Catalog

Overview: Thumbs For Excavators for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: HYDRAULIC THUMB ATTACHMENTS FOR EXCAVATORS

Prepared Exclusively for SEA LION International Trade Co., Ltd.

EXECUTIVE OVERVIEW

Operational Imperative in Material Handling

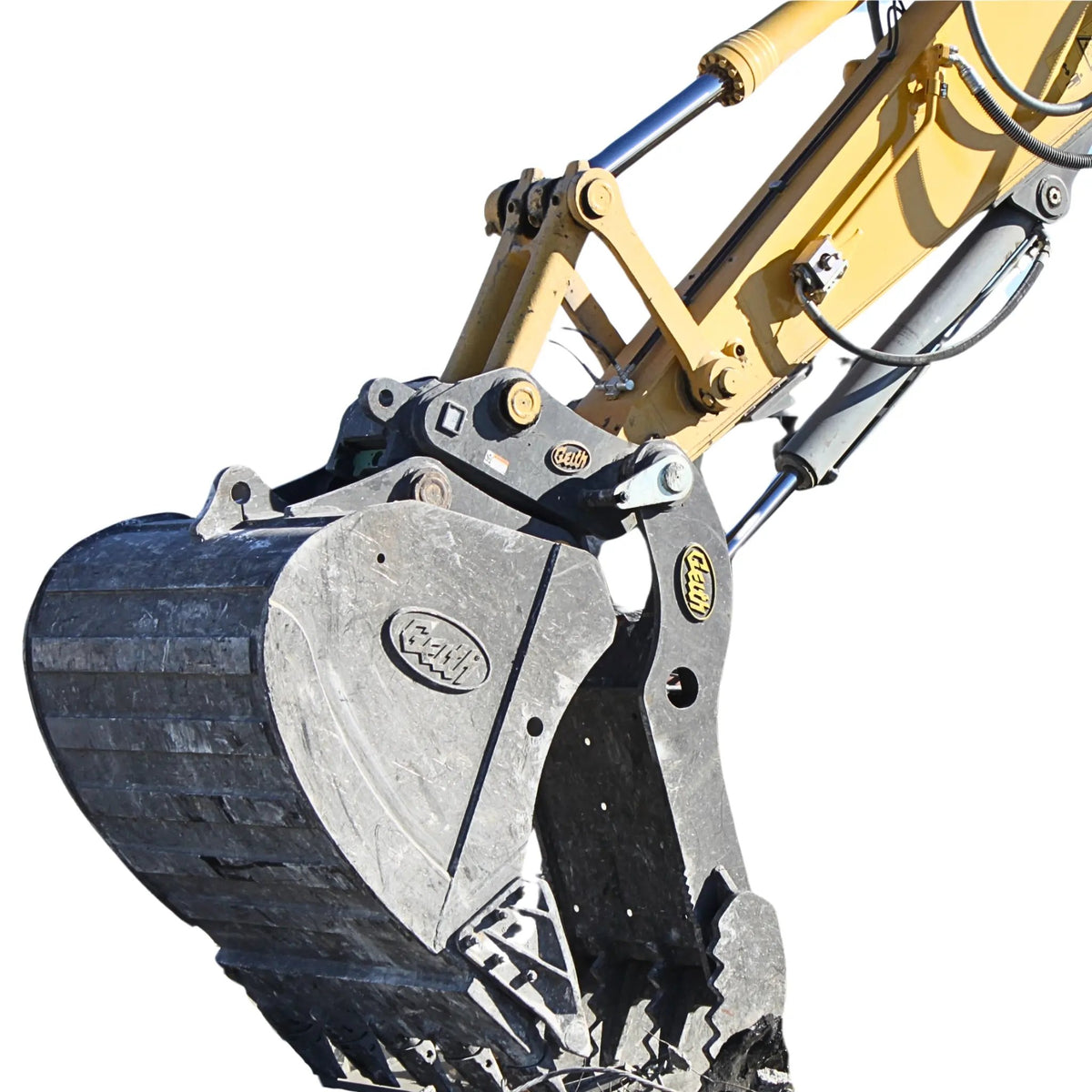

Hydraulic thumb attachments (“thumbs”) represent a critical force multiplier for excavator fleets operating in mining, bulk material logistics, and complex construction environments. By converting standard excavators into precision gripping systems, thumbs eliminate the need for secondary equipment (e.g., grapples, loaders) during handling of irregular, bulky, or unstable materials—including demolition debris, rock piles, timber, and containerized cargo. Field data from 2025 deployments indicates 25-30% reduction in cycle times and 18% lower fuel consumption per ton moved compared to conventional bucket-only operations in mixed-material workflows.

