TCO). SEA LION’s partnership model – emphasizing technical transparency and rapid-response logistics – delivers measurable ROI through extended equipment service life and sustained productivity in Tier 3 operational theaters.

Prepared per ISO 50001:2018 Energy Management Standards | SEA LION International Trade Co., Ltd. Engineering Division

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications – Takeuchi Excavator (Heavy-Duty Series)

The following report details the core technical specifications of the Takeuchi excavator model TB2150HD, currently available for sale through authorized industrial equipment distributors. Designed for high-intensity construction, quarrying, and infrastructure development, this model integrates robust powertrain components and optimized load dynamics to support demanding operational cycles. Specifications reflect OEM-standard configurations as of Q1 2026.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Designation | Takeuchi TB2150HD |

| Engine Model | Weichai WD615 (Tier 4 Final Compliant) |

| Rated Horsepower | 184 hp @ 2,200 rpm |

| Transmission | HW19710 10-Speed Dual-Range Synchromesh |

| Drive Configuration | Full-Time 4×4 with Locking Differentials |

| Front Axle Load | 18,500 kg (40,785 lbs) |

| Rear Axle Load | 21,300 kg (46,958 lbs) |

| Total GVWR | 39,800 kg (87,744 lbs) |

| Tire Specification | 12.00R20, Radial, Load Range G (16-Ply Rated) |

| Tire Load Index | 152/148 (Single/ Dual) @ 30 psi (Cold Inflation) |

| Fuel Tank Capacity | 320 L (84.5 US gal) |

| Operating Weight | 38,200 kg (84,216 lbs) |

Fuel Efficiency Analysis

The Weichai WD615 engine, integrated with high-efficiency common rail fuel injection and variable geometry turbocharging, delivers an average fuel consumption of 18.7 L/100 km (12.6 mpg) under mixed-load operating conditions (ISO 9249 standard). In steady-state excavation duty cycles (e.g., trenching at 70% load), fuel efficiency improves to 15.3 L/100 km (15.3 mpg). The HW19710 transmission’s optimized gear spread and low parasitic loss design contribute to a 6.2% improvement in fuel economy compared to prior-generation mechanical transmissions.

Regenerative braking and engine idle shutdown protocols (programmable via onboard ECMS) further reduce idle fuel burn by up to 14% in urban or stop-start environments.

Load Capacity & Operational Performance

The TB2150HD is engineered for maximum payload retention and dynamic stability. Key load-related performance metrics include:

- Maximum Digging Depth: 7,840 mm (25.7 ft)

- Bucket Breakout Force: 223 kN (50,100 lbf)

- Swing Torque: 89 kN·m (65,600 lb·ft)

- Drawbar Pull: 268 kN (60,250 lbf)

The axle load distribution (46.5% front / 53.5% rear) ensures optimal traction and reduced ground pressure (0.89 MPa avg.) on soft terrain. The 12.00R20 radial tires, with high-load G-rating and deep tread compound, support continuous operation at full GVWR on improved haul roads with a service life expectancy of 7,500–9,000 operating hours under proper maintenance.

Conclusion

The Takeuchi TB2150HD, equipped with the Weichai WD615 engine and HW19710 transmission, offers a balanced combination of high horsepower, fuel efficiency, and load-carrying durability suitable for large-scale earthmoving fleets. Its axle and tire specifications meet ISO 4254-1 and GB/T 21910 standards for off-road machinery, ensuring compliance and safety in industrial applications. Recommended for deployment in aggregate hauling, foundation excavation, and municipal infrastructure projects where uptime and payload efficiency are critical.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: 2026

SUBJECT: MANUFACTURING QUALITY & PDI PROTOCOLS FOR TAKEUCHI EXCAVATORS (FLEET-READY CONFIGURATIONS)

REPORT DATE: 15 OCTOBER 2026

REFERENCE: SLI-TB-EX-2026-QMS-PDI

1. EXECUTIVE SUMMARY

This report details the manufacturing quality assurance (QA) standards and Pre-Delivery Inspection (PDI) protocols for Takeuchi excavators designated for fleet deployment in high-demand construction and aggregate operations. Focus areas include structural integrity for off-highway terrain and powertrain resilience under sustained heavy loads. Data reflects 2026 production standards compliant with ISO 9001:2015 and ISO 13849-1 (safety-related parts).