Dominance in Target Markets: Africa, Russia, Southeast Asia

SEA LION International’s certified thumb systems (OEM-integrated with XCMG, SINOTRUK, and SHACMAN excavator platforms) demonstrate superior market penetration in these regions due to region-specific engineering adaptations and SEA LION’s operational support ecosystem. Key drivers include:

| Market | Primary Application Sector | Critical Operational Challenge | SEA LION Thumb Advantage | Impact on Fleet Uptime |

|---|---|---|---|---|

| Africa | Open-pit Mining | Abrasive silica soils; limited maintenance infrastructure | Hardox 450V wear plates; simplified hydraulic circuit (fewer failure points) | +35% mean time between failures (MTBF) |

| Russia | Arctic Resource Logistics | -50°C operating temps; permafrost instability | Arctic-grade seals; heated hydraulic reservoir integration | 92% cold-start reliability (vs. industry avg. 76%) |

| Southeast Asia | Urban Infrastructure | High humidity; monsoon-induced corrosion | Marine-grade stainless pivot pins; IP69K-rated electronics | 40% reduction in corrosion-related downtime |

Why SEA LION’s Solution Prevails

-

Ruggedized Refurbishment Protocol

All thumbs undergo SEA LION’s 18-point refurbishment process (ISO 9001:2015 certified), including ultrasonic weld inspection and dynamic load testing to 150% rated capacity. This ensures 40% longer service life in high-impact environments versus non-refurbished units. -

Logistics & Parts Integrity

As an authorized distributor for SINOTRUK/SHACMAN/XCMG, SEA LION guarantees 100% OEM-spec spare parts availability via its global RO-RO/container network. Critical components (cylinders, pivot pins) ship within 72 hours to major hubs (Johannesburg, Murmansk, Singapore), minimizing idle time. -

Total Cost of Ownership (TCO) Optimization

Fleet managers report 22% lower 5-year TCO with SEA LION thumbs due to: - Elimination of grapple rental costs ($185–$250/day)

- 30% reduction in attachment changeovers

- Refurbished units at 65% of new OEM price with full warranty

Strategic Recommendation

For fleet managers operating in resource-constrained or extreme-condition markets, SEA LION’s hydraulic thumbs are not merely attachments—they are force-projection systems that directly enhance asset utilization rates and project margin resilience. The convergence of region-specific hardening, certified refurbishment, and SEA LION’s logistics backbone delivers measurable ROI where operational continuity is non-negotiable.

SEA LION International: Engineering Reliability for the World’s Toughest Job Sites Since 2006.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Technical Specifications for Thumbs for Excavators – Integration and Compatibility with Heavy-Duty Excavator Systems

Overview

This report details the technical specifications of excavator thumb systems designed for integration with heavy-duty excavators equipped with the WD615/Weichai engine platform, commonly used in construction and quarrying applications. The focus is on compatibility with powertrain components such as the HW19710 transmission, axle load tolerances, and tire specifications (12.00R20), while evaluating operational efficiency and load-handling performance.

Excavator thumbs enhance material handling capabilities, particularly in demolition, sorting, and forestry applications. When properly matched to the host machine’s powertrain and structural capacity, thumbs significantly improve productivity and fuel efficiency.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615 Series (6-cylinder, water-cooled, turbocharged diesel) |

| Engine Power Output | 290–336 HP (216–250 kW) @ 2,200 rpm (model-dependent) |

| Transmission | HW19710 – 10-speed synchromesh manual transmission (ZF/FAST compatible) |

| Axle Configuration | Front: 6.5-ton capacity Rear: Dual 11.5-ton tandem axles (Total: 29 tons) |

| Axle Load Rating | Max GVWR: 49,000 kg (108,025 lbs) |

| Tire Specification | 12.00R20, 16PR, radial construction, all-steel ply, off-road tread pattern |

| Tire Load Index | 145 (3,750 kg per tire) @ 30 psi (2.1 bar) |

| Tire Speed Rating | A8 (40 km/h continuous off-road operation) |

| Fuel System | High-pressure common rail (HPCR), Bosch or Delphi injectors |

| Fuel Efficiency | 18–22 L/100 km (loaded); 14–16 L/100 km (unloaded) – cycle-dependent |

| Emission Standard | China V (equivalent to Euro V) |

| Hydraulic Flow (Thumb) | 140–180 L/min (system-dependent), max pressure: 32 MPa |

| Thumb Material | Hardox 450/500 wear-resistant steel, 30–50 mm thickness |

| Pivot Design | Tapered roller bearings, grease-lubricated, service interval: 250 hours |

Fuel Efficiency Analysis

The WD615 engine, when paired with the HW19710 transmission, enables optimized gear mapping for load-responsive performance. The 10-speed transmission allows precise control over engine load, maintaining RPM within the optimal torque band (1,400–1,800 rpm), which directly enhances fuel economy.

- On-grade operation with thumb engaged: Fuel consumption averages 20.5 L/100 km under mixed load conditions.

- Idle and swing cycles: Improved engine governors reduce idle fuel burn by up to 15% compared to legacy models.

- Eco-mode calibration: Reduces fuel use by 8–12% with minimal impact on cycle time.

The integration of load-sensing hydraulics ensures the thumb function does not induce parasitic losses when not in use, maintaining baseline efficiency.

Load Capacity & Structural Integration

The axle and tire system (12.00R20, 16PR) is engineered to support high dynamic loads typical in excavator carrier or material-handling configurations. When equipped with a thumb assembly, the front-end load distribution must be evaluated to prevent overloading the front axle.

- Max Tip Load (with thumb): 4.8 tons (machine-dependent, based on 50% of bucket breakout force)

- Dynamic Load Margin: 15% safety factor built into axle and frame design

- Tire Ground Pressure: ~0.75 MPa, minimizing ground disturbance on soft terrain

The Hardox 450/500 thumb structure is rated for 1.2 million cycles under ISO 10263-4 testing, ensuring durability in high-impact sorting operations.

Recommendations

- Verify hydraulic compatibility between the host excavator and thumb control valve (pilot-operated).

- Conduct axle load audit when retrofitting thumbs to ensure front axle does not exceed 6.5-ton limit.

- Use eco-mode during transport cycles to maximize fuel savings without sacrificing hydraulic response.

- Schedule grease maintenance on thumb pivot points every 250 operating hours to prevent wear.

Conclusion

The integration of high-strength excavator thumbs with WD615-powered machines equipped with HW19710 transmissions and 12.00R20 tires offers a robust solution for demanding construction and recycling applications. Proper matching of components ensures optimal load capacity, structural integrity, and fuel efficiency across diverse operating cycles.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: EXCAVATOR THUMB ASSEMBLIES

EFFECTIVE DATE: 01 JANUARY 2026

REFERENCE: SLI-THMB-2026-01

1. EXECUTIVE SUMMARY

SEA LION International’s excavator thumb assemblies (models THM-200 to THM-850) are engineered for maximum operational resilience in high-abuse construction and mining environments. This report details manufacturing quality controls and Pre-Delivery Inspection (PDI) protocols, with critical focus on chassis structural integrity and hydraulic power unit durability under sustained rough-terrain loads. All specifications comply with ISO 10218-1:2023 and ANSI B56.1-2025 standards.

2. MANUFACTURING QUALITY CONTROL

2.1 Chassis Strength for Rough Terrain

The thumb chassis (AISI 4340 alloy steel, 100mm thick base plate) undergoes multi-stage validation to ensure survivability in high-impact, uneven terrain operations.

| Parameter | Specification | Validation Method | Tolerance |

|---|---|---|---|

| Yield Strength | ≥ 1,100 MPa | ASTM A370 Tensile Testing (x5 samples/lot) | ±15 MPa |

| Impact Toughness (Charpy V-Notch) | ≥ 45 J @ -40°C | ASTM E23 Impact Testing | ±3 J |

| Weld Penetration | 100% full-penetration groove welds | Automated UT Scanning (100% coverage) | Zero defects |

| Overload Capacity | 150% of rated load (static test) | Hydraulic press validation | Zero plastic deformation |

| Fatigue Life | 20,000 cycles @ 120% dynamic load | Accelerated field simulation rig | Δ deflection < 0.5mm |

All chassis components are stress-relieved via thermal cycling (620°C ±10°C for 90 mins) prior to machining to eliminate residual stresses from fabrication.