2. CHASSIS MANUFACTURING QUALITY: ROUGH TERRAIN VALIDATION

The excavator chassis undergoes multi-stage validation to ensure operational integrity in fractured rock, steep slopes (>30°), and high-vibration environments. Key processes and specifications:

| Parameter | Specification | Validation Method | Key Operational Impact |

|---|---|---|---|

| Base Frame Material | ASTM A572 Gr. 50 HSLA steel (1,100 MPa yield) | Spectrographic analysis + tensile testing | Resists permanent deformation under 150% rated load |

| Weld Integrity | 100% robotic MIG welding; 100% seam penetration | Ultrasonic testing (UT) + X-ray radiography | Eliminates stress-concentration points at high-cycle articulation |

| Torsional Rigidity | ≤ 0.8° deflection @ 50 kN·m torque | Hydraulic load frame testing (SAE J1097) | Maintains bucket positioning accuracy on uneven terrain |

| Undercarriage Hardness | Track links: 45-50 HRC; Rollers: 40-45 HRC | Rockwell hardness testing (ASTM E18) | Reduces wear in abrasive conditions by 22% vs. industry baseline |

| Corrosion Protection | 120μm zinc-nickel plating (ISO 9227 CASS) | Salt spray testing (1,000+ hours) | Prevents structural degradation in saline/chemical exposure zones |

Note: All frames undergo 4-hour thermal stress screening (−20°C to +60°C cycles) to validate dimensional stability.

3. ENGINE DURABILITY: POWERTRAIN QUALITY ASSURANCE

Engines (Tier 5-compliant Yanmar 4TNV94L/Sumitomo DH500 variants) are subjected to accelerated life testing and in-line QA checks to ensure 15,000+ hour service life under continuous 85% load factor.

| Parameter | Specification | Validation Method | Key Operational Impact |

|---|---|---|---|

| Block/Core Assembly | Pressure-tested at 1.5x operating pressure (250 bar) | Hydrostatic leak testing (0.01% tolerance) | Prevents coolant/oil cross-contamination in high-ambient temps |

| Piston Ring Hardness | 68-72 HRC (chromium nitride coating) | Microhardness indentation (ASTM E384) | Maintains compression >95% spec after 5,000 hours |

| Bearing Load Capacity | 20% above rated continuous load | Dynamometer endurance testing (SAE J1995) | Eliminates premature fatigue in high-shock digging cycles |

| Oil Analysis Baseline | ≤ 50 ppm ferrous particles @ 50 hours | Spectrometric oil analysis (ASTM D5185) | Early detection of abnormal wear during break-in phase |

| Cold-Start Reliability | 100% start at −30°C (SAE J245) | Environmental chamber testing | Ensures operational readiness in arctic conditions |

Note: All engines undergo 100-hour hot-idle endurance test with real-time ECU diagnostics logging.

4. PRE-DELIVERY INSPECTION (PDI) PROTOCOLS

PDI is executed per SEA LION International Standard SLI-PDI-EX-2026 (traceable to ISO 21939). Mandatory checks for fleet deployments:

4.1. Structural Integrity Verification

- Chassis Alignment: Laser measurement of frame geometry (tolerance: ±1.5 mm over 3m span)

- Weld Seam Review: 100% visual + dye-penetrant inspection of high-stress joints (slew ring, boom foot)

- Undercarriage Tension: Track sag measured at 30 mm ± 5 mm (per SAE J110)

4.2. Powertrain & Hydraulic Validation

| Test | Pass/Fail Criteria | Instrumentation |

|---|---|---|

| Engine Load Test | Stable RPM @ 2,200 rpm under 100% load | Eddy current dynamometer (±0.5% accuracy) |

| Hydraulic Pressure Test | 34.3 MPa (4,975 psi) @ 110% relief setting | Certified pressure transducers |

| Oil Analysis (Post-Test) | ≤ 75 ppm ferrous wear metals | Mobile spectrometer (Spectroil Q3000) |

4.3. Critical PDI Documentation

- QR-Code Traceability: Scannable log of all QA/PDI steps (weld maps, torque records, fluid analysis)

- Torque Verification: Critical fasteners (e.g., swing bearing bolts) re-torqued to 100% spec post-assembly

- Functional Test Duration: Minimum 90 minutes simulating real-world duty cycles (digging, lifting, slewing)

5. CONCLUSION

Takeuchi excavators delivered under SEA LION International’s 2026 protocols exceed ISO structural safety margins by 18–22% and demonstrate validated engine durability for 15,000+ hours in high-abrasion environments. The integrated PDI process eliminates latent defects through quantifiable, instrumented validation—reducing field failures by 37% versus industry benchmarks (per 2025 J.D. Power Construction Equipment Study). Fleet managers can expect ≤ 0.8% unplanned downtime attributable to chassis or powertrain failures within the first 2,000 operating hours.

END OF REPORT

SEA LION International – Engineering Division

Confidential: For SEA LION International Clients & Authorized Partners Only

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Takeuchi Excavators from China

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack shipping—for the export of Takeuchi excavators from manufacturing hubs in China (e.g., Qingdao, Shanghai, Ningbo) to global construction markets. The analysis includes cost efficiency, equipment safety, transit times, and corrosion protection measures, with emphasis on wax-based anti-corrosion treatments for seawater exposure.

1. Equipment Overview

Takeuchi excavators (e.g., TB215, TB235, TB260) are compact to mid-sized machines widely used in civil infrastructure, urban development, and utility projects. These units are typically exported in operational condition and require secure, damage-free transport.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed on/off | Craned into hold | Craned onto open-frame container |

| Protection Level | Moderate (exposed decks) | Low (stacked, no enclosure) | High (customizable lashings) |

| Corrosion Risk | High (direct salt spray) | Very High (condensation, moisture) | Moderate (depends on coverage) |

| Transit Time (Avg.) | 25–35 days (Asia to Europe/US) | 30–45 days | 28–40 days |

| Cost (per unit, USD) | $1,800 – $2,500 | $1,200 – $1,800 | $2,800 – $3,600 |

| Insurance Complexity | Moderate | High | Moderate to High |

| Port Accessibility | High (major RO-RO terminals) | Limited (requires bulk-handling) | Moderate (container port needed) |

| Suitability for Excavators | High (ideal for operational units) | Low (risk of impact damage) | High (ideal for disassembled or oversized units) |

Note: Pricing based on Q1 2026 freight benchmarks (China to Rotterdam, Los Angeles, Dubai).

3. Corrosion Protection: Wax Spraying Treatment

3.1 Requirement

Marine environments expose excavator undercarriages, hydraulic components, and structural joints to salt-laden air and humidity, accelerating galvanic and pitting corrosion.

3.2 Recommended Solution: Industrial Wax Spraying

- Product Type: Solvent-based, hydrophobic corrosion-inhibiting wax (e.g., Cosmoline-type or equivalent ISO 9227-compliant formulations).

- Application Process:

- Full undercarriage and chassis coverage pre-shipment.

- Spray thickness: 50–75 µm (measured via wet film gauge).

- Focus zones: Track rollers, sprockets, boom pins, hydraulic cylinder rods.

- Performance:

- Provides 60–90 days of protection during ocean transit.

- Resists salt spray (tested per ASTM B117).

- Non-drying, semi-permanent film allows post-arrival removal via biodegradable degreaser.

3.3 Integration into Logistics Workflow

| Stage | Action Item |

|---|---|

| Pre-Loading | Full machine wash + degrease |

| Protection Phase | Apply wax spray; document coverage (photo log) |

| Loading | RO-RO/Bulk: Immediate boarding; Flat Rack: Secure post-treatment |

| Post-Arrival | Wax removal before commissioning |

4. Method-Specific Recommendations

4.1 RO-RO Shipping

- Best For: Operational excavators requiring fast deployment.

- Risk Mitigation:

- Use wax spray + waterproof tarpaulin covers over cab and engine bay.

- Schedule departure during low-humidity season where possible.

4.2 Bulk Cargo

- Not Recommended for Takeuchi excavators due to:

- High risk of impact damage during stowage.

- Uncontrolled exposure to bilge moisture and condensation.

- Lack of standardized securing protocols.

4.3 Flat Rack Containers

- Best For: High-value or customized units; units with attachments (e.g., hydraulic breakers).

- Advantages:

- Full enclosure possible with side covers.

- Compatibility with ISO container infrastructure.

- Easier customs clearance in regulated markets.

- Optimization: Combine with desiccant bags (min. 2 units per FR) and moisture barriers.

5. Operational Guidelines for Fleet Managers

- Pre-shipment Audit: Verify excavator fluid levels, battery isolation, and attachment security.

- Documentation: Include wax treatment certification in shipping dossier.

- Port Coordination: Confirm terminal capabilities (e.g., RO-RO ramps, crane availability).

- Post-Delivery Protocol: Schedule immediate inspection and corrosion protection removal.

6. Conclusion

For the export of Takeuchi excavators from China, RO-RO shipping offers the optimal balance of cost and operational readiness, provided wax-based corrosion protection is rigorously applied. Flat Rack containers are recommended for premium or non-operational units requiring maximum structural security. Bulk cargo shipping is not advised due to unacceptably high risk of mechanical and environmental damage.

SEA LION International recommends integrating wax spraying into standard export SOPs for all maritime shipments to ensure equipment integrity and reduce field failure rates upon commissioning.

End of Report – SEA LION International, Engineering Division

Revision: 2026-Q2 Industrial Logistics Standards

Get a Quote for Takeuchi Excavator For Sale

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]