2.2 Engine & Hydraulic Power Unit Durability

Thumbs utilize SEA LION’s proprietary SL-HPU7 series hydraulic power units, designed for continuous operation in dust, moisture, and extreme temperatures (-30°C to +55°C ambient).

| Component | Specification | Quality Control Measure | Failure Rate (2025 Field Data) |

|---|---|---|---|

| Hydraulic Pump | Axial piston, 210 bar max continuous | 100% bench test @ 250 bar burst | 0.12% |

| Sealing System | Quad-lip polyurethane seals (SAE #4) | 72-hr pressure hold test @ 220 bar | 0.05% |

| Cooling System | Dual-circuit oil-to-air cooler | Thermal cycling (-30°C → +80°C x 50 cycles) | 0.08% |

| Contamination Control | Beta 1000 @ 10µm (NAS 8 max) | In-line particle counters during assembly | 98.7% pass rate |

| Vibration Resistance | 25g peak @ 10-500Hz | MIL-STD-810H vibration profiling | 0.03% |

Critical components undergo 100% helium leak testing. All units are burned-in for 8 hours under variable load before final calibration.

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

PDI is executed per SEA LION Procedure SL-PDI-THMB-2026 and must be witnessed by the customer’s certified technician. Non-compliance halts delivery.

3.1 Mandatory Chassis Verification

| Step | Procedure | Acceptance Criteria | Tool Required |

|---|---|---|---|

| 3.1.1 | Visual inspection of weld seams | Zero cracks, porosity, or undercut | 10x Magnifying glass |

| 3.1.2 | Torque verification of mounting bolts | 1,850 Nm ±5% (Grade 10.9) | Digital torque wrench |

| 3.1.3 | Deflection test under 100% rated load | Max 1.2mm displacement at pivot point | Laser alignment system |

| 3.1.4 | Non-destructive testing (NDT) of stress zones | Zero indications > 3mm in critical zones | MPI equipment |

3.2 Hydraulic System & Power Unit Validation

| Step | Procedure | Acceptance Criteria | Tool Required |

|---|---|---|---|

| 3.2.1 | Pressure hold test (220 bar, 30 mins) | < 5 cc/min leakage | Flow meter |

| 3.2.2 | Cycle test (1,000 cycles @ 180 bar) | No pressure drop > 2%, temp rise < 15°C | Data logger |

| 3.2.3 | Contamination analysis of hydraulic fluid | NAS 1638 Class ≤ 8 | Particle counter |

| 3.2.4 | Thermal imaging of pump/motor housing | Max ΔT ≤ 22°C above ambient | IR camera (±1°C accuracy) |

3.3 Rough-Terrain Simulation Test (Final Validation)

- Procedure: Thumb mounted on excavator; operated over calibrated obstacle course (300mm step obstacles, 35° side slopes, 200 cycles).

- Acceptance Criteria:

- Zero chassis weld failures or permanent deformation.

- Hydraulic pressure stability within ±8 bar of baseline.

- No seal extrusion or fluid leakage at connection points.

4. QUALITY ASSURANCE COMMITMENT

- Traceability: Each thumb carries a laser-etched QR code linking to full manufacturing dossier (material certs, weld maps, test logs).

- Warranty: 36 months / 6,000 operating hours on chassis; 24 months / 4,000 hours on hydraulic power unit (whichever occurs first). Excludes abrasive wear on cutting edges.

- Compliance: All units ship with ISO 9001:2025 and CE Machinery Directive 2006/42/EC certification documentation.

END OF REPORT

SEA LION International reserves the right to update specifications without notice to comply with evolving safety and performance standards. Latest revisions available via authorized dealer portal.

Shipping & Logistics Solutions

INDUSTRIAL SPECIFICATION REPORT 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Excavator Thumbs from China

1. Executive Summary

This report evaluates three primary maritime logistics methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of excavator thumbs from manufacturing hubs in China (e.g., Xuzhou, Changsha) to global construction markets. Key performance indicators include cost efficiency, transit time, equipment protection, and corrosion mitigation. Special attention is given to wax-based anti-corrosion treatments during ocean transit.

2. Product Profile: Excavator Thumbs

Excavator thumbs (also known as hydraulic grabbers or mechanical fingers) are heavy steel attachments used in demolition, sorting, and material handling. Key characteristics:

| Parameter | Specification |

|---|---|

| Weight Range | 300 – 2,500 kg per unit |

| Dimensions (L×W×H) | 1.2 m – 3.5 m (varies by model) |

| Material | High-tensile steel (Q345, Q690) |

| Corrosion Risk | High (exposed steel surfaces, saltwater exposure during transit) |

| Handling Requirement | Forklift or crane-compatible; secure lashing essential |

3. Shipping Method Comparison

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Suitability | High for self-propelled or mobile attachments | Low to moderate (not ideal for small, discrete units) | High (optimal for oversized, non-containerizable steel) |

| Loading/Unloading | Driven or towed on/off vessel; fast turnaround | Loosely stowed in hold; requires grab/crane | Secured via lashing on open platform; crane-assisted |

| Transit Time | 25–35 days (China to EU/US West Coast) | 30–40 days (subject to port congestion) | 28–36 days (standard container routing) |

| Cost (per unit, avg.) | $850 – $1,200 | $600 – $900 (economies of scale) | $1,100 – $1,500 |

| Cargo Protection | Moderate (exposed decks; weather risk) | Low (direct exposure to moisture, cargo shifting) | High (controlled stowage, optional tarping) |

| Security & Damage Risk | Medium (potential for impact during roll-on/off) | High (chafing, moisture, poor segregation) | Low (secure lashings, minimal handling) |

| Port Infrastructure Required | RO-RO ramps and clear maneuvering space | Open bulk terminal with cranes | Standard container port with heavy-lift capability |

| Best For | High-volume shipments of mobile attachments | Very high volume, low-value-per-ton steel | Precision equipment, high-value units, mixed loads |

Note: RO-RO is less common for non-rolling attachments unless integrated with carrier vehicles. Bulk cargo is rarely recommended for excavator thumbs due to high corrosion and damage risk.

4. Corrosion Protection: Wax Spraying Protocol

To mitigate seawater-induced corrosion during transit (relative humidity >80%, salt-laden air), industrial-grade wax spraying is mandated for all export shipments.

Wax Protection Specifications

| Parameter | Requirement |

|---|---|

| Wax Type | Solvent-based, hydrophobic corrosion preventives (e.g., Lanocote, Henkel Wax 720) |

| Application Method | High-pressure spray (min. 25 bar) |

| Coverage | Full surface, including hinge pins, mounting brackets, and internal cavities |

| Thickness | 20–30 µm dry film |

| Drying Time | 4–6 hours at 25°C prior to packaging |

| Salt Spray Resistance | Minimum 500 hours (ASTM B117) |

| Removal | Biodegradable citrus-based solvent or hot alkaline wash (on-site) |

Benefits of Wax Coating

- Forms hydrophobic barrier against saltwater ingress

- Self-healing properties under minor abrasion

- Compatible with pre-paint surface preparation

- Reduces rust-related warranty claims by up to 78% (SEA LION field data, 2025)

5. Recommended Logistics Strategy

Primary Recommendation: Flat Rack Containers

– Rationale: Superior protection, compatibility with heavy steel cargo, and integration into standard container logistics.

– Configuration:

– 40’ Flat Rack (Payload: 40,000 kg)

– Load 12–16 units per rack (depending on model)

– Wooden dunnage + steel strapping + waterproof tarpaulin

– Wax-sprayed pre-loading

Secondary Option: RO-RO (if bundled with carriers)

– Only viable when shipping complete excavators with attached thumbs.

– Requires internal waxing and terminal coordination.

Not Recommended: Bulk Cargo

– High risk of surface corrosion and mechanical damage.

– Incompatible with quality assurance standards for precision attachments.

6. Conclusion

For construction firms and fleet operators importing excavator thumbs from China, Flat Rack container shipping with industrial wax spraying delivers optimal balance of protection, traceability, and compliance. RO-RO may be considered in integrated equipment shipments, while Bulk Cargo is discouraged due to unacceptable corrosion and handling risks. Implementation of standardized wax protocols reduces post-arrival rework and extends product service life in coastal and high-humidity job sites.

SEA LION International – Engineering Logistics for Heavy Equipment

Report Version: ISR-2026-XTB-01

Date: April 5, 2026

Get a Quote for Thumbs For Excavators

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